Professional Documents

Culture Documents

Srdmanual

Uploaded by

api-264268525Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Srdmanual

Uploaded by

api-264268525Copyright:

Available Formats

394 111/111 693

PC-SRD User's Manual

4-July-2014

Copyright 2014 Computational Dynamics Ltd. CD-adapco

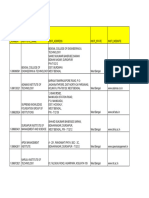

Typefaces and conventions used in SPEED manuals

Item Format Example or explanation

Main text Courier New 10 pt Switched reluctance motor

Parameters Courier New Bold Slots, Poles, Torque

Menu items

Arial 10pt bold

Menu items, functions, or items in

dialog boxes.

Parameter values Courier New BLV, ToothFlux

Emphasis Italic

Short-cut keys [Bold] [Ctrl+S]

Design sheet

extracts

Courier New 9pt Design sheet extracts

Related Technical Notes and Manuals

1 PC-SRD GoFER Manual

2 Explanation of UG98 Parameters

3 Multi-stroke dynamic simulation

4 Fully-pitched windings

Abbreviations

E degrees

.. Two dots following a parameter indicate an input value, to

distinguish it from an option or an output parameter with

the same name.

AWG American wire gage

d,q Direct and quadrature axes

e.g. exempli gratia, "for example"

EMF Electro-motive force (volts)

FE, FEA Finite-element, finite-element analysis

FEA-SR-MGC Special mag. curve calculator that uses PC-FEA 1 and provides

complete sets of mag. curves, or just a few points, for

comparison with PC-SRD's internal mag. curves.

GDF Geometry Definition Format. .gdf files are text files used

for transferring geometric and other data between

SPEED programs and PC-FEA and other finite-element programs.

GoFER lit. "Go to Finite-Elements and Return". The finite-element

link. This acronym emphasizes the particular feature of

SPEEDs finite-element links, in that they automate the

entire process of a range of specific finite-element

calculations and return data to the motor design program.

lb (or lbf) pound (or pound force). 1 lbf = 4.45 N

mag. curves Magnetization curves

Match MGC Mag. curve viewer

mm millimetre. 25.4 mm = 1 inch

MMF Magneto-motive force (amperes)

i.e. id est, "that is"

lit. "literally"

p.u. Per-unit

PWM Pulse-width modulation

q.v. quod vide, lit. "which see": in other words, "go and look

that up too"

RMS Root-mean-square

SEM SPEEDs Electric Motors, the theory manual of SPEED. The

chapter number may be indicated; e.g., SEM/4.

Ted Template editor

L Parameter or function not available in Distributor versions.

Contents

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2. PC-SRDsfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Outlineeditor[Ctrl+1] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Templateeditor,Ted[Ctrl+3] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Selectingmaterials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Dynamicdesign(Singlestroke)[Ctrl+2] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5 ThermalTransient[Ctrl+T] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.6 Multi-stroketransientsimulation[Ctrl+K] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.7 Windagelosscalculation[Ctrl+W] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.8 Auto-search[Ctrl+A] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.9 Statictorquecurves[Ctrl+Y] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.10 Ranging[Ctrl+B] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.11 Torque/Speedcharacteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.12 Designsheet[Ctrl+4] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.13 Customdesignsheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.14 Results|Graphs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.15 Realignmag.curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.16 Usingfinite-elementswithPC-SRD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.17 Finite-elementlinks[Ctrl+L]and[F11] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.18 Fully-pitchedwindings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.19 Multi-stroketransientsimulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3. Definitionofparameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.1 InputparametersintheOutlineeditor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.2 DefinitionofUnimeshparameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.3 InputparametersinTed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

3.4 Outputparametersinthedesignsheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

3.5 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

3.6 Referencediagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

4. Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

PC-SRD 9.04 User's manual 1. Introduction Page 1

Fig. 1 "Manual" design process

1. Introduction

Function

PC-SRD is intended for designing and calculating switched reluctance machines

including their electronic control. The theory behind PC-SRD can be found in SPEEDs

Electric Motors, the text that is used with the SPEED training courses, [1].

Intended use

PC-SRD is a PC-based CAD program for the design and performance calculation of

switched reluctance motors, including basic parameters of the drive and its control.

The program is designed to be fast in operation, with an efficient user interface.

Its main use is in

(a) studying/learning the switched reluctance motor and drive;

(b) sizing or preliminary design;

(c) calculating parameters for system simulation; and

(d) recording and modifying designs of production motors.

PC-SRD can be calibrated using adjustment parameters to improve the agreement

between calculation and measurement.

How do I use PC-SRD?

Starting from a performance requirement, the motor is designed by a cut-and-try

process of assigning parameters to one of PC-SRD's predetermined motor models or

templates, and then calculating the performance using one of PC-SRD's calculating

procedures, Fig. 1.

The process is repeated until the objectives are achieved. To make the motor design

fast and efficient, PC-SRD has an outline editor for modifying the cross-section and

other motor dimensions. There is a template editor for electrical parameters, drive

parameters, and several other inputs. PC-SRD also includes a material database for

steels. The performance calculation or analysis is either at a single operating

point, or over a whole speed/torque range. It includes a time-stepping model of

the drive, so that current and torque waveforms can be obtained. There is a design

sheet containing a wide range of performance parameters including the dimensions,

and details of the winding and the drive. All this data is presented in the

successful format used for many years in the SPEED Laboratory.

Page 2 1. Introduction PC-SRD 9.04 User's manual

Fig. 2 Automation, scripting, and database relationships

Scripting

The scripting language can be used to automate many processes, or to create new

algorithms or processes not already embedded in the program. It can also be used to

interface PC-SRD to other software. Fig. 2 shows how scripting can be used to

automate the variation of design parameters and the successive execution of PC-SRD.

(For studying the effect of simple parameter variations over a specified range of

values, the simpler internal ranging function can be used within PC-SRD).

Finite-element analysis

PC-SRD has two types of finite-element link or "GoFER" (lit., "Go to finite-elements

and return"):

(a) The Unimesh GoFER [Ctrl+L] excecutes a specialized "mag. curve

calculator" FEA-SR-MGC which relies on PC-FEA and the "Unimesh"

definition of boundary nodes generated within PC-SRD itself. Although

this uses an earlier version of PC-FEA, it is optimized for the

calculation of mag. curves and is recommended for that purpose.

(b) The GDF GoFER uses the GDF editor, which can also provide links to

other finite-element programs. The PC-FEA link is particularly useful

because of its speed. Fig. 2 shows the finite-element calculation

supporting the performance calculation.

What PC-SRD doesn't do

Design with PC-SRD is interactive and fast. However, PC-SRD doesn't synthesize

optimized designs by itself. The user produces them, using PC-SRD as a calculating

tool rather like a specialized spreadsheet program. PC-SRD improves the productivity

of the design engineer, but it doesn't do his/her job. As with any computer

program, the user should continually question the accuracy and check the results,

preferably against measurements.

PC-SRD 9.04 User's manual PC-SRDs functions Page 3

Fig. 3 PC-SRDs main menu

2. PC-SRDs functions

The common functions of all SPEED Windows programs are described in the

WinSPEED manual. This section provides further information specific to PC-SRD.

Function Hotkey Purpose

File, Options, Window, Help, Outline, Template, Design Sheet, Information, Scripting, Steel Database,

Calculator, Unit Converter

See WinSPEED manual

Data

Outline editor Ctrl+1 Display and edit the cross-section geometry

Template editor, Ted Ctrl+3 Edit non-geometric parameters

Materials Ctrl+M Select materials

External data files Ctrl+E Specify locations and names of external data

files

I/O Units Ctrl+U Select units

Titles Create or edit title, subtitle, and comment

to go with each datafile

Custom editor Ctrl+

Shift+3

Create, edit, or select a floating template

editor containing a subset of PC-SRDs

parameters. See WinSPEED manual.

Analysis

Dynamic design Ctrl+2 Calculate operating point at constant speed

Thermal simulation Ctrl+T Transient thermal calculation

Multi-stroke Ctrl+K Multi-stroke dynamic simulation (variable

speed)

Windage Ctrl+W Calculate windage loss

Ranging Ctrl+B Calculate a range or batch of cases or

designs

Autosearch Ctrl+A Automatic search for preset torque

Static torque curves Ctrl+Y Calculate static torque curves

Page 4 PC-SRDs functions PC-SRD 9.04 User's manual

Results

Design sheet Ctrl+4 Complete listing of input and output

parameters

Custom design sheet Custom listing of parameters, formatted

according to the template contained in the

text file Custom.dss; for formatting

instructions, see WinSPEED manual.

Tabbed design sheet Ctrl+

Shift+F4

The design sheet formatted in tabbed pages

Custom output Ctrl+

Shift+4

Create, edit, or select a floating design

sheet containing a subset of PC-SRDs

parameters. See WinSPEED manual.

Thermal design sheet Listing of thermal parameters formatted

according to the template contained in the

text file Thermal.dss; for formatting

instructions, see WinSPEED manual.

Graphs/waveforms Ctrl+G,

Ctrl+

Shift+G

Graphical output

Harmonic analysis Ctrl+H Harmonic analysis of PC-SRDs waveforms

Tools (See WinSPEED manual).

Calculator F4 Simple arithmetic operations on PC-SRDs

parameters

Scripting F7 Open the script editor

Unit converter Utility for converting units

Steel database Ctrl+5 Execute the Steel Database Manager for

editing or creating records of steel data

Realign mag curves Re-align external mag. curve data in PC-

SRD format

Current profile

editor

Ctrl+7 Open the current profile editor

GoFER (Unimesh) Ctrl+L Execute finite-element link via Unimesh and

FEA-SR-MGC

GoFER (FE link) F11 Execute finite-element link via GDF

(geometry definition file)

Match MGC Ctrl+F11 View, compare, and adjust mag. curves

FEA Viewer View the flux-plot produced by the Unimesh

GoFER

Export data Data transfer to other programs

PC-SRD 9.04 User's manual Data * Outline editor Page 5

Fig. 4 The outline editor

2.1 Outline editor [Ctrl+1]

The outline editor is for editing the motor cross-section.

Dimensions are defined in 3 and in the reference diagrams.

When you change a parameter, PC-SRD checks the validity of the new value. If the

data is invalid, an error message may appear and the drawing may disappear.

Unfortunately this may deprive you of visual clues as to what is wrong, so it is

advisable to proceed cautiously with careful changes, starting with a valid design.

Error-checking is not exhaustive, so it is advisable to check the drawing visually.

The cross-section can be copied to the Windows clipboard using [Ctrl+C]. The zoom

function is described in the WinSPEED manual. Use [F8]and/or [F6] to change the

appearance of the display.

Hotkeys

A/U Aligned/unaligned positions

O Origin (= previous aligned

position if units of control

angles are Emech; or previous

unaligned position if units are

Eelec. [Ctrl+U])

F/R Forward/reverse 1/4 stroke

D/E Forward/reverse 1 mechE

[/] Turn-on angle Th0/ Turn-off

angle ThC

{/} Reference firing angles (multi-

stroke simulation) (on/off)

(/) Braking angles (on/off)

J/N Start/end of pole overlap

K/M Start/end of maximum overlap

Z zero-volt loop angle ThZ

H/L Start/end of wide-pole overlap

(stepped-gap rotors)

C Centre: midway between U and A

V Valley point (JRH108)

Page 6 Data * Outline editor PC-SRD 9.04 User's manual

Angle sets the rotor in any defined position. Angle is in mechE or elecE according

to the selection of default units for control angles ([Ctrl+U], CtrlAng), and is

consistent with Th0, ThC and ThZ (3), so it can show the rotor at particular firing

angles. The centrelines on the active rotor and stator poles line up when the rotor

is in the aligned position, if Ntp = 1. Angle is saved with the other motor

parameters when you save the datafile.

If the number of stator or rotor poles is changed, reset the rotor angle using [A].

To change the polarity of any coil, left-click on the polarity label (N or S) when

Outline | Show coils is selected. PC-SRD automatically changes the polarity of all the

pole-coils in the same phase winding.

Outside-rotor (exterior-rotor) motors can be modelled if Rsh > R0 > R1 > R2 > R3,

i.e., Rsh becomes the largest radius and R3 becomes the smallest radius. There is

no need to change the sign of Gap, and no other changes are necessary. An example

is provided with File* New*Examples.

PC-SRD 9.04 User's manual Data * Template editor Page 7

Fig. 5 The template editor, Ted .

2.2 Template editor, Ted [Ctrl+3]

Ted contains all the input parameters of the motor and control, including the

dimensional parameters that appear in the outline editor. For parameter

definitions, see 3. Use [F8] to change the appearance of the display.

The data is divided into tabbed pages: for example Simulation parameters and Thermal

parameters are on separate pages. Ted does no error-checking, so any errors will not

show up until a Dynamic design is run.

Page 8 Data | Materials PC-SRD 9.04 User's manual

Fig. 6 Selecting steel [Ctrl+M]

Fig. 7 Specifying external datafiles

2.3 Selecting materials [Ctrl+M]

The materials associated with the current design datafile can be selected using

Data*Materials [Ctrl+M]; see the WinSPEED manual.

Units [Ctrl+U]

Default units for input/output can be selected using Data * I/O Units [Ctrl+U]; see the

WinSPEED manual.

External data files [Ctrl+E]

Some of PC-SRDs analysis functions require external data that is usually provided

in ASCII text files; also, PC-SRD writes data in this form. Use [Ctrl+E] to

specify the locations and names of these files. The Show before simulation checkbox

determines whether the filenames will be displayed before a calculation is

undertaken.

PC-SRD 9.04 User's manual Analysis * Dynamic design Page 9

1

Also known as the i-psi loop, because it is an xy-plot of current (i) and flux-linkage (psi or ).

2

Default colours when the graph background is black.

Fig. 8 Waveforms of phase currents (i

1

, i

2

, i

3

); normalized flux-linkage

(psi), per-unit overlap, and torque, vs. rotor position.

Press [Enter] to step through subsequent graphs. Press [L] to see

the legend; or [G] to see the graticule.

2.4 Dynamic design (Single stroke) [Ctrl+2]

Dynamic design is the main calculating procedure of PC-SRD. It calculates the

performance by simulating the operation over one stroke at constant speed.

After a Dynamic design, waveforms of current, torque, flux-linkage and related

quantities can be viewed by Results | Dynamic Design Graphs | Current + Torque, etc. The

two most important graphs are the current and torque waveforms, Fig. 8; and the

energy-conversion loop,

1

Fig. 9.

Currents, flux-linkage and torque [Ctrl+G]

Phase currents i

1

,i

2

,i

3

,... i

5

[A} Red, Yellow, Blue, Green, Magenta

2

Phase 1 normalized flux-linkage Cyan

Phase 1 p.u. overlap between rotor and stator poles Dark red

Phase 1 electromagnetic torque (T

1

, T

1x

: see p. 10) Colours depend on MagCurv

Total electromagnetic torque White

Average electromagnetic torque Green

DC Link current Yellow

The trapezoidal waveform of per-unit overlap between the active stator poles and the

active rotor poles corresponds to the ideal inductance profile that would be

obtained with no fringing flux around the pole corners, no interference between

phases, and no magnetic saturation. The overlap profile is scaled so that the

aligned value has the same ordinate as the peak current. The ratio between its

maximum and minimum values is approximately equal to the unsaturated inductance

ratio. It is provided solely for guidance in determining firing angles, and is not

used in calculations.

The aligned (A) and unaligned (U) positions are marked with vertical lines; in Fig.

8, A ' 90E and U ' 45E. The range of the graphs can be set with GRange, p. 66.

Page 10 Analysis * Dynamic design PC-SRD 9.04 User's manual

Fig. 9 Energy-conversion loop

T

e[avg]

'

Strokes/rev WConv

2B

. (1)

Energy-conversion loop and average electromagnetic torque

The energy-conversion loop is an xy-plot of flux-linkage and current i in one

phase. In Fig. 9 it is superimposed on the magnetization curves, which represent

the static flux-linkage/current characteristics of one phase (with no current

flowing in any other phase).

The mean electromagnetic torque is calculated from the area of the energy-conversion

loop, WConv in Fig. 9, according to the equation

This equation is the preferred method for calculating average electromagnetic

torque, because it does not rely on localized differentiation of the coenergy or

stored field energy. See below.

The dynamic loop in Fig. 9 should not extend too far to the right, because

magnetization curve data above im is extrapolated, and becomes progressively less

accurate as im is exceeded. If you are working with internal mag curves, im can be

increased by increasing Bm (3).

Instantaneous torque

The torque waveform T in Fig. 8 represents the total instantaneous electromagnetic

torque calculated by 'shifting and adding' the torques of the individual phases: no

account is taken of mutual coupling between phases. The torque waveform is highly

variable and depends on speed, load, and firing angles. This is an inherent

characteristic of the SR motor.

Fig. 8 also shows the instantaneous torque of one phase calculated by two methods,

both of which are based on the differentiation of co-energy with respect to rotor

position [SEM/4]. T

1

is based on an approximate "gauge curve" model of the mag.

curves (see p. 67; also [6,14] and SEM/4); but T

1x

is based on a piecewise curve-fit

of the mag. curves using cubic splines. T

1x

is available only when MagCurv is Extl,

Froh/X, Univ/X or UG98/X,and it should be regarded as more rigorous and probably

more accurate than T

1

. Especially when MagCurv = Froh, the instantaneous torque

waveform is not rigorous and may become inaccurate at light load, if the machine is

unsaturated. It can be checked by comparing TLoop with Twfm (3).

PC-SRD 9.04 User's manual Analysis * Dynamic design Page 11

Magnetization curves

Magnetization curves ("mag. curves") represent the static flux-linkage of a phase

winding as a function of current over the whole range of rotor positions between the

unaligned and aligned positions. A typical set of mag. curves is shown in Fig. 9,

together with the dynamic i- loop: that is, the locus of the point (i, ) during

one stroke. Mag. curves are essential for the Dynamic design calculation.

PC-SRD can calculate the mag. curves from the geometry, the winding details, and the

B/H data of the stator and rotor steels. Alternatively it can import mag. curves

obtained by measurement or finite-element analysis. Because of the importance of the

mag. curves, PC-SRD has an inbuilt facility for displaying, comparing and adjusting

sets of mag. curve data in different formats, Match MGC, [Ctrl+F11].

With "internal" mag. curves, PC-SRD approximates the mag. curves with the "gauge

curve" model, which it uses to compute the entire energy-conversion stroke very

quickly "on the fly". In this case, very few parameters are needed to characterize

or calibrate the mag. curves. With "external" mag. curves, however, PC-SRD curve-

fits the mag. curves with a set of cubic splines, with up to 900 data points. As

well as flux-linkage, stored field energy is also represented in this curve-fit.

The "external mag. curve" simulation algorithm is more rigorous than the "internal"

one, but for improved accuracy it can be applied to internally-generated mag. curves

using "/X" values of MagCurv. The options are summarized in the following table:

MagCurv

Internal mag. curves Froh

Univ

UG98

The nonlinear algebraic relationship between

current, flux-linkage, and position is solved

locally using a fast interpolation algorithm

based on so-called "gauge curves". This method

is optimized for speed.

External mag. curves Extl The nonlinear algebraic relationship between

current, flux-linkage, and position is solved

using a cubic-spline representation of

externally-generated mag. curves. This method is

optimized for accuracy, but it is much slower.

/X procedures Froh/X

Univ/X

UG98/X

The same as External mag. curves, except that the

mag. curves are calculated internally by PC-

SRD and are not imported from an external source.

Mag. curve files

When Dynamic design runs with internal mag. curves, it writes them to an ASCII file

whose default name is "IPSI.psi". This file is called the "IPSI file" or i- file.

With external mag curves, a valid IPSI file must be specified for the current design,

using [Ctrl+E]. The format of the IPSI file is defined in the File Formats manual.

By default, it has the filename extension .psi. The i- data is also written to

a second ASCII file called "IPSI.mgc", whose format is more convenient for

comparison with finite-element calculations or test data. Files in .mgc format can

be converted into .psi format via Tools | Realign mag curves. Both formats can be viewed

with Match MGC, [Ctrl+F11]. Only the static mag. curves are stored in the IPSI file.

Magnetic coupling between phases

Except with fully-pitched windings, PC-SRD neglects mutual inductance between

phases, and superimposes flux-linkages and torques from different phases after the

fully nonlinear calculation of a single phase has been completed. The effect of

coupling between phases can be assessed to a certain degree using the Unimesh

finite-element analysis with a second phase excited, or with the [F11] GoFER; but

the results of this magnetic analysis cannot be used in PC-SRD.

Page 12 Analysis * Dynamic design PC-SRD 9.04 User's manual

Fig. 10 Simple thermal

equivalent circuit

Fig. 11 Thermal circuit when

HTC is nonzero.

Thermal calculations in Dynamic design

The steady-state thermal model in PC-SRD is based

on a simple thermal equivalent circuit whose

parameters are DegCW, HTC, and ct_Liner. If HTC =

0, the model has a single thermal resistance DegCW

as shown in Fig. 10. The temperature rise is

calculated as TempRise = DegCW WTotal, and it can

apply to any point T in the machine, provided that

DegCW is specified with the appropriate value. By

default, T is assigned to the winding conductor

temperature T_Cond. Then DegCW should be specified

as the total thermal resistance from the winding

conductors to ambient. The model gives no

information about the temperature distribution

within the machine, because all the losses are

lumped together and injected at a single point. It

makes no distinction between temperatures inside

the machine and at the frame surface.

A slightly more complex thermal model is shown in Fig. 11. In this case PC-

SRD calculates the thermal resistance ThRFS from the frame surface to the ambient

as ThRFS = 1/(HTC FSArea), where HTC is the specified heat transfer coefficient

and FSArea is the frame surface area. DegCW is now considered to be in series with

ThRFS, and can be used to represent an internal thermal resistance.

A further refinement is that if ct_Liner is non-

zero, PC-SRD calculates the thermal resistance of

the slot liners using the inside surface area of

the slot SSArea: thus

ThRslot = ct_Liner Liner / SSArea / Ns

where SSArea is for one slot. This thermal

resistance is combined with DegCW. Because the

coilsides have contact with the slot liner over

only a fraction of the area SSArea, it may be

necessary to compensate for this by increasing the

value of DegCW, or by modifying the value of

ct_Liner. For example, if thermal contact is

maintained over only 30% of the inside area of the

slot, then the correct value of ThRslot will be

equal to the calculated value divided by 0@3. This

could be corrected by augmenting DegCW by (1/0@3

!1) ThRslot = 2@33 ThRslot. Alternatively,

ct_Liner could be increased by the factor 1/0@3.

If TempIt = true, the thermal calculations are

iterative. The Dynamic design is repeated with a

new value of winding resistance which is

recalculated from the temperature rise at every

iteration. The iteration continues until the

winding temperature converges to a final value. The

result is assigned to T_Cond and it is at point

T in Fig. 11.

PC-SRD also calculates the thermal capacity of the entire motor C_motor [kJ/EC], and

the thermal time-constant thermTC [min]. The components of C_motor are available

separately when the transient thermal calculation is run.

Note: In previous versions ThermTC was calculated using ThRFS only, but this has been changed to the sum

of all thermal resistances in series. Also, in previous versions with TempIt = true, the increase in

resistivity of copper was incorrectly calculated unless T_Wdg = T_amb.

PC-SRD 9.04 User's manual Analysis | Thermal Page 13

Fig. 12 Thermal transient equivalent circuit

2.5 Thermal Transient [Ctrl+T]

Analysis | Thermal [Ctrl+T] is an independent transient calculation in which the losses

are assumed to be constant at the values calculated in the most recent Dynamic

design. The calculation uses a thermal equivalent circuit whose parameters can be

edited in Ted/Thermal; see Fig. 12.

Thermal capacitances are calculated by PC-SRD from the weights and specific heats

of the various materials in the motor. They can be modified by the addition of

supplementary thermal capacitances.

Thermal resistances representing heat transfer by conduction, radiation, convection,

and direct cooling are, in the main, required to be provided by the user although

some are calculated from rule-of-thumb formulas.

By switching off the losses (XLoss = 0), cooldown can be modelled from a defined set

of initial temperatures.

Page 14 Analysis | Multi-stroke PC-SRD 9.04 User's manual

Fig. 13 Speed vs. time in multi-stroke simulation

Fig. 14 Currents and torque during

multi-stroke simulation

Fig. 15 Energy-conversion diagram showing

multiple-loops

2.6 Multi-stroke transient simulation [Ctrl+K]

Whereas Dynamic design is restricted to constant speed and load, multi-stroke

transient simulation covers several revolutions with variable speed, variable load,

and variable control parameters. Several additional control parameters must be

correctly specified for this simulation to run successfully: see Ted/2. The block

diagram used by PC-SRD is described in a separate technical note, "MultiStroke".

The main uses of multiple-stroke simulation are:

1. to study motion control, e.g. step responses, "trapezoidal moves",

speed changes etc.;

2. to simulate the effects of load torques that vary with rotor position;

3. to study the effects of changes in control system parameters, including

variable firing angles and PID control of the current;

4. to study the effects of discretization (i.e. digital representation)

of speed and other parameters; finite encoder resolution; and

processing delays; and

5. to study the effects of faults and disturbances.

The output is in the form of graphs showing the currents, speed, etc. throughout the

simulation. Multi-stroke simulation can use external files containing tables of

control data. Their formats are given in a separate document.

PC-SRD 9.04 User's manual Analysis * Windage loss Page 15

Fig. 17 Auto-search

Fig. 16 Windage loss parameters

2.7 Windage loss calculation [Ctrl+W]

PC-SRD can calculate the windage loss based on a NASA report by James Vrancik [12].

The result can be saved into the main datafile via the parameters Wf0, RPM0. The

calculation allows various options, for example, to change the density or viscosity

of the air and to adjust constants in Vranciks equations.

2.8 Auto-search [Ctrl+A]

Auto-search provides a limited degree of automation in which the set-point current

iHi or the turn-on angle Th0 can be varied to achieve a target value of torque. If

the search fails, PC-SRD displays an appropriate message.

Page 16 Analysis | Static torque curves PC-SRD 9.04 User's manual

Fig. 18 Static torque curves: torque vs. rotor position for currents up to iTTh.

Fig. 19 Static flux-linkage curves, showing flux-linkage vs. rotor position for

currents up to iTTh.

2.9 Static torque curves [Ctrl+Y]

PC-SRD calculates the static torque curves, i.e., curves of electromagnetic torque

vs. rotor position from the unaligned to the aligned position over a range of

currents from 0 to iTTh; see Fig. 18. The calculation also makes available a set

of curves of flux-linkage vs. position (psi!theta curves), Fig. 19. Use Results * T-

theta Graphs to view the curves.

PC-SRD 9.04 User's manual Analysis * Ranging, Torque/Speed Page 17

2.10 Ranging [Ctrl+B]

Ranging is the calculation of a batch of designs, in which a number of parameters

are stepped through a series of values. The design sheets are available for all

steps, and graphs can be plotted showing the variation of any parameter against any

other parameter. Ranging is intended to assist in the selection of an optimum value

for one or more parameters. It is described in the WinSPEED manual. A variation

range can be assigned to an individual parameter using [Ctrl+R] in Ted. Note that

ranging has no intelligence: it merely grinds out a repetitive series of

calculations quickly and presents the results efficiently.

2.11 Torque/Speed characteristics

The torque/speed characteristic cannot be calculated automatically in PC-SRD as it

can in the other SPEED motor design programs, because it depends on several

parameters (such as firing angles) which must vary as the speed and torque vary, and

there is no standard way in which these variations are implemented. A torque/speed

characteristic can, however, be obtained using ranging. In a simple example, the

turn-on angle Th0 would be varied linearly as the speed increases.

Page 18 Results * Design sheet PC-SRD 9.04 User's manual

2.12 Design sheet [Ctrl+4]

PC-SRD 8.8 (8.8.0.1) 13-Apr-2008 18:14:51

d:\test\sr1.srd

SPEED Laboratory

PC-SRD main title

PC-SRD sub-title

Dimensions:--------------------------------------------------------------------

Rsh 12.5 mm Ntp 1 Gap 0.3 mm

R0 30 mm Nph 3 Lstk 50 mm

R1 45 mm Nr 4 BetaR 32 mDeg

R2 65 mm Ns 6 BetaS 30 mDeg

R3 80 mm D1s 2 mm D2s 2 mm

fil_R 2 mm tpr_R 3 mDeg tab 0 mm

fil_S 2 mm tpr_S 3 mDeg tpr_T 4 mDeg

Stroke 30 mDeg SPW 23.449 mm RPW 24.807 mm

StepGap NoStep FluxPths Normal Jag Normal

FrLgth 75 mm FrThk 5 mm CapThk 5 mm

Lshaft 150 mm Dshaft 25 mm

ASlam 9768.59 mm^2 ARlam 3910.791 mm^2 ARslot 489.914 mm^2

Winding Data:------------------------------------------------------------------

Np 150 T_Cond 144.245 C Rph 2.398 ohm

Paths 1 SFill 0.3 Lau 208.736 mH

NSH 1 M.L.T. 202.05 mm Lu 15.331 mH

Aslot 648.462 mm^2 NwkPP 1 Lau/Lu 13.616

SFill 0.3 SFill 0.3 WireSpec SFill

WDia 0.909 mm ACond 0.648 mm^2 L/ends 94.349 mm

Coils/Ph 2 Tph 300 Nss 2

Ext 0 mm Polarity NSN

Rcc 0 ohm Lcc 0 mH

Control Data:------------------------------------------------------------------

Vs 150 V iHi 30 A DuCy 1

rpm 1000 rpm iLo 30 A Dwell 30 m

Th0 50 m Rq 0 ohm %Dwell 33.333 %

ThC 80 m Vq 1 V Strk/Rev 12

ThZ 65 m Vd 0.6 V Fph 66.667 Hz

VsMax 180 V Rs 0 ohm

tq_ON 0 usec tq_OFF 0 usec fChop 11 kHz

Regulate Current CProfile false Chopping Soft

NChops 0 NCL 0 NVD 0

fChopAct 0 kHz fChopAvg 0 kHz fChopEst 0 kHz

CtsCond false tDwell 5 ms HBAmps 0 A

ISLA 1 Tol 8 PhEnable 1 1 1

Performance:-------------------------------------------------------------------

TorqSh 8.227 Nm WCu 254.736 W Q_rms 4.527 kVA/kW

PowerSh 861.564 W WIron 17.911 W Q_pk 9.322 kVA/kW

Eff 75.962 % Wwf 0 W WCucc 0 W

sigma 1.873 psi WTotal 272.647 W TempRise 124.245 C

PLoop 879.475 W PElec 1134.211 W Doing Motoring

Vdc 150 V

Currents:----------------------------------------------------------------------

IWPk 11.748 A IWMean 3.784 A IWrms 5.952 A

IQchPk 11.748 A IQchMean 3.165 A IQchRMS 5.705 A

IQcmPk 11.748 A IQcmMean 3.165 A IQcmRMS 5.705 A

IDchPk 10.635 A IDchMean 0.619 A IDchRMS 1.698 A

IDcmPk 10.635 A IDcmMean 0.619 A IDcmRMS 1.698 A

Jrms 9.179 A/mm IDC(wfm) 7.636 A DCripple 4.916 A

continued/...

PC-SRD 9.04 User's manual Results * Design sheet Page 19

Iron Losses:-------------------------------------------------------------------

Rotor: M19 24 gage

WlbFeRY 3.147 W/kg RCfCh 8.500E-03 RCfa 1.308

WlbFeRP 3.142 W/kg RCfCe 4.820E-06 RCfb 0.356

PRYE 1.214 W PRYH 1.515 W BRYMax 1.213 T

PRPE 0.814 W PRPH 1.022 W BRPMax 1.711 T

Stator: M19 24 gage

WlbFeSY 4.248 W/kg SCfCh 8.500E-03 SCfa 1.308

WlbFeSP 2.366 W/kg SCfCe 4.820E-06 SCfb 0.356

PSYE 4.832 W PSYH 5.938 W BSYMax 1.415 T

PSPE 1.133 W PSPH 1.444 W BSPMax 1.81 T

WEC 7.992 W WHYS 9.919 W XFe 1

Stf 0.97 IronLoss Orig

WFe0R 3.157 W/kg WFe0S 3.157 W/kg

Steady-State Thermal Model:----------------------------------------------------

T_Cond 144.245 C TFrame 91.5 C T_amb 20 C

TempRise 124.245 C TempIt true T_Wdg 23.7 C

ct_Liner 0.2 W/m C Liner 0.2 mm SlotPeri 35.666 mm

DegCW 0.1 C/W ThRslot 0.093 C/W SSArea 1783.322 mm^2

HTC 42 W/mC ThRFS 0.262 C/W FSArea 90792.028 mm^2

C_motor 4.046 kJ/C ThermTC 30.73 min

Supplementary Output:----------------------------------------------------------

Settings...

MagCurv UG98/X FluxPths Normal FluxWfms Real

Weights and mechanical..

WtCu 1.048 kg WtFe 5.076 kg Wt_Tot 6.124 kg

WtFrame 1.23 kg WtShaft 0.574 kg

RotJ 1.330E-03 kg-m RotJsh 4.487E-05 kg-m

Force and torque..

TRFbase 1482.403 N TRFpk 1578.779 N FUnbal 1111.802 N

TRPP 10.012 Nm TRrms 3.293 Nm TVR 25.865 kNm/m^3

TRPPpu 1.192 TRrmspu 0.392 Tpk 35.438 Nm

Energy conversion loop..

TLoop 8.398 Nm Twfm 8.401 Nm WConv 4.397 J

MagLdg 0.269 T ElecLdg 52.535 kA/m MagGear 2

OPK 1.847 Kus 0.732 ERatio 0.733

VAsMax 7.239 J UConvMax 6.009 J WConvMax 5.333 J

Ks 0.887 Ku 0.825 RConv 1.602 J

ERmax 0.737 VAWmin 1.357 TLoopMax 10.185 Nm

Mag curves..

Bm 2 T Bs 1.3 T Lau0 206.252 mH

Psim 716.542 mVs Psis 465.752 mVs Lu0 10.785 mH

im 11.523 A i_s 2.231 A Lss 1.134 mH

Xim 1 XLu 1 ETFCalc V5+Lss

X_Np 1 X_Lstk 1

dLu 4.546 mH dLau 2.484 mH a_ETF 1

L_min 15.331 mH L_max 208.736 mH Lmax/min 13.616

Pg 5.060E-03 mWb/At Lg 113.86 mH Ag 1172.45 mm^2

Electrical..

PsiMax 630.856 mVs ThQ 104.188 m

Th_X 80 m Th0_gen 75.813 m ThC_gen 100 m

RhoT 2.564E-08 ohm-m TFRho 1.488 ConvLoss 21.219 W

InnerAcc true IDC(pwr) 7.703 A

End of Design sheet------------------------------------------------------------

Page 20 Results * Design sheet PC-SRD 9.04 User's manual

The design sheet shows all the input and output design parameters of the motor and

drive, and their relevant units. Use the [8],[9] keys or the mouse to scroll

through the data. The help line displays information about the highlighted

parameter. If the help line is not visible, use the mouse cursor to select the

parameter. The output parameters are described in 3. Input and output parameters

have different colours, which can be changed using Design sheet | Options [F8].

Hard copy of the design sheet can be obtained using File * Print [Ctrl+P].

Alternatively, [Ctrl+C] can be used to copy the window to the clipboard. The design

sheet can also be saved to a text (.txt) or Rich Text Format (.rtf) file using

Design sheet * Save Design sheet.

The calculator [F4] accepts arithmetic expressions such as Power/746. For

parameters with names containing punctuation marks, use double quotes, e.g.

"%Dwell".

2.13 Custom design sheet

A custom design sheet can be set up by first creating a template file containing the

names of variables that are normally available in the standard design sheet,

together with user-defined expressions as in the design sheet calculator [F4] . The

custom design sheet can include complete pre-defined sections from the standard

design sheet.

The custom design sheet can be displayed whenever the main design sheet is

available. It has all the same features as the main design sheet including the

calculator [F4] and printing facilities.

To identify the custom design sheet file (*.DSS file) to PC-SRD, use Options|General.

The custom design sheet template file can be created or edited using a text editor.

Check the release disk for *.DSS files to see an example. It should have the

filename extension .DSS. It can contain 4 main types of formatting information:

plain text, predefined sections, standard variables and user-defined expressions.

Any number of template files may be created.

The syntax of the custom design sheet is described in the WinSPEED manual. The

custom design sheet can include whole sections from the normal design sheet by

entering the specific section name on a separate line in the .DSS template file.

The section names are those used in the design sheet, preceded by the @ symbol:

@DIMENSIONS

@WINDINGDATA

@CONTROLDATA

@CURRENTS

@PERFORMANCE

@IRONLOSSES

@SUPPLEMENTARYOUTPUT

@THERMALANALYSIS

@USERDEFINEDFORMULA

@STEADYSTATETHERMALMODEL

PC-SRD 9.04 User's manual Results * Design sheet Page 21

Fig. 20 Stator pole flux waveforms

2.14 Results | Graphs

After an Analysis such as Dynamic design, etc., several graphs are usually available

such as those in Figs. 8 and 9. When the graph window is active, the Graph menu

appears, with options such as [Z] (show zero), [G] (show grid), [L] (show legend),

[F8] (Options), [Ctrl+C] (copy to clipboard), Save graph data and Edit Graph. Note

that [Ctrl+C] simultaneously copies data in a numerical format that can be pasted

into a spreadsheet. Save graph data writes the data to a file.

Flux waveforms

The number of flux waveforms for stator poles is equal to the number of phases. The

number of flux waveforms for stator yoke sections depends on the number of poles and

phases. For example, in a three-phase 6/4 motor there are six stator yoke sections,

but there are only three different waveforms of stator yoke flux. After the first

three stator yoke sections, the waveforms repeat. The first three sections form a

"base sequence". PC-SRD plots the curves only for the base sequence. The number of

different flux waveforms for rotor poles and rotor yoke sections is determined in

a similar way.

The flux waveforms are normalized to the peak flux in one stator pole. They are

either "ideal" or "real", depending on the value of FluxWfms, (Ted/2). Ideal flux

waveforms are made up of straight line segments constructed geometrically from the

firing angles and the numbers of poles and phases, taking the winding polarities

into account. Real flux waveforms are constructed point-by-point from the actual

simulated flux-linkage waveform calculated during Dynamic design.

The file formats for flux and tooth radial force waveforms are given in the File

Formats manual.

Page 22 Tools * Realign mag curves PC-SRD 9.04 User's manual

Fig. 21 Realign mag curves

30 0 0

31

0.000E+0000 0.000E+0000

1.558E+0000 2.388E-0002

. . . . . . . . . . . . .

. . . . . . . . . . . . .

4.674E+0001 7.165E-0001

31

0.000E+0000 0.000E+0000

1.558E+0000 2.388E-0002

. . . . . . . . . . . . .

. . . . . . . . . . . . .

4.674E+0001 7.165E-0001

. . . . . . . . . . . . .

. . . . . . . . . . . . .

31

0.000E+0000 0.000E+0000

1.144E-0001 2.388E-0002

. . . . . . . . . . . . .

. . . . . . . . . . . . .

1.152E+0001 7.165E-0001

.mgc file format

2.15 Realign mag. curves

Realign mag curves converts mag. curve data in the external .mgc file format into the

internal .psi format used in PC-SRD. It is used when it is required to use external

mag. curve data, for example, from meaurements or finite-element calculations.

The .mgc file contains a series of curves, each of which is at a constant rotor

position. The example above is for 30 curves (i.e., 30 positions), starting with

the unaligned curve and ending with the aligned curve. Each curve contains 31

points. Within each of the 30 blocks, each line has a pair of numbers (i, ) in

order of increasing current at the same rotor position. This format is considered

convenient for FE data or measured mag. curve data. In contrast, the internal .psi

file format represents the curves at constant flux-linkage levels, because PC-SRD

uses flux-linkage as the independent variable. (See File Formats manual).

Realign can scale the (i,) data as it is read in. For example, if the psi-values

are in mV-s, enter an "adjustment factor" of 0@001 for so that PC-SRD will read

values in V-s. Another use of the scale factors is when you change the number of

turns per pole. For example, if you double the number of turns per pole, the -

values should be doubled (2) and the i-values should be halved (0@5). Again, if the

size of the motor is scaled up, you can apply appropriate scaling factors. In this

way the same set of mag. curves can be used to cover a range of designs.

Automatic addition of end-effects

It can add PC-SRDs internally-calculated end-effects during the conversion, so that

mag. curve data from 2D finite-element analysis can be modified for end-effects.

This provides a half-way-house between full 3D FE analysis and simpler 2D FE

analysis, which is generally not accurate for switched reluctance motors, especially

around the unaligned position.

End-effects are added as the data is read from the original .mgc file. They are

expressed as additional inductances computed in the most recent Dynamic design with

internal mag. curves. For each point there is a current i and a flux-linkage .

As is read from the .mgc file, it is scaled by the adjustment factor ScPsi; the

current is scaled by the scale factor Sci, and an additional flux-linkage is added

to account for end-turn inductance dL at the corresponding rotor angle:

Psi := ScPsi * X_Lstk * Psi + dL * (Sci * i)

The factor X_Lstk is a scaling factor for stack length. dL varies from dLu at the

unaligned position to dLau at the aligned position. These are displayed (together

with the method of end-effect calculation) in the dialog box, Fig. 21.

PC-SRD 9.04 User's manual Tools * Realign mag curves Page 23

Fig. 22 DC offset C ExtIfd and external mag. curve data

At intermediate positions between unaligned and aligned, PC-SRD uses an exponential

"roll-off" function to vary dL from the larger value dLu at the unaligned position

to the smaller value dLau at the aligned position. The "Roll off" can be adjusted

in Fig. 21, or by means of the parameter a_ETF which is in Ted/2.

If a_ETF = 1, the roll-off is nearly linear. If a_ETF = 10, the roll-off is sharp.

Fractional values (e.g. 0@1) can be used to get a straight roll-off, but zero is not

admitted. Probably the best value is about 1. This is not too sharp, but allows

the end-effects to fall off quickly between the tip-to-tip position (J in Fig. 71

on p. 103) and the unaligned position.

Re-alignment of external mag. curve data with DC offset

When dcOffset = true, external mag. curve data may be in the form shown in Fig. 22,

where i is the phase current and psi is the phase flux-linkage. Because of the DC

offset current ExtIfd, the flux-linkage values at zero current are non-zero. PC-SRD

cannot re-align this mag. curve data directly. It requires that every mag. curve

include the point (0,0), so that the set of mag. curves looks like an ordinary set

with origin OO instead of O.

During re-alignment, the point (0,0) is added to every mag. curve as it is read in,

and the current ExtIfd is added to every value of current in the file. This places

all the curves to the right of the origin OO by the amount ExtIfd. The offset

current ExtIfd must be included in the .mgc file on the first line: thus

NCurves ExtIfd

instead of

NCurves

The current ExtIfd (external Ifd) is referred to the phase winding using the turns

ratio described under IOffs in Ted/2; it is not the actual current in the DC

winding. If ExtIfd is zero or absent from the .mgc file, PC-SRD will assume that

it is zero, and the results will be unpredictable.

Page 24 Tools * Realign mag curves PC-SRD 9.04 User's manual

Re-alignment of nonsymmetric mag curves

When StepGap = Stepped and NonSym = true, the first line of the .mgc file must

contain iUC as well as ExtIfd and NCurves : thus

NCurves ExtIfd iUC

where iUC identifies the curve for the unaligned position (or the nearest curve

to the unaligned position).

Summary of re-alignment procedure

(a) Run PC-SRD with the main datafile for the motor whose mag. curves are to be re-

aligned, with ETFCalc set to the desired method and all other parameters

(including X_Lstk and X_Np) at their desired values, and with MagData = Froh

or UG98. (It doesn't particularly matter whether you run with internal or

external mag. curves: all you are doing here is calculating the values of dLu

and dLau, the end-turn "inductances").

(b) Execute the realignment procedure and check or edit the parameters in the

dialog box, Fig. 21.

(d) Run PC-SRD with MagData = Extl (external mag. curves) and the .psi file you

have just created (containing the re-aligned curves).

Note : PC-SRD also writes a file called Realignd.mgc which contains the re-aligned

mag. curves in the .mgc format. This data includes the scaling factors and the

end-turn adjustments, and corresponds exactly to the new .psi file, but it is in the

same format as the original .mgc data. If you have plotted those curves, perhaps

with software like a spreadsheet, this will make it easy to plot the new re-aligned

curves by the same method. The .mgc files can also be compared with mag. curves

calculated by PC-FEA, using Match MGC, [Ctrl+F11].

PC-SRD 9.04 User's manual Tools * Realign mag curves Page 25

3

PC-SRD fits straight lines OU and OS, and a parabola SA, and interpolates all other points.

Fig. 23 Adjusting the mag. curves. Simple finite-element calculations can be used to

adjust key points such as the three "magic points" U,S and A. See also Fig. 57.

2.16 Using finite-elements with PC-SRD

Finite-element results can be used with PC-SRD in three main ways:

A. To check particular points on the mag. curves, for example, the three "magic

points" U,S, and A in Fig. 23. With the simplest internal mag. curve models

PC-SRD calculates only the three points U, S and A.

3

These points can be

calculated quickly using FE analysis, and then adjusted via the adjustment

factors XLau, Xim, XPsim, XLu, etc. This approach is fast and efficient.

B. To calculate complete sets of external mag. curves for use with PC-SRD. This

requires many more finite-element calculations but is desirable when it is

necessary to study the intermediate mag. curves and their effect on the current

waveforms. If the finite-element calculations are 2D, PC-SRDs internally

calculated end-effect factors can be applied using the Re-align function.

C. The [F11] GoFER (p. 28) has a powerful set of analysis capabilities including

the ability to calculate with current in several phases at the same time. It

uses PC-FEA 5.5 and is compatible with the i-psi GoFER in PC-BDC.

Switching off the end-effects in PC-SRD

For comparison with 2D FE calculations, the end-effects can be switched off in PC-

SRD by setting ETFCalc = Off & Lss. This is legitimate when optimizing the shape

of a lamination, but the end-effects should be switched on again before running

Dynamic design or any other Analysis procedure.

The U,S,A points are important in the sense of confirming the boundary within which

the energy conversion loop will lie, and the more accurate they are, the less likely

it is that there will be an error in the basic sizing of the machine.

When adjusting the A point, it is advisable to try to arrange the FE solution so

that adjustments can be made via Xim rather than XPsim, because the core losses are

calculated from flux-densities derived from the corrected value of Psim and

therefore it is not advisable to vary XPsim far from 1.

Page 26 Finite-element links PC-SRD 9.04 User's manual

Fig. 24 Unimesh nodes in the outline editor appear only when the rotor is between the

unaligned [U] and aligned [A] positions. Set FELinkID = PCFEA.

Fig. 25 Unimesh GoFER. The Run button executes the original FEA-SR-MGC process

using PC-FEA 2. The PC-FEA button executes a similar process using the

latest version of PC-FEA.

2.17 Finite-element links [Ctrl+L] and [F11]

PC-SRD has two different kinds of finite-element link: an older one for fast,

automatic calculation of the mag. curves, and a newer one with additional GoFER

functions similar to those found in other SPEED programs.

1. Tools*GoFER (SRD Unimesh) [Ctrl+L]

The Unimesh GoFER is for automatic finite-element calculation of a single position

or for generating a complete set of mag. curves. Details are given in the PC-SRD

GoFER manual, but a summary is shown here, including the use of Match MGC to compare

the FE results with PC-SRD's mag. curves. The FE calculations are done by PC-FEA 2.

Step 1 setting up the Unimesh boundary nodes

Use the Unimesh tabbed page in the outline editor to adjust the distribution of

boundary nodes where necessary. The parameters are defined in 3 and Fig. 51.

Step 2 selecting the Unimesh GoFER option

The example uses the "USA points" option.

PC-SRD 9.04 User's manual Finite-element links Page 27

Fig. 27 Progress of the Unimesh finite-

element calculation

U

A

S

im

End-effect error

in FE result

Fig. 28 The USA points computed by PC-FEA are superimposed on PC-SRD's mag. curves

in Match MGC. The U point is computed at the same current im as the A

point; this current results from the particular choice of Bm. Likewise the

S point is defined by the choice of Bs.

Fig. 26 The link to PC-FEA displays the

location of the data files.

Some of the problem parameters can be

edited in the FESRD.INI file. Click on

the FELink line to edit this file.

Step 3 Running the PC-FEA MGC calculator

All three points are calculated automatically.

Step 4 Checking the results in Match MGC

The agreement between PC-FEA and PC-SRD is very good at the S and A points on the

aligned mag. curve, but there is a noticeable discrepancy at the U point because of

the end-effects (which are not switched off in the PC-SRD mag. curves in this

example). The tabbed page "Parameters" can be used to make adjustments (including

setting ETFCalc = Off & Lss). Run PC-SRD again with [Ctrl+2]to see the effect of

adjustments.

Page 28 Finite-element links PC-SRD 9.04 User's manual

Fig. 29 F11 GoFER : Single load-point

Fig. 30 The GDF editor. Adjustments can be made here to the boundary node

distribution, material assignments, excitation levels and other details

before passing control to the finite-element program.

2. Tools*GoFER (FE Link) [F11]

The [F11] GoFER uses PC-FEA 5.5 and is the standard method adopted with all the

other SPEED motor design programs. It is described in detail in the PC-SRD GoFER

manual. It creates a geometry definition file (.GDF) which has a published format

and is designed for users and third-party finite-element developers to create links

independently of the SPEED Laboratory. The standard FE link [F11] is described in

the WinSPEED manual. The .GDF file links efficiently to SPEEDs own finite-element

program PC-FEA 5.5. For more details about the PC-FEA finite-element program

itself, consult the PC-FEA manual.

Step 1 Create the GDF file [F11]

First complete a Dynamic design calculation with PC-SRD, [Ctrl+2]. Then select

Tools|GoFER|FE Link [F11]. The GoFER dialog will appear:

Select Single load point. Options [F6] are described in the PC-SRD GoFER manual. Use

Whole motor for the solution domain, with Stator tooth on x-axis. Click OK or press

[F11] again. The GDF Editor opens, Fig. 30.

PC-SRD 9.04 User's manual Finite-element links Page 29

Fig. 31 Finite-element mesh in PC-FEA using GDF link [F11]

Fig. 32 Single load-point flux-plot in PC-FEA using GDF link [F11],

with current in more than one phase.

Step 2 Run PC-FEA

Press [F11] again to run PC-FEA. When PC-FEA is run from the GDF editor, it starts

in the script window, where further adjustments can be made to the problem

definition, but at a more detailed level than in PC-SRD or the GDF editor. From the

script window, click Run or press [F11] to create the mesh, Fig. 31. Click Continue

or press [F8] to complete the solution, as shown in Fig. 32.

Page 30 Finite-element links PC-SRD 9.04 User's manual

Fig. 33 i-psi diagram with superimposed finite-element calculation from the

[F11] i-psi GoFER; end-effects applied

Fig. 34 i-psi diagram with superimposed finite-element calculation from the

[F11] i-psi GoFER; no end-effects applied to the finite-element data

The i-psi GoFER

The i-psi GoFER is selected in Fig. 29. The options, GDF Editor, PC-FEA script and

PC-FEA mesh windows are similar to those of the Single load point GoFER, and only

typical results are described here.

Fig. 33 shows the normal i-psi diagram after running the i-psi GoFER. In the Graph

menu, when this window is active, select Show FE i-psi loop. The example was run with

Regulate = iHi, and with rq_dLau = 0 and rq_dLu = 0, which causes PC-SRD to apply

its own end-effect factors to the 2D finite-element data. Fig. 34, on the other

hand, was run with rq_dLau = rq_dLu = 0@0001, which effectively disables the

addition of end-effect factors to the finite-element data. A third option is to run

PC-SRD with ETFCalc = Off & Lss, which removes the end-effects from PC-SRD,

permitting a comparison of pure 2D calculations from both programs.

PC-SRD 9.04 User's manual Finite-element links Page 31

Fig. 35 i-psi diagram with finite-element calculation from the [F11] i-psi

GoFER; no end-effects are applied to the finite-element data

Fig. 36 Flux-linkage waveform with finite-element calculation from the [F11]

i-psi GoFER; no end-effects are applied to the finite-element data

After running th i-psi GoFER, Tools|FE Results|IPL viewer can be used to open the graphic

windows in Figs. 35 and 36. These windows are in the classic style of the MatchFE

window in PC-BDC, and they have a similar function : to compare PC-SRD's calculation

with the finite-element calculation. No end-effects are applied to the finite-

element data, so it is possible to compare only the 2D part of PC-SRD's calculation

and this can be done by setting ETFCalc = Off & Lss.

While Fig. 35 shows the complete i-psi loop, Fig. 36 shows the flux-linkage

waveform (plotted vs. rotor position).

In this example, only Phase 1 is conducting. However, it is possible to perform

this calculation with current in the other phases, and also to display the i-psi

loops of the other phases in Fig. 36. This is described in the PC-SRD GoFER manual.

Page 32 Fully-pitched windings PC-SRD 9.04 User's manual

4

Note: SPEED does not have any commercial interest or research programs in this field: these aspects

should be pursued directly with the patentholder. The calculations in PC-SRD are based entirely on the

composite phase concept, as used previously in connection with short fluxpaths. The composite phase

is a physically derived concept, based purely on the physical distribution of ampere-turns: its

implementation in PC-SRD is based solely on this principle and does not use the matrix theory in this

section (originally published as a release note with PC-SRD 6.95 in June 1998). The matrix theory is

included here as an alternative viewpoint, to help express the composite phase in the correct context

with respect to the original work of [13].

Fig. 37 Conventional short-pitched

winding with 2 coils/pole in series;

i.e., Paths = 1. Each coilside occupies

only of the slot area. The ampere-

conductor distribution shown here lasts

for 30E in a 6/4 or 15E in a 12/8; i.e.,

60E elec.

Fig. 38 Fully-pitched winding with 2

phases conducting. The particular

ampere-conductor distribution shown here

is represented by a single composite

phase that conducts for 30E in a 6/4 or

15E in a 12/8; i.e., 60E elec., but the

individual phase currents are maintained

for twice this, i.e., for 120 E elec.

2.18 Fully-pitched windings

PC-SRD can model one of the configurations of fully-pitched windings (fpw) described

by Dr. B. Mecrow in Ref. [13] and U.S. Patent 5545938.

4

The particular

configuration is the one corresponding to "excitation A" in Ref. [13], that is, 2

phases conducting for 2/3 of a cycle with unipolar currents. Because PC-SRD models

only one phase at a time, it treats the fpw configuration internally as a single

composite phase connected as shown in Fig. 2, with both the dotted and the solid-

line coils connected together in parallel. It is restricted to 3-phase motors that

are eligible for this winding configuration, notably the 6/4 and the 12/8. The

fully-pitched winding option is selected by setting FluxPths = fpw.

The numbers of coils/phase, coils/pole, and turns/coil remain the same as in the

conventional short-pitched winding (spw). In the 6/4 machine, two Np-turn coils

occupy the same slots and the end-windings are laid in opposite directions, making

a double-layer winding. The normal configuration of pole-coils assumed by PC-SRD is

shown in Fig. 38, with Paths = 1, i.e., all coils in series.

The i-Psi diagram is plotted with the composite phase current i

A

; text files

containing current waveforms also contain this current. However, several parameters

in the design sheet and the template editor refer to only one of the two phases in Fig. 39

(such as phase c shown in solid line). These parameters are prefixed with "fp":

for example fpIWrms is the r.m.s. winding current in one of the two fully-pitched

phases in Fig. 2. At low speeds, it is assumed that the current-regulators keep the

two phase currents equal at all instants, as indicated by the separate current-

sensor symbols in Fig. 2. At high speeds, if the currents are not chopped, they

cannot be assumed equal and the results will be meaningless.

Simplified account of the fully-pitched winding

In the normal operation of a 3-phase switched reluctance motor, each phase winding

occupies about 1/3 of the available slot area and at low speed it conducts for only

about 1/3 of the time. The simplest notion of fully-pitched windings is to replace

the ampere-conductors of each original phase by a distribution of ampere-conductors

from 2 phases wound with fully-pitched coils. The particular scheme described in

[13] does this in such a way that the whole area of each slot is used for 2/3 of the

PC-SRD 9.04 User's manual Fully-pitched windings Page 33

Fig. 39 Creating a fully-pitched

coil of 2N

p

turns from

the two short-pitched

N

p

-turn coils of a

normal phase winding.

W

Cu

' R

c

I

2

A

N

ph

'

R

ph

2

(I

a

2)

2

N

ph

' R

ph

I

2

a

N

ph

. (3)

time (i.e., 120E conduction instead of only 60E). If the current-density and copper

cross-section were kept the same, the MMF/pole would increase by a factor of 2.

However, the copper losses within the slots would also increase by a factor of 2.

To retain the same copper losses, the phase current must be reduced by the factor

1//2, but even so the MMF/pole is still increased by /2.

Because the fully-pitched windings have longer end-turns, the phase resistance is

increased by a certain ratio f

R

, so that for equal copper losses the phase current

must be reduced by 1//(2 f

R

)

.

The factor f

R

depends on the L/D ratio of the motor

and on the number of poles, and decreases towards unity as the L/D ratio increases.

If f

R

is greater than the "break-even" value of 2, any gain in MMF/pole will be at

the expense of increased copper losses. The value of f

R

is calculated and displayed

as fpRR.

A fully-pitched coil can be formed from two

short-pitched coils by "dragging" one

coilside from each pole-coil to a position

180 Eelec away to create a single coil of

180E pitch, with 2N

p

turns in series. The

wire size, the slot-fill factor, and the

number of turns in series per phase remains

the same. See Fig. 3.

The resistance of the fully-pitched coil

increases only as a result of the increase

in end-turn length; its value is 2f

R

R

coil

,

where f

R

> 1 is the ratio of mean turn-

length in the fpw and spw coils, and R

coil

is the resistance of one short-pitched

coil. In Fig. 2 or Fig. 3, with only one

fully-pitched coil per phase, R

ph

=

2f

R

R

coil

. In general with N

s

stator poles

and N

ph

phases, there will be N

ss

/2 =

N

s

/N

ph

/2a coils in series per phase, where

a is the number of parallel paths, and R

ph

= f

R

N

ss

R

coil

. For the SPW winding, there

are N

ss

coils in series per phase and R

ph

= N

ss

R

coil

. Therefore all the increase in

R

ph

in the fpw winding is due to the increase in mean turn-length, provided that the

turns are as shown in Figs. 1 and 2.

The composite phase is made up of two fully-pitched coils in parallel, Fig. 2. The

effective resistance is R

c

= R

ph

/2. The r.m.s. current I

a

in one fully-pitched coil

is

The /2 multiplying factor comes from the fact that one fully-pitched phase

contributes to two composite phases; in one electrical cycle it carries two pulses

of current, normally operating for 2/3 of a rotor pole-pitch instead of only 1/3.

The factor comes from the antiparallel connection, such that each fully-pitched

phase carries only half the current of the active composite phase.

The total copper loss and the current density in the copper are given by

and

The composite phase in Fig. 2 is magnetically equivalent to the SPW phase in Fig.

1. It has the same inductance except for the increased end-winding inductance in

the fpw coils. With nonlinear steel, this property is unaltered, and all the PC-

SRD parameters, Lu, Lau, im, Psim and Psis are identical for the spw phase and the

composite phase in Figs. 1 and 2. Moreover, 1A in the composite phase produces

exactly the same MMF/pole and exactly the same flux-pattern with the same flux-

densities, as it does in the spw phase in Fig. 1. With the same voltage source, if

the conduction angle in the composite phase connection is the same as for the normal

I

a

' 2

1

2

I

A

' I

A

/ 2 (2)

J ' I

a

/A

cond

(4)

Page 34 Fully-pitched windings PC-SRD 9.04 User's manual

5

The current-regulator set-point iHi refers to the current in one fully-pitched coil, and not in the

terminal leads to the composite phase since these are fictional. PC-SRD assumes that the individual

fully-pitched phase currents are switched and regulated independently; the composite phase connection

is therefore an effective or virtual connection, not a physical one. For equal copper losses iHi must

be reduced by the factor 1//(2f

R

) compared to the value used with the SPW winding.

2N

p

i

1

' 2N

p

i

a

& 2N

p

i

b

& 2N

p

i

c

(5)

i

1

' i

a

& i

b

& i

c

(6)

i

1

i

2

i

3

'

1 &1 &1

&1 1 &1

&1 &1 1

@

i

a

i

b

i

c

(7)

Fig. 40 Orientation

of phases

and pole

fluxes

phases in the spw machine, with the same current-limit, then the torque/speed

characteristics of the two machines in Figs. 38 and 39 will be identical, apart from

the effect of end-turn inductance and the increase in resistance represented by f

R

.

These values are not the same for the fully-pitched phases a,b,c. 1A of composite

phase current requires only A of fully-pitched phase current, but since this flows

in 2N

p

turns/pole and two phases are conducting at once, the MMF/pole is the same

as with 1A flowing in two N

p

-turn spw coils.

PC-SRD displays the parameters Lu, Lau, im, Psim and Psis for the composite phase

and not for the individual fully-pitched phases. The reason for this is to make it

easier to see the essential difference between the fpw and spw machines, conferring

the same advantages as a good per-unit system would: that is, to show that the

fundamental behaviour is independent of the number of turns and really only depends

on the quantities of copper and iron and the degree to which they are worked (i.e.,

the electric and magnetic loadings).

PC-SRD also displays the i-Psi diagram (energy-conversion diagram) in terms of the

composite-phase current and flux-linkage. The composite phase comprises two

"component" fully-pitched phases that are temporarily in parallel and therefore have

the same flux-linkage as each other, both being equal to the flux-linkage

A

of the

composite phase; see eqn. (46) below. On the other hand the instantaneous composite

phase current is the sum of the currents in the two component fully-pitched phases;

since these are assumed to be equal, the instantaneous composite phase current is

twice the instantaneous current in each fully-pitched component phase; see eqns.

(31!32) below.

5

Relationships between windings expressed by connection transformations

The relationships between the SPW phases 123 and the FPW

phases abc can be expressed by connection matrices, as

indicated by Mecrow in Ref. [13]. The matrix equations

can be extended to include the composite phases, as

shown here. For the simple cases modelled in PC-SRD,

the matrix equations do not add any new understanding.

They are included here so that comparisons can be made

with Mecrows papers, in which different numbers of

turns per phase were used, giving different matrix

coefficients. The matrix equations would be useful in

future if the PC-SRD model is extended to some of the

more complex cases described by Mecrow.

The reference locations and orientations of the fully-

pitched phases are shown in Fig. 41, together with the

directions of the pole fluxes

1

,

2

,

3

, which are

aligned with spw phases 1,2,3 respectively (see Fig.

38, which shows spw phase 1).

Since spw phase 1 links only flux

1

flowing in the

poles at 12 oclock and 6 oclock, evidently

i.e.,

Repeating this for spw phases 2 and 3, we get

PC-SRD 9.04 User's manual Fully-pitched windings Page 35

i

a

i

b

i

c

'

0 & &

& 0 &

& & 0

@

i

1

i

2

i

3

(9)

[i

abc

] ' [C]

&1

@[i

123

] (10)

[i

123

] ' [C]@[i

abc

] (8)

[R

abc

] ' [C]@[R

123

] . (15)

2N

p

i

c

' & N

p

i

1

& N

p

i

2

(11)

i

c

' &

1

2

i

1

&

1

2

i

2

(12)

Fig. 41 Formation of

fully-pitched coil

from short-pitched

coils.

R

a

R

b

R

c

'

1 &1 &1

&1 1 &1

&1 &1 1

@

R

1

R

2

R

3

(14)

R

a

' 2N

p

M

1

& 2N

p

M

2

& 2N

p

M

3

' R

1

& R

2

& R

3

(13)

which can be written

where [C] is the 33 matrix in eqn. (27) and [i

123

] and [i

abc

] are column vectors.

The inverse of eqn. (28) is

which can be written

Another way of looking at the equivalence between the fully-

pitched and short-pitched windings is shown in Fig. 42. The

"go" and "return" coilsides of the coils in spw phases 1 and

2 are bunched together and assigned to fpw phases abc

according to the following table:

SP

Phase

Coil Go Return

1 1 !c +b

1 2 !b +c

2 1 !a +c

2 2 !c +a

Evidently

giving

and likewise for i

b

and i

c

. These relationships concur with eqns. (30) and (31).

For the flux-linkage, by inspection from Fig. 40 or Fig. 41,

and for all three fpw phases

which can be written

Page 36 Fully-pitched windings PC-SRD 9.04 User's manual

' &i

b

& i

c

'

i

1

i

3

2

i

1

i

2

2

' i

1

i

2

i

3

2

' i

1

& i

a

' (23)

[v

123

] ' [Z

123

][i

123

] (18)

[v

abc

] ' [C]

!1

[v

123

] ' [Z

123

][C][i

abc

] (19)

[i

123

]

t

[R

123

] ' [[C] [i

abc

]]

t

[C]

&1

[R

abc

] ' [i

abc

]

t

[C]

t

[C]

&1

[R

abc

]

' [i

abc

]

t

[R

abc

] .

(17)

[v

abc

] ' [C]

!1

[Z

123

][C][i

abc

] ' [Z

abc

][i

abc

] (20)

[Z

abc

] '

Z

1

Z

2

Z

3

!Z

1

!Z

2

Z

3

&Z

1

Z

2

!Z