Professional Documents

Culture Documents

Matching of Turbine and Compressor

Uploaded by

api-271354682Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Matching of Turbine and Compressor

Uploaded by

api-271354682Copyright:

Available Formats

SRM University

Propulsion-II

Compressor-Turbine Matching

The problem of matching turbine and compressor performance has great importance

for jet engines, which must operate under conditions involving large variations in thrust, inlet

pressure, and temperature, and flight Mach number. Matching the components of turbofan

and turboprop engines involves similar considerations and procedures.

Essentially the matching problem is simple, though the computation can be length.

The steady-state engine performance at each speed is determined by two conditions:

continuity of flow and a power balance. The turbine mass flow must be the sum of the

compressor mass flow and the fuel flow, minus compressor bleed flow. Also the power

output of the turbine must be equal to that demanded by the compressor.

In principle, the matching computations could proceed as follows:

1. Select operating speed

2. Assume turbine inlet temperature

3. Assume compressor pressure ratio

4. Calculate compressor work per unit mass

5. Calculate turbine pressure ratio required to produce this work

6. Check to see if compressor mass flow plus fuel flow equals turbine mass flow; if not,

assume a new value of compressor pressure ratio and repeat steps 4, 5, and 6 until

continuity is satisfied.

7. Now calculate the pressure ratio across the jet nozzle from the pressure ratios across

the diffuser, compressor, combustor, and turbine.

8. Calculate the area of jet nozzle outlet necessary to pass the turbine mass flow

calculated in step 6 with pressure ratio calculated in step 7 and the stagnation

temperature calculated. If the calculated area does not equal the actual exit area,

assume a new value of turbine inlet temperature (step-2) and repeat the entire

procedure.

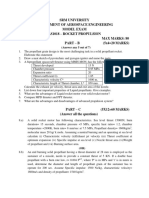

The designer will try to match turbine and compressor so that the compressor is operating

near its peak efficiency through the entire range of operation, as shown in the below figure,

where the operating line (i.e., the locus of stead-state matching condition) runs through the

centres of the islands defined by the constant-efficiency lines.

Fig Operating line on a compressor map

A.Vinoth Kumar Department of Aerospace Engineering

Page 21

SRM University

Propulsion-II

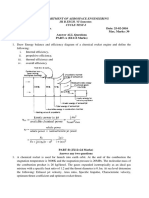

Compressor Work m a C p T03 T02

Turbine Work m a m f C p T04 T05

W.K.T specific work of compressor

is equal to specific work of turbine

Compressor Work Turbine Work

mass flow rate

mass flow rate

m

f C pg T04 T05

a

m a C pa T03 T02

ma

m

m

f

a

C pa T03 T02 C pg T04 T05

T

T

C paT02 03 1 C pgT04 1 05

T04

T02

1

P g 1 g

C paT02 P03 a a

1 t C pg T04 1 05

c P02

P04

the above equation is for ideal condition

For actual condition

1

P g 1 g

C paT02 P03 a a

1 mt C pg T04 1 05

P

c P02

04

where m mechanical efficiency

Turbine Pressure Ratio

1

C paT02 P03 a a

P05

1

1

TPR

P04 ct C pg T04 P02

Compressor Pressure Ratio

P03 ct C pg T04

1

CPR

C paT02

P02

P g 1 g

1 05

P04

A.Vinoth Kumar Department of Aerospace Engineering

g 1

a a 1

Page 22

You might also like

- Choice of Blade Profile, Pitch and ChordDocument6 pagesChoice of Blade Profile, Pitch and Chordapi-27135468260% (5)

- Aerodynamics 2 Two Mark QuestionsDocument15 pagesAerodynamics 2 Two Mark QuestionsGCVishnuKumarNo ratings yet

- Turbine - Compressor Matching PDFDocument30 pagesTurbine - Compressor Matching PDFDileep100% (2)

- AE2353 Wind Tunnel Techniques Anna University Question BankDocument3 pagesAE2353 Wind Tunnel Techniques Anna University Question BankaeroherozNo ratings yet

- 2.shrenck's Curveschrenk Curve, Adp-2, Aircraft Design Project-2Document3 pages2.shrenck's Curveschrenk Curve, Adp-2, Aircraft Design Project-2Balaji Aero50% (2)

- Turbojet Engine DesignDocument27 pagesTurbojet Engine DesignYasser BahaaNo ratings yet

- 05-PT11-Cascade Aerodynamics (Compatibility Mode)Document45 pages05-PT11-Cascade Aerodynamics (Compatibility Mode)Venkat Pavan100% (1)

- Propulsion Question Bank 1Document14 pagesPropulsion Question Bank 1aeroherozNo ratings yet

- Aero Engineering Thermodynamics Question BankDocument10 pagesAero Engineering Thermodynamics Question Bankmurjass85No ratings yet

- Questions and Answers in AerodynamicsDocument16 pagesQuestions and Answers in AerodynamicsD.Viswanath85% (27)

- Thermodynamics Lab Manual - SDocument32 pagesThermodynamics Lab Manual - SGurunath AeroNo ratings yet

- 2 Marks With AnswersDocument9 pages2 Marks With AnswersAeronaughtycs HamdanNo ratings yet

- Critical, Supercritical, and Subcritical OperationDocument1 pageCritical, Supercritical, and Subcritical OperationAbdul Kalam C S100% (1)

- Aerodynamics II NotesDocument166 pagesAerodynamics II NotesAlexShearNo ratings yet

- Moving Normal ShockwaveDocument10 pagesMoving Normal ShockwaveWaqas Shamraiz50% (2)

- Modern Compressible Flow - Anderson John D, JRDocument5 pagesModern Compressible Flow - Anderson John D, JRShashank Ch0% (2)

- AeroEngineTech 5 FransLoekito 4776887Document5 pagesAeroEngineTech 5 FransLoekito 4776887Frans LoekitoNo ratings yet

- MSI Centrifugal Impeller Structural Resonance PDFDocument9 pagesMSI Centrifugal Impeller Structural Resonance PDFJigneshNo ratings yet

- Lecture Notes Aerospace PropulsionDocument104 pagesLecture Notes Aerospace PropulsionJuan GarcíaNo ratings yet

- AEroelasticityDocument61 pagesAEroelasticityKashif AyazNo ratings yet

- Centrifugal Compressor Degree of ReactionDocument16 pagesCentrifugal Compressor Degree of ReactionNihanth Wagmi100% (1)

- As-Ii 2marksDocument11 pagesAs-Ii 2marksrobinston jeyasingh0% (1)

- Rr312102 Aircraft PerformanceDocument8 pagesRr312102 Aircraft PerformanceSrinivasa Rao GNo ratings yet

- Gas Dynamics and Jet Propulsion (SMEX1015) PDFDocument103 pagesGas Dynamics and Jet Propulsion (SMEX1015) PDFshyam sundarNo ratings yet

- AE 6604 Aircraft Materials and Processes-Question Bank Unit I Part - BDocument3 pagesAE 6604 Aircraft Materials and Processes-Question Bank Unit I Part - BRahul100% (1)

- Sbu 678Document125 pagesSbu 678prana132No ratings yet

- 5-Axial and Radial Flow Gas TurbinesDocument19 pages5-Axial and Radial Flow Gas TurbinesAddisu DersoNo ratings yet

- Ae8302 Elements of Aeronautical Engineering Part B & Part C Questions - Unit WiseDocument1 pageAe8302 Elements of Aeronautical Engineering Part B & Part C Questions - Unit WiseShobiNo ratings yet

- Gas Turbine Combustion Chamber Design Aspects & Current TrendsDocument24 pagesGas Turbine Combustion Chamber Design Aspects & Current TrendsPRAVEENNo ratings yet

- Anna University Propulsion - I Question PapersDocument10 pagesAnna University Propulsion - I Question Papersmurjass85No ratings yet

- Aeroelasticity Power Point.Document22 pagesAeroelasticity Power Point.Adrian Arasu0% (1)

- MCQs ME6604 SCAD MSM by EasyEngineeringDocument93 pagesMCQs ME6604 SCAD MSM by EasyEngineeringrameshneupane33% (3)

- Needham and Gerard Methods For Determining Crippling StressesDocument2 pagesNeedham and Gerard Methods For Determining Crippling StressesAravind Phoenix100% (4)

- Propulsion - II 2 Marks by Nambi RajanDocument12 pagesPropulsion - II 2 Marks by Nambi RajanNambi RajanNo ratings yet

- Aero Engine Maintenance and Repair Two Marks With AnswerDocument7 pagesAero Engine Maintenance and Repair Two Marks With AnswerHariharanNo ratings yet

- Axial Flow CompressorDocument25 pagesAxial Flow Compressormithruslove100% (1)

- Propulsion and Fuel System IntegrationDocument36 pagesPropulsion and Fuel System IntegrationNouman Nadeem0% (1)

- As-Ii Notes PDFDocument218 pagesAs-Ii Notes PDFJason Jeevan50% (2)

- Report of Fluent Simulation of Aerofoil NACA 4412Document19 pagesReport of Fluent Simulation of Aerofoil NACA 4412احمد عبد المحمود100% (3)

- CFD Analysis of Can CombustorDocument25 pagesCFD Analysis of Can CombustorMoses DevaprasannaNo ratings yet

- Turbo Machines Question BankDocument9 pagesTurbo Machines Question BankSHASHI Kumar100% (1)

- Unit - 1-Rayleigh and Fanno FlowDocument86 pagesUnit - 1-Rayleigh and Fanno Flowmebrahtu100% (4)

- Axial, Radial TurbinesDocument91 pagesAxial, Radial TurbinesAkshay Deshpande100% (2)

- Impulse and Reaction Blading of Gas TurbinesDocument4 pagesImpulse and Reaction Blading of Gas Turbinesapi-271354682100% (3)

- Copyjjjj of Viva Voice QuestionDocument6 pagesCopyjjjj of Viva Voice QuestionVigy BossNo ratings yet

- Combustor DesignDocument61 pagesCombustor DesignJoshua Jones100% (1)

- Aerodynamics-II Part B QuestionsDocument7 pagesAerodynamics-II Part B QuestionsAeronaughtycs Hamdan100% (1)

- Aircraft Structures - II 2 Mark by Nambi RajanDocument10 pagesAircraft Structures - II 2 Mark by Nambi RajanNambi RajanNo ratings yet

- Gate Question and Answer For Aerospace by Vinothkumar AnnamalaiDocument138 pagesGate Question and Answer For Aerospace by Vinothkumar Annamalaiapi-271354682No ratings yet

- Unit I Introduction To Design For Static StrengthDocument47 pagesUnit I Introduction To Design For Static StrengthSanketHedduri0% (2)

- Aerodynamics ReviewDocument9 pagesAerodynamics Reviewaerogem618No ratings yet

- Analytical Design of Radial Turbine Design-NasaDocument162 pagesAnalytical Design of Radial Turbine Design-Nasamrbookani100% (1)

- 15 BTurbocharger MatchingDocument8 pages15 BTurbocharger MatchingBhupender RamchandaniNo ratings yet

- 15 BTurbocharger MatchingDocument8 pages15 BTurbocharger Matchingvkrishnakumar_designNo ratings yet

- Ch-6-W-12-Gas TurbinesDocument50 pagesCh-6-W-12-Gas TurbinesArkew Bogale100% (2)

- PTC 4Document3 pagesPTC 4akinkanalangNo ratings yet

- Technical Inquiry On PTC 4 - 1998, PTC 6 - 1996, and PTC 46 - 1996Document2 pagesTechnical Inquiry On PTC 4 - 1998, PTC 6 - 1996, and PTC 46 - 1996Onkar PatelNo ratings yet

- Simulation Methods Used To Analyze The Performance Ge Pg6541b Gas Turbine Utilizing Low Heating Value FuelsDocument10 pagesSimulation Methods Used To Analyze The Performance Ge Pg6541b Gas Turbine Utilizing Low Heating Value FuelsMike Erbes100% (1)

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- As1018 6 Sem 5Document2 pagesAs1018 6 Sem 5api-271354682No ratings yet

- 15as304 Air Breathing Propulsion SyllabusDocument2 pages15as304 Air Breathing Propulsion Syllabusapi-271354682No ratings yet

- As1018 6 Sem 7Document2 pagesAs1018 6 Sem 7api-271354682No ratings yet

- As1018 6 Sem 6Document2 pagesAs1018 6 Sem 6api-271354682No ratings yet

- Air Breathing Propulsion Unit-1Document37 pagesAir Breathing Propulsion Unit-1api-271354682No ratings yet

- Gate Question and Answer For Aerospace by Vinothkumar AnnamalaiDocument138 pagesGate Question and Answer For Aerospace by Vinothkumar Annamalaiapi-271354682No ratings yet

- Propulsion2 QPDocument12 pagesPropulsion2 QPapi-271354682100% (1)

- As1018 6 Sem 4Document5 pagesAs1018 6 Sem 4api-271354682No ratings yet

- Rocket Propulsion ct-1 2017 QPDocument5 pagesRocket Propulsion ct-1 2017 QPapi-271354682100% (1)

- Assignment 3Document3 pagesAssignment 3api-271354682No ratings yet

- Rocket Propulsion Unit-3Document53 pagesRocket Propulsion Unit-3api-271354682100% (4)

- Cycle Test 2 Rocket PropulsionDocument3 pagesCycle Test 2 Rocket Propulsionapi-271354682No ratings yet

- List of Rockets AssignmentDocument4 pagesList of Rockets Assignmentapi-271354682No ratings yet

- As0306 Propulsion IIDocument3 pagesAs0306 Propulsion IIapi-271354682No ratings yet

- Intake and Nozzle Problems NumericalDocument7 pagesIntake and Nozzle Problems Numericalapi-271354682100% (1)

- Air Breathing Propulsion Unit-3Document22 pagesAir Breathing Propulsion Unit-3api-271354682No ratings yet

- Rocket Propulsion-2 ct-1 QP Key-2016Document3 pagesRocket Propulsion-2 ct-1 QP Key-2016api-271354682No ratings yet

- Program 1Document35 pagesProgram 1api-271354682No ratings yet

- Lab Manual Stud CP II To Be Used With The Right One 1Document21 pagesLab Manual Stud CP II To Be Used With The Right One 1api-271354682No ratings yet

- Rocket Propulsion Unit-4Document21 pagesRocket Propulsion Unit-4api-271354682100% (1)

- Rocket Propulsion Unit-5Document44 pagesRocket Propulsion Unit-5api-271354682No ratings yet

- Rocket Propulsion-2 ct-2 qp-2016Document5 pagesRocket Propulsion-2 ct-2 qp-2016api-271354682No ratings yet

- Air Breathing Propulsion Unit-2Document54 pagesAir Breathing Propulsion Unit-2api-271354682No ratings yet

- Rocket Propulsion Unit-2Document8 pagesRocket Propulsion Unit-2api-271354682No ratings yet

- Rocket Propulsion Unit-1Document47 pagesRocket Propulsion Unit-1api-271354682100% (4)

- Rockets History and EvolutionDocument11 pagesRockets History and Evolutionapi-271354682No ratings yet

- Numerical ProblemsDocument12 pagesNumerical Problemsapi-271354682No ratings yet

- Item 103 Structure ExcavationDocument3 pagesItem 103 Structure ExcavationGerry Velicaria100% (1)

- Spring Support Used in PipingDocument7 pagesSpring Support Used in Pipingashish.mathur1No ratings yet

- ITC Guide For Thesis PreparationDocument26 pagesITC Guide For Thesis PreparationPanha MenhNo ratings yet

- Fiber Optic CablesDocument24 pagesFiber Optic CablesARCC2030No ratings yet

- Pdca Cycle Problem SolvedDocument3 pagesPdca Cycle Problem Solvedjose luisNo ratings yet

- New V70 XC70 Owners Manual MY05 en Tp7551Document226 pagesNew V70 XC70 Owners Manual MY05 en Tp7551dynax4No ratings yet

- DataDocument194 pagesDataddlaluNo ratings yet

- Aircon Maintenance Singapore NdurwDocument5 pagesAircon Maintenance Singapore Ndurwchinfrench0No ratings yet

- Iso 5294 1989Document9 pagesIso 5294 1989a.mursadinNo ratings yet

- The Effects of Dissolved Sodium Chloride (Nacl) On Well Injectivity During Co2 Storage Into Saline AquifersDocument20 pagesThe Effects of Dissolved Sodium Chloride (Nacl) On Well Injectivity During Co2 Storage Into Saline AquifersMuhammad FatchurroziNo ratings yet

- FC-M6100 SM-BB52: DEORE CranksetDocument1 pageFC-M6100 SM-BB52: DEORE CranksetDon JonesNo ratings yet

- PayrollBatchLoader v4Document158 pagesPayrollBatchLoader v4MaheshNo ratings yet

- Histogram PorositasDocument2 pagesHistogram PorositasajnmboNo ratings yet

- Comparacion Planta Meg - TegpdfDocument18 pagesComparacion Planta Meg - TegpdfJulian RomeroNo ratings yet

- Annex 1 - Air Dryer Duct DRG List - 140717Document1 pageAnnex 1 - Air Dryer Duct DRG List - 140717vemanreddy29No ratings yet

- Rail Mechanical PropertiesDocument46 pagesRail Mechanical PropertiesAGnes Stephani MuntheNo ratings yet

- CS 450 Assignment 5 SolutionsDocument3 pagesCS 450 Assignment 5 Solutionshidrovo3589No ratings yet

- HARMAN Infinity Processing White PaperDocument2 pagesHARMAN Infinity Processing White PaperSound Technology LtdNo ratings yet

- 9.shift RegistersDocument36 pages9.shift RegistersJagan GNNo ratings yet

- Important RCC Questions-Short and LongDocument15 pagesImportant RCC Questions-Short and LongmailjoelsamuelNo ratings yet

- Textile Shop Management SystemDocument6 pagesTextile Shop Management SystemVedha TechnologiesNo ratings yet

- Makalah Program PDFDocument10 pagesMakalah Program PDFIvanFolkNo ratings yet

- FRP Fish TanksDocument33 pagesFRP Fish TanksA.Subin DasNo ratings yet

- HKTM StokDocument406 pagesHKTM Stokfratk8093No ratings yet

- 1 Introduction To Thermal System DesignDocument43 pages1 Introduction To Thermal System DesignAbhishek KullurNo ratings yet

- IM KR180A E 4thDocument80 pagesIM KR180A E 4thbatizap batizapNo ratings yet

- Air PollutionDocument18 pagesAir PollutionKimjinNo ratings yet

- Roof Manual p10Document1 pageRoof Manual p10AllistairNo ratings yet

- MBA Database Marketing and FinanceDocument9 pagesMBA Database Marketing and FinanceSelvam RajNo ratings yet

- Free Gear Calculator - KHK GearsDocument5 pagesFree Gear Calculator - KHK GearslawlawNo ratings yet