Professional Documents

Culture Documents

Cement Balanced Plug Technique

Uploaded by

zapspazCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cement Balanced Plug Technique

Uploaded by

zapspazCopyright:

Available Formats

CEMENT PLUGS | BALANCED PLUG

TECHNIQUE

admin | November 27, 2009 | Comments (0)

CEMENT PLUGS

The process of setting a cement plug involves the placement of a relatively small amount of cement slurry inside

an open hole or inside casing. The main reasons for setting a cement.

plug are as follows:

(a) To plug back a zone or abandon a well

(b) To sidetrack above a fish or to initiate a sidetrack

(c) To provide a seal for open hole testing

(d) To cure a lost circulation zone.

The two common techniques for setting a cement plug are:

1. Balanced Plug Bailer

2. Dump Bailer

BALANCED PLUG TECHNIQUE

Tubing or drill pipe is run into the hole to the desired setting depth and the spacers and cement are pumped. The

volume of spacer pumped is such that they are equal in height both inside the tubing and the annulus, see Figure

6.12. This is to ensure that the hydrostatic pressures inside the drillpipe and the annulus are exactly the same;

hence the name balanced

plug. The plug is usually placed with a smaller pipe than the drillpipe, called stinger. The stinger length should be

the plug length plus 100 ft. Setting Procedure:

(a) Run the cement stinger to 300 ft below the bottom setting depth for the plug.

(b) Spot a viscous mud pill having the same density as the mud in hole. The volume of the pill should be

sufficient to cover the 300 ft interval. A pill is not required if the cement plug is to be set on bottom, or on top of a

bridge plug.

(c) Pull the stinger back 300 ft.

(d) Pump a 10-20 bbl weighted spacer (preflush). The exact volume will depend on the hole size. Water should

only be used with Water Based Mud (WBM) and if hydrostatic conditions allow its use.Surfactants are required

for Oil Based Mud (OBM). Base Oil on its own can only be used if hydrostatic conditions allow its use. However,

its use will greatly enhance the chances of a successful plug.

(e) Pump sufficient volume for a 500 ft plug or as specified in the drilling programme. The

slurry should be displaced at maximum rate. The rate should be slowed down to 2 barrels per

minute (BPM) when the cement is 10-20 bbls away from the ported sub in the stinger and kept at this rate.

(f) Pump sufficient spacer behind the cement to balance the pre-flush.

(g) Displace with mud to the balanced position.

(h) Pull back slowly to at least 500 ft above the top of the plug and reverse circulate clean.

Note:If a series of plugs are to be set on top of each other, then reverse circulate clean immediately above the

bottom plug before attempting to set the next plug.

(i) Pull out of hole.

You might also like

- Roof-Plan Lay OutDocument33 pagesRoof-Plan Lay OutEugen GacheNo ratings yet

- GrantPrideco Drill Pipe Data TablesDocument24 pagesGrantPrideco Drill Pipe Data TablesMaximo Biarrieta RodriguezNo ratings yet

- Well Control Data Sheet: Well: All Values in Have To Be EnteredDocument11 pagesWell Control Data Sheet: Well: All Values in Have To Be Enteredmiguel rojasNo ratings yet

- DOP 205 - Rev 6Document21 pagesDOP 205 - Rev 6Fernando AybarNo ratings yet

- Well Control ExerciseمهمDocument133 pagesWell Control ExerciseمهمAsad babil BabilNo ratings yet

- Hydril Ram Annular Good Diagrams BOP ProductsDocument44 pagesHydril Ram Annular Good Diagrams BOP ProductsSharad Chandra Naik100% (7)

- Hydraulic Basics - LunchBox SessionsDocument27 pagesHydraulic Basics - LunchBox SessionsAnonymous jlLBRMAr3O50% (2)

- Cut and Thread ProcedureDocument4 pagesCut and Thread ProcedurezapspazNo ratings yet

- Cut and Thread ProcedureDocument4 pagesCut and Thread ProcedurezapspazNo ratings yet

