Professional Documents

Culture Documents

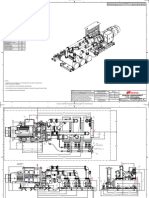

04 Mechanical

Uploaded by

Bhavesh PanchalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04 Mechanical

Uploaded by

Bhavesh PanchalCopyright:

Available Formats

6

Dewberry Architects Inc.

SYMBOL

DESCRIPTION

-CEILING DIFFUSER, ROUND NECK

(CEILING DIFFUSERS ARE 4-WAY THROW UNO)

SYMBOL

DESCRIPTION

-TERMINAL UNIT, VARIABLE/CONSTANT AIR

VOLUME WITH ELECTRIC HEAT

-FIRE DAMPER

(WITH ACCESS PANEL)

-TERMINAL UNIT, VARIABLE/CONSTANT AIR

VOLUME WITH ELECTRIC HEAT

-FIRE & SMOKE DAMPER

(WITH ACCESS PANEL)

-ROUND DIFFUSER

-CEILING RETURN

-EXISTING FIRE DAMPER TO REMAIN

-CEILING EXHAUST

-TERMINAL UNIT, VARIABLE/CONSTANT AIR

VOLUME, FAN POWERED

-EXISTING FIRE & SMOKE DAMPER TO REMAIN

-CEILING DIFFUSER, RECTANGULAR OR

SQUARE NECK (CEILING DIFFUSERS

ARE 4-WAY THROW UNO)

SA-1

-SOUND ATTENUATOR

-SUPPLY REGISTER OR GRILLE

(VERTICAL MOUNT, SIDEWALL)

-TERMINAL UNIT, VARIABLE/CONSTANT AIR

VOLUME, FAN POWERED, WITH ELECTRIC

HEAT

-MOTOR OPERATED CONTROL DAMPER (MOD)

M

-RETURN/EXHAUST REGISTER OR GRILLE

(VERTICAL MOUNT, SIDEWALL)

-ELECTRIC DUCT HEATER

(W/ PANEL CLEARANCE)

-AIR FLOW MEASURING STATION

FM

-REVISION REFERENCE

-MANUAL BALANCING DAMPER

-DETAIL REFERENCE: TOP-DETAIL#,

BOTTOM-DRAWING# SHOWN ON

-THERMOSTAT/TEMPERATURE SENSOR

-HUMIDISTAT/HUMIDITY SENSOR

-DUCT SMOKE DETECTOR

-HYDRONIC REHEAT COIL

-DOOR GRILLE

UC

1

M-1

-INLINE CENTRIFUGAL FAN

-UNDERCUT DOOR

-CONNECT TO EXISTING

-PACKAGED TERMINAL AIR CONDITIONER

(PTAC)

-ACCESS DOORS, VERTICAL OR HORIZONTAL

-DEMOLISH TO POINT INDICATED

-MOTORIZED CONTROL DAMPER

M

TS

-TEMPERATURE SENSOR

-PRESSURE SENSOR

-STAINLESS STEEL DUCTWORK

UP

DN

-CHANGE OF ELEVATION

-FLEXIBLE CONNECTION

-FLEXIBLE DUCT

12x8

-BACKDRAFT DAMPER

BD

-FLAT OVAL DUCT

-TRANSITION, CONCENTRIC

-NEUTRAL RELATIVE PRESSURE

24x12

-NEW DUCTWORK, FIRST DIMENSION IS SIDE SHOWN

-POSITIVE RELATIVE PRESSURE

+

_

-NEGATIVE RELATIVE PRESSURE

24x12

-EXISTING DUCTWORK TO REMAIN

-SHEET NOTE CALLOUT

24x12

-EXISTING DUCTWORK TO BE REMOVED

-SHEET NOTE CALLOUT

SYMBOL

DESCRIPTION

1. CONNECTION TO EQUIPMENT SHALL BE VERIFIED WITH MANUFACTURER'S CERTIFIED

DRAWINGS. TRANSITIONS TO ALL EQUIPMENT SHALL BE VERIFIED AND PROVIDED

FOR EQUIPMENT FURNISHED.

AFD

-ADJUSTABLE FREQUENCY DRIVE

LD

-LINEAR DIFFUSER

AFF

-ABOVE FINISHED FLOOR

MBH

-THOUSAND BTUs PER HOUR

AFR

-ABOVE FINISHED ROOF

MCA

-MINIMUM CIRCUIT AMPS

AHU

-AIR HANDLING UNIT

MOCP

-MAXIMUM OVER CURRENT PROTECTION

AP

-ACCESS PANEL

MOD

-MOTOR OPERATED CONTROL DAMPER (MOD)

BOP

-BOTTOM OF PIPE

NC

-NORMALLY CLOSED

BHP

-BRAKE HORSEPOWER

NO

-NORMALLY OPEN

BTU

-BRITISH THERMAL UNIT

NTS

-NOT TO SCALE

-CENTER LINE

OA

-OUTSIDE AIR

-CFM (CUBIC FEET PER MINUTE)

OAL

-OUTSIDE AIR LOUVER

CD

-CEILING DIFFUSER

PRV

-PRESSURE REDUCING VALVE

CT

-COOLING TOWER

PRS

-PRESSURE REDUCING STATION

CV

-CONSTANT AIR VOLUME

PSI

-POUNDS PER SQUARE INCH

-CHANGE IN PRESSURE

PSIG

-PSI GAUGE

-CHANGE IN TEMPERATURE

PTAC

-PACKAGED TERMINAL AIR CONDITIONER

CFM

-CUBIC FEET PER MINUTE

PVC

-POLYVINYL CHLORIDE PIPE

CU

-CONDENSING UNIT

RA

-RETURN AIR

DDC

-DIRECT DIGITAL CONTROLS

RHC

-REHEAT COIL

DN

-DOWN

RHP

-ROOFTOP HEAT PUMP

EAT

-ENTERING AIR TEMPERATURE

RPM

-REVOLUTIONS PER MINUTE

ESP

-EXTERNAL STATIC PRESSURE

RS/L

-REFRIGERANT SUCTION & LIQUID LINES

EWT

-ENTERING WATER TEMPERATURE

RTU

-ROOFTOP AIR HANDLING UNIT

FCU

-FAN COIL UNIT

SA

-SUPPLY AIR

FD

-FIRE DAMPER

SP

-STATIC PRESSURE

FF

-FINAL FILTERS

TSP

-TOTAL STATIC PRESSURE

FLA

-FULL LOAD AMPS

UNO

-UNLESS NOTED OTHERWISE

FPM

-FEET PER MINUTE

V/PH

-VOLTS/PHASE

GPM

-GALLONS PER MINUTE

VAV

-VARIABLE AIR VOLUME

KW

-KILOWATT

VFD

-VARIABLE FREQUENCY DRIVE

LAT

-LEAVING AIR TEMPERATURE

LWT

-LEAVING WATER TEMPERATURE

2. DIMENSIONS SHALL BE FIELD-VERIFIED AND COORDINATED PRIOR TO PROCUREMENT OR

FABRICATION. COORDINATE THE WORK WITH OTHER TRADES INVOLVED. FIELD MODIFICATIONS

SUCH AS OFFSETS IN PIPING OR DUCTWORK (INCLUDING DIVIDED DUCTWORK) NEEDED DUE TO

OBSTRUCTIONS OR INTERFERENCES SHALL BE PROVIDED AT NO ADDITIONAL COST. FOR PROJECTS

INVOLVING RENOVATION, COORDINATE NEW WORK WITH EXISTING ELEMENTS SUCH AS THE

BUILDING STRUCTURE AND ARCHITECTURAL FEATURES, SPRINKLER PIPING, LIGHTS, PLUMBING, AND

ELECTRICAL CONDUIT.

3. DUCT CONSTRUCTION SHALL BE IN ACCORDANCE WITH THE LATEST EDITION OF THE

SMACNA HVAC DUCT CONSTRUCTION STANDARD.

4. SEE SPECIFICATIONS FOR GAUGES, THICKNESS, BRACING, REQUIREMENTS, ETC., OF DUCTWORK.

5. PROVIDE AIR TURNING VANES IN ALL 90 DEGREE RECTANGULAR DUCT ELBOWS.

6. DUCT SIZES AND ALL OPENINGS THROUGH BUILDING CONSTRUCTION SHALL SUIT EQUIPMENT

FURNISHED.

7. COORDINATE DIFFUSER, GRILLE AND REGISTER LOCATIONS WITH ARCHITECTURAL

REFLECTED CEILING PLANS AND EQUIPMENT OF ALL TRADES.

8. LOCATE THERMOSTATS, TEMPERATURE SENSORS, HUMIDISTATS, AND HUMIDITY SENSORS AT 48"

ABOVE FINISHED FLOOR UNLESS NOTED OTHERWISE. COORDINATE LOCATIONS WITH OTHER

EQUIPMENT, FURNITURE, AND DOOR SWINGS.

9. ALL EQUIPMENT, DUCTWORK, ETC., SHALL BE SUPPORTED AS DETAILED AND/OR SPECIFIED. PROVIDE

ADDITIONAL SUPPORTS AS REQUIRED TO PROVIDE A VIBRATION-FREE, RIGID INSTALLATION.

10. ALL DUCT SIZES SHOWN ARE INSIDE CLEAR DIMENSIONS.

11. DAMPERS AND INSIDES OF DUCTS VISIBLE THROUGH GRILLES, REGISTERS AND DIFFUSERS SHALL BE

PAINTED FLAT BLACK.

12. REFER TO TYPICAL DETAILS FOR PIPING AND INSTALLATION OF EQUIPMENT.

13. TRAPPED CONDENSATE DRAINS FROM ALL MECHANICAL EQUIPMENT SHALL BE PROVIDED FOR

PROPER DRAINAGE TO SUIT EQUIPMENT FURNISHED.

14. ACCESS PANELS IN DUCTWORK AND CEILINGS SHALL BE PROVIDED WHERE REQUIRED FOR

OPERATION, BALANCING OR MAINTENANCE OF ALL MECHANICAL EQUIPMENT.

15. ALL DUCTWORK AND PIPING IS SHOWN SCHEMATICALLY. PROVIDE ALL TRANSITIONS, TURNING

VANES, ELBOWS, FITTINGS, ETC., TO ALLOW SMOOTH FLOWS. ALL SPLIT DUCT FITTINGS SHALL

TRANSITION TO FULL SIZE OF THE SUM OF BOTH BRANCHES, UPSTREAM OF SPLIT.

16. PROVIDE CONCRETE HOUSEKEEPING PAD UNDER ALL FLOOR-MOUNTED EQUIPMENT. REFER TO

SPECIFICATIONS FOR DETAILED REQUIREMENTS.

17. VERIFY FINISH WITH ARCHITECT PRIOR TO PURCHASING GRILLES, REGISTERS, DIFFUSERS, LOUVERS

AND OTHER AIR DISTRIBUTION DEVICES.

18. PROVIDE FLEXIBLE DUCT CONNECTIONS ON ALL DUCTWORK CONNECTING TO EACH FAN, AIR

HANDLING UNITS, AND FAN COIL UNITS.

-TRANSITION, SQUARE TO ROUND

10x8

-DUCT ELBOW, POSITIVE PRESSURE (SUPPLY), FIRST

DESCRIPTION

24x12

-SHEET NOTE CALLOUT

-TRANSITION, ECCENTRIC

SYMBOL

UP W/IN FLOOR

DOWN

-CEILING MOUNTED ACCESS DOOR

19. PROVIDE TRANSITIONS AT DIFFUSER NECKS AS REQUIRED TO MATCH SIZES OF FLEX DUCTS TO BE

CONNECTED.

-SQUARE THROAT TEE

DIMENSION INDICATES SIDE TO WHICH ARROW IS POINTING

20. INTERRUPTIONS TO EXISTING SERVICES SHALL BE SCHEDULED FOR TIMES OTHER THAN NORMAL

OPERATING HOURS (SUCH AS NIGHTS AND WEEKENDS). SUCH INTERRUPTIONS TO SERVICES SHALL

NOT BE MADE WITHOUT THE PRIOR WRITTEN CONSENT OF THE OWNER'S REPRESENTATIVE AND

PROPER COORDINATION WITH OTHER TRADES. PRE-WORK SHALL BE PERFORMED TO MAKE THE

SHUTDOWN PERIOD AS BRIEF AS POSSIBLE.

-DUCT ELBOW, EXHAUST

-DUCT ELBOW, NEGATIVE PRESSURE, RETURN

-RADIUS TEE

12x8

21. ALL EQUIPMENT, DUCTWORK, ETC., TO BE REMOVED SHALL REMAIN PROPERTY OF THE OWNER OR

DISPOSED OF LEGALLY, AS DIRECTED BY OWNER.

-DUCT ELBOW UP THROUGH ROOF OR SLAB ABOVE

401 SW Water St.

Suite 701

Peoria, IL 61602

309.282.8000 Phone

309.282.8001 Fax

-RECTANGULAR DUCT SECTION UP, POSITIVE PRESSURE,

SUPPLY OR OUTSIDE AIR

22. MAINTAIN CLEARANCE OF A MINIMUM OF 6" BETWEEN DUCTWORK, PIPING, EQUIPMENT, ETC., AND ALL

FIRE RATED AND FIRE/SMOKE RATED PARTITIONS, TO ALLOW FOR INSPECTIONS OF RATED WALLS.

-RECTANGLE-TO-ROUND TAKE-OFF

23. LOCATE ALL OUTSIDE AIR INTAKES A MINIMUM OF 10' CLEAR FROM ALL PLUMBING VENTS AND

EXHAUST AIR DISCHARGE LOCATIONS.

-RECTANGULAR DUCT SECTION UP,

NEGATIVE PRESSURE, RETURN

-STANDARD BRANCH TAKE-OFF

-RECTANGULAR DUCT SECTION UP, EXHAUST

-ROUND DUCT SECTION UP

24. DUCT RUNOUTS TO DIFFUSERS SHALL MATCH THE SIZE OF THE DIFFUSER NECK.

25. WATER PRESSURE DROPS THROUGH COIL CONTROL VALVES SHALL NOT EXCEED 5 PSI.

-SPIN-IN TAKE-OFF

114400 North 49th Street

Clearwater, FL.

DESCRIPTION

HVAC GENERAL NOTES

Pinellas County Jail Phase I

Infrastructure Criteria Package - Drawings

SYMBOL

HVAC ABBREVIATIONS

Pinellas County

HVAC SYMBOL LEGEND

26. UNLESS OTHERWISE NOTED, ALL EQUIPMENT AND VALVE DRAINS SHALL BE INDEPENDENTLY PIPED

FULL SIZE TO THE NEAREST PLUMBING DRAIN.

-FLAT OVAL DUCT SECTION UP

-SQUARE THROAT ELBOW

W/TURNING VANES

27. SLEEVE AND SEAL ALL PIPING PENETRATIONS THROUGH BUILDING PARTITIONS. PROVIDE MANUAL AIR

VENTS AT ALL HIGH POINTS IN CHILLED WATER AND HOT WATER PIPING.

28. PIPING, DUCTWORK, LEAK PROTECTION APPARATUS, OR OTHER EQUIPMENT FOREIGN TO ELECTRICAL

SWITCHBOARDS, PANELBOARDS, DISTRIBUTION BOARDS, OR MOTOR CONTROL CENTERS SHALL NOT

BE INSTALLED WITHIN THE REQUIRED SPACE FOR WORKING CLEARANCES OR DEDICATED SPACES OF

THE ELECTRICAL EQUIPMENT, EXTENDING IN FRONT OF AND FROM FLOOR TO STRUCTURAL CEILING

WITH A WIDTH AND DEPTH OF THE ELECTRICAL EQUIPMENT IN ACCORDANCE WITH NEC-110.26.

-RADIUS ELBOW

SEAL

-RECTANGULAR/ROUND BRANCH TAKE-OFF

OR ROUND/ROUND BRANCH TAKE-OFF

PRELIMINARY DOCUMENTS

-EXHAUST DUCT UP THROUGH SLAB W/

FAN ON ROOF ABOVE

NOT FOR CONSTRUCTION

-EXHAUST FAN ON ROOF W/ DUCT DOWN

THROUGH ROOF

KEY PLAN

HVAC PIPING SYMBOL LEGEND

SYMBOL

DESCRIPTION

SYMBOL

DESCRIPTION

HVAC EQUIPMENT TAGS

SYMBOL

EQUIP.

CWS

-CONDENSER WATER SUPPLY

-FLOW DIRECTION

CWR

-CONDENSER WATER RETURN

-GATE VALVE

-CHILLED WATER SUPPLY

-BALL VALVE

CHWS

CHWR

DESCRIPTION

TAG

A

- P-TRAP

-AIR DISTRIBUTION DEVICE

200

CFM

-TWO-WAY CHECK VALVE

SCALE

MV

AHU NUMBER

-MANUAL VENT

-CHILLED WATER RETURN

-CALIBRATING BALANCING VALVE

CD

-CONDENSATE

-BUTTERFLY VALVE

CR

-CONDENSATE RETURN

-GAS COCK

-PRESSURE GAUGE

PC

-PUMPED CONDENSATE

-UNION

-RELIEF VALVE

AHU-1

HWR

HWS

-HOT WATER SUPPLY

HPS

-HIGH PRESSURE STEAM SUPPLY

MPS

-MEDIUM PRESSURE STEAM SUPPLY

-LOW PRESSURE STEAM SUPPLY

-STRAINER

FM

-FLOW METER

-CONTROL VALVE

-WATER METER

-SOLENOID VALVE

-PSI REG.

-CHECK VALVE

HPR

-HIGH PRESSURE STEAM RETURN

MPR

-MEDIUM PRESSURE STEAM RETURN

-FLOW SWITCH

LPR

-LOW PRESSURE STEAM RETURN

-SLOPE DIRECTION (DOWN)

-REFRIGERANT LIQUID

-FLEX CONNECTION

RL

RS

-REFRIGERANT SUCTION

-VALVE ON RISER

-CAP

-CONNECTION, BOTTOM

VARIABLE/CONSTANT AIR VOLUME TERMINAL UNITS

VTU - VARIABLE TERMINAL UNIT

CTU - CONSTANT TERMINAL UNIT

PTU - PARALLEL TERMINAL UNIT

STU - SERIES TERMINAL UNIT

AHU NUMBER

TERMINAL NUMBER

VTU-1-1

No.

Description

Date

-COUPLING

-O.S.&Y. GATE VALVE

-ELBOW, 90

-STEAM TRAP

-ELBOW, 45

-THREE-WAY CONTROL VALVE

-ELBOW, TURNED DOWN

-45 PIPE RISE (R) / DROP (D)

-ELBOW, TURNED UP

-PIPE ANCHORS

-REHEAT COIL

RHC-1-1

TERMINAL UNIT TYPE

-INLINE PUMP

-CONNECTION, TOP

-TEE, OUTLET DOWN

-TEE, OUTLET UP

-INLINE PUMP

12" = 1'-0"

COIL NUMBER

-HOT WATER RETURN

LPS

AHU NUMBER

-AIR HANDLING UNIT

-THERMOMETER

REVISIONS

DRAWN BY

HAT

APPROVED BY

LTE

CHECKED BY

LTE

DATE

-CONCENTRIC REDUCER

-ECCENTRIC REDUCER

03/19/2014

TITLE

MECHANICAL

LEGEND

A

NOTE: SOME SYMBOLS SHOWN ON THIS LEGEND MAY NOT PERTAIN TO THIS PROJECT

PROJECT NO.

M-000

SHEET NO.

50057109

Dewberry Architects Inc.

401 SW Water St.

Suite 701

Peoria, IL 61602

309.282.8000 Phone

309.282.8001 Fax

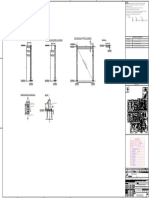

SAFE HARBOR

GENERAL NOTES:

(N)CHWS/R BRANCH TO

NEW BUILDING

1.

ALL EXISTING, PLASTIC CHILLED WATER PIPING SHALL BE

DEMOLISHED/ABANDONED. ANY METALLIC BRANCH PIPING

THAT IS CONNECTED TO PLASTIC MAIN PIPE SHALL BE

DISCONNECTED FROM THE PLASTIC PIPE. METAL ENDS SHALL

BE CAPPED AND LEFT IN SUITABLE CONDITION FOR

CONNECTION TO NEW, METALLIC UNDERGROUND CHILLED

WATER LINES. CONTRACTOR TO VERIFY WHERE PLASTIC PIPE

ENDS AND METAL PIPE BEGINS.

2.

FINAL PIPE SIZE TO BE DETERMINED BY FINAL DESIGN BUILD

CONTRACTOR.

(N)CHWS/R DISTRIBUTION

(E)4" CHWS/R

(E)4" CHWS/R

"M1"

(E)6" CHWS/R

(E)6" CHWS/R

(E)1" BALL VALVES

(N) CHWS/R DISTRIBUTION

(E)8" CHWS/R

"B"

145TH AVE N

HEALTH CARE FACILITY

(E)4" CHWS/R

(E) CHWS/R

VALVE BOX

"A"

SHERIFF ADMIN.

2' V ALLEY GU TTER

(E)4" CHWS/R

(E)4" CHWS/R

"C"

D

"M2"

49TH ST N

(E)3" CHWS/R

(E)3" CHWS/R

(E)8" CHWS/R

142ND AVE N

(N) 20" CHWS/R DISTRIBUTION RUN PARALLEL TO EXISTING

PIPING SERVING CENTRAL/INTAKE AND HOUSING A-G

(E) CHWS/R

CENTRAL DIVISION

POND

POND

114400 North 49th Street

Clearwater, FL.

(N)CHWS/R DISTRIBUTION

Pinellas County

Pinellas County Jail Phase I

Infrastructure Criteria Package - Drawings

CR

OS

SB

AYO

U

(N)CHWS/R BRANCH TO

NEW BUILDING

SEAL

PRELIMINARY DOCUMENTS

NOT FOR CONSTRUCTION

PINELLAS COUNTY

CRIMINAL COURT

COMPLEX

SOUTH DIVISION

(E) CHWS/R

(N)CHWS/R PIPING BRIDGED OVER TO

STATE ATTORNEY/ CJC CENTER

"G"

MAINTENANCE

KEY PLAN

POND

"F"

"E"

"D"

"C"

POND

SCALE

1" = 100'-0"

SIR LB021

(FI R 1/2" LB1344 0.30' S., 0.50' W.)

OHE

OHE

OHE

LAND LINE

JURISDICT IONAL WET

No.

Description

Date

REVISIONS

DRAWN BY

HAT

APPROVED BY

LTE

CHECKED BY

LTE

DATE

JUVENILE DETENTION CENTER

03/19/2014

TITLE

MECHANICAL SITE

PLAN

EDGE OF W ATER

ASPHALT WALK

MECHANICAL SITE PLAN

140TH AVE N

FIR 1/2" LB1344

PROJECT NO.

EDGE OF W ATER

M-001

Scale: 1" = 100'-0"

SHEET NO.

50057109

1

2

3

4

5

6

7

1.1

USED OIL TANK

6.9

Keynotes

AREA TO BE PROVIDED WITH DEDICATED CHILLED

WATER FAN COIL UNIT.

AREA TO BE EXHAUSTED. FAN TO BE CHEMICAL

RATED.

AREA TO BE EXHAUSTED.

VAV BOX WITH ELECTRIC HEAT. PROVIDE ACCESS

PANEL AS REQUIRED.

PROVIDE LINT TRAP.

DRYER EXHAUST FAN. ROUTE TO EXTERIOR WALL.

COMBUSTION AIR MAKE UP FAN. ROUTE TO

EXTERIOR WALL.

Dewberry Architects Inc.

401 SW Water St.

Suite 701

Peoria, IL 61602

309.282.8000 Phone

309.282.8001 Fax

NEW OIL TANK

A

S

WORKER

STAGING

122

LOADING

DOCK

105

PROGRAM

MEETING ROOM

111

4

STORAGE

SALLYPORT

SERVICE DRIVE

103

DOCK

STORAGE

102

BULK REFIG

STORAGE

109

JANITOR

142

3

INMATE

TOILET

119

4

INMATE

TOILET

113

STORAGE

112

JANITOR

114

SEARCH

123

Pinellas County

3

INMATE

TOILET

121

DOCK

STAGING

107

SECURITY

ELECTRONICS

101

Pinellas County Jail Phase I

Infrastructure Criteria Package - Drawings

PROGRAM

MEETING ROOM

116

PROGRAM

MEETING ROOM

110

BULK DRY

STORAGE

108

STAFF

4

3

118

STAIR

A

SA1

MEDIUM PRESSURE SUPPLY DUCT ESTIMATED 80x30

FEC

FEC

C

CO AND NO2 SENSORS LINKED TO ALARM

ELEVATOR

A

EA

1

ELECTRICAL

140

CART

WASH

139

OFFICE/

137

WATER

HEATER

124

ELEVATOR

B

EB

114400 North 49th Street

Clearwater, FL.

A.1

A.1

STAIR

B

SB1

ELEVATOR

C

EC

SEAL

3

STAFF

TOILET

125

NOT FOR CONSTRUCTION

AIR

1

COMPRESSOR

126

GARBAGE/

RECYCLE DOCK

106

PRELIMINARY DOCUMENTS

KEY PLAN

3

UTILITY

WASH

136

TRASH COMPACTOR

CLEAN LAUNDRY

STORAGE

135

CENTRAL

LAUNDRY

138

SCALE

D

1/8" = 1'-0"

4

T

S

PARKING AREA

WATER TANK

STORAGE

104

DRYERS

127

STORAGE

134

MAINTENANCE

SUPPLY

133

T

7

S

4

T

RISER

ROOM

132

UNIFORM

STORAGE

131

INMATE

TOILET

129

BREAK

ROOM

130

CHEMICAL

STORAGE

128

2

No.

E.9

E.9

2448

2448

Description

Date

REVISIONS

DRAWN BY

HAT

APPROVED BY

LTE

CHECKED BY

LTE

DATE

03/19/2014

TITLE

1.1

FIRST FLOOR MECHANICAL PLAN

6.9

FIRST FLOOR

MECHANICAL

PLAN

Scale: 1/8" = 1'-0"

PROJECT NO.

M-110

SHEET NO.

50057109

1

2

3

4

5

6

1.1

6.9

5

SECURED

STORAGE

209

401 SW Water St.

Suite 701

Peoria, IL 61602

309.282.8000 Phone

309.282.8001 Fax

A.1

DRY FOOD

STORAGE

204

Dewberry Architects Inc.

Keynotes

ROUTE EXHAUST DUCTWORK, APPROXIMATELY 60x20, TO

KITCHEN HOODS. COORDINATE WITH KITCHEN

DESIGNER.

ROUTE MAKE UP DUCTWORK, APPROXIMATELY 50x20, TO

KITCHEN EQUIPMENT. COORDINATE WITH KITCHEN

DESIGNER.

ROUTE SUPPLY AND DUCTING TO MECHANICAL CHASE.

AREA TO BE EXHAUSTED.

AREA TO BE EXHAUSTED. FAN TO BE CHEMICAL RATED.

AREA TO BE PROVIDED WITH DEDICATED CHILLED

WATER FAN COIL UNIT.

REFRIGERATER/ FREEZER AREA. SEE KITCHEN

EQUIPMENT PLANS.

BREAK

ROOM

211

A.1

CHEMICAL STORAGE

(SECURE)

216

WARE WASH

AREA

215

EQUIPMENT

STORAGE

203

UNIFORM

205

TRAY

MAKE-UP

220

OFFICE

213

INMATE

TOILET

207

H

C

JAN/EQUIP

SUPPLIES

202

KITCHEN/LAUNDRY

STORAGE

201

CORRIDOR

210

4

INMATE

TOILET

208

FOOD SERVICE

MGMT OFFICE

214

STORAGE

218

CART STORAGE

AND WASHING

219

STAFF

TOILET

206

Pinellas County

STORAGE/

FUTURE LINK

217

CORRIDOR

212

4

4

STAIR

A

SA2

CORRIDOR

221

CORRIDOR

250

FEC

FEC

6

4

4

TRASH

HOLDING

246

ICE/BEV.

234

ELEVATOR

A

EA

ELEVATOR

B

EB

ELEC

233

DAIRY

COLDROOM

247

JAN

249

114400 North 49th Street

Clearwater, FL.

Pinellas County Jail Phase I

Infrastructure Criteria Package - Drawings

STAIR

B

SB2

ELEVATOR

C

EC

D2

D2

C1

C1

SEAL

E1

E2

G

E1

E2

G

D1

STAFF DINING

MULTI-PURPOSE

232

NOT FOR CONSTRUCTION

12"X12"

1075 CFM

.27" S.P.

G G

FIRE CABINET

G

G

G

STEAM CO N DEN SATE

TRAP AN D ST RAI N ER

12"X10"

1456 CFM

.39" S.P.

9"X8"

538 CFM

.07" S.P.

G G

12"X12"

937 CFM

.27" S.P.

SAFET Y VA LVE

VALVE

1/ 2" N PT

SATE

12"X9"CO N DEN

RETU RN

1217 CFM

STEAM

.37" S.P.

CO N TRO L

SAFET Y VA LVE

STEAM CO N DEN SATE

TRAP AN D ST RAI N ER

STEAM

CO N TRO L

VALVE

1/ 2" N PT

12"X12"

937 CFM

.27" S.P.

1

C

STEAM CO N DEN SATE

TRAP AN D ST RAI N ER

APPROXIMATE RETURN DUCT SIZE 70x24

SAFET Y VA LVE

12"X10"

1353 CFM

.43" S.P.

1/ 2" N PT

CO N DEN SATE

RETU RN

11"X8"

1012 CFM

.29" S.P.

SCALE

12"X12"

937 CFM

.27" S.P.

JAN

228

STEAM

CO N TRO L

VALVE

SAFET Y VA LVE

#321.2L

STEAM CO N DEN SATE

TRAP AN D ST RAI N ER

1/ 2" N PT

CO N DEN SATE

RETU RN STEAM

CO N TRO L

VALVE

#321.1L

SAFET Y VA LVE

CO N DEN SATE

12"

X9"

RETU RN

1216 CFM

.37" S.P.

12"X12"

937 CFM

.27" S.P.

12"X10"

1379 CFM

.42" S.P.

12"X10"

809 CFM

.20" S.P.

C D

KEY PLAN

#321.2R

FINISHED BULK

COLDROOM

243

SERVING

231

#321.6L

STEAM

CO N TRO L

VALVE

BULK MEAT

COLDROOM

242

FOOD PREP

SERVICE AREA

230

D

PRELIMINARY DOCUMENTS

CORRIDOR

222

FINISH PRODUCE

COLDROOM

245

HOT FOOD

PRODUCTION

235

12"X11"

1648 CFM

.47" S.P.

CORRIDOR

251

D1

#321.6R

BULK PRODUCE

COLDROOM

248

STEAM CO N DEN SATE

TRAP AN D ST RAI N ER

1/8" = 1'-0"

12"X12"

937 CFM

.27" S.P.

4

FAUCET, TANGENT DRAW-OFF

ARE OPTIONAL

H C

DEN SATE

12"X10"CO N RETU

RN

1352 CFM

.43" S.P.

1/ 2" N PT

12"X10"

809 CFM

.20" S.P.

#321.1R

G G

THAW/PULL

241

11"X8"

1011 CFM

.29" S.P.

BULK

COLDROOM

242

FIRE CABINET

C

D

MULTI-PURPOSE

223

STAFF

TOILET

227

CORRIDOR

229

STAFF 4

TOILET

226

APPROXIMATE SUPPLY DUCT SIZE 96x24

A/V

CLOSET

224

REF

DAILY DRY

STORAGE

236

FINISH VEG

PREP

237

REF

FINISH MEAT

PREP

238

-10 FREEZER

239

-20 FREEZER

240

MIC MIC

E.9

E.9

C

F

7

CONNECTOR TO

CENTRAL TOWER

CN

No.

Description

Date

REVISIONS

DRAWN BY

HAT

APPROVED BY

LTE

CHECKED BY

LTE

DATE

03/19/2014

TITLE

1.1

SECOND FLOOR MECHANICAL PLAN

Scale: 1/8" = 1'-0"

6.9

SECOND FLOOR

MECHANICAL

PLAN

PROJECT NO.

M-120

SHEET NO.

50057109

1

1

2

3

4

5

6

7

8

9

10

11

1.1

6.9

12

13

14

Keynotes

GENERATOR RADIATOR. PIPE TO AND FROM

GENERATOR.

THREE- WAY CATALYST INSTALLED ON EXHAUST GAS

PIPE.

ROUTE EXHAUST GAS PIPE SHORTEST DISTANCE TO

ABSORPTION CHILLER.

NEW CHILLED WATER FAN COIL UNIT. ROUTE OUTSIDE

AIR THROUGH ROOF. COORDINATE ROOF PENETRATIONS

WITH STRUCTURAL.

AREA TO BE PROVIDED WITH DEDICATED CHILLED

WATER FAN COIL UNIT.

AREA TO BE EXHAUSTED.

ROOFTOP CHILLED WATER AIR HANDLER. PROVIDE

MANUFACTURER'S CLEARANCES. SUPPLY AND RETURN

DUCTING PENETRATIONS TO BE COORDINATED WITH

STRUCTURE.

ROOFTOP MAKE UP FAN FOR KITCHEN EQUIPMENT.

COORDINATE WITH KITCHEN DESIGNER. COORDINATE

ROOF PENETRATIONS WITH STRUCTURAL.

ROOFTOP EXHAUST FAN FOR KITCHEN EQUIPMENT.

COORDINATE WITH KITCHEN DESIGNER. COORDINATE

ROOF PENETRATIONS WITH STRUCTURAL.

ROUTE ABSORPTION CHILLER EXHAUST THROUGH ROOF

TO MUFFLER. COORDINATE ROOF PENETRATIONS WITH

STRUCTURAL.

PROVIDE DEDICATED DX/ CHILLED WATER UNIT FOR

ELEVATOR MACHINE ROOM.

ACOUSTICAL TREATED WALL. PROVIDE ACOUSTICAL

WRAP FOR PIPING PENETRATIONS.

REFRIGERANT PURGE SYSTEM FAN.

PROVIDE OUTSIDE AIR DROP FOR PURGE SYSTEM.

Dewberry Architects Inc.

401 SW Water St.

Suite 701

Peoria, IL 61602

309.282.8000 Phone

309.282.8001 Fax

13

14

E

FUTURE ELECTRIC CHILLER

ELECTRIC CHILLER

CHWPFUTURE

ABS

CWP-2

ABS

CHWP-2

ABS

CWP-1

ABS

A.1

CHWP-1

ABS

Pinellas County Jail Phase I

Infrastructure Criteria Package - Drawings

CWPFUTURE

ABS

CONTROL

CONFERENCE RM

313

ELECTRIC CHILLER

FUTURE ABSORPTION CHILLER

ABSORPTION CHILLER

10

CONTROL

ROOM

302

FUTURE SYS PUMP

SYS PUMP

CHW FAN COIL

REF

Pinellas County

A.1

OFFICE

4301

10

REF

B

CHW FAN COIL

5

STAIR

A

SA3

STAFF

TOILET

305

CWP- FUTURE

VESTIBULE

303

CHWP-FUTURE

CHW FAN COIL

ELEVATOR

LOBBY

CWP-3

CHWP-3

CWP- 2

CHWP-2

CWP-1

CHWP-1

CHW/ DX FAN COIL

CHW FAN COIL

ELEVATOR

A

EA

310

WATER

TREATMENT AND

HYDRONIC

SPECIALTIES AREA

CHW FAN COIL

GENERATOR

CONTROL

309

11

CHEMICAL

STORAGE

COUPON RACK AND

CHEMICALS

ELEVATOR

C

EC

STAIR

B

SB3

CHW FAN COIL

I.T.

ROOM

5

306

SEAL

SHOT FEEDER &

PUMPS

ELECTRICAL

114400 North 49th Street

Clearwater, FL.

312

PRELIMINARY DOCUMENTS

NOT FOR CONSTRUCTION

LAUNDRY CHW AHU

KEY PLAN

C

8

1

GAS ENGINE

SCALE

9

1/8" = 1'-0"

D

GENERATOR

ROOM

311

EXTERIOR

ROOF

ER1

EXTERIOR

ROOF

ER2

KITCHEN CHW AHU

B

FUTURE GAS ENGINE

KITCHEN EQUIPMENT

CONDENSING UNIT

No.

Description

Date

REVISIONS

E.9

E.9

12

DRAWN BY

HAT

APPROVED BY

LTE

CHECKED BY

LTE

DATE

03/19/2014

20" CHWS/R PIPING TO SOUTH CAMPUS.

SEE STRUCTURAL AND ARCHITECTURAL FOR ROUTING.

TITLE

1.1

6.9

THIRD FLOOR

MECHANICAL

PLAN

THIRD FLOOR PIPING PLAN

PROJECT NO.

Scale: 1/8" = 1'-0"

M-130

SHEET NO.

50057109

1.1

6.9

Dewberry Architects Inc.

Keynotes

ROUTE CONDENSER PIPING FROM TOWER

THROUGH ROOF SLAB TO PUMP LOCATED IN

MECHANICAL ROOM. COORDINATE ROOF

PENETRATION WITH STRUCTURAL.

GENERATOR ROOM INTAKE FAN. COORDINATE

FAN WITH STRUCTURE. PROVIDE PENTHOUSE.

PROVIDE SILENCERS AS REQUIRED.

GENERATOR ROOM EXHAUST FAN.

COORDINATE FAN WITH STRUCTURE. PROVIDE

PENTHOUSE. PROVIDE SILENCERS AS

REQUIRED.

ABSORPTION CHILLER MUFFLER AND

SILENCER. PROVIDE HEAT RECOVERY SYSTEM.

401 SW Water St.

Suite 701

Peoria, IL 61602

309.282.8000 Phone

309.282.8001 Fax

A

A.1

FUTURE MUFFLER

FUTURE 2-CELL

COOLING TOWER

(ELECTRIC CHILLER)

2-CELL COOLING TOWER

(ELECTRIC CHILLER)

2-CELL COOLING TOWER

(ELECTRIC CHILLER)

(2) SINGLE-CELL COOLING TOWERS

(ABSORPTION CHILLERS)

(1) FUTURE

Pinellas County

STAIR

A

SA4

114400 North 49th Street

Clearwater, FL.

MUFFLER

Pinellas County Jail Phase I

Infrastructure Criteria Package - Drawings

A.1

SEAL

C

1

PRELIMINARY DOCUMENTS

STAIR

B

SB4

NOT FOR CONSTRUCTION

KEY PLAN

C

2

SCALE

1/8" = 1'-0"

No.

FUTURE SUPPLY FAN

Description

Date

FUTURE EXHAUST FAN

REVISIONS

E.9

E.9

DRAWN BY

HAT

APPROVED BY

LTE

CHECKED BY

LTE

DATE

03/19/2014

TITLE

1.1

ROOF PIPING PLAN

6.9

ROOF

MECHANICAL

PLAN

Scale: 1/8" = 1'-0"

PROJECT NO.

M-140

SHEET NO.

50057109

Dewberry Architects Inc.

401 SW Water St.

Suite 701

Peoria, IL 61602

309.282.8000 Phone

309.282.8001 Fax

PIPING SYMBOL LEGEND

-FLOW DIRECTION

-GATE VALVE

-BALL VALVE

-CALIBRATING BALANCING VALVE

-BUTTERFLY VALVE

-GAS COCK

Pinellas County Jail Phase I

Infrastructure Criteria Package - Drawings

-STRAINER

-CONTROL VALVE

-CHECK VALVE

-FLOW SWITCH

-FLEX CONNECTION

-O.S.&Y. GATE VALVE

Pinellas County

-THREE-WAY CONTROL VALVE

-THERMOMETER

-TWO-WAY CHECK VALVE

MV

-MANUAL VENT

CHWP-1

-PRESSURE GAUGE

CHWP-2

FUTURE CHWP

ABSORPTION CHWP

EXPANSION TANK

FUTURE ABSORPTION CHWP

BYPASS

-RELIEF VALVE

FM

-FLOW METER

-WATER METER

-INLINE PUMP

-INLINE PUMP

FUTURE CHILLER

FROM BLDG

AIR SEPARATOR

114400 North 49th Street

Clearwater, FL.

-UNION

TO BLDG.

FUTURE SYSTEM PUMP

SEAL

CH-2

PRELIMINARY DOCUMENTS

NOT FOR CONSTRUCTION

SYSTEM PUMP

KEY PLAN

CH-1

SCALE

NOT TO SCALE

ABSORPTION CHILLER

FUTURE ABSORPTION CHILLER

No.

Description

Date

REVISIONS

CHILLED WATER PIPING DIAGRAM

No Scale

DRAWN BY

HAT

APPROVED BY

LTE

CHECKED BY

LTE

DATE

03/19/2014

TITLE

MECHANICAL

DIAGRAMS

A

PROJECT NO.

M-200

SHEET NO.

50057109

Dewberry Architects Inc.

401 SW Water St.

Suite 701

Peoria, IL 61602

309.282.8000 Phone

309.282.8001 Fax

PIPING SYMBOL LEGEND

-FLOW DIRECTION

-GATE VALVE

-BALL VALVE

-CALIBRATING BALANCING VALVE

-BUTTERFLY VALVE

-GAS COCK

-STRAINER

-CONTROL VALVE

-CHECK VALVE

-FLOW SWITCH

-FLEX CONNECTION

Pinellas County

-O.S.&Y. GATE VALVE

-THREE-WAY CONTROL VALVE

-THERMOMETER

CT-ABSORPTION FUTURE

CT-ABSORPTION

CT-1

CT-2

CT-FUTURE

-TWO-WAY CHECK VALVE

-RELIEF VALVE

MV

-MANUAL VENT

-PRESSURE GAUGE

FM

-FLOW METER

-WATER METER

-INLINE PUMP

-INLINE PUMP

FUTURE

CWP-ABSORPTION

CWP-ABSORPTION

CWP-1

FUTURE CHILLER

CH-2

CWP-2

CWP- FUTURE

114400 North 49th Street

Clearwater, FL.

Pinellas County Jail Phase I

Infrastructure Criteria Package - Drawings

-UNION

SEAL

CH-1

PRELIMINARY DOCUMENTS

NOT FOR CONSTRUCTION

KEY PLAN

ABSORPTION CHILLER

SCALE

FUTURE ABSORPTION CHILLER

NOT TO SCALE

No.

Description

Date

REVISIONS

CONDENSER WATER PIPING DIAGRAM

No Scale

DRAWN BY

HAT

APPROVED BY

LTE

CHECKED BY

LTE

DATE

03/19/2014

TITLE

MECHANICAL

DIAGRAMS

A

PROJECT NO.

M-201

SHEET NO.

50057109

Dewberry Architects Inc.

401 SW Water St.

Suite 701

Peoria, IL 61602

309.282.8000 Phone

309.282.8001 Fax

REFER TO P201, DETAIL 9 FOR FURTHER DETAIL

PLUMBING SYSTEM

TO

HEAT RECOVERY RECIRC PUMP

E

HOT EXHAUST GAS

HEAT RECOVERY HEAT EXCHANGER, SHELL IN TUBE

EXHAUST BYPASS VALVE

NO

NC

NO

ENGINE HIGH TEMP RADIATOR

Pinellas County

FLEX CONNECTION (TYP)

NATURAL GAS

GENSET

ABSORPTION CHILLER

3-WAY CATALYTIC

HIGH TEMP PUMP

RETURN TEMPERAURE

REGULATING 3-WAY VALVE

EXPANSION TANK

COGENERATOR DIAGRAM

114400 North 49th Street

Clearwater, FL.

SILENCER

Pinellas County Jail Phase I

Infrastructure Criteria Package - Drawings

FROM

No Scale

SEAL

PRELIMINARY DOCUMENTS

NOT FOR CONSTRUCTION

KEY PLAN

FUTURE EXPANSION TANK ON TOP OF RADIATOR

12" MAX.

EXPANSION TANK ON TOP OF RADIATOR

FLOW LIMITING

VALVES

SCALE

MOUNT HEAT EXCHANGER AS CLOSE

AS POSSIBLE TO RADIATOR.

NOT TO SCALE

TYPICAL FLEXIBLE CONNECTIONS

HOT WATER PIPING

(200 F.) OFF THE DUAL ENGINES

PIPING TO PLUMBING SYSTEM

SEE PLUMBING FOR CONTINUATION

REFER TO P201, DETAIL 9 FOR FURTHER DETAIL

TYPICAL SHUT-OFF VALVE

12" MAX.

RADIATOR

HEAT EXCHANGER

No.

Description

Date

REVISIONS

COGENERATOR DIAGRAM

No Scale

DRAWN BY

HAT

APPROVED BY

LTE

CHECKED BY

LTE

DATE

03/19/2014

TITLE

MECHANICAL

DIAGRAMS

A

PROJECT NO.

M-202

SHEET NO.

50057109

Dewberry Architects Inc.

401 SW Water St.

Suite 701

Peoria, IL 61602

309.282.8000 Phone

309.282.8001 Fax

AUTOMATIC FLOW

CONTROL

DEVICE PRESET BY MANUF.

W/ P & T TEST PORTS,

STRAINER, AND DRAIN.

(PRE-MANUF. SINGLE

ASSEMBLY ACCEPTABLE)

THREE WAY

CONTROL

VALVE

EXTENDED OPERATOR

ON BALANCE DAMPER

SPIN-IN FITTING W/VOLUME

CONTROL DAMPER (INSUL.

PER SPEC.)

MANUAL AIR VENT

W/AUTO

SHUT-OFF COCK

DRAW BAND

(PRE-MANUF. SINGLE

ASSEMBLY ACCEPTABLE)

STEEL RODS W/THREADED

ENDS (TYP. 4 PLACES)

SUPPORT FROM STRUCTURE

ABOVE AS REQUIRED

THREADED CAP, HAND TIGHTENED

COIL

RETURN

SPRING VIB. ISOLATORS

THREADED CAP WITH 1/4" DIA.

HOLE DRILLED IN TOP, HAND

TIGHTENED.

UNION

PROVIDE WITH FILTER

OVER OPENING

FLEXIBLE DUCT MAX.

8'-0" IN LENGTH

FULLY EXTENDED.

COOLING COIL

FLEX CONN. (TYP.)

SA

SUPPLY

FAN

RA

PLUG

COCK

SHUT-OFF VALVE (TYP.)

DRAW BAND

DRAIN PAN

SLOPE TO DRAIN

BLANK-OFF PLATES

WHERE REQUIRED

P/T TEST PORTS

CASING SLEEVE

FLOAT SWITCH

UNION (TYP.)

DIFFUSER CONE (INSUL. PER SPEC.)

SNUBBER

CONDENSATE DRAIN PIPING DIMENSIONS:

THERMOMETER W/SEPARABLE WELL (TYP.)

CEILING TEE

ROUTE MAIN CONDENSATE

LINE TO FLOOR DRAIN

A = FULL SIZE OF UNIT DRAIN CONNECTION

B > 1-1/2" TIMES FAN SUCTION STATIC PRESSURE

C > FAN DISCHARGE STATIC PRESSURE PLUS 1/2" INCH

BALL VALVE

CEILING

GALVANIZED SHEET METAL SECONDARY

DRAIN PAN TO EXTEND 3" BEYOND UNIT

ON ALL SIDES BY 1-1/2" DEEP

COORDINATE MOUNTING/CURB HEIGHT AS REQUIRED TO PROVIDE PROPER CONDENSATE DRAINAGE.

FLEX. CONNECTION (TYP.)

NOTES: 1. PROVIDE (4 x DIA.) OF STRAIGHT PIPE ON BOTH SIDES OF

BALANCING VALVE

2. ALL COMPONENTS FULL LINE SIZE UNLESS NOTED OTHERWISE

3. LOCATE UNIONS TO ALLOW FOR COIL PULL

LIGHT

3-WAY COIL PIPING DIAGRAM (FCU-4)

NOT TO SCALE

AHU CONDENSATE DRAIN TRAP

NOT TO SCALE

DIFFUSER MOUNTING

NOT TO SCALE

FAN COIL UNIT

NOT TO SCALE

GEAR W/HAND WHEEL

5" AND LARGER

LEVER LATH HANDLE

W/MEMORY STOP

4" AND SMALLER

THREE LAYERS OF 5/8" GYPBOARD, REFER

TO SPECIFICATION SECTION 15910

DAMPER, TYPICAL

MANUAL BALANCING

PRESSURE GAUGE

BUTTERFLY

VALVE (TYP.)

TOP OF DUCT TO BE

AS HIGH AS POSSIBLE

TAP, TYPICAL 45

DEGREE BOOT

114400 North 49th Street

Clearwater, FL.

PRESSURE GAUGE &

COCK (TYP.)

Pinellas County Jail Phase I

Infrastructure Criteria Package - Drawings

DIFFUSER NECK (INSUL. PER SPEC.)

AIR FLOW

STRAINER W / BLOWDOWN

Pinellas County

SNUBBER

BALL VALVE

EXTEND TREATMENT

ACROSS OPEN CEILING

SEE PLAN DRWGS.

DIFFERENTIAL

PRESSURE

TRANSMITTER

P/T PORT W/BLOWDOWN

VALVE (TYP.)

DRAW BAND

NON-SLAM CHECK

VALVE

SEAL

FLEXIBLE CONNECTER

SILENCER

SUPPLY

DUCT

FLEXIBLE

CONNECTOR

DIAMETER TO MATCH

SYSTEM PIPING

DIAMETER

PRELIMINARY DOCUMENTS

NOT FOR CONSTRUCTION

s" PUMP DRAIN,

EXTEND TO FLOOR

NEAREST DRAIN

SUCTION DIFFUSER W/INTEGRAL

STRAINER & 3/4" BLOW DOWN

VALVE. EXTEND TO NEAREST

FLOOR DRAIN

FLEXIBLE DUCT

SPIN-IN FITTING W/VOLUME

CONTROL DAMPER (INSUL. PER

SPEC. REQ'D.)

PIPE SUPPORT

RADIUS ELBOWS MAY

BE USED IN LIEU OF

SQUARE ELBOWS

KEY PLAN

WALL

DIAMETER TO MATCH PUMP

INLET DIAMETER

NOISE CONTROL TREATMENT AT DUCT SILENCER

NOT TO SCALE

CONCRETE

HOUSEKEEPING

PAD

PIPE SUPPORT

SPLIT-CASE DOUBLE SUCTION PUMP

NOT TO SCALE

TYPICAL FLEX DUCT CONNECTION

NOT TO SCALE

TYPICAL PRESSURE DUCTWORK

SCALE

NOT TO SCALE

NOT TO SCALE

VALVES ABOVE TUBE

PULL (TYP.)

ACTUATOR & VALVE

BY CONTROLS

CONTRACTOR (TYP.)

LUG TYPE BUTTERFLY

VALVE W/GEAR

OPERATOR (TYP.)

120 VAC

BEACON

ALARM WIRING PER

ASHRAE 15 TO EMS

TEMP. SENSOR

(TYP.)

A

DIFFERENTIAL PRESSURE

SENSOR/TRANSMITTER

(TYP.)

CWS

ANALOG OUTPUT

WIRING

PROVIDE NEW REMOTE

ALARM BEACON

OUTSIDE ALL

CHILLER ROOM

ENTRY DOORS

REFRIGERANT

MONITOR

PANEL

ROCK FREE BACKFILL

1'-0" MIN.

PITTWRAP JACKETING

FLEXIBLE

CONNECTOR

FLEX CONNECTION

RESETTING RELIEF ASSEMBLY

BY EQUIPMENT MANUFACTURER

FOAMGLASS INSULATION

SAMPLE TUBE

FLANGED JOINT

6".

SAND BACKFILL

6".

6" MIN.

COMPRESSION

COUPLING

FILTER

FULL SIZE OF VENT

OPENING (MIN.) OR AS

CODE REQUIRES

CHILLER

12" TO 18"

GRAVEL

No.

Description

Date

RELIEF VENT

TO CHILLER

PIPE

CHWR

SAMPLE LINES

SUPPORT TO

COLUMN OR

WALL

NOTES:

1.

PROVIDE REFRIGERANT MONITOR CAPABLE OF

SENSING R-123 REFRIGERANT.

2.

NEW EXHAUST FAN.

3.

PROVIDE TWO REFRIGERANT SAMPLE LINES I

LOCATIONS AS SHOWN ON PLANS.

CHILLER DIFFERENTIAL PRESSURE

SWITCH TO CHILLER CONTROL PANEL

PRESSURE GAUGE W/

SNUBBER & BALL

VALVES (TYP.)

CONNECT NEW

RELIEF PIPING TO

EXISTING RELIEF

PIPING HEADER.

6" MIN.

THERMOMETER (TYP.)

CHWS

CWR

R OOF

COMPRESSOR

SUCTION

CONNECTION

RELIEF PIPING SHALL BE SIZED

AND INSTALLED IN ACCORDANCE

WITH ASHRAE STANDARD 15.

MINIMUM RELIEF PIPING SIZE

INDICATED ON FLOOR PLAN.

DEVIATION FROM SIZE INDICATED

IS ACCEPTABLE ONLY AFTER

RECOMMENDATION FROM

CHILLER MANUFACTURER AND

APPROVAL OF THE ENGINEER.

COORDINATE RELIEF PIPING

REQUIREMENTS WITH CHILLER

MANUFACTURER.

REVISIONS

CONTROL

PANEL

CONDENSER

TO CONTROL

PANEL

DRAWN BY

HAT

APPROVED BY

LTE

CHECKED BY

LTE

DATE

VIBRATION ISOLATION

SPRINGS (TYP.)

EVAPORATOR

03/19/2014

TITLE

HOUSEKEEPING

PAD

MECHANICAL

DETAILS

FLANGED ELBOW W/

LIFT PLATE (TYP.)

FLOOR SLAB

FLOOR

6" MINIMUM

MECHANICAL JOINT (SIMILIAR

TO A VICTAULIC COUPLING)

r" FL x r" NPT DRAIN

VALVE (5'-0" ABOVE FLR.)

PETE'S PLUG (TYP.)

PROJECT NO.

UNDERGROUND PIPING INSTALLATION

NOT TO SCALE

REFRIGERANT MONITORING

NOT TO SCALE

10 RELIEF PIPING

NOT TO SCALE

11 WATER COOLED CHILLER

NOT TO SCALE

12

M-300

SHEET NO.

50057109

You might also like

- Hvac General Notes Hvac Abbreviations Hvac Symbol LegendDocument10 pagesHvac General Notes Hvac Abbreviations Hvac Symbol LegendTeoxNo ratings yet

- Electrical Codes PDFDocument16 pagesElectrical Codes PDFcosmin1991No ratings yet

- General Notes: Electrical Symbol Legend: Fire Alarm/Detection System Basic Materials Cont. Basic MaterialsDocument16 pagesGeneral Notes: Electrical Symbol Legend: Fire Alarm/Detection System Basic Materials Cont. Basic Materialsjohn benedict orbeNo ratings yet

- Electrical Riser Diagram PDFDocument6 pagesElectrical Riser Diagram PDFMulti PhaseNo ratings yet

- Lighting Plans PDFDocument11 pagesLighting Plans PDFMulti PhaseNo ratings yet

- Atlantic Version: Applicator Data ODocument4 pagesAtlantic Version: Applicator Data OChung LeNo ratings yet

- A0110 - Construction PlansDocument1 pageA0110 - Construction PlansMuhammad AbuBakarNo ratings yet

- Uci Mce Stru D S-20.6Document1 pageUci Mce Stru D S-20.6Thanh Đạt NguyễnNo ratings yet

- B224-FCC-LT-PID-111-11011 TO 11047 - LEGEND P&IDsDocument33 pagesB224-FCC-LT-PID-111-11011 TO 11047 - LEGEND P&IDsSahadev SinghaNo ratings yet

- 4124 Ai Du 21130i046s01 Is01 - Checkprint - DineshDocument1 page4124 Ai Du 21130i046s01 Is01 - Checkprint - Dineshamit bagchiNo ratings yet

- 2015 0526 DWG Fire DDSetDocument16 pages2015 0526 DWG Fire DDSetnadiruuzaman sizanNo ratings yet

- LOS1-A-2204-OPS-PH1A - Rev 11 - Plan - Builders Work - Level 02Document1 pageLOS1-A-2204-OPS-PH1A - Rev 11 - Plan - Builders Work - Level 02Tosin FamuyiwaNo ratings yet

- 422e 428e Hydo PDFDocument2 pages422e 428e Hydo PDFdenis100% (1)

- DX Split Unit - YorkDocument200 pagesDX Split Unit - YorkFaiyaz Bin Mazid AhmedNo ratings yet

- Floor PlanDocument36 pagesFloor PlanDarlyn Sagre100% (3)

- Legend Sheet P&ID For As-Built - Drafting On 20210722-2Document1 pageLegend Sheet P&ID For As-Built - Drafting On 20210722-2Ludi D. LunarNo ratings yet

- Main Control Valve: 345C Excavator Hydraulic System - AttachmentDocument2 pagesMain Control Valve: 345C Excavator Hydraulic System - AttachmentVladimirNo ratings yet

- Fin Pid GnalDocument113 pagesFin Pid GnalVijay GuptaNo ratings yet

- Plano ElectricoDocument2 pagesPlano Electricomauricio suarezNo ratings yet

- WH#6Document4 pagesWH#6EAC Alim KhanNo ratings yet

- GRS Electrical IFC PDFDocument9 pagesGRS Electrical IFC PDFHendrix LevaNo ratings yet

- DRP001 Ouf Gal 940110 K Ecr 001 003 S1Document1 pageDRP001 Ouf Gal 940110 K Ecr 001 003 S1pathanNo ratings yet

- V9616-7 - EN051 - General Arrangement Drawing - ADocument3 pagesV9616-7 - EN051 - General Arrangement Drawing - Asunnudwi10No ratings yet

- Cat Dcs Sis ControllerpolmatikDocument2 pagesCat Dcs Sis Controllerpolmatikimam nahrowiNo ratings yet

- Acs 6t UsermanualDocument4 pagesAcs 6t UsermanualMuhammad rizkiNo ratings yet

- P&ID For Air CoolersDocument9 pagesP&ID For Air CoolersAvinash ShuklaNo ratings yet

- 4124 Ai Du 21110S006S01 Is01 - CheckprintDocument1 page4124 Ai Du 21110S006S01 Is01 - CheckprintamitNo ratings yet

- Notes:: Operating Workstation Engineering Workstation /historian ServerDocument1 pageNotes:: Operating Workstation Engineering Workstation /historian ServerFathy RamadanNo ratings yet

- 15 000-Bcl2000414-El-Dr-1 - AfcDocument1 page15 000-Bcl2000414-El-Dr-1 - AfcYousab JacobNo ratings yet

- So Do Thuy Luc 345C PDFDocument2 pagesSo Do Thuy Luc 345C PDFdoxuanquylcNo ratings yet

- PlumbingDocument14 pagesPlumbingRaizen TanNo ratings yet

- 2.symbol and AbbreviationsDocument1 page2.symbol and Abbreviationshambi1986No ratings yet

- Changes Per All Backcircled: NotesDocument1 pageChanges Per All Backcircled: Notesheri_prasetyadiNo ratings yet

- E1 Monaco 2402Document1 pageE1 Monaco 2402carloNo ratings yet

- Abts Uqair-B.2Document1 pageAbts Uqair-B.2Anonymous BZQOJwWIh6No ratings yet

- 3 MD P&ID TurbosopladorDocument5 pages3 MD P&ID TurbosopladorYhony Gamarra VargasNo ratings yet

- 2342-Aa00-Ml-259 - 0 - Sleepers Elevation Optimization ReportDocument5 pages2342-Aa00-Ml-259 - 0 - Sleepers Elevation Optimization Reportyusuf.yuzuakNo ratings yet

- L L L L: Section Section SectionDocument1 pageL L L L: Section Section SectionajmainNo ratings yet

- PID Booklet As Built Without PFD Rev - Part75Document1 pagePID Booklet As Built Without PFD Rev - Part75megarezky235No ratings yet

- Electrical Dwg.Document14 pagesElectrical Dwg.nurul momenNo ratings yet

- View-U View-A View-B View-C: Reference DrawingsDocument1 pageView-U View-A View-B View-C: Reference DrawingsAnonymous BZQOJwWIh6No ratings yet

- 9 Jones ST - Building Review - 200227 - PL PDFDocument8 pages9 Jones ST - Building Review - 200227 - PL PDFLeonardo Jr. SasingNo ratings yet

- 60421-WWL-XX-02-DR-E-67001: Laing The Jeweller (Glasgow) LTDDocument1 page60421-WWL-XX-02-DR-E-67001: Laing The Jeweller (Glasgow) LTDSohail SurveNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- FP-01 Front PageDocument1 pageFP-01 Front PageBerlin Andrew SionNo ratings yet

- Diagrama Hidraulico Caterpillar 345cDocument2 pagesDiagrama Hidraulico Caterpillar 345cJose Miguel Gary Vargas100% (1)

- D10T - Hidraulic System 529-Up - Diagrama - SISDocument2 pagesD10T - Hidraulic System 529-Up - Diagrama - SISmichael_villarroel5338No ratings yet

- Schedule of Loads: Notes and SpecificationsDocument1 pageSchedule of Loads: Notes and SpecificationsAngelice Alliah De la CruzNo ratings yet

- DSGN DRWN CHKD Appd AG CB CCS CB: GMR Goa International Airport LimitedDocument10 pagesDSGN DRWN CHKD Appd AG CB CCS CB: GMR Goa International Airport LimitedAditya KNo ratings yet

- Material TraceabilityDocument24 pagesMaterial TraceabilityStanley AlexNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- 2342-AA00-ML-258 - 0 - Machinery Design RulesDocument5 pages2342-AA00-ML-258 - 0 - Machinery Design Rulesyusuf.yuzuakNo ratings yet

- Drawings Electric Forklift Charging StationsDocument14 pagesDrawings Electric Forklift Charging StationsRafael de la cruzNo ratings yet

- Ref.09 - OS00002 - E - BW31.ZA3.UM01&EZ18285 - EN - X2Document32 pagesRef.09 - OS00002 - E - BW31.ZA3.UM01&EZ18285 - EN - X2IliyanPetrovNo ratings yet

- Da 950092 001Document1 pageDa 950092 001munnaNo ratings yet

- Alloys For Industrial EngineeringDocument62 pagesAlloys For Industrial EngineeringAdel AbduoNo ratings yet

- Schematic Design Drawings: CsidetailDocument36 pagesSchematic Design Drawings: CsidetailBarani BaraniNo ratings yet

- Experimental Study On The Banana Fiber RCDocument4 pagesExperimental Study On The Banana Fiber RCAfsin Ecer.No ratings yet

- Flexural Strength of Reinforced Polymer Concrete Made With Recycled Plastic WasteDocument7 pagesFlexural Strength of Reinforced Polymer Concrete Made With Recycled Plastic WastepicottNo ratings yet

- Lecture 4 Splice Sleeves Report-G&WDocument9 pagesLecture 4 Splice Sleeves Report-G&Wkai kaiNo ratings yet

- Cyprus National Annex en 1992-4Document9 pagesCyprus National Annex en 1992-4Anonymous PibYPghNo ratings yet

- Dokadeck 30Document60 pagesDokadeck 30Fatjon MurseliNo ratings yet

- PDF 1506373766Document91 pagesPDF 1506373766Saša LučićNo ratings yet

- Part 1: Short-Answer Question (20/100) : CIV420: HydraulicsDocument3 pagesPart 1: Short-Answer Question (20/100) : CIV420: HydraulicsRobert BuiNo ratings yet

- Vertical Thrust Block Design (DN 600)Document25 pagesVertical Thrust Block Design (DN 600)ARSENo ratings yet

- Cambr Palos MapDocument1 pageCambr Palos MapLyonsMastersNo ratings yet

- Engeurocode Training - En1994-1-1 PDFDocument34 pagesEngeurocode Training - En1994-1-1 PDFAbdulla AljundiNo ratings yet

- Concrete Strip Roads For The FarmDocument4 pagesConcrete Strip Roads For The FarmRoshanNo ratings yet

- Checklist For Fabrication & Installation of Tensile Fabric ShadesDocument1 pageChecklist For Fabrication & Installation of Tensile Fabric ShadesSun ShadeNo ratings yet

- Cleaning Disinfecting Boreholes enDocument4 pagesCleaning Disinfecting Boreholes enChijioke ObiNo ratings yet

- List of Unauthorized Construction of Building Department-I, South Zone 01.06.2018 To 30.09.2018Document10 pagesList of Unauthorized Construction of Building Department-I, South Zone 01.06.2018 To 30.09.2018BALAJI ASSOCIATESNo ratings yet

- Chapter 2: Properties of Fluids ESOE 505221 Fluid Mechanics 1Document27 pagesChapter 2: Properties of Fluids ESOE 505221 Fluid Mechanics 1Hazem AlmasryNo ratings yet

- Design of Eductor PumpDocument14 pagesDesign of Eductor PumpchawarepNo ratings yet

- Computer Models For Nonlinear Analysis of Reinforced and Prestressed Concrete StructuresDocument20 pagesComputer Models For Nonlinear Analysis of Reinforced and Prestressed Concrete StructuresLavinia DamianNo ratings yet

- Fluid Mechanics - Lecture 7 - 9 - Viscous + NNF Pipe FlowxDocument61 pagesFluid Mechanics - Lecture 7 - 9 - Viscous + NNF Pipe Flowxking4lifeNo ratings yet

- Road Runoff Water-Quality Mitigation by Permeable Modular Concrete PaversDocument10 pagesRoad Runoff Water-Quality Mitigation by Permeable Modular Concrete PaversIorhan M. Dias VendruscoloNo ratings yet

- 16-9 Accuracy of Erected SteelworkDocument8 pages16-9 Accuracy of Erected SteelworkZuberYousufNo ratings yet

- Chapter II-Branching and Pipe NetDocument39 pagesChapter II-Branching and Pipe NetArah Louise ApostolNo ratings yet

- Waste Water Treatment ProcessDocument15 pagesWaste Water Treatment ProcessDihadihaNo ratings yet

- Micro Planning For Highways and Structures From Ch.45 To Ch.67Document46 pagesMicro Planning For Highways and Structures From Ch.45 To Ch.67Ravi ValakrishnanNo ratings yet

- Experiment 1: Forces in A Roof Truss With A Central and Wind LoadDocument5 pagesExperiment 1: Forces in A Roof Truss With A Central and Wind LoadAinur NasuhaNo ratings yet

- Calculation Sheet: Padeye Calculations LoadsDocument14 pagesCalculation Sheet: Padeye Calculations Loadsandi_nu0% (1)

- House Construction Calculations For BegginersDocument67 pagesHouse Construction Calculations For BegginersBernard DavidNo ratings yet

- 1 PTBarsBrochure-Oct2015Document6 pages1 PTBarsBrochure-Oct2015Dong-Yong KimNo ratings yet

- Residential Building Design Using Excel Program Final PDF FreeDocument28 pagesResidential Building Design Using Excel Program Final PDF FreeCamille Joy CucioNo ratings yet