Professional Documents

Culture Documents

Circ Base

Uploaded by

Mario Sajulga Dela CuadraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Circ Base

Uploaded by

Mario Sajulga Dela CuadraCopyright:

Available Formats

"CIRCBASE" --- STEEL COLUMN CIRCULAR BASE PLATE ANALYSIS

Program Description:

"CIRCBASE" is a spreadsheet program written in MS-Excel for the purpose of analysis of steel column base

plates. Specifically, pipe columns base plates may be subjected to axial loads (compression only), with or

without column bending, plus shear. Base plate bearing pressure is checked as well as bolt tension, if

applicable. If shear is present, bolt shear as well as interaction of bolt tension and shear, if applicable, are

calculated. Finally, a propoesed base plate thickness is is checked.

This program is a workbook consisting of two (2) worksheets, described as follows:

Worksheet Name Description

Doc This documentation sheet

Complete method Circular base plate analysis

Program Assumptions and Limitations:

1. This program follows the procedures and guidelines of "Design of Monopole Bases", by Daniel Horn, P.E.

2. This program follows the procedures and guidelines of the AISC 9th Edition Allowable Stress (ASD) Manual

(2nd Revision, 1995) for round hollow structural tube & column base plates subjected to flexure.

3. For steel interaction of anchor bolt tension and shear, this program follows:

Appendix D of ACI 318-02, "Building Code Requirements For Structural Concrete"

4. For concrete bearing, this program follows:

Section 10.17 of ACI 318-02, "Building Code Requirements For Structural Concrete"

5. User has option to take out some of the total shear though friction between column base and grout based

on column dead load and coefficient of friction, thus reducing amount of shear to be taken by anchor bolts.

6. Additional assumptions used in this program are as follows:

a. The column is centered on a circular base plate in both directions.

b. The column & base plate are centered on a round pedestal in both directions.

b. Axial column load, 'P' > 0 for the case with moment.

7. This program contains numerous comment boxes which contain a wide variety of information including

explanations of input or output items, equations used, data tables, etc. (Note: presence of a comment box

is denoted by a red triangle in the upper right-hand corner of a cell. Merely move the mouse pointer to the

desired cell to view the contents of that particular "comment box".)

8. For the addition of gusset plates to the baseplate, this program derives the baseplate moments from

"Theory of Plates and Shells", by S. Tomonshenko. (1st Edition, 1940)

a. Table 26 - Deflection & Bending Moments for a Uniformly Loaded Plate with Two Opposite Edges

Simply Supported, the Third Edge Free and the Fourth is Built In (Page 218)

GROUTED BASE PLATES

Per AISC 9th Edition Manual (ASD) and "Design of Monopole Bases" (Daniel Horn, P.E.)

based on the Complete Circular Base Plate Method

Job Name: Job No.:

Subject: Originator: Checker:

Input Data:

Column Loadings:

Axial Load, P = 11.00 kips

Axial Load, P(DL) = 0.00 kips

Shear Load, V = 3.00 kips e = 88.55 in

Moment @ Base, M = 974.00 in-kips y = 9.95 in

Design Parameters:

Mod./High seismic risk region? Yes

Is a grout pad present? Yes

yo = 2.55 in

Column Outer Dia., OD(col) = 16.000 in di = 16 in

Column wall thick, tcol = 0.500 in

Column Yield stress, Fy(col) = 35.000 ksi

Base Plate O.D., B = 25.000 in

Base Plate I.D., di = 16.000 in

Base Plate thick, t(PL) = 1.750 in

Plate Yield Stress, Fy = 36.00 ksi

Baseplate gussets present? Yes

Gusset Plate thick, tg = 0.500 in

Gusset Plate height, hg = 12.000 in

No. of Gusset Plates, Ng = 8 BC = 20 in

Concrete Strength, f 'c = 4.000 ksi B = 25 in

Coef. of Friction, = 0.55

Conc. Ped. diameter, OD(ped) = 30.00 in

ACI load factor, LF = 1.38

Anchor Bolt/Rod Data:

Total No. of Bolts, Nb = 6 bolts

Bolt Circle Dia, BC = 20.00 in

Bolt Diameter, db = 1 1/4 in

Anchor Bolt Material = F1554 (36)

Iteration:

q(start) = 86.0000 in Start value should approx. equal eccentricity

q(calc) = 83.4276 in

Delta = 2.5724 Change q(start) until Delta = 0.