- Drillbit Class If I ErDocument19 pagesDrillbit Class If I ErCharly Oswald ArgolloNo ratings yet

- Top CO - Catalog February 2015 - R6 PDFDocument36 pagesTop CO - Catalog February 2015 - R6 PDFzapspazNo ratings yet

- Sajad Falah Radha PDFDocument5 pagesSajad Falah Radha PDFSajad FalahNo ratings yet

- Construction of VSP Gun-PitDocument7 pagesConstruction of VSP Gun-PitzapspazNo ratings yet

- Carbonate Matrix Acidizing TreatmentsDocument23 pagesCarbonate Matrix Acidizing TreatmentszapspazNo ratings yet

- Softdrill NL Torque & Drag - Getting StartedDocument12 pagesSoftdrill NL Torque & Drag - Getting StartedKatya Fnx100% (1)

- Drilling Fluid FunctionsDocument28 pagesDrilling Fluid FunctionsChristian Olascoaga MoriNo ratings yet

- ZXXXXDocument12 pagesZXXXXMikael MarkovNo ratings yet

- Practical Design To Eurocode 2 - Lecture 1 Intro and BackgroundDocument39 pagesPractical Design To Eurocode 2 - Lecture 1 Intro and Background이동욱No ratings yet

- Theory of Structures - Floor SystemsDocument31 pagesTheory of Structures - Floor SystemsLawrence Babatunde OgunsanyaNo ratings yet

- Gas Down Choke Pressure - Upstream Pressure at Choke For Dry GasesDocument2 pagesGas Down Choke Pressure - Upstream Pressure at Choke For Dry GasesKALESANG LA BODONo ratings yet

- Grand Prideco Drill Collars CatalogDocument13 pagesGrand Prideco Drill Collars CatalogzapspazNo ratings yet

- Well Description: Lead Slurry 999 2276 10 550 Tail Slurry 212 1038 550 650Document8 pagesWell Description: Lead Slurry 999 2276 10 550 Tail Slurry 212 1038 550 650Nitin GandhareNo ratings yet

- Specialty Casing ConnectorsDocument24 pagesSpecialty Casing ConnectorszapspazNo ratings yet

- Directional DrillingDocument67 pagesDirectional DrillingAhmed AbdellateefNo ratings yet

- SPE - IADC 65515 HPHT Horizontal Sand Control CompletionDocument7 pagesSPE - IADC 65515 HPHT Horizontal Sand Control CompletionBruceNo ratings yet

- Spe 179056 MSDocument18 pagesSpe 179056 MSVeronica ArronithaNo ratings yet

- API Standards and Well ControlDocument9 pagesAPI Standards and Well ControlRobertok1234No ratings yet

- API Standards and Well ControlDocument9 pagesAPI Standards and Well ControlRobertok1234No ratings yet

- Kadanwari Well Integrity Test ProgramDocument28 pagesKadanwari Well Integrity Test ProgramsalmanNo ratings yet

- The Use of Pore-Pressure Coefficients in PracticeDocument5 pagesThe Use of Pore-Pressure Coefficients in PracticeRodolfo100% (1)

- Drilling Fluid AdditivesDocument4 pagesDrilling Fluid AdditiveszapspazNo ratings yet

- JPT SpeDocument144 pagesJPT SpeZenga Harsya PrakarsaNo ratings yet

- PDC Drill Bits Optimized For Shale DevelopmentDocument2 pagesPDC Drill Bits Optimized For Shale DevelopmentzapspazNo ratings yet

- The Fundamentals The FundamentalsDocument55 pagesThe Fundamentals The FundamentalsJose PerozoNo ratings yet

- Horizontal Lifeline System (HLLS) - 1 Span: A Rupt R FmaxDocument1 pageHorizontal Lifeline System (HLLS) - 1 Span: A Rupt R FmaxnagiA ahmedNo ratings yet

- Water Paper SpeDocument10 pagesWater Paper SpeUdi0% (1)

- 1.11 Fracture GradientsDocument36 pages1.11 Fracture GradientszapspazNo ratings yet

- Moment Distribution MethodDocument62 pagesMoment Distribution Methoddixn__100% (2)

- GP Tool Joint Dimensional ValueDocument3 pagesGP Tool Joint Dimensional ValuecalamarejoNo ratings yet

- Pressure Tests of Piping SystemsDocument14 pagesPressure Tests of Piping SystemsharishcsharmaNo ratings yet

- SLP - For Torque and Drag Guidelines To PERFORMDocument134 pagesSLP - For Torque and Drag Guidelines To PERFORMLuis EscaleraNo ratings yet

- Pressure-Volume-Temperature For Oil: PVT Analysis - PVT RelationshipDocument21 pagesPressure-Volume-Temperature For Oil: PVT Analysis - PVT RelationshipyerkoNo ratings yet

- SKPP3513 Assignment 3Document5 pagesSKPP3513 Assignment 3Zul AtfiNo ratings yet

- 12 - Determinations of Cut Off Vshale-Por-SwDocument26 pages12 - Determinations of Cut Off Vshale-Por-SwSyafrin Kultsum Naura AzzaNo ratings yet

- Bha#44 SMG-X2 ST3 20211009Document65 pagesBha#44 SMG-X2 ST3 20211009Jose Miguel Vaca CharriasNo ratings yet

- Free Point Calculation v03Document2 pagesFree Point Calculation v03prasarnboonNo ratings yet

- Petroleum Handbook EngineeringDocument9 pagesPetroleum Handbook EngineeringJuan PabloNo ratings yet

- CementingDocument27 pagesCementingrezaNo ratings yet

- CementingDocument43 pagesCementingMax SinghNo ratings yet

- Driller MethodDocument1 pageDriller MethodReza AgungNo ratings yet

- What Is ECD ? - GSR/WGP/WGO - G Fletcher Jan 2008Document9 pagesWhat Is ECD ? - GSR/WGP/WGO - G Fletcher Jan 2008Joaquin Dix'sNo ratings yet

- Ses - 01 - Prs - 02 - SPE - ATW - EOR - Castillo - PDFDocument23 pagesSes - 01 - Prs - 02 - SPE - ATW - EOR - Castillo - PDFJose CondorNo ratings yet

- Basic DrillingDocument65 pagesBasic DrillingAboZaidNo ratings yet

- Mr. Bentum CASINDocument19 pagesMr. Bentum CASINSarkodie KwameNo ratings yet

- Directional Drilling ToolsDocument21 pagesDirectional Drilling ToolsSunny BbaNo ratings yet

- Example BHA Tally Directional Drilling 8.5 SectionDocument2 pagesExample BHA Tally Directional Drilling 8.5 Sectionfauzanhaq1602No ratings yet

- BG - Well Integrity HandbookDocument9 pagesBG - Well Integrity Handbookwalter.tajuNo ratings yet

- Archie's Equation UncertaintyDocument3 pagesArchie's Equation UncertaintyGeñito VoltioNo ratings yet

- Calculo de Temperatura de CirculacionDocument1 pageCalculo de Temperatura de CirculacionrichisitolNo ratings yet

- Max Pull On Drill StringDocument1 pageMax Pull On Drill StringMuhammad ShahrukhNo ratings yet

- M=350.17 (γ Wor Γ Gor Ρ γ: 6,000 bbl/dDocument23 pagesM=350.17 (γ Wor Γ Gor Ρ γ: 6,000 bbl/dHoa NguyenNo ratings yet

- Mud Report 1Document65 pagesMud Report 1Brahim LetaiefNo ratings yet

- Tpao Production Group: Operation History of G.KIRTEPE 1Document40 pagesTpao Production Group: Operation History of G.KIRTEPE 1gregNo ratings yet

- Reverse Circulating With Coiled TubingDocument21 pagesReverse Circulating With Coiled Tubingtony100% (1)

- Home WorkDocument3 pagesHome WorkAG Y0% (1)

- Reservoir Inflow Performance: PET-332 E Production Engineering & Surface FacilitiesDocument36 pagesReservoir Inflow Performance: PET-332 E Production Engineering & Surface Facilities000No ratings yet

- Applications of Directional DrillingDocument11 pagesApplications of Directional Drillingkrsunil17No ratings yet

- PEG4102 LabDocument13 pagesPEG4102 LabAlex StollNo ratings yet

- SPE 77942 Smart Well Solutions For Thin Oil Rims: Inflow Switching and The Smart Stinger CompletionDocument10 pagesSPE 77942 Smart Well Solutions For Thin Oil Rims: Inflow Switching and The Smart Stinger CompletionJuan Manuel ReinaNo ratings yet

- Cementing Design Liner GeneralDocument5 pagesCementing Design Liner GeneralnkhamidyNo ratings yet

- Tutorial Sheet No - 4Document23 pagesTutorial Sheet No - 4ali jabbarNo ratings yet

- Annulus B CheckDocument1 pageAnnulus B Checkeng7mohamed7hashimNo ratings yet

- 3 KickDocument63 pages3 KickAmirah Razali100% (2)

- TX RRC Guidelines For Permitting SWDs in Seismic AreasDocument16 pagesTX RRC Guidelines For Permitting SWDs in Seismic Areasluis blandonNo ratings yet

- ProTech1Ch6 PDFDocument61 pagesProTech1Ch6 PDFweldsv100% (1)

- Orkiszewski CorrelationDocument3 pagesOrkiszewski CorrelationLuis Abdul-MelendezNo ratings yet

- Actions and Data Required Before The KillDocument86 pagesActions and Data Required Before The KillGMNo ratings yet

- Tech/drilling/Casing Design ExDocument43 pagesTech/drilling/Casing Design ExSohaib RashidNo ratings yet

- Stuck Point WorksheetDocument5 pagesStuck Point Worksheetjose perozoNo ratings yet

- Paper Water Coning and Gas ConingDocument7 pagesPaper Water Coning and Gas ConingClaudia Toding AlloNo ratings yet

- Fishing Operations: Date Bha # BHA Run DescriptionDocument6 pagesFishing Operations: Date Bha # BHA Run DescriptionRamy SaidNo ratings yet

- Water Drive Oil ReservoirDocument2 pagesWater Drive Oil ReservoirJoseph YepezNo ratings yet

- Guidelines For KICK OFF PlugDocument2 pagesGuidelines For KICK OFF PlugLenin DiazNo ratings yet

- Guidelines For Abandonment PlugDocument2 pagesGuidelines For Abandonment PlugLenin DiazNo ratings yet

- Foraco Reverse Circulation DrillingDocument4 pagesForaco Reverse Circulation DrillingzapspazNo ratings yet

- ALS Corpro Core Quickview DatasheetDocument2 pagesALS Corpro Core Quickview DatasheetzapspazNo ratings yet

- PDF SMB PDFDocument6 pagesPDF SMB PDFzapspazNo ratings yet

- Acidizing Oil Natural Gas Briefing Paper v2Document5 pagesAcidizing Oil Natural Gas Briefing Paper v2Radu Teodor GoranNo ratings yet

- PDCTechnology DC P52-54 MarApr2005 PDFDocument4 pagesPDCTechnology DC P52-54 MarApr2005 PDFzapspazNo ratings yet

- SWOT TemplatesDocument11 pagesSWOT TemplateszapspazNo ratings yet

- Composition of Crude OilDocument2 pagesComposition of Crude Oilzapspaz100% (1)

- Api Purchasing Guide 2015-08-29 PDFDocument20 pagesApi Purchasing Guide 2015-08-29 PDFQaiser HafeezNo ratings yet

- Calendar TemplatesDocument12 pagesCalendar TemplateszapspazNo ratings yet

- 1101 Sandface Comp PosterDocument1 page1101 Sandface Comp Posterdavid_avilesNo ratings yet

- PDF SMB PDFDocument6 pagesPDF SMB PDFzapspazNo ratings yet

- Fiche Circulation Inverse PDFDocument4 pagesFiche Circulation Inverse PDFzapspazNo ratings yet

- Backoff Basics - Stuck Pipe PDFDocument4 pagesBackoff Basics - Stuck Pipe PDFzapspazNo ratings yet

- Casing Sizes and DriftsDocument2 pagesCasing Sizes and DriftsAbdulaziz AbdullahNo ratings yet

- DC - Part - 3 - Answers With BitDocument10 pagesDC - Part - 3 - Answers With BitNicat NezirovNo ratings yet

- Marine Plywood PropertiesDocument2 pagesMarine Plywood Propertiessujith s pNo ratings yet

- Solved Problems Shear StressDocument2 pagesSolved Problems Shear StressA'TINSB19No ratings yet

- Strengthening of Concrete Structures With Textile Reinforced Mortars - State-Of-The-Art ReviewDocument20 pagesStrengthening of Concrete Structures With Textile Reinforced Mortars - State-Of-The-Art ReviewEdward TsaiNo ratings yet

- Aci Note ScipDocument16 pagesAci Note ScipChandan MukherjeeNo ratings yet

- BS 5268 - 7.5 Structural Use of Timber PDFDocument28 pagesBS 5268 - 7.5 Structural Use of Timber PDFTom YeeNo ratings yet

- Cpq07-Civil-Issue For Construction-119Document1 pageCpq07-Civil-Issue For Construction-119Gerson FrançosoNo ratings yet

- Office of The Municipal Engineer Improvement of Multi-Purpose Hall/ Repair and RehabilitationDocument21 pagesOffice of The Municipal Engineer Improvement of Multi-Purpose Hall/ Repair and RehabilitationVicent John ParedesNo ratings yet

- Inspection and Maintenance of Steel Girders-12Document10 pagesInspection and Maintenance of Steel Girders-12vpmohammedNo ratings yet

- Harmonic Analysis and Design of Skew BridgeDocument16 pagesHarmonic Analysis and Design of Skew BridgesarikareddyNo ratings yet

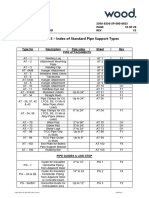

- PIPE SUPPORTS Table ListDocument10 pagesPIPE SUPPORTS Table ListCosminMarianNo ratings yet

- NMBS Castellated Beams CourseDocument62 pagesNMBS Castellated Beams CourseSeifeldin Ali MarzoukNo ratings yet

- Civil Work QuantitiesDocument6 pagesCivil Work QuantitiesashokNo ratings yet

- Physical Mechanisms of Hard Rock Fragmentation Under Mechanical Loading A ReviewDocument4 pagesPhysical Mechanisms of Hard Rock Fragmentation Under Mechanical Loading A Reviewjing xiaoNo ratings yet

- Tower Foundation BOM For SST 30m 4L 290kph - HDocument20 pagesTower Foundation BOM For SST 30m 4L 290kph - Hhenjie mirasolNo ratings yet

- Engineering and Design: Revision of Thrust Block Criteria in TM 5-813-5/AFM 88-10, Vol 5 Appendix CDocument17 pagesEngineering and Design: Revision of Thrust Block Criteria in TM 5-813-5/AFM 88-10, Vol 5 Appendix CtevredeNo ratings yet

- Bu Mat - MD408 17 TL 59Document2 pagesBu Mat - MD408 17 TL 59Larry Wayne Sumpter, JrNo ratings yet

- Universal Belt Filter PressDocument2 pagesUniversal Belt Filter PressSebastian Gomez BetancourtNo ratings yet

- Main Building BOQ 1Document4 pagesMain Building BOQ 1Shoon Lai AungNo ratings yet

- Project Report CE523Document41 pagesProject Report CE523salmanamu681No ratings yet

- Name of Work: - Constructing A Submersible Bridge On River Amaravati Near Village Avadar Pardimokha RoadDocument4 pagesName of Work: - Constructing A Submersible Bridge On River Amaravati Near Village Avadar Pardimokha RoaddhwaniNo ratings yet

- DEFLECTION Using Simplified Method of IsDocument8 pagesDEFLECTION Using Simplified Method of IsWHITE SHADOWNo ratings yet