Professional Documents

Culture Documents

Formulas, Facts and Figures

Uploaded by

Eko KurniawanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Formulas, Facts and Figures

Uploaded by

Eko KurniawanCopyright:

Available Formats

TECHNICAL REFERENCE

FORMULAS, FACTS AND FIGURES

Threaded Pipe Fitting Size, Chart and Dimensions

Compressed Air Pressure Loss Reference Tables

- Pressure Loss in Air Hoses

- Pressure Loss in Threaded Pipe Fittings

Surface Area Reference Tables

- Universal Beams

- Universal Columns

- Taper Flange Beams, Channels, Junior Universal Beams

- Square and Rectangular Hollow Sections

- Circular Hollow Sections

- Steel Plate

- Equal and Unequal Angles

Basic Area and Volume Calculation Formulas

- Rectangle, Triangle, Circle, Cylinder, Cone, Sphere

Conversion Calculation Factors: Imperial < to > Metric

- Length, Area, Volume, Speed - Velocity, Flow Rate

- Weight - Mass, Bulk - Density, Pressure, Vacuum, Power, Temperature

Conversion Reference Tables: Imperial < to > Metric

- Pressure

- Temperature

- Ventilation Flow Rates

- Compressed Air Supply Flow Rates

Quick Reference Guide to Relevant AS, ISO Standards

Technical Reference Section

Threaded Fitting Sizes

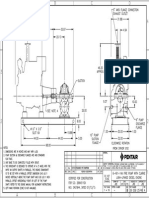

INSTRUCTIONS

1. Place male fitting on the sizing circles

and match the size.

2. The fitting size is printed outside and

below the corresponding sizing

circle.

1/8

1/4

3/8

1/2

3/4

1

1 1/4

1 1/2

Male Thread

Outside Diameter

Type

(approx.)

per Inch

1/8 BSP

9.5mm

(3/8)

28

1/8 NPT

9.5mm

(3/8)

27

1/4 BSP

12.7mm (1/2)

19

1/4 NPT

12.7mm (1/2)

18

3/8 BSP

15.9mm (5/8)

19

3/8 NPT

15.9mm (5/8)

18

1/2 BSP

20.7mm (13/16)

14

1/2 NPT

20.7mm (13/16)

14

3/4 BSP

26.2mm (1 1/32)

14

3/4 NPT

26.2mm (1 1/32)

14

1 BSP

31.8mm (1 1/4)

11

1 NPT

31.8mm (1 1/4)

11 1/2

1 1/4 BSP

41.3mm (1 5/8)

11

1 1/4 NPT

41.3mm (1 5/8)

11 1/2

1 1/2 BSP

47.6mm (1 7/8)

11

1 1/2 NPT

47.6mm (1 7/8)

11 1/2

2 BSP

58.7mm (2 5/16)

11

2 NPT

58.7mm (2 5/16)

11 1/2

Number of Threads

Blastmaster Catalogue

14

Section 14

301

Technical Reference Section

Compressed Air Pressure Loss in Air Hose

HOSELINE PRESSURE LOSS (psi)

Inside

Diameter

(in.)

3/4

Hose

Length

(ft)

50

50

Line Pressure (psig)

Free Air

(cfm)

60

80

100

120

140

160

180

200

220

120

150

180

210

60

3.1

5.3

8.1

2.7

4.1

5.8

7.7

240

270

300

330

360

390

420

450

1 1/4

1 1/2

50

50

200

250

300

350

2.4

3.7

5.2

7.0

400

450

500

550

600

650

700

750

800

8.9

300

400

500

600

700

800

900

1000

2.1

3.7

5.6

8.0

80

2.4

4.2

6.4

9.0

12.0

2.1

3.2

4.6

6.1

100

2.0

3.5

5.2

7.4

9.9

12.7

50

14

302

Section 14

Blastmaster Catalogue

600

800

1000

1200

1400

1600

1800

2000

2200

2400

2600

2800

1.9

3.2

5.0

7.0

9.3

150

200

300

2.9

4.5

6.3

8.4

10.8

13.6

16.6

2.4

3.6

5.1

6.9

8.9

11.1

13.5

1.8

2.8

3.9

5.3

6.8

8.5

10.4

1.2

1.9

2.7

3.6

4.6

5.8

7.1

16.2

12.4

8.4

2.6

3.5

2.0

2.7

1.3

1.8

4.5

5.6

6.9

8.2

9.7

11.3

13.0

14.8

3.4

4.3

5.3

6.3

7.4

8.7

10.0

11.4

2.3

2.9

3.6

4.3

5.0

5.9

6.8

7.7

2.3

3.1

1.8

2.4

1.2

1.6

4.0

5.0

6.2

7.4

8.7

10.2

11.7

13.3

15.0

3.1

3.9

4.7

5.7

5.7

7.8

9.0

10.2

11.5

2.1

2.6

3.2

3.9

4.6

5.3

6.1

6.9

7.8

2.5

3.6

4.9

6.3

7.8

9.5

1.9

2.8

3.7

4.8

6.0

7.3

1.3

1.9

2.5

3.2

4.1

4.9

14.0

11.4

13.6

15.8

8.8

10.4

12.1

6.0

7.1

8.3

2.7

3.8

5.2

6.7

8.4

10.4

12.5

14.7

2.2

3.1

4.2

5.5

6.9

8.5

10.2

12.0

14.1

16.2

1.7

2.4

3.2

4.2

5.3

6.5

7.8

9.2

10.8

12.4

1.1

1.6

2.2

2.8

3.6

4.4

5.3

6.3

7.3

8.5

2.7

3.8

4.0

2.3

3.2

4.3

7.9

9.8

12.0

6.5

8.1

9.9

11.8

13.9

5.5

6.9

8.4

10.0

11.9

13.8

15.9

2.9

4.1

5.5

2.4

3.4

4.5

2.0

2.9

3.8

7.0

8.8

10.8

5.8

7.3

8.9

10.7

12.6

14.6

4.9

6.2

7.6

9.1

10.7

12.4

14.3

2.9

4.4

6.3

8.5

10.9

2.4

3.7

5.2

7.0

9.0

11.2

13.6

2.0

3.1

4.4

5.9

7.7

9.5

11.6

1100

1200

1300

2

120

2.5

3.9

5.5

7.4

9.6

12.1

2.1

3.2

4.5

6.1

7.9

9.9

12.2

14.6

Technical Reference Section

Compressed Air Pressure Loss in Air Hose

HOSELINE PRESSURE LOSS (psi)

Inside

Diameter (in.)

2 1/2

Hose

Length

(ft)

50

Line Pressure (psig)

Free Air

(cfm)

1000

1500

2000

2500

60

1.7

3.7

6.5

10.0

3000

3500

4000

4500

3

50

80

100

120

150

200

300

2.9

5.1

7.9

2.4

4.2

6.5

2.0

3.6

5.5

2.9

4.5

2.2

3.4

1.5

2.3

11.2

9.3

12.4

7.9

10.6

13.7

6.4

8.7

11.2

14.0

4.9

6.6

8.6

10.7

3.3

4.5

5.8

7.3

2.5

3.6

4.9

2.1

3.1

4.1

2.5

3.4

1.9

2.6

1.3

1.7

6.3

7.9

9.6

11.5

5.3

6.7

8.2

9.8

4.4

5.5

6.7

8.0

3.3

4.2

5.1

6.1

2.3

2.8

3.5

4.2

13.6

11.5

13.5

15.6

9.4

11.0

12.7

14.5

7.2

8.4

9.8

11.1

4.9

5.7

6.6

7.6

2000

2500

3000

3500

2.5

3.9

5.5

7.5

2.0

3.0

4.4

5.9

4000

4500

5000

5500

9.8

7.6

9.6

11.7

6000

6500

7000

7500

THREADED PIPE FITTINGS

PRESSURE LOSS CONVERSION TABLE

Expressed as length in feet of straight piping giving equivalent pressure loss

Nominal

Pipe Inside

Size

Diameter

(in.)

Actual

Pipe Inside

Size

Diameter Gate

(in.)

Valve

Long Radius

Ell or on Run

of Standard

Tee

Standard Ell

or on Run of

Tee Reduced

in Size

50 Percent

1/2

3/4

1

1 1/4

1 1/2

0.622

0.824

1.049

1.380

1.610

0.36

0.48

0.61

0.81

0.94

0.62

0.82

1.05

1.38

1.61

2

2 1/2

3

4

5

2.067

2.469

3.068

4.026

5.047

1.21

1.44

1.79

2.35

2.94

6

8

10

12

6.065

6.981

10.020

11.940

3.54

4.65

5.85

6.96

Angle

Valve

Close

Return

Bend

Tee

Through

Side

Globe

Outlet

Valve

1.55

2.06

2.62

3.45

4.02

8.65

11.4

14.6

19.1

22.4

3.47

4.60

5.82

7.66

8.95

2.10

4.12

5.24

6.90

8.04

17.3

22.9

29.1

38.3

44.7

2.07

2.47

3.07

4.03

5.05

5.17

6.16

6.16

7.67

10.1

28.7

34.3

42.6

56.0

70.0

11.5

13.7

17.1

22.4

28.0

10.3

12.3

15.3

20.2

25.2

57.4

68.5

85.2

112

140

6.07

7.98

10.00

11.0

15.2

20.0

25.0

29.8

84.1

111

139

166

33.8

44.6

55.7

66.3

30.4

40.0

50.0

59.6

168

222

278

332

Blastmaster Catalogue

14

Section 14

303

Technical Reference Section

Surface Areas

SURFACE AREAS OF

UNIVERSAL BEAMS

Universal Beams

Designation

14

Profile Profile

Distance Surface

Area per

metre

Profile

Surface

Area per

tonne

mm

m2/m

760 UB 244

220

197

173

147

2580

2570

2550

2530

2510

690 UB 140

125

Profile

Surface

Area Less

Area of

One Flange

Face per

metre

Profile

Surface

Area Less

Area of

One Flange

Face per

tonne

m2/tonne mm

m2/m

m2/tonne

2.58

2.57

2.55

2.53

2.51

10.6

11.7

13.0

14.6

17.0

2310

2300

2280

2270

2250

2.31

2.30

2.28

2.27

2.25

9.47

10.4

11.6

13.1

15.2

2330

2320

2.33

2.32

16.6

18.5

2080

2070

2.08

2.07

14.8

16.5

610 UB 125

113

101

2090

2080

2070

2.09

2.08

2.07

16.7

18.4

20.4

1870

1860

1840

1.87

1.86

1.84

14.9

16.4

18.2

530 UB 92

82

1860

1850

1.86

1.85

20.1

22.6

1650

1640

1.65

1.64

17.9

20.0

460 UB 82

74

67

1650

1640

1630

1.65

1.64

1.63

20.1

22.0

24.3

1460

1450

1440

1.46

1.45

1.44

17.8

19.4

21.5

410 UB 60

54

1490

1480

1.49

1.48

25.0

27.6

1310

1310

1.31

1.31

22.0

24.3

360 UB 57

51

45

1370

1360

1360

1.37

1.36

1.36

24.2

26.9

30.3

1200

1190

1190

1.20

1.19

1.19

310 UB 46

40

1250

1240

1.25

1.24

27.0

30.7

1080

1080

250 UB 37

31

1070

1060

1.07

1.06

28.8

33.8

200 UB 30

25

923

915

0.923

0.915

30.9

36.1

304

Section 14

Profile

Distance

Less One

Flange

Face

SURFACE AREAS OF

UNIVERSAL COLUMNS

Universal Columns

Profile Profile

Distance Surface

Area per

metre

Profile

Surface

Area per

tonne

mm

m2/m

310 UC 283

240

198

158

137

118

97

1940

1900

1870

1840

1820

1810

1790

21.2

23.5

26.5

250 UC 89

73

1.08

1.08

23.4

26.6

925

916

0.925

0.916

24.8

29.2

789

782

0.789

0.782

26.5

30.8

Blastmaster Catalogue

Designation

Profile

Distance

Less One

Flange

Face

Profile

Surface

Area Less

Area of

One Flange

Face per

metre

Profile

Surface

Area Less

Area of

One Flange

Face per

tonne

m2/tonne mm

m2/m

m2/tonne

1.94

1.90

1.87

1.84

1.82

1.81

1.79

6.85

7.94

9.45

11.6

13.3

15.4

18.5

1620

1590

1560

1530

1510

1500

1480

1.62

1.59

1.56

1.53

1.51

1.50

1.48

5.71

6.61

7.86

9.68

11.0

12.8

15.3

1500

1480

1.50

1.48

16.8

20.4

1250

1230

1.25

1.23

13.9

16.9

200UC 60

52

46

1200

1190

1190

1.20

1.19

1.19

20.2

22.9

25.7

999

991

984

0.999

0.991

0.984

16.8

19.0

21.3

150 UC 37

30

23

912

900

889

0.912

0.900

0.889

24.5

30.0

38.0

758

747

737

0.758

0.747

0.737

20.4

24.9

31.5

100 UC 15

563

0.563

38.0

464

0.464

31.3

Technical Reference Section

Surface Areas

SURFACE AREAS OF

TAPER FLANGE BEAMS

CHANNELS AND

JUNIOR UNIVERSAL BEAMS

Designation

Profile Profile

Distance Surface

Area per

metre

mm

m2/m

Profile

Surface

Area per

tonne

Profile

Distance

Less One

Flange

Face

EXTERNAL SURFACE AREAS

OF HOLLOW SECTIONS

Profile

Surface

Area Less

Area of

One Flange

Face per

metre

Profile

Surface

Area Less

Area of

One Flange

Face per

tonne

m2/tonne mm

m2/m

m2/tonne

Taper Flange Beams

178 x 89

152 x 76

125 x 65

100 x 45

658

562

470

349

0.658

0.562

0.470

0.349

29.4

31.4

35.7

48.5

569

486

405

304

0.569

0.486

0.405

0.304

25.4

27.2

30.8

42.2

1130

932

834

737

678

638

580

480

374

286

1.13

0.932

0.834

0.737

0.678

0.638

0.580

0.480

0.374

0.286

20.7

23.2

23.5

29.4

29.6

30.5

32.8

35.7

40.0

43.0

1030

842

744

662

603

563

505

415

324

246

1.03

0.842

0.744

0.662

0.603

0.563

0.505

0.415

0.324

0.246

18.8

21.0

21.0

26.4

26.4

26.9

28.5

30.9

34.6

37.0

Channels

380 x 100

300 x 90

250 x 90

230 x 75

200 x 75

180 x 75

150 x 75

125 x 65

100 x 50

74 x 40

Rectangular

Square

Junior Universal Beams

180 UB 22

18

691

685

0.691

0.685

31.1

37.8

601

595

0.601

0.595

27.1

32.9

150 UB 18

14

584

576

0.584

0.576

32.4

41.1

509

501

0.509

0.501

28.3

35.8

Designation

Profile Surface Area

Nominal Per

Thickness metre

t

Per

tonne

Nominal

Size

DxB

Nominal Per

Thickness metre

t

mm x mm

mm

m2/m

m2/tonne

mm x mm

mm

0.975

0.982

0.989

0.772

0.778

0.786

0.569

0.575

0.583

0.589

0.467

0.474

0.481

0.487

0.366

0.372

0.379

0.385

0.389

0.329

0.335

0.340

0.278

0.284

0.288

0.291

0.227

0.233

0.237

0.240

0.182

0.186

0.189

13.8

16.3

20.6

13.9

16.5

20.7

14.2

16.7

20.9

26.7

14.3

16.8

21.1

26.8

14.6

17.1

21.3

27.1

32.9

21.5

27.3

36.6

21.8

27.5

33.3

41.2

22.2

27.8

33.6

41.5

28.4

34.2

42.0

254. x 152. 9.5

8.0

6.3

203. x 152. 9.5

8.0

6.3

203. x 102. 9.5

8.0

6.3

4.9

152. x 102. 9.5

8.0

6.3

4.9

152. x 76. 8.0

6.3

4.9

127. x 76. 8.0

6.3

4.9

127. x 64. 6.3

4.9

4.0

127. x 51. 6.3

4.9

3.6

102. x 76. 6.3

4.9

3.6

102. x 51. 6.3

4.9

4.0

3.2

76. x 51.

6.3

4.9

4.0

3.2

76. X 38. 4.0

3.2

64. X 38. 4.0

3.2

254. x 254. 9.5

8.0

6.3

203. x 203. 9.5

8.0

6.3

152. x 152. 9.5

8.0

6.3

4.9

127. x 127. 9.5

8.0

6.3

4.9

102. x 102. 9.5

8.0

6.3

4.9

4.0

89. x 89.

6.3

4.9

3.6

76. x 76.

6.3

4.9

4.0

3.2

64.x 64.

6.3

4.9

4.0

3.2

51. x 51.

4.9

4.0

3.2

as either the approved nor standard nor complying method nor formula nor calculation for any of the topics or aspects referred to, and neither is

any claim made as to the completeness or accuracy of the information. It is the responsibility of the reader and/or users of this information to

separately determine and verify the correct method, formula, factor, procedure, data, etc. for determining any such topics or aspects as directed

Blastmaster expressly disclaims any liability for the use or misuse of the information.

ProfileSurfacArea

Nominal

Size

DxB

DISCLAIMER: All and any tables, calculations, factors, formulas, etc information on any of these pages are a guide only and shall not be taken

or required or indicated in or by any work specifications and/or standards.

Designation

Blastmaster Catalogue

Per

tonne

m2/m

m2/tonne

0.772

0.778

0.786

0.670

0.677

0.684

0.569

0.575

0.583

0.589

0.467

0.474

0.481

0.487

0.423

0.430

0.436

0.372

0.379

0.385

0.354

0.360

0.364

0.329

0.335

0.340

0.329

0.335

0.340

0.278

0.284

0.288

0.291

0.227

0.233

0.237

0.240

0.211

0.215

0.186

0.189

13.9

16.5

20.7

14.0

16.5

20.8

14.2

16.7

20.9

26.7

14.3

16.8

21.1

26.8

16.9

21.2

26.9

17.1

21.3

27.1

21.4

27.2

33.0

21.5

27.3

36.6

21.5

27.3

36.6

21.8

27.5

33.3

41.2

22.2

27.8

33.6

41.5

33.9

41.8

34.2

42.0

Section 14

305

14

Technical Reference Section

Surface Areas

EXTERNAL SURFACE

AREAS OF CIRCULAR

HOLLOW

SECTIONS

STEEL PLATE AREAS

Steel Plate Thicknesses

Designation

Actual

Outside

Diameter

Nominal

Thickness

t

Per

metre

Per

tonne

Size

mm

kg/m2

One Side

m2/tonne

Both Sides

m2/tonne

mm

mm

m2/m

m2/tonne

3.

24.14

41.42

82.84

4.

32.18

31.07

62.14

5.

30.23

24.86

49.72

6.

48.27

20.71

41.42

457

406.4

355.6

323.9

273.1

219.1

168.3

165.1

139.7

114.3

101.6

88.9

76.1

60.3

14

48.3

42.4

306

External Surface Area

Section 14

9.5

6.4

9.5

6.4

9.5

6.4

9.5

6.4

9.3

6.4

4.8

8.2

6.4

4.8

7.1

6.4

4.8

5.4

4.9

5.4

4.9

5.4

4.5

4.9

4.0

5.9

4.9

4.0

3.2

5.9

4.5

3.6

3.2

5.4

4.5

3.6

5.4

4.0

3.2

4.9

4.0

3.2

1.44

1.44

1.28

1.28

1.12

1.12

1.02

1.02

0.858

0.858

0.858

0.688

0.688

0.688

0.529

0.529

0.529

0.519

0.519

0.439

0.439

0.359

0.359

0.319

0.319

0.279

0.279

0.279

0.279

0.239

0.239

0.239

0.239

0.189

0.189

0.189

0.152

0.152

0.152

0.133

0.133

0.133

13.7

20.2

13.7

20.2

13.8

20.3

13.8

20.3

14.2

20.4

27.0

16.1

20.5

27.1

18.7

20.7

27.3

24.4

26.8

24.5

26.9

24.8

29.5

27.3

33.2

23.1

27.5

33.3

41.3

23.4

30.1

37.1

41.6

25.9

30.6

37.6

26.6

34.7

42.6

29.4

35.2

43.1

Blastmaster Catalogue

8.

64.37

15.54

31.08

10.

80.46

12.43

24.86

12.

96.56

10.36

20.72

16.

128.70

7.77

15.54

20.

160.90

6.21

12.42

25.

201.10

4.97

9.94

28.

225.29

4.44

8.88

32.

257.40

3.88

7.77

36.

289.60

3.45

6.90

40.

321.80

3.11

6.22

45.

362.00

2.76

5.52

50.

401.30

2.49

4.98

55.

442.50

2.26

4.52

60.

482.70

2.07

4.14

70.

563.20

1.78

3.56

80.

643.70

1.56

3.12

90.

724.10

1.38

2.76

100.

804.60

1.24

2.48

110.

885.00

1.13

2.26

120.

965.50

1.04

2.08

140.

1126.00

0.89

1.78

160.

1287.00

0.78

1.56

180.

1448.00

0.69

1.38

200.

1609.00

0.62

1.24

225.

1810.00

0.55

1.10

250.

2011.00

0.50

1.00

Technical Reference Section

Surface Areas

SURFACE AREAS OF ANGLES

Designation

Surface Area

Designation

Surface Area

Designation

Surface Area

Nominal

Leg Size

AxB

Nominal

Thickness

Per

metre

Per

tonne

Nominal

Leg Size

AxB

Nominal

Thickness

Per

metre

Per

tonne

Nominal

Leg Size

AxB

Nominal

Thickness

Per

metre

Per

tonne

mm

mm

m2/m

m2/tonne

mm

mm

m2/m

m2/tonne

mm

mm

m2/m

m2/tonne

150 x 100 12

10

0.491

0.491

21.8

27.3

150 x 90

16

12

10

8

0.471

0.471

0.471

0.471

16.9

21.8

27.2

33.0

125 x 75

12

10

8

6

0.392

0.392

0.392

0.392

22.2

27.6

33.2

42.8

Equal Angles

200 x 200 26

20

18

16

13

Unequal

Angles

0.788

0.788

0.788

0.788

0.788

10.3

13.1

14.5

16.2

19.7

65 x 65

10

8

6

5

0.255

0.255

0.255

0.255

28.3

33.9

43.4

55.9

55 x 55

6

5

0.215

0.215

43.6

60.0

50 x 50

8

6

5

3

0.195

0.195

0.195

0.195

34.3

43.7

56.0

84.4

6

5

3

0.175

0.175

0.175

44.2

56.5

85.1

100 x 75

10

8

6

0.342

0.342

0.342

27.6

33.2

42.9

6

5

3

0.155

0.155

0.155

44.4

56.9

84.9

75 x 50

8

6

5

0.245

0.245

0.245

34.1

43.6

56.3

6

5

3

0.115

0.115

0.115

45.0

57.4

85.4

65 x 50

8

6

5

0.225

0.225

0.225

34.1

43.6

55.9

6

5

3

0.0953

0.0953

0.0953

45.8

57.7

85.1

150 x 150 19

16

12

10

0.590

0.590

0.590

0.590

14.0

16.7

21.6

26.9

125 x 125 16

12

10

8

0.491

0.491

0.491

0.491

16.9

21.8

27.3

33.0

100 x 100 12

10

8

6

0.392

0.392

0.392

0.392

22.2

27.6

33.2

42.8

90 x 90

10

8

6

0.352

0.352

0.352

27.7

33.2

42.9

30 x 30

10

8

6

5

0.292

0.292

0.292

0.292

27.8

33.5

42.9

55.5

25 x 25

75 x 75

45 x 45

40 x 40

DISCLAIMER: All and any tables, calculations, factors, formulas, etc information on any of these pages are a guide only and shall not be taken as either the approved nor standard

nor complying method nor formula nor calculation for any of the topics or aspects referred to, and neither is any claim made as to the completeness or accuracy of the information.

It is the responsibility of the reader and/or users of this information to separately determine and verify the correct method, formula, factor, procedure, data, etc. for determining any

such topics or aspects as directed or required or indicated in or by any work specifications and/or standards.

Blastmaster expressly disclaims any liability for the use or misuse of the information.

Blastmaster Catalogue

Section 14

307

14

Technical Reference Section

Basic Area and Volume Formulae

RECTANGLE

Area = Length x Width

TRIANGLE

H

Area = 1/2 x Base x Perpendicular Height

CIRCLE

Area = / x radius2

Circumference = 2 x / x radius

(or / x diameter)

CYLINDER

Area (ends not included) = 2 x / x radius x Height

Volume = / x radius2 x Height

CONE

Area (excluding base) = / x radius x slant height

Volume = 1/3 x / x radius2 x height

S

H

slant height = 3 radius2 + perpendicular height2

14

SPHERE

Area = 4 x / x radius2

Volume = 4/3 x / x radius3

308

Section 14

Blastmaster Catalogue

Technical Reference Section

Conversion Factors

IMPERIAL TO METRIC

METRIC TO IMPERIAL

Length

Length

thousandth of inch (thou or mil)

inches (in)

feet (ft)

x 25.4 = m

x 25.4 = mm

x 0.3048 = m

microns (m)

millimetres (mm)

metres (m)

Area

x 0.03937 = thou or mil

x 0.03937 = in

x 3.28083 = ft

Area

square inches (in )

square feet (ft2)

2

x 645.16 = mm

x 0.0929 = m2

square millimetres (mm2)

square metres (m2)

Volume

cubic inches (cu in)

cubic feet (cu ft)

cubic feet (cu ft)

US gallons (gal)

quart (qt)

fluid ounces (fl oz)

Volume

x 16.38716 = cm or mL

x 0.028317 = m3

x 28.31701 = L

x 3.7854 = L

x 0.9464 = L

x 29.57 = mL

3

Speed - Velocity

feet per minute (ft/min)

feet per second (ft/s)

x 0.00508 = m/s

x 0.03048 = m/s

x 0.47195 = L/s

x 0.028317 = m3/min

x 1.69902 = m3/hr

x 3.7854 = L/min

x 0.4536 = kg

kilograms (kg)

x 2.11887 = CFM

x 35.3145 = CFM

x 0.58857 = CFM

x 0.26417 = US gpm

x 2.2046 = lb

Bulk - Density

x 16.0185 = kg/m

x 0.016019 = kg/L

kilograms per cubic metre (kg/m3)

kilograms per litre (kg/L)

x 0.062428 = lb/cuft

x 62.4277 = lb/cuft

Pressure

x 6.8947 = kPa

x 0.0068947 = MPa

x 0.068947 = bar

Vacuum

inches of mercury (in. Hg)

inches of mercury (in. Hg)

litres per second (L/s)

cubic metres per minute (m3/min)

cubic metres per hour (m3/hr)

litres per minute (L/min)

Weight - Mass

Pressure

pounds per square inch (psi)

pounds per square inch (psi)

pounds per square inch (psi)

x 196.85 = ft/min

x 3.28083 = ft/s

Flow Rate

Bulk - Density

pounds per cubic foot (lb/cuft)

pounds per cubic foot (lb/cuft)

x 0.061023 = cu in

x 35.3145 = cu ft

x 0.035315 = cu ft

x 0.26417 = US gal

x 1.05668 = qt

x 0.03381 = fl oz

metres per second (m/s)

metres per second (m/s)

Weight - Mass

pounds (lb)

cubic centimetres (cm3)

cubic metres (m3)

litres (L)

litres (L)

litres (L)

millilitres (mL)

Speed - Velocity

Flow Rate

cubic feet per minute (CFM)

cubic feet per minute (CFM)

cubic feet per minute (CFM)

US gallons per minute (gpm)

x 0.00155 = in2

x 10.7639 = ft2

kilopascals (kPa)

Megapascals (MPa)

bar (bar)

x 0.145 = psi

x 145.04 = psi

x 14.504 = psi

Vacuum

x 3.38638 = -kPa

x 13.596 = in. H2O

kilopascals vacuum (-kPa)

inches of water (in. H2O)

x 0.2953 = in. Hg

x 0.07355 = In. Hg

14

Power

horsepower (hp)

Power

x 0.7457 = kW

Temperature

degrees Fahrenheit (F)

kilowatts (kW)

x 1.341 = hp

Temperature

- 32, then x 0.5555 = C

degrees Celsius (C)

x 1.8, then +32 = F

Blastmaster Catalogue

Section 14

309

Technical Reference Section

Conversion Tables

PRESSURE

psi to bar, kPa (MPA)

TEMPERATURE

bar, kPa (MPa) to psi

degrees Fahrenheit

degrees Celsius

psi

bar

kPa

bar

kPa

psi

40

50

60

2.8

3.4

4.1

276

345

414

1

2

3

100

200

300

14.5

29

43.5

70

80

90

4.8

5.5

6.2

483

552

621

4

5

6

400

500

600

58

72.5

87

100

110

120

6.9

7.6

8.3

689

758

827

7

8

9

700

800

900

101.5

116

130.5

130

140

150

9.0

9.6

10.3

10

11

12

68.9

103

138

100

200

250

1000

1100

1200

MPa

10

20

25

145

159.5

174

1000

1500

2000

896

965

1034

MPa

6.9

10.3

13.8

2500

3000

3500

172

207

241

17.2

20.7

24.1

300

350

400

30

35

40

4351

5076

5800

4000

5000

6000

276

345

414

27.6

34.5

41.4

500

600

700

50

60

70

7250

8700

10150

7000

8000

9000

10000

20000

30000

35000

40000

`50000

483

552

621

689

1380

2070

2410

2760

3450

48.3

55.2

62.1

68.9

137

206

241

275

344

800

900

1000

1500

2000

2500

3000

3500

4000

80

90

100

150

200

250

300

350

400

11600

13050

14500

21750

29000

36260

43500

50760

58000

-20

-10

-4

0-ZERO

10

14

20

30

32

40

50

59

68

70

80

86

90

100

104

122

140

158

176

194

212

230

248

266

284

300

-28.9

-23.3

-20

-17.8

-12.2

-10

-6.7

-1.1

0-ZERO

4.4

10

15

20

21.1

26.7

30

32.2

37.8

40

50

60

70

80

90

100

110

120

130

140

148.9

1450

2900

3626

14

DISCLAIMER: All and any tables, calculations, factors, formulas, etc information on any of these pages are a guide only and shall not be taken as either the approved nor standard

nor complying method nor formula nor calculation for any of the topics or aspects referred to, and neither is any claim made as to the completeness or accuracy of the information.

It is the responsibility of the reader and/or users of this information to separately determine and verify the correct method, formula, factor, procedure, data, etc. for determining any

such topics or aspects as directed or required or indicated in or by any work specifications and/or standards.

Blastmaster expressly disclaims any liability for the use or misuse of the information.

310

Section 14

Blastmaster Catalogue

Technical Reference Section

Conversion Tables

VENTILATION FLOW RATES

CFM

Litres/min

m3/min

m3/hr

m3/min

CFM

m3hr

CFM

500

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

15000

20000

25000

30000

35000

40000

45000

50000

75000

100000

14,159

28,317

56,634

84,951

113,270

141,590

169,900

198,220

226,540

254,850

283,170

424,760

566,340

707,930

849,510

991,100

1,132,700

1,274,300

1,415,900

2,123,800

2,831,700

14.16

28.32

56.63

84.95

113.3

141.6

169.9

198.2

226.5

254.9

283.2

424.8

566.3

707.9

849.5

991.1

1133

1274

1416

2124

2832

849.5

1699

3398

5097

6796

8495

10,194

11,893

13,592

15,291

16,990

25,485

33,980

42,476

50,971

59,466

67,961

76,456

84,951

127,427

169,902

15

25

50

75

100

125

150

200

250

300

400

500

600

700

800

900

1000

1250

1500

2000

2500

529.7

882.9

1765

2648

3531

4414

5297

7062

8829

10,590

14,130

17,660

21,190

24,720

28,250

31,780

35,310

44,140

52,970

70,630

88,290

1000

2000

3000

4000

5000

7500

10,000

12,500

15,000

20,000

25,000

30,000

35,000

40,000

45,000

50,000

60,000

75,000

100,000

125,000

150,000

588.6

1177

1766

2354

2943

4414

5886

7357

8828

11,770

14,710

17,660

20,600

23,540

26,490

29,430

35,310

44,140

58,860

73,570

88,290

COMPRESSED AIR SUPPLY FLOW RATES

CFM

litres/second

litres/second

CFM

100

150

200

250

300

350

400

450

500

600

700

900

1000

1200

1400

47.2

70.8

94.4

118

142

165

189

212

236

283

330

425

472

566

661

35

40

50

75

100

125

150

175

200

250

300

350

400

500

600

74.2

84.8

106

159

212

265

318

371

424

530

636

742

848

1059

1271

14

Blastmaster Catalogue

Section 14

311

Technical Reference Section

Quick Reference Guide to Relevant AS and ISO Standards

PAINTS/COATINGS

PAINTS/COATINGS

Glossary of Terms

AS2310

Test Methods

Solvent Flashpoint

AS2106

Sampling Procedures

AS1580-102.1

Soluble Lead Content

AS1580-501

Wet Film Thickness

AS1580-107

Painting of Buildings

AS2311

Climatic Conditions for Painting

AS3894-7

AS3894-3

Dry Film Thickness

Site Inspection Reports

AS1580-108

AS3894-3

Daily surface & ambient conditions AS3894-10

ISO2178

Equipment

AS3894-11

ISO2808

Coating

AS3894-12

Daily blast & paint

AS3894-13

ISO2360

Adhesion

AS1580-408

Daily painting

AS3894-14

AS3894-9

Paint Systems Etch Primers

AS3750-17

ISO2409

Inorganic Zinc Silicate

AS3750-15

Metallic & Related Coatings

AS1397

ISO4624

Continuity (Porosity)

AS3894-1

AS4534

AS3894-2

AS4680

ISO2746

AS4791

AS4792

ISO8289

Hardness

ISO2063

ISO2064

Metallic Coatings Methods of Test AS2331

AS1580-405

ISO2815

Hard Dry Conditions

AS1580-401.5

Cure

AS3894-4

Gloss

AS1580-602

ISO1461

ISO2064

External fusion-bonded epoxy

AS3862

AS3894-8

Corrosion Prevention

AS2312

ISO2813

ISO12944

Degree of substrate corrosion

ISO7668

AS1580-481.1

Density

AS1580-202.1

Degree of blistering

AS1580-481.0

Evaluation of degradation

ISO4628

Visual inspection of

metal products

AS3978

DISCLAIMER: The above information does not represent nor purport to be a full nor complete nor accurate list of Australian Standards, Joint Australian/New Zealand Standards or ISO

Standards. It is the responsibility of the reader and/or users of this information to separately determine and verify each and/or any relevant or appropriate or required or necessary or

updated or accurate standards and/or their contents for any particular topic or aspect. Blastmaster expressly disclaims any liability for the use or misuse of the above information.

14

312

Section 14

Blastmaster Catalogue

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Cert DWG DFP - For Fuel HandlingDocument1 pageCert DWG DFP - For Fuel HandlingEko Kurniawan100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Heavy Hex Structural Bolts, ASTM A325, Type 1, ASTM A563 Grade DH Heavy Hex Nut, Hot Dip GalvanizedDocument2 pagesHeavy Hex Structural Bolts, ASTM A325, Type 1, ASTM A563 Grade DH Heavy Hex Nut, Hot Dip GalvanizedZoebairNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Abrasive Sand-Blasting Procedure PDFDocument5 pagesAbrasive Sand-Blasting Procedure PDFEko Kurniawan100% (5)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Cranes NotesDocument72 pagesCranes NotesEko KurniawanNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Lysaght Spandek Dec 2013Document6 pagesLysaght Spandek Dec 2013Eko KurniawanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Storage Tank Erection Procedure PDFDocument6 pagesStorage Tank Erection Procedure PDFEko Kurniawan89% (19)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Welding and Cutting Safety ProcedureDocument4 pagesWelding and Cutting Safety ProcedureEko Kurniawan100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Standard Metric and USA Bolt DimensionsDocument1 pageStandard Metric and USA Bolt DimensionsEko Kurniawan100% (2)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Radiography Examination Procedure For Asme Boiler, Pressure Vessel and PipingDocument15 pagesRadiography Examination Procedure For Asme Boiler, Pressure Vessel and PipingEko Kurniawan100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- 602Document1 page602Eko KurniawanNo ratings yet

- NDT Structural SteelDocument35 pagesNDT Structural Steeltinz_3100% (2)

- E-Waste Regulation Draft in IndonesiaDocument20 pagesE-Waste Regulation Draft in IndonesiaIkhwan Wahyudi RahmanNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Environmental Regulations For Demolition Project ChecklistDocument5 pagesEnvironmental Regulations For Demolition Project ChecklistEko KurniawanNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Lifting PlanDocument10 pagesLifting PlanEko Kurniawan100% (4)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Making Surrey tanks safeDocument6 pagesMaking Surrey tanks safeEko KurniawanNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Exide Demo PlanDocument34 pagesExide Demo PlanEko KurniawanNo ratings yet

- Environmental Regulations For Demolition Project ChecklistDocument5 pagesEnvironmental Regulations For Demolition Project ChecklistEko KurniawanNo ratings yet

- Class 150 & 300 Steel Pipe Flange Bolt Sizes & Patterns in 38 charactersDocument2 pagesClass 150 & 300 Steel Pipe Flange Bolt Sizes & Patterns in 38 characterskh88hmiNo ratings yet

- Storage Tank RemovalDocument3 pagesStorage Tank RemovalEko KurniawanNo ratings yet

- DG12122 - IND - NIA Gantt Chart - Rev03 PDFDocument2 pagesDG12122 - IND - NIA Gantt Chart - Rev03 PDFEko KurniawanNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Class 150 & 300 Steel Pipe Flange Bolt Sizes & Patterns in 38 charactersDocument2 pagesClass 150 & 300 Steel Pipe Flange Bolt Sizes & Patterns in 38 characterskh88hmiNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- CMS Deliverable Review Process PDFDocument43 pagesCMS Deliverable Review Process PDFEko KurniawanNo ratings yet

- Procedure Natural Gas Piping Purging HazardsDocument4 pagesProcedure Natural Gas Piping Purging HazardsEko KurniawanNo ratings yet

- PQ - Woqod - AALCO GroupDocument104 pagesPQ - Woqod - AALCO GroupJason RazatlabNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Metric Conversions: SurfaceDocument3 pagesMetric Conversions: SurfaceSachin KarekarNo ratings yet

- Measurement Units and Quantity Surveying BasicsDocument11 pagesMeasurement Units and Quantity Surveying BasicsVince JecielNo ratings yet

- QB-DPPDocument54 pagesQB-DPPd anjilappa100% (1)

- Medical Gas Cylinder Data Chart: BOC: Living HealthcareDocument7 pagesMedical Gas Cylinder Data Chart: BOC: Living HealthcareAgustin CesanNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Conversion Unidades en MoliendaDocument2 pagesConversion Unidades en MoliendaRive RoskyNo ratings yet

- 3rd Quarter Exam in TLE 8Document3 pages3rd Quarter Exam in TLE 8gerlie cerbaniaNo ratings yet

- Hand-Out 1Document5 pagesHand-Out 1Mae ZelNo ratings yet

- Exercise 29Document3 pagesExercise 29titanitafathNo ratings yet

- Lesson Plan For Demo TeachingDocument6 pagesLesson Plan For Demo TeachingPaño Burce MilletNo ratings yet

- Def Stan 91 090 Issue 5 AvgasDocument20 pagesDef Stan 91 090 Issue 5 AvgasHimzo CerkezovicNo ratings yet

- © Ncert Not To Be Republished: A I E, A N M MDocument10 pages© Ncert Not To Be Republished: A I E, A N M MbnkjayaNo ratings yet

- IS 2386 Part 2Document21 pagesIS 2386 Part 2Reshmita PallaNo ratings yet

- Ecotechnics Car AC Service MachinesDocument2 pagesEcotechnics Car AC Service MachinesMagnus Mototech100% (1)

- Mathematics: Quarter 2 - Module 1: MeasurementDocument12 pagesMathematics: Quarter 2 - Module 1: MeasurementMark Galang100% (2)

- Marvac CatalogueDocument40 pagesMarvac CataloguedhavaleshNo ratings yet

- Aa Microlab300 Cat 8Document52 pagesAa Microlab300 Cat 8DARWIN FERNANDO MONTOYA GONZALEZNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Civil Handbook by P N Khanna PDFDocument688 pagesCivil Handbook by P N Khanna PDFhherizo118788% (8)

- Use Pharmaceutical Calculation Techniques and TerminologiesDocument62 pagesUse Pharmaceutical Calculation Techniques and TerminologiesKena Samuel100% (3)

- E288Document3 pagesE288Muhammad Masood Abbas100% (1)

- Why PPM Is Ambiguous? - Mass Voulme or AtomicDocument3 pagesWhy PPM Is Ambiguous? - Mass Voulme or Atomiclram70No ratings yet

- Practice Problems with Scientific Notation, Exponents, Significant Figures, Unit Conversions, and Density CalculationsDocument4 pagesPractice Problems with Scientific Notation, Exponents, Significant Figures, Unit Conversions, and Density CalculationsNoora MojaddediNo ratings yet

- P3 Term 3 Plan 2023-2024Document3 pagesP3 Term 3 Plan 2023-2024winata linggaNo ratings yet

- Data BCV 275-50 E2-FDocument4 pagesData BCV 275-50 E2-FHoang Minh HungNo ratings yet

- br4 HckeyDocument170 pagesbr4 HckeyMarjorie LaYon67% (12)

- Mohindra Fasteners Ltd. Automatic Tri-Valent Plating Plant LayoutDocument10 pagesMohindra Fasteners Ltd. Automatic Tri-Valent Plating Plant LayoutRohtash fastner100% (1)

- M Stage 6 P840 02 AFPDocument18 pagesM Stage 6 P840 02 AFPwaniaaawaseemNo ratings yet

- Appendix Units of Measure: A.1 Abbreviations For SI UnitsDocument5 pagesAppendix Units of Measure: A.1 Abbreviations For SI UnitslformigoniNo ratings yet

- Technofondi General CatalogDocument28 pagesTechnofondi General CatalogYein YeeNo ratings yet

- Number LineDocument10 pagesNumber Lineshawn1loweNo ratings yet