Results:

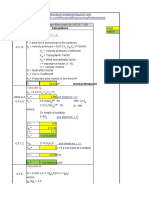

Calculate the area of the outer circle:

r = 12.50 in = B/2

y = lo = 9.95 in = r-e+q

yo = 2.55 in = r-lo

A1 = 182.24 in^2 = r^2*p/2-yo*(r^2-yo^2)-r^2*asin(yo/r)

(continued)

PL bearing

area

Complete Method

GROUTED BASE PLATES

Per AISC 9th Edition Manual (ASD) and "Design of Monopole Bases" (Daniel Horn, P.E.)

based on the Complete Circular Base Plate Method

Job Name: Job No.:

Subject: Originator: Checker:

Results (continued):

Calculate the area of the inner circle

ri = 8.00 in = di/2

l = 5.45 in = ri-e+q

yc = 2.55 in = max(ri-l or -ri), or 0 if l<0

Ac = -60.50 in^2 = -ri^2*p/2+yc*(ri^2-yc^2)+ri^2*asin(yc/ri), or 0 if l<0

AT = 166.55 in^2 = A1+Ac+(n-1)*Ab+n*Ab

y1 = 6.70 in = [2*(r^2-yo^2)^1.5]/3*A1

Q1 = 14,915 in^3 = A1*(e-y1)

y1c = 4.81 in = 0 if l<0, or [-2*(ri^2-yc^2)^1.5]/(3*Ac)

Qc = -5,066 in^3 =Ac*(e-y1c), or 0 if l<0

QT = 13,833 in^3 = Q1 + Qbolt + Qc

Calculate the moments of inertia

I1 = 1,221,916 in^4

Ic = -424,371 in^4

Ibolt = 356,488 in^4

IT = 1,154,032 in^4 = I1+Ic+Ibolt

q(calc) = 83.43 in = IT/QT

Concrete Results:

Eccentricity, e = 88.55 in = ABS(M/P)

Min. Eccentricity, e(min) = 4.41 in = (B^4-di^4)/(8*B*(B^2-di^2))

Method Valid

ACI load factor, LF = 1.38

Conc bearing stress, fc(max) = 1.77 ksi = P*y/(q*AT-QT)

Factored bear stress, fc(max,f) = 2.44 ksi = LF*fc(max)

ybc = 4.88 in = BC/2-e+q(calc)

Conc bearing stress, fbc = 0.87 ksi @ bolt circle = P*ybc/(q*AT-QT)

Factored bearing stress, fbc,f = 1.53 ksi @ bolt circle = LF*fbc

Strength reduction factor, = 0.65

PL to ped edge dist, d1a = 2.50 in = [OD(ped)-di]/2

Min. bear length, d1 = 2.50 in = min[ d1a , r(col) ]

Conc bear area O.D., OD(bear) = 30.00 in = B+2*d1

Conc bear area I.D., ID(bear) = 11.00 in = di-2*d1

Baseplate bearing area, APL = 289.81 in^2 = p/4*(B^2-di^2)

Concrete bearing area, Aconc = 611.83 in^2 = p/4*[OD(bear)^2-ID(bear)^2]

(Aconc/APL) = 1.45

Allow. bear. stress, fc(allow) = 3.21 ksi = *0.85*(f 'c)*(Aconc/APL)

fc(max,f) fc(allow), O.K.

