Professional Documents

Culture Documents

Slipform Rate Analysis

Uploaded by

chaithra_14Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Slipform Rate Analysis

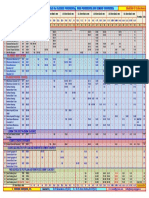

Uploaded by

chaithra_14Copyright:

Available Formats

1. PRESENTATION ON RATE ANALYSIS By- Y.P.

Thippeswamy

2. RATE ANALYSIS Why it is required ? To know Cost of item Requirement of Labour

Requirement of Material Requirement of Plant To control the cost of project

3. COST Cost of a item include fallowing 1. Labour cost 2. Material cost 3. Plant cost

4. LABOUR COST Example Manual carriage of material up to a lead of 50 meter 0.52

1000 Nos Bricks 3 044 Cu m Rock ( Excavated) 2 0.28 Cu m Earth 1 Male coolie Per

unit Unit Description Sl no 0.25 MT Steel 5 0.2 MT Cement 4

5. LABOUR COST Per unit Unit Concrete in Foundation Sl no 0.07 Cu m Vibrator with

operator 4 0.07 Cu m Mixer with operator 3 2.5 Cu m Male coolie 2 0.17 Cu m Mason 1

6. LABOUR COST 1.0 MT Bar bender 1 10 MT Helper 2 Per unit Unit Steel Shuttering

Sl no R/F steel 0.58 Sq m Helper 2 0.28 Sq m Carpenter 1

7. LABOUR COST Per unit Unit Plastering Sl no 0.02 Sq m Helper 2 0.02 Sq m White

washer 1 White washing 0.05 Sq m Helper 2 0.05 Sq m Mason 1

8. COST OF MATERIAL Material cost at source Taxes and royalty Transportation cost

from source to site Loading and unloading Shrinkage wherever applicable

9. PLANT COST Capacity of plant Hire charge with driver/ operator Cost of Fuel Cost of

mob. Oil Efficiency of plant OR Capacity of plant Cost of Plant Cost of Transportation

Depreciation Cost of erection and dismantling Cost of Fuel and Oil Cost of operation

Spares

10. Simple example of Rate Analysis Carriage of Cement for a lead of 10 Km including

Loading & Unloading. Quantity Per Trip ( Average ) - 9 MT Cycle Time (I) Time for

Loading :By Manual - 50 Min (ii) Time Lost In Acceleration - 2 Min (iii) Travel time (

Average speed 20 km/hr) - 30 Min (iv) Unloading Turning and accelaration time - 40

Min (v) Travel Back time (Av. Speed 30 km/hr) - 20 Min Total 142 Min (C) No of Trips

in 8 hrs =8x60/142 = 3.38 Trips Contd.

11. (d) Quantity of Material transport in 8 hrs = 9MTX3.38 =30.42 MT (e) Cost of

carriage per shift (i) Hire charges of truck with driver Rs.1500.00 (ii) Cost of Diesel

[(3.38x(10x2)]+3 For Turning Etc. 1 ltr per 2.5 km, 20 km/2.5= 70.6 ltrs. @Rs.35.00

Rs.2471.00 (iii) Cost of Loading & Unloading 6 Coolie @ Rs. 100.00 Rs. 600.00 Cost

per MT =4571.00/30.42=150.26 Add contractors profit 10 % = 15.00 Total cost per MT

= 165.26 Say Rs.165.00

12. Rate Analysis of Slip form Shuttering

Example Barsinghsar Chimney Approximate dia of shell at bottom 15 m No of yokes

required 24 Total Quantity of shuttering Involved 10100 Sq m A.COST OF YOKES

AND TRUSSES (i) Slip form truss - 24 MT (ii) Wt. of Yokes and accessories for 24 Sets

- 24 MT Total 48 MT = (48 MT @ Rs. 50000.00)40% = 960000.00 B.FORM PANNELS

( EN-8, 4MM THK PLATE) (i) (2.45X24X2X1.16)@31.4kG/Sq m = 3.75 MT @50000/= 187500 (ii) Less scrap Value ( 3.75x 10000) = 37500 Total cost of Form panels

=150000

13. C. COST OF JACK RODS ( EN-8 MATERIAL) 1 stage Up to 65 m 32 Dia

2x4x2x65m = 1040 m x 6.32/1000 = 6.57 MT 25 Dia 2x4x2x65m = 1040m x

3.85/1000 = 4.00 MT Add Wastage @ 3% = 0.32 MT Add Extraction loss @ 15% = 1.63

MT Total = 12.52 MT Consider 50% Depreciation/loss( 12.52x50%)=6.26 MT Cost of

Jack Rods 6.26 x 50000 = 313000 Add for studs and hard ware =100000 Total cost of

Jack rods Rs.413000/14. D. JACKS,POWER PACKS,HYDRAULIC HOSES ETC. Jacks 6 MT cap

6x2x2= 24 Nos + 4 spares= 28Nos 28Nos@70000/- = 1960000 Jacks 3 MT cap

6x2x2= 24 Nos + 4 spares= 28Nos 28Nos@40000/- = 1120000 Extraction Jacks 4 Nos @

60000/- =240000 Power packs 2 Nos =500000 Total cost of jackS =3820000/- Consider

30% Depreciation ( 3820000x30%) = 1146000/- Hydraulic Hoses etc. LS = 250000/- Net

cost of Jacks Etc. = 1396000/15. E. TIMBER AND CONSUMABLES Timber for walk way and platforms 11.35 Cu m

For Hanging & working Plat form 7.54 Cu m Add 5% wastage 0.95 Cu m Total 19.84 Cu

m Total Cost of Timber 18.84x15850/- = Rs.314464/- F. HYDRAULIC OIL AND

SUNDRY ITEMS Hydraulic oil 750 Ltr @ Rs.75/- = 56250 Sundry and hardware LS.

=100000 Spares Ls =100000 Grease MP 3 300 Kg @ 125/- = 37500 Total cost

=Rs.293750/16. G. LABOUR Erection 48 MT@ 4000/- = 192000 Operation Mechanic / Operator

2x2x3mnthxRs.6000 = 72000 Khalasi / helper 6x2x3mnthxRs.4500 = 162000 Ground

Control 2x2x3mnthxRs.4000 = 48000 Clericle staff 1x2x3mnthx Rs.4000 =24000

Add on ( a+b+c+d) Incentive,OT,Terminal benefits on completion @ 50% = 153000

Dismantling of slip form 48 MT @ 5000/- =240000 Shifting and storage LS = 25000

Total Labour = 916000

17. TOTAL COST OF SLIP FORM =Rs.4443214 Cost per Sq m of Shuttering

=4443214/10100 =439.93 SAY =Rs.440/18. THANK YOU

1. SUBMITTED BY:-JAYVANT CHOUDHARYDEEPENDRA PAYASI

2. STRUCTURALTYPES OF STAIRCASESCOMPONENTS OF

STAIRCASESINTRODUCTION NUMERICALDESIGN STEPSPOINTS OF

CONSIDERATIONSBEHAVIOUR OF STAIRCASES REFERENCESPROBLEM

3. STAIRS CONSIST OF STEPS ARRANGED IN A SERIES FORTHE PURPOSE OF

GIVING ACCESS TO DIFFERENTFLOORS OF BUILDING.SINCE STAIR IS

OFTEN THE ONLYMEANS OF COMMUNICATION BETWEEN THEVARIOUS

FLOORS OF BUILDING,THE LOCATIONREQUIRES GOOD AND CAREFUL

CONSIDERATION.

4. TREAD:-THE UPPER HORIZONTALPORTION OF STEP OVER WHICH FOOTIS

PLACED DURING ASCENDING ANDDESCENDING A STAIRWAY.RISER:-THE

VERTICAL MEMBER OFSTEP.IT IS USED TO SUPPORT ANDCONNECT

SUCCESSIVE TREADS.HEADROOM:-THE VERTICAL HEIGHTBETWEEN THE

TREAD OF ONE FLIGHTAND CEILING OF OVERHEADCONSTRUCTION.IT

SHOULD BESUFFICIENT SO AS NOT TO CAUSE ANYDIFFICULTY TO PERSON

USING THESTAIRS.

5. STRINGERS:-THESE ARE THE SLOPINGMEMBERS OF THE STAIR,USED

TOSUPPORT THE END OF STEPSWINDERS:-THESE ARE THE STEPS USEDFOR

CHANGING THE DIRECTION OFSTAIRS .THESE ARE USUALLYTRIANGULAR

IN PLAN.FLIGHT:-THIS CONSIST OF SERIES OFSTEPS PROVIDED BETWEEN

LANDINGSRUN OR GOING:-TOTAL LENGTH OFSTAIRS IN HORIZONTAL

PLAININCLUDING LENGTH OF LANDINGS

6. LANDING:-THIS IS THE HORIZONTAL PLATFORM PROVIDED AT THE

HEAD OF SERIES OF STEPS .IT IS USED AS A RESTING PLACE DURING USE

OF STAIRS .IT FACILITATES CHANGE OF DIRECTION OF FLIGHT HAND

RAIL:-IT IS AN INCLINED RAIL PROVIDED AT CONVINIENT HEIGHT OVER

STEPS .IT SERVES AS GUARD RAIL AND PROVIDE ASSISTANCE TO USER OF

STAIRS . BALUSTERS:-IT IS INDIVIDUAL VERTICAL MEMBER MADE OF

TIMBER,METAL OR MASONARY FIXED BETWEEN STRING AND HAND RAIL

TO GIVE SUPPORT TO HAND RAIL.BALUSTERS HAND RAIL

7. NOSING:-IT IS THE PROJECTING PART OFTREAD BEYOND THE FACE OF

RISER.IT ISUSUALLY ROUNDED TO GIVE PLEASINGEFFECT TO TREAD AND

MAKE STAIRCASECONVINIENT AND EASY TO USE.LINE OF NOSING:-THIS IS

THE STRAIGHTLINE TOUCHING THE NOSING OF VARIOUSSTEPS AND

PARALLEL TO SLOPE OF LINE.PITCH OR SLOPE:-VERTICAL ANGLE MADEBY

LINE OF NOSING WITH HORIZONTAL LINE OF NOSING NOSING

ALL8. STRAIGHT STAIRS:- THIS MAY BE CONTINUOUS WITH TWOFLIGHTS

WITHSTEPS LEAD IN ONE DIRECTION ADOPTED WHEN STAIRCASE IS

NARROWANDAN INTERMIDIATE LANDING PROVIDED MOSTLY IN

PORCH,ENTRANCEETCLONG DOG-LEGGED STAIRS:- CONSIST OF TWO

STRAIGHT FLIGHTS RUNNING IN OPPOSITE DIRECTIONS THERE IS NO

SPACE BETWEEN THE FLIGHTS IN PLAN LANDING IS PROVIDED AT

LEVEL WHICH DIRECTION OF FLIGHT CHANGES

9. QUARTER TURN NEWEL:- A STAIR TURNING THROUGH 90 WITH THE

HELP OF LEVEL LANDING USED IN SHOPS AND PUBLIC BUILDINGSOPEN

NEWEL A WELL OR OPENING ISPOPULARLY KNOWN AS OPEN

WELLSTAIRSSTAIRS:- THE OPENING IS GENERALLY

USEDFORLEFTBETWEEN FORWARD ANDBACKWARD FLIGHT A SHORT

FLIGHT MAY OR MAY NOTPROVIDED IN THESEINSTALLATION OF LIFT

STAIRS

THESE STAIRS MAY HAVE10. GEOMETRICAL STAIRS :- THIS TYPE OF

STAIR ISANYGEOMETRICAL SHAPE AND THEY REQUIRE NONEWEL POST

SIMILAR TO OPENNEWEL STAIR EXCEPT THE WELL FORMEDBETWEEN

FORWARD AND CHANGE OF DIRECTION IN SUCH STAIRS

ISACHIEVEDBACKWARD FLIGHTIS CURVED BY WINDERS AND NOT

BYLANDINGS CIRCULAR STAIRS:- ALL THE STEPS ARE RADIATE FROM A

NEWI POST OR WELL HOLE ALL THE STEPS ARE WINDERS THIS IS

PROVIDED WHERE SPACE IS LIMITED AND TRAFFIC IS CASUAL MOSTLY

LOCATED AT REAR OF BUILDING

11. INCLINED STAIR FLIGHT1)STAIRS SPANNING IN LONGITUDINAL

DIRECTION:- TOGEATHER WITHLANDING ARE SUPPORTED ON WALL &IN

FIG (a) THEBEAMS INEFFECTIVE SPAN ISCONSIDERED BETWEEN THE

CENTRE TOCENTRE OF SUPPORTS FIG (b) OF TRANSVERSE SPANNING

OFLANDINGS SPAN IS TAKEN AS SSHOWN IN IN CASE OF OPEN WELL

STAIRS WHERESPAN PARTLY CROSS AT RIGHT ANGLESFIG THELOAD ON

COMMEN AREA MAY DISTRIBUTEDAS ONE HALF IN EACH DIRECTION IN

FIG (C)

12. 2)STAIR SLAB SPANNING IN THE TRANSVERSE FOLLOWING ARE THE

MOST COMMONEXAMPLES OF SLAB SPANNINGDIRECTION:- IN THESE

SLABS WIDTH OF FLIGHTINTRANSVERSE DIRECTION AS SHOWN

INFIGURE MINIMUM THICKNESS OF 75 TO 80 MMSHOULD

BEBEINGSMALL(1-1.5M) MINIMUM PERCENTAGEREINFORCEMENT TO

RESIST MAX BENDINGMOMENTPROVIDED SHOULD BE PROVIDED

LANDING13. THE WIDTH OF THE LANDING WIDTH OF STAIRSSHOULD

NOT BE LESS THAN THE WIDTHOF STAIRS RESIDENTIAL:-0.8 TO 1 M PUBLIC

:- 1.8 TO 2 TREADM RESIDENTIAL:-220-250 MM PUBLIC:- 250-300MM NOT

LESS THAN 200MM IN ANY CASE RISER RESIDENTIAL:-150-180 MM PUBLIC:120-150MM PITCHNOT MORE THAN 200MM IN ANY CASE SHOULD NOT BE

MORE THAN 38

HEAD ROOM14. CLEARENCE LENGTH OFSHOULD NOT BE LESS THAN

2.1M FLIGHT NO OF STEPS SHOULD BE MINIMUM 3 AND MAXIMUM 12

15. 1) GEOMETRICAL DESIGN:- ASSUME SUITABLE TREAD AND RISER NO OF

RISER= (F/F HEIGHT) RISE NO OF RISERS IN ONE FLIGHT=0.5(NO OF

RISERS) NO OF TREAD = (NO OF RISERS 1) GOING DISTANCE= (NO OF

TREAD) (TREAD WIDTH) WIDTH OF LANDING WIDTH OF STAIR

16. 2) STRUCTURAL DESIGN:-2.1) EFFECTIVE SPAN CALCULATION:EFFECTIVE SPAN CALCULATION=C/C DISTANCE BETWEEN SUPPORTS IF

NOT GIVEN WIDTH OF SUPPORT CAN BE TAKEN IN BETWEEN 200 TO 300

MM2.2)TRIAL DEPTH OF WAIST SLAB:- ACCORDING TO IS 456:2000 ARTICLE

23.2.1 BY CALCULATING RATIO OF SPAN TOEFFECTIVE DEPTH AND AFTER

THAT RATIO IS MULTIPLYING BY THEMODIFICATION FACTOR

17. MODIFICATION FACTOR CAN BE CALCULATED BY ASSUMING %

OFTENSION REINFORCEMENT

18. ALTERNATE METHOD:-1) THE THICKNESS OF WAIST SLAB(t) NORMAL

TO SLOPE CAN BE ASSUMED AS(L/20) FOR SIMPLY SUPPORTED SLAB (L/25)

FOR CONTINUOUS SLAB WHENWAIST SLAB SPANNING IN LONGITUDINAL

DIRECTION2) IN CASE OF TREAD-RISER STAIRS SPANNING

LONGITUDINALLY THETHICKNESS OF RISER & TREAD SLAB KEPT SAME

WITH VALUES OF (SPAN/25)FOR SIMPLY SUPPORTED AND (SPAN/30) FOR

CONTINUOUS STAIRCASES (MINIMUM THICKNESS OF 80 MM SHOULD BE

PROVIDED)

19. 3) LOAD CALCULATION:-CALCULATIONS SHOULD BE MADE BY

CONSIDERING WIDTH OFSLAB EQUAL TO 1 METRE3.1) SELF WEIGHT OF

SLAB = 25 D (R+T)/T (KN-M)3.2)WT OF STEPS = 25 0.5 R (KNM)3.3)WT OF FLOOR FINISH = 1 1 (KN-M) (ASSUME)3.4)LIVE LOAD = 3

KN/M (RESIDENTIAL BUILDING) = 4-5 KN/M (PUBLIC BUILDING)3.5) NET

LOAD(W) =W +W +W+W3.6)FACTORED LOAD = W=1.5 W

20. 4) CALCULATION OF DESIGN MOMENTS:-FIND MAX BENDING EITHER

BY DRAWING SHEAR FORCE AND BENDINGMOMENT DIAGRAM OR BY

CONSIDERING IT EQUALS TO (0.125W L)5)CHECK FOR EFFECTIVE

DEPTH:- d = (M/(Rub)) d provided6)CHECK FOR REINFORCEMENT:6.1)CALCULATE MAIN STEEL(Ast) Ast =0.5Fck/Fy (1 (1 (4.6M/Fckbd))bd

Ast Ast minimum FOR Fe 250 Ast min = 0.12 % of GROSS AREA FOR Fe 415 Ast

min = 0.15 % of GROSS AREA6.2) PROVIDE SUITABLE DISTRIBUTION

STEEL=Ast min

21. 7) CHECK FOR SHEAR:-7.1)CALCULATE MAX DESIGN SHEAR FORCE:- Vud

= 0.5 WL7.2)CALCULATE SHEAR RESISTED BY CONCRETE:- Vuc = k c

bd Vud < Vuc VALUES OF c AND k CAN BE OBTAINED BY THE

FOLLOWING TABLES

22. 8) PROVISION OF DEVELOPMENT LENGTH:- Ld req = (0.87 Fy )/4

WHERE = DIAMETRE OF BAR PROVIDED = DESIGN BOND STRESS9)

CHECK FOR DEFLECTION:- CALCULATE ACTUAL % OF REINFORCEMENT L/d

provided < L/d max10) SUMMARY AND DETAILING

REINFORCED CONCRETE DESIGN-23. DESIGN OF REINFORCED

CONCRETEN.KRISHNARAJU,R.N.PRANESH CIVIL ENGINEERING DRAWINGGURCHARANSTRUCUTRES-S.RAMAMRUTHAM SINGH,SUBHASHCHANDER

You might also like

- Rate Analysis For ShutteringDocument2 pagesRate Analysis For ShutteringJames JohnsonNo ratings yet

- Rate Analysis: 7 Wall Paneling - Akustik + Wood Wall PanelsDocument2 pagesRate Analysis: 7 Wall Paneling - Akustik + Wood Wall PanelsDeepa Junnarkar DegwekarNo ratings yet

- Kerb Stone Rate AnalysisDocument2 pagesKerb Stone Rate AnalysisYashashree Group100% (1)

- Rate Analysis For CenteringDocument1 pageRate Analysis For Centeringbd_gupta_3No ratings yet

- 07 Cement ConsumptionDocument2 pages07 Cement Consumptiontechdocu100% (4)

- 60 - Master Gradation Table of All Aggregates For Pavements and Cement ConcretesDocument1 page60 - Master Gradation Table of All Aggregates For Pavements and Cement ConcretesV Venkata Narayana100% (3)

- Rate Analsis Chapter No 25 Iron WorkDocument76 pagesRate Analsis Chapter No 25 Iron WorkSarin100% (1)

- UPPWD Skelton OldDocument200 pagesUPPWD Skelton OldVijay Kumar86% (7)

- Analysis of Boundary WallDocument7 pagesAnalysis of Boundary WallsamirNo ratings yet

- Standard Data Book (Roads & Bridges)Document353 pagesStandard Data Book (Roads & Bridges)shariqabideen81% (63)

- Rate Analysis HUme PipesDocument14 pagesRate Analysis HUme PipesSarin67% (3)

- Cost Analysis of Hot-Cold MixDocument8 pagesCost Analysis of Hot-Cold MixChManikumarNo ratings yet

- Item No. Description Unit Rate Code Rate (RS) Quantity Labour Cost (RS) Material Cost (RS)Document1 pageItem No. Description Unit Rate Code Rate (RS) Quantity Labour Cost (RS) Material Cost (RS)RANADIP100% (2)

- Rate Analysis - Mastic Asphalt & BitumenDocument7 pagesRate Analysis - Mastic Asphalt & BitumenA MNo ratings yet

- Analysis of Rate For Fabrication and Fitting of Gate 7Document1 pageAnalysis of Rate For Fabrication and Fitting of Gate 7Farhat Khan100% (1)

- Factual Civil Engineering: Cement ReconcilationDocument5 pagesFactual Civil Engineering: Cement ReconcilationDeepak Kaushik100% (1)

- Rate Analysis Morang - FinalDocument27 pagesRate Analysis Morang - Finalnitish JhaNo ratings yet

- Analysis of False CeilingDocument3 pagesAnalysis of False CeilingMuhammad Shahid HussainNo ratings yet

- Unit Cum: Taking Output 191 Cum (450 Tonnes)Document2 pagesUnit Cum: Taking Output 191 Cum (450 Tonnes)HPSIDC MehatpurNo ratings yet

- Rate Analysis of OBD PaintDocument2 pagesRate Analysis of OBD PaintDarshan Raghunath100% (2)

- Sample Gabion Bandhara Estimate Rock Toe PDFDocument18 pagesSample Gabion Bandhara Estimate Rock Toe PDFrushikesh rautNo ratings yet

- Concrete Rate AnalysisDocument5 pagesConcrete Rate Analysisnawazkhan2367% (6)

- Rate Analysis SheetDocument5 pagesRate Analysis Sheetkishan sojitra100% (1)

- Rate Analysis of Excavation in EarthworkDocument5 pagesRate Analysis of Excavation in EarthworkAnonymous KUNMyMBEE100% (2)

- Rate Analysis For ShutteringDocument2 pagesRate Analysis For ShutteringSarin100% (2)

- Boddabada Cause Way ESTIMATEDocument18 pagesBoddabada Cause Way ESTIMATED.V.Srinivasa RaoNo ratings yet

- 5.estimation of Shoring N Structing - Edited by HBIDocument5 pages5.estimation of Shoring N Structing - Edited by HBINIK MUHAMMAD FIRDAUS NIK HASSIMNo ratings yet

- BT Road Estimate ModelDocument5 pagesBT Road Estimate Modelsasidharkatari91572No ratings yet

- Dar Vol2 Update Dec 2021Document1,226 pagesDar Vol2 Update Dec 2021sspawarNo ratings yet

- Rate 69Document37 pagesRate 69Mishal Limbu100% (1)

- Rate Analysis Civil Engg..FormatDocument63 pagesRate Analysis Civil Engg..FormatLuojisi Cil100% (1)

- Code Description Unit Quantity Rate Amount: Sub Head: 16-Road WorkDocument2 pagesCode Description Unit Quantity Rate Amount: Sub Head: 16-Road WorkSanjan Sameer100% (1)

- Rate Analysis For Road ConstructionDocument5 pagesRate Analysis For Road ConstructionDipesh Shrestha68% (19)

- Civil Engineering Softwares List Super Civil CDDocument10 pagesCivil Engineering Softwares List Super Civil CDVijay Sharma100% (2)

- Analysis of Rates of Various Building ItemsDocument3 pagesAnalysis of Rates of Various Building Itemsveera_swamy250% (2)

- Rate Analysis For Concrete With GgbsDocument13 pagesRate Analysis For Concrete With GgbsyashupalgowdaNo ratings yet

- Rate AnalysisDocument14 pagesRate AnalysispsycinNo ratings yet

- Rate Analysis of Morang - CDocument16 pagesRate Analysis of Morang - Crashmi bhailaNo ratings yet

- Venkat Rigid Pavement Tables of Joints and SteelDocument2 pagesVenkat Rigid Pavement Tables of Joints and SteelV Venkata NarayanaNo ratings yet

- Civil TipsDocument5 pagesCivil Tipssanojev83% (6)

- Price Variation Bid Project Cost in HAMDocument6 pagesPrice Variation Bid Project Cost in HAMUmesh Mishra100% (2)

- Rate Analysis-MS Ladder at TerraceDocument1 pageRate Analysis-MS Ladder at TerraceRajagopal CRNo ratings yet

- Data Rates-Canal Works Part 1Document20 pagesData Rates-Canal Works Part 1vpmohammedNo ratings yet

- Rate Analysis r4Document60 pagesRate Analysis r4Akshay dareNo ratings yet

- Analysis of Rate For Liner+pileDocument6 pagesAnalysis of Rate For Liner+pileFahad Zulfiqar100% (1)

- Book DetailsDocument1 pageBook DetailsHatender Tomar0% (1)

- Analysis For BuildingDocument51 pagesAnalysis For BuildingPerkresht PawarNo ratings yet

- MoRTH - DPR ChecklistDocument8 pagesMoRTH - DPR ChecklistGanesh GuptaNo ratings yet

- Venkat FlexiblePavement DesignDocument86 pagesVenkat FlexiblePavement DesignV Venkata Narayana100% (5)

- BT Road From Akshitha Hospital (Srinivasapuram Road) To By-Pass RoadDocument12 pagesBT Road From Akshitha Hospital (Srinivasapuram Road) To By-Pass Roadsasidharkatari91572No ratings yet

- Sump Estimate APRSCL 15-4-2011Document102 pagesSump Estimate APRSCL 15-4-2011pandu123456No ratings yet

- Overhead Standards As Per Standard Rate Analysis Book (MoRTH)Document3 pagesOverhead Standards As Per Standard Rate Analysis Book (MoRTH)murugeshuniv90% (10)

- Rate AnalysisDocument46 pagesRate AnalysisbulganinganguliNo ratings yet

- Consumption of MaterialDocument14 pagesConsumption of MaterialRita Saigal72% (18)

- Rate Analysis Manual For Rural RoadsDocument76 pagesRate Analysis Manual For Rural RoadsSaumya Banerjee80% (5)

- Flat SlabDocument19 pagesFlat SlabParamveer SinghNo ratings yet

- Cost EstimateDocument11 pagesCost Estimate8790922772No ratings yet

- Three Phase Induction Motors: Output Equation of Induction MotorDocument7 pagesThree Phase Induction Motors: Output Equation of Induction MotoraaparumugamNo ratings yet

- Faculty of Applied Engineering and Urban PlanningDocument22 pagesFaculty of Applied Engineering and Urban PlanningHazem Almasry100% (1)

- Up-Aces Ce Quiz 2011Document8 pagesUp-Aces Ce Quiz 2011Homer BatalaoNo ratings yet

- Paper 1Document10 pagesPaper 1chaithra_14No ratings yet

- C Wall AlternateDocument1 pageC Wall Alternatechaithra_14No ratings yet

- 5624 (Foundation Bolt - Specification)Document9 pages5624 (Foundation Bolt - Specification)Bhaskar1411No ratings yet

- Silo DesignDocument42 pagesSilo Designchaithra_14No ratings yet

- Silo DesignDocument42 pagesSilo Designchaithra_14No ratings yet

- Pests and Diseases Identification in MangoDocument4 pagesPests and Diseases Identification in MangoBaino Olpugad Gerald100% (1)

- Soal Pts GSL 8 - Inggris - JWBNDocument9 pagesSoal Pts GSL 8 - Inggris - JWBNRindah Tiara SariNo ratings yet

- How To ComboDocument15 pagesHow To Combosapabapjava2012No ratings yet

- What's New: Contemporary Quiz#5Document2 pagesWhat's New: Contemporary Quiz#5Christian Castañeda100% (1)

- Principal's Corner: School ProfileDocument7 pagesPrincipal's Corner: School ProfileAngel Mae LabadorNo ratings yet

- Mazada Consortium LimitedDocument3 pagesMazada Consortium Limitedjowila5377No ratings yet

- The Impact of Employees' Commitment Towards Food Safety at Ayana Resort, BaliDocument58 pagesThe Impact of Employees' Commitment Towards Food Safety at Ayana Resort, Balirachelle agathaNo ratings yet

- Deck Manual PDFDocument217 pagesDeck Manual PDFBozidar TomasevicNo ratings yet

- Chap 5 - MOMDocument27 pagesChap 5 - MOMladdooparmarNo ratings yet

- Excel Tips Tricks e-BookV1.1 PDFDocument20 pagesExcel Tips Tricks e-BookV1.1 PDFSulabhNo ratings yet

- How To Query Asham Tele Points (Telebirr)Document13 pagesHow To Query Asham Tele Points (Telebirr)Fayisa ETNo ratings yet

- Alexander OsterwalderDocument2 pagesAlexander Osterwalderamelia990% (1)

- Op Amps and Linear Integrated Circuits 4th Edition by Gayakwad Ramakant A Textbook PDF Download PDFDocument1 pageOp Amps and Linear Integrated Circuits 4th Edition by Gayakwad Ramakant A Textbook PDF Download PDFNiraj KapoleNo ratings yet

- High Low MethodDocument4 pagesHigh Low MethodSamreen LodhiNo ratings yet

- Toro 006Document2 pagesToro 006Eric CNo ratings yet

- DSO Digital Storage Oscilloscope: ApplicationDocument2 pagesDSO Digital Storage Oscilloscope: ApplicationmsequipmentsNo ratings yet

- Exercises-Consumption Based Planning PDFDocument4 pagesExercises-Consumption Based Planning PDFfitroniNo ratings yet

- S&S PDFDocument224 pagesS&S PDFMohammed MateenNo ratings yet

- The Big Table of Quantum AIDocument7 pagesThe Big Table of Quantum AIAbu Mohammad Omar Shehab Uddin AyubNo ratings yet

- Stas 500-2-80 RDocument4 pagesStas 500-2-80 RSzabolcs KovacsNo ratings yet

- FAUDI Aviation Diesel - Company Profile-ENDocument6 pagesFAUDI Aviation Diesel - Company Profile-ENAttila HontváriNo ratings yet

- List of ItemsDocument5 pagesList of ItemsMoiNo ratings yet

- RWB 60-856 Inst - Op. Mantto.Document52 pagesRWB 60-856 Inst - Op. Mantto.Daniel Dennis Escobar Subirana100% (1)

- Psyc 1100 Research ExperimentDocument10 pagesPsyc 1100 Research Experimentapi-242343747No ratings yet

- Pure Theory of Law Hans Kelson-Ltp..Document45 pagesPure Theory of Law Hans Kelson-Ltp..ShabnamNo ratings yet

- B1+ Exam MappingDocument3 pagesB1+ Exam Mappingmonika krajewskaNo ratings yet

- Chapter 1 To7 With Course OutlineDocument34 pagesChapter 1 To7 With Course Outlinerk_kamatchi3483No ratings yet

- Simulation and Analysis of 10 Gbps APD Receiver With Dispersion CompensationDocument5 pagesSimulation and Analysis of 10 Gbps APD Receiver With Dispersion CompensationMohd NafishNo ratings yet

- Soft-Starter: Programming ManualDocument162 pagesSoft-Starter: Programming ManualThaylo PiresNo ratings yet

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (242)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesFrom EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesNo ratings yet

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyFrom EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyRating: 4 out of 5 stars4/5 (1)

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Civil Engineer's Handbook of Professional PracticeFrom EverandCivil Engineer's Handbook of Professional PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyFrom EverandSodium Bicarbonate: Nature's Unique First Aid RemedyRating: 5 out of 5 stars5/5 (21)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishFrom EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishRating: 4 out of 5 stars4/5 (3)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Estimating Construction Profitably: Developing a System for Residential EstimatingFrom EverandEstimating Construction Profitably: Developing a System for Residential EstimatingNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- THE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEFrom EverandTHE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATERating: 4 out of 5 stars4/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsFrom EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsRating: 1 out of 5 stars1/5 (4)

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyFrom EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyRating: 4 out of 5 stars4/5 (1)

- Real Life: Construction Management Guide from A-ZFrom EverandReal Life: Construction Management Guide from A-ZRating: 4.5 out of 5 stars4.5/5 (4)