Professional Documents

Culture Documents

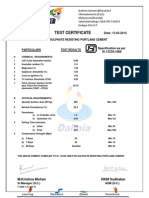

According To PS: 232-2008 (R) Grade 53

Uploaded by

Sufian AhmadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

According To PS: 232-2008 (R) Grade 53

Uploaded by

Sufian AhmadCopyright:

Available Formats

According to PS: 232-2008 ( R ) Grade 53

Date

Chemical Composition

PS: 232-2008 ( R ) Grade 53

Silicon Dioxide

SiO2

20.15

Aluminium Trioxide

AI2O3

4.55

Ferric Oxcide

Fe2O3

3.6

Calcium Oxide

CaO

62.34

Magnesium Oxcide

2.28

Sulphate

MgO

SO3

2.91

Potassium Oxcide

K2O

0.73

Sodium oxcide

Na2O

0.04

Chloride

Cl

0.038

Insoluable Residue

IR

1.36

Loss on Ignition

LOI

3.81

Lime Saturation Factor

LSF

0.94

Alumina Ratio

AM

C3A

1.26

Tricalcium Aluminates

Tetracalcium Aluminoferrate

C4AF

Alkalis Equivalent

AE

Results

5.97

10.94

0.52

Physical and Mechanical Properties

Compressive Strength Test method IS-4031 (Part 6)-1988

Results

3 days

47.20

7 days

55.80

28 days

66.50

Initial &Final Setting Time Test method PS: 232-2008 ( R )

Results

Initial Time

195

Final Time

265

Standard Consistency,Finenes & Expansion Test method PS: 232-2008 ( R )

Results

A. Lechatlier's Expansion

0.02

B. Autoclave Expansion

0.01

Fineness by Blaine m2 /Kg Min.

Standard Consistency

338

26.10

All the above chemical, mechanical and physical analysis comply with the above mentioned standard requirements.

Approved by

Optimization Department

21. Sep. 2013

Standard Requirements

maximum

6% Max

3 % Max

3.0% Max

4.0% Max

0.8 Min, 1.02 Max

0.66 Min

Standard Requirements

minimum

27.0 Mpa

37.0 Mpa

53.0 Mpa

Standard Requirements

minimum

30 (mts) Min

600 (mts) Max

Standard Requirements

minimum

10.0 mm

0.80%

225 sq.m/Kg Min.

ed standard requirements.

Calculations:

C3A= 2.65 AI2O3 - 1.692 Fe2O3

AE= Na2O + 0.658 K2O

You might also like

- Cement Technology Cement Manufacturing: C E M E N T A D D I T I V E SDocument57 pagesCement Technology Cement Manufacturing: C E M E N T A D D I T I V E Sshani5573No ratings yet

- Cement IndustryDocument27 pagesCement IndustryAhmed Mahmoud100% (1)

- QUESTIONNAIRE FOR PYROPROCESSING MODIFICATION COMPANYDocument8 pagesQUESTIONNAIRE FOR PYROPROCESSING MODIFICATION COMPANYVijay BhanNo ratings yet

- 3500TPD Cement Plant Heat BalanceDocument2 pages3500TPD Cement Plant Heat BalanceIrshad HussainNo ratings yet

- Pre-Homogenization Factor PDFDocument6 pagesPre-Homogenization Factor PDFAfqan B-v0% (1)

- Grinding AidDocument7 pagesGrinding Aidjitendra ojhaNo ratings yet

- Cement BookDocument21 pagesCement BookKeshav NandaNo ratings yet

- 3 SOP For Cleaning of Clinker Cooler DischargeDocument3 pages3 SOP For Cleaning of Clinker Cooler DischargekakaNo ratings yet

- Myanmar Cement-1Document14 pagesMyanmar Cement-1Mohammed AbdoNo ratings yet

- ATC Report on Dynamic Separator Gap IssuesDocument4 pagesATC Report on Dynamic Separator Gap IssuesDilnesa EjiguNo ratings yet

- Performing A Cement Plant Operations AuditDocument6 pagesPerforming A Cement Plant Operations AuditJa Phe TiNo ratings yet

- Snowman FormationDocument1 pageSnowman FormationKEERTHI INDUSTRIES100% (1)

- Estimating Glass Content in Granulated Blast Furnace SlagDocument1 pageEstimating Glass Content in Granulated Blast Furnace Slagsaji kumarNo ratings yet

- Cement grinding and production overviewDocument9 pagesCement grinding and production overviewMob Morphling KurustienNo ratings yet

- Kiln Plant Optimization TechniquesDocument10 pagesKiln Plant Optimization TechniquesPaulo VidasNo ratings yet

- KC 1.4 CalcinationDocument4 pagesKC 1.4 CalcinationCarlos HernanNo ratings yet

- Energy Auditing and Recovery For Dry Type Cement Rotary Kiln Systems A Case StudyDocument12 pagesEnergy Auditing and Recovery For Dry Type Cement Rotary Kiln Systems A Case Study1977julNo ratings yet

- Minor ElementsDocument50 pagesMinor ElementsnaldsonNo ratings yet

- It's A Product of An Intimate Mixture of Correctly ProportionedDocument28 pagesIt's A Product of An Intimate Mixture of Correctly ProportionedshahriarNo ratings yet

- Cement Kiln Process Chemistry: Cemnet Training - Course Ckpc01 Module 3.4 - DioxinsDocument6 pagesCement Kiln Process Chemistry: Cemnet Training - Course Ckpc01 Module 3.4 - DioxinsElwathig BakhietNo ratings yet

- IEE Handout 2Document2 pagesIEE Handout 2Sunil DeshmukhNo ratings yet

- Holderbank: Binder 1 Materials Technology IDocument2 pagesHolderbank: Binder 1 Materials Technology IlatiefNo ratings yet

- 031 Introduction Cement Grinding With Ball Mill SystemsDocument4 pages031 Introduction Cement Grinding With Ball Mill SystemsCesar Orlando Guarniz JustinianoNo ratings yet

- 1Document5 pages1Dee HsNo ratings yet

- Pozzolana Role PDFDocument36 pagesPozzolana Role PDFOsman QaasimNo ratings yet

- Common Problems in Cement Plant: One Issue From Each SectionDocument7 pagesCommon Problems in Cement Plant: One Issue From Each SectionYhaneNo ratings yet

- KPI Handbook V9-2017Document42 pagesKPI Handbook V9-2017Neimar HahmeierNo ratings yet

- BasicCementChem - CIL2Document30 pagesBasicCementChem - CIL2D'izmi D'barcaNo ratings yet

- Alite Modification by SO3 in Cement ClinkerDocument7 pagesAlite Modification by SO3 in Cement ClinkerRaúl Marcelo Veloz100% (2)

- Chapter 3 ClinkerDocument179 pagesChapter 3 ClinkerAli Hüthüt100% (1)

- 1,2,6a - Flames and Gas FiringDocument29 pages1,2,6a - Flames and Gas FiringMohamed SaadNo ratings yet

- V5 Process Technology 3Document441 pagesV5 Process Technology 3Pavel ParfenovNo ratings yet

- Technological Advancement in Cement Manufacturing Industry: System Length DiameterDocument16 pagesTechnological Advancement in Cement Manufacturing Industry: System Length Diameterfaran100% (3)

- Interim Report on Raw Mix Design for Shiva Cement LtdDocument9 pagesInterim Report on Raw Mix Design for Shiva Cement LtdParamananda SinghNo ratings yet

- Amrit Cement Industrial ReportDocument38 pagesAmrit Cement Industrial Reportmanish mohan upadhyayNo ratings yet

- Impact of calcium sulfates on cement properties and concrete workabilityDocument10 pagesImpact of calcium sulfates on cement properties and concrete workabilitycemsavantNo ratings yet

- Influence of Grinding Method and Particle Size Distribution On The Properties of Portland-Limestone CementsDocument11 pagesInfluence of Grinding Method and Particle Size Distribution On The Properties of Portland-Limestone CementsJohn GiannakopoulosNo ratings yet

- Tube Mill OptimisationDocument7 pagesTube Mill OptimisationJoko DewotoNo ratings yet

- Process Measurements ScheduleDocument25 pagesProcess Measurements ScheduleShivesh RanjanNo ratings yet

- Pyroprocessing: A Concise Guide to the High-Temperature Conversion of Raw Materials into ClinkerDocument27 pagesPyroprocessing: A Concise Guide to the High-Temperature Conversion of Raw Materials into ClinkerTitan Titanovsky KoraagNo ratings yet

- Boulder Formation in Cement Silos by Chettinad Cement CoDocument11 pagesBoulder Formation in Cement Silos by Chettinad Cement CoWaka OngetiNo ratings yet

- Mod 6Document49 pagesMod 6mkpq100% (1)

- The Effect of Coal Ash On Synthesis and Properties of C3SDocument6 pagesThe Effect of Coal Ash On Synthesis and Properties of C3SNam HuynhNo ratings yet

- Operating Manual for Slag Grinding UnitDocument41 pagesOperating Manual for Slag Grinding UnitPushpendra Kumar KushwahaNo ratings yet

- Physical Testing of Clinker & CementDocument61 pagesPhysical Testing of Clinker & CementDineshNo ratings yet

- 04 VDZ VT10 EnglishDocument153 pages04 VDZ VT10 EnglishYhane100% (1)

- Advancement in Refractories used for Cement Rotary kiln(CRKDocument75 pagesAdvancement in Refractories used for Cement Rotary kiln(CRKmahendra sen100% (1)

- Measurements of The Quality of Cement Produced From Looped LimestoneDocument30 pagesMeasurements of The Quality of Cement Produced From Looped LimestoneCharlie Dean100% (1)

- Ghid Coprocesare HolcimDocument135 pagesGhid Coprocesare HolcimnevedemjoiNo ratings yet

- Draft Report SucofindoDocument1 pageDraft Report SucofindoDwi Yon KustiyonoNo ratings yet

- Draft Report SucofindoDocument1 pageDraft Report SucofindoDwi Yon KustiyonoNo ratings yet

- Chapter 00 TOC - noPWDocument4 pagesChapter 00 TOC - noPWAndy Rei KouNo ratings yet

- 24th WK OPC43GDocument1 page24th WK OPC43GPandianKalaimaniNo ratings yet

- DALMIA CEMENT TEST CERTIFICATEDocument1 pageDALMIA CEMENT TEST CERTIFICATEtgpackia82No ratings yet

- Test Certificate: Ultratech Cement LimitedDocument1 pageTest Certificate: Ultratech Cement LimitedkvijayasokNo ratings yet

- Glycerine Ecogreen SpecDocument1 pageGlycerine Ecogreen SpecrusyadNo ratings yet

- Aspal - EDS: Tescan Vega3SB / Fisika UNMDocument1 pageAspal - EDS: Tescan Vega3SB / Fisika UNMMuhammad AgusalimNo ratings yet

- Gasoline 95 Octane Product SpecificationsDocument3 pagesGasoline 95 Octane Product SpecificationsVishnu PillaiNo ratings yet

- Form For Refund Hostel Security FullDocument1 pageForm For Refund Hostel Security FullSufian AhmadNo ratings yet

- Dam Lecture3Document6 pagesDam Lecture3atac101No ratings yet

- Literature ReviewDocument2 pagesLiterature ReviewSufian AhmadNo ratings yet

- Influence of Superplasticizer On Strengt PDFDocument3 pagesInfluence of Superplasticizer On Strengt PDFSufian AhmadNo ratings yet

- Construction ManagementDocument53 pagesConstruction ManagementRaniPaviNo ratings yet

- PG Exam Date Sheet Spring 2015Document1 pagePG Exam Date Sheet Spring 2015Sufian AhmadNo ratings yet

- Aggregate Testing Lab: Type in Name of Group: Type in Name of Captain: Type in Name of Group MembersDocument15 pagesAggregate Testing Lab: Type in Name of Group: Type in Name of Captain: Type in Name of Group MembersjalkunjNo ratings yet

- Appl For Any Student RequirementsDocument2 pagesAppl For Any Student RequirementsSufian AhmadNo ratings yet

- Advanced Structural Mechanics: National University of Science and Technology PakistanDocument1 pageAdvanced Structural Mechanics: National University of Science and Technology PakistanSufian AhmadNo ratings yet

- Presterssed Concrete Structures: National University of Science and Technology PakistanDocument2 pagesPresterssed Concrete Structures: National University of Science and Technology PakistanSufian AhmadNo ratings yet

- Sieve analysis particle size distribution chartDocument11 pagesSieve analysis particle size distribution chartSufian AhmadNo ratings yet

- Overview of The Construction Industry, Chapter 2Document35 pagesOverview of The Construction Industry, Chapter 2Sufian AhmadNo ratings yet

- Aggregate Testing Lab: Type in Name of Group: Type in Name of Captain: Type in Name of Group MembersDocument15 pagesAggregate Testing Lab: Type in Name of Group: Type in Name of Captain: Type in Name of Group MembersjalkunjNo ratings yet

- Details 2Document1 pageDetails 2Sufian AhmadNo ratings yet

- Strength and Destruction of Brittle Matrices-3!3!2015Document9 pagesStrength and Destruction of Brittle Matrices-3!3!2015Sufian AhmadNo ratings yet

- Lecture 09 Analysis and Design of Flat Plate SlabsDocument68 pagesLecture 09 Analysis and Design of Flat Plate SlabsSufian Ahmad100% (1)

- Cec4 LEC2Document31 pagesCec4 LEC2Sufian AhmadNo ratings yet

- Introduction To OSHA: Subpart C 29 CFR - 1926.1-1926.35Document77 pagesIntroduction To OSHA: Subpart C 29 CFR - 1926.1-1926.35Sufian AhmadNo ratings yet

- Construction Risk Management: Types, Analysis & Response StrategiesDocument20 pagesConstruction Risk Management: Types, Analysis & Response StrategiesSufian AhmadNo ratings yet

- Cec4 LEC1Document49 pagesCec4 LEC1Yasir FahadNo ratings yet

- Tall BuildingDocument42 pagesTall BuildingLila KhatiwadaNo ratings yet

- Cec4 LEC3Document34 pagesCec4 LEC3Sufian AhmadNo ratings yet

- Driving School Course DistributionDocument1 pageDriving School Course DistributionSufian AhmadNo ratings yet

- Pakistan Engineering Council: Application Form For Registered EngineerDocument7 pagesPakistan Engineering Council: Application Form For Registered EngineerSufian AhmadNo ratings yet

- Denmark Paper Syed Ali RizwanDocument10 pagesDenmark Paper Syed Ali RizwanSufian AhmadNo ratings yet

- Dr. Rizwan ThesisDocument168 pagesDr. Rizwan ThesisSufian AhmadNo ratings yet

- Civil TranscriptDocument1 pageCivil TranscriptSufian AhmadNo ratings yet

- Environmental SignificanceDocument1 pageEnvironmental SignificanceSufian AhmadNo ratings yet

- Comparison of ASP and TFDocument1 pageComparison of ASP and TFSufian AhmadNo ratings yet