Steel Results:

beff = 8.38 in = p*B/Nb

y = 2.88 in = B/2-e+q(calc)

fpole = 0.51 ksi = P*y/[q(calc)*AT-QT]

(continued)

Steel Results (continued):

Complete Method

GROUTED BASE PLATES

Per AISC 9th Edition Manual (ASD) and "Design of Monopole Bases" (Daniel Horn, P.E.)

based on the Complete Circular Base Plate Method

Job Name: Job No.:

Subject: Originator: Checker:

Compression Side:

No. of Gusset Plates, Ng = 8.00 plates

Gusset spacing, b = 10.73 in = 2*p*([r+r(col)]/2)/Ng

Baseplate Length, L = 4.50 in = 0.5[B-OD(col)]

L/b = 0.42

L/b Mx My

x = b/2 y = L1 x = b/2 y = 0

0 0 -0.500 fc*L^2

0.333 0.0078 fc*b^2 -0.428 fc*L^2

0.5 0.0293 fc*b^2 -0.319 fc*L^2

0.667 0.0558 fc*b^2 -0.227 fc*L^2

1 0.0972 fc*b^2 -0.119 fc*L^2

1.5 0.1230 fc*b^2 -0.124 fc*b^2

2 0.1310 fc*b^2 -0.125 fc*b^2

3 0.1330 fc*b^2 -0.125 fc*b^2

0.1330 fc*b^2 -0.125 fc*b^2

Conc bearing stress, fc(max) = 1.77 ksi = P*y/(q*AT-QT)

Cx = 0.0189

Mx = 3.845 in-kips/in = Cx*fc*b^2

Cy = -0.3718

My = -13.310 in-kips/in = Cy*fc*L^2

M(max) = 13.31 in-kips

f(max) = 4.99 ksi = [6*M(max)]/t(PL)^2

f(all) = 27.00 ksi = 0.75*Fy f(max) f(all), O.K.

Tension Side:

M(max) = 38.12 in-kips = Pten*[BC-OD(col)]/2

f(max) = 8.92 ksi = 6*M*(max)/[beff*t(PL)^2]

f(all) = 27.00 ksi = 0.75*Fy f(max) f(all), O.K.

Column Wall:

Gusset spacing, b = 10.73 in = 2*p*([r+r(col)]/2)/Ng

Rcol = 8.00 in = OD(col)/2

m = 1.75 in = t(PL)

a = 2.00 in = 2*(tg+t)

Z = 0.21 = 1/[ (0.177*a*m/sqrt(Rcol*t))(m/tcol)^2+1.0]

Vg = 85.38 kips = fc*b*L

Mg = 192.11 in-kips = *fc*b*L^2

fb(pole wall) = 13.78 ksi

fb(allow) = 21.00 ksi = 0.6*Fy(col) fb(pole wall) fb(allow), O.K.

Column to Baseplate Weld:

Sweld = 201.06 in^2 =(p/4)*OD(col)^2

Weld force, fwm = 4.84 kips/in = M/Sweld

Allowable weld stress, w = 14.85 ksi = 0.7071*0.3*(70 ksi)

Req'd weld size, h = 0.326 in = fwm/w

(continued)

Steel Results (continued):

This table is taken from

Theory Of Plates And

Shells (Timoshenko)

Weld design assumes 70

ksi electrodes

Complete Method

GROUTED BASE PLATES

Per AISC 9th Edition Manual (ASD) and "Design of Monopole Bases" (Daniel Horn, P.E.)

based on the Complete Circular Base Plate Method

Job Name: Job No.:

Subject: Originator: Checker:

Gusset / Column / Baseplate Weld:

tg = 0.5 in

hg = 12 in

b1 = 6.28 in

Determine moment of inertia of gusset/baseplate section

Item b h y A A*y A*y^2 Io

1 6.28 1.75 0.88 11.00 9.62 8.42 2.81

2 0.50 12.00 7.75 6.00 46.50 360.38 72.00

Totals 13.75 17.00 56.12 368.79 74.81

Baseplate effective width, b1 = 6.28 in = p*OD(col)/Ng

Location of gusset/basepl neutral axis, ybar = 3.30 in = A*y/A

Gusset/basepl moment of inertia, I1 = 258.28 in^4 = Io+(A*y^2)-[(A*y)*ybar]

# of welds, Nw = 2.00 welds

Allowable weld stress, w = 14.85 ksi = 0.7071*0.3*(70 ksi)

Bending stress @ t.o. gusset, t = 7.77 ksi

Bending stress @ b.o. gusset, b = 2.46 ksi

Shear force @ face of baseplate, fv = 8.82 kips/in = Vg*[(b1)*t(PL)]*[ybar-*t(PL)]/I1

Horizontal weld force, fvw = 4.41 kips/in = fv/Nw

Horizontal req'd weld size, h = 0.30 in = fvw/w

Bending force on vert. weld, fbw = 1.94 k/in = t*tg/Nw

Vertical shear on weld, fsw = 3.56 k/in = Vg/(hg*Nw)

Resultant weld force, frw = 4.05 k/in = SQRT(fbw^2+fsw^2)

Req'd weld size, v = 0.27 in = frw/w

(continued)

Anchor Bolt/Rod Steel Tension and Shear (Per ACI 318-02):

Tensile strength reduction factor, = 0.75

t(PL) = 1.75 in

Weld design assumes 70

ksi electrodes

Complete Method

GROUTED BASE PLATES

Per AISC 9th Edition Manual (ASD) and "Design of Monopole Bases" (Daniel Horn, P.E.)

based on the Complete Circular Base Plate Method

Job Name: Job No.:

Subject: Originator: Checker:

Shear strength reduction factor, = 0.65

ACI load factor, LF = 1.38

A.B. Spacing, s = 10.47 in = p*BC/Nb

Max. bolt tension, Pten = Tb = N = 19.06 kips (See following page)

Max. factored bolt tension, Nu = 26.30 kips = LF*N

Bolt Shear, V(bolts) = 3.00 kips = V(total)-1/2**P(DL)

Bolt Shear, Vb = Vu = 0.69 kips/bolt = V(bolts)/Nb

Ase = 0.97 in^2

Fy(bolt) = 36.00 ksi

Fut(bolt) = 58.00 ksi

Ns = 31.61 kips/bolt = 0.75**Ase*Fut(bolt)

Vs = 13.15 kips/bolt = 0.75*0.8**0.6*Ase*Fut(bolt)

Tension interaction = 0.832 = Nu/(Ns) S.R. 1.00, O.K.!

Shear interaction = 0.042 = Vu/(Vs) S.R. 1.00, O.K.!

Interaction check = 0.885 = Nu/(Ns) + Vu/(Vs) S.R. 1.20, O.K.!

Steel anchor strength is OKAY!

* Shear strength of anchors with grout pads shall be multiplied by 0.8 ACI 318-02, Sect. D.6.1.3

* Anchor strength reduced by 75% due to seismic region ACI 318-02, Sect. D3.3.3

(continued)

Individual Anchor Bolt Forces:

Bolt # ybolt n Abt n*Abolt Qbolt Ibolt Pbolt

1 0.00 8.04 0.969 7.79 689.84 61086.71 7.08

Complete Method

GROUTED BASE PLATES

Per AISC 9th Edition Manual (ASD) and "Design of Monopole Bases" (Daniel Horn, P.E.)

based on the Complete Circular Base Plate Method

Job Name: Job No.:

Subject: Originator: Checker:

2 8.66 7.04 0.969 6.82 544.96 43537.76 -4.29

3 8.66 7.04 0.969 6.82 544.96 43537.76 -4.29

4 0.00 8.04 0.969 7.79 689.84 61086.71 7.08

5 -8.66 8.04 0.969 7.79 757.31 73619.33 19.06

6 -8.66 8.04 0.969 7.79 757.31 73619.33 19.06

Totals 44.81 3984 356,488

Max bolt tension, N = 19.06 kips

Note:

1. Tension (uplift) load = positive (+)

2. Compression (downward) load = negative (-)

3. Qbolt = n*Abolt*(e-ybolt)

4. n*Abolt = n*Abt (tension zone)

5. n*Abolt = (n-1)*Abt (compression zone)

6. Ibolt = [ n*Abt^2/(4p) + n*Abt*(e-ybolt)^2]

7. Pbolt = P*[e-ybolt-q(calc)]/(q(calc)*AT-QT)*[n*Abt]

Comments:

1. Controlling strength design load case was 1.2*[Ds+Do+AF]+1.0*E(+Z) where Mx = 1340 in-kips.

2. Controlling service load case was Ds+Do+AF+0.7*E(+Z) where Mx = 974 in-kips.

3. ACI concrete load factor used for design = (1340 in-k)/(974 in-k) = 1.376, say 1.38.

Complete Method

You might also like

- Wind On Pipes and TraysDocument4 pagesWind On Pipes and TraysAnonymous h87K4sTNo ratings yet

- RAFTER-COLUMN CONNECTION DESIGNDocument6 pagesRAFTER-COLUMN CONNECTION DESIGNpriantomoNo ratings yet

- Wind Load AS1170 2Document15 pagesWind Load AS1170 2Divesh rahulNo ratings yet

- Structural analysis and design of shedDocument24 pagesStructural analysis and design of shedvtalexNo ratings yet

- Warn OK OK OK: ACI 318M-14 PIP STE05121 AISC Design Guide 1Document11 pagesWarn OK OK OK: ACI 318M-14 PIP STE05121 AISC Design Guide 1hemantcabhaleNo ratings yet

- AnchorageWithCircularBasePlate-DÍAZ CORNEJO ROBERTDocument3 pagesAnchorageWithCircularBasePlate-DÍAZ CORNEJO ROBERTRobert Díaz CornejoNo ratings yet

- Beam DesignDocument7 pagesBeam DesignKasi ViswanathanNo ratings yet

- Flust-Extended End Plate ConnectionDocument8 pagesFlust-Extended End Plate ConnectionamachmouchiNo ratings yet

- Seimic Response of Liquid Storage TankDocument4 pagesSeimic Response of Liquid Storage TanklucianduNo ratings yet

- Wall FootingDocument1 pageWall FootingImranSohailNo ratings yet

- Base Plate Design Excel DesignDocument120 pagesBase Plate Design Excel DesignOmPrakash33% (3)

- Design of Base Plate by EurocodeDocument13 pagesDesign of Base Plate by EurocodeBharati MajlekarNo ratings yet

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearDocument4 pagesConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearVenu GopalNo ratings yet

- Moment Splice - BackupDocument74 pagesMoment Splice - BackupKiran AcharyaNo ratings yet

- Base Plate BiaxilDocument26 pagesBase Plate BiaxilvijaystructuralNo ratings yet

- Column Design AnalysisDocument18 pagesColumn Design AnalysisSurya FahmiNo ratings yet

- Anchor Bolt CalculationsDocument5 pagesAnchor Bolt Calculationssivaguruswamy thangarajNo ratings yet

- Anchor Chair Design CheckDocument5 pagesAnchor Chair Design CheckManish542No ratings yet

- Design of Stairs Design of Stairs From Ground To Landing Material PropertiesDocument3 pagesDesign of Stairs Design of Stairs From Ground To Landing Material PropertiesJohn Paul Hilary EspejoNo ratings yet

- Anchor Bolt Design For Portal and Connecting BridgeDocument2 pagesAnchor Bolt Design For Portal and Connecting BridgeAbhinav YadavNo ratings yet

- AISC ASD Base Plate Thickness V2016-2Document9 pagesAISC ASD Base Plate Thickness V2016-2yusuf_jtNo ratings yet

- Bolt Connection Design Based On AISC 360-10/16: Input Data & Design SummaryDocument1 pageBolt Connection Design Based On AISC 360-10/16: Input Data & Design SummaryKaren Esther Acuña VelasquezNo ratings yet

- Vertical Vessel Foundation Design Input Parameters: Geometrical DescriptionDocument8 pagesVertical Vessel Foundation Design Input Parameters: Geometrical DescriptionAnonymous xcFcOgMiNo ratings yet

- BasePlate 1 Check 46.8TDocument63 pagesBasePlate 1 Check 46.8TrustamriyadiNo ratings yet

- Calculation of Base Shear (Ubc-1997) Location: Rancakusumba SubstationDocument2 pagesCalculation of Base Shear (Ubc-1997) Location: Rancakusumba SubstationDS IchaqueNo ratings yet

- Cdo CalcDocument3 pagesCdo CalcJeric FarinNo ratings yet

- Crack WidthDocument6 pagesCrack Widthnitin400No ratings yet

- Design of Steel Beam (Asd) : Case 1: LC LB Lu Case 2: LB LC and Non-CompactDocument2 pagesDesign of Steel Beam (Asd) : Case 1: LC LB Lu Case 2: LB LC and Non-CompactAndro RebuyasNo ratings yet

- Base Plate Design SummaryDocument3 pagesBase Plate Design SummarySơn Nguyễn-LêNo ratings yet

- Design Slip-Critical Steel ConnectionDocument9 pagesDesign Slip-Critical Steel ConnectionKURONo ratings yet

- Calculation For Base Plate ConnectionDocument85 pagesCalculation For Base Plate ConnectionpriantomoNo ratings yet

- Concrete Anchor Foundation Bolt Design Calculations With Example According To ACI 318 Appendix D - Breakout Strength in ShearDocument5 pagesConcrete Anchor Foundation Bolt Design Calculations With Example According To ACI 318 Appendix D - Breakout Strength in ShearMohammad AasimuddinNo ratings yet

- Base Plate1Document6 pagesBase Plate1jobees7850No ratings yet

- Dynamic Active Earth Pressure On Retaining StructuresDocument10 pagesDynamic Active Earth Pressure On Retaining StructurescristiannecivilNo ratings yet

- Double Angle Connection Design ChecksDocument13 pagesDouble Angle Connection Design ChecksrunkirNo ratings yet

- Two Way Slab Design (DRAFT)Document72 pagesTwo Way Slab Design (DRAFT)ابو عمر الأسمريNo ratings yet

- Steel Building Brace Connection DesignDocument4 pagesSteel Building Brace Connection Designmoganna73No ratings yet

- Moment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16Document4 pagesMoment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16gyanwapiNo ratings yet

- Foundation DesignDocument18 pagesFoundation Designhemantkle2uNo ratings yet

- Anchor Design for 219mm Pole SupportDocument1 pageAnchor Design for 219mm Pole SupportS A K ClostreNo ratings yet

- Pad Foundation DesignDocument4 pagesPad Foundation Designg4goharNo ratings yet

- Composite Beam Simply Supported DesignDocument12 pagesComposite Beam Simply Supported DesignMario FeghaliNo ratings yet

- Ring Wall Foundation Design CalculationsDocument6 pagesRing Wall Foundation Design Calculationsraghav abudhabiNo ratings yet

- Calculation of Wind Loads As Per IS:875 For STACKDocument67 pagesCalculation of Wind Loads As Per IS:875 For STACKshangz1511No ratings yet

- Fin Plate To Column Flange - LRFDDocument23 pagesFin Plate To Column Flange - LRFDkalpanaadhiNo ratings yet

- Vessel Supported On 2 PedestalsDocument7 pagesVessel Supported On 2 PedestalsNitesh SinghNo ratings yet

- RCFooting Design WebDocument3 pagesRCFooting Design WebDavid ShutteNo ratings yet

- Design of Chequered Plate DesignDocument2 pagesDesign of Chequered Plate DesignadihindNo ratings yet

- Base Plate Design (Pin) Asd For CompressionDocument54 pagesBase Plate Design (Pin) Asd For CompressionEmdadul HuqNo ratings yet

- Beam to Beam Connection PropertiesDocument22 pagesBeam to Beam Connection PropertieskalpanaadhiNo ratings yet

- GF SlabDocument8 pagesGF Slabcheligp1981No ratings yet

- Wind Load GTPOGTDocument2 pagesWind Load GTPOGTAnonymous 2CMPbqwBNo ratings yet

- Sample Shear ConnectionDocument1 pageSample Shear ConnectionmaheshbandhamNo ratings yet

- Fixed Base Plate Design - ArhDocument3 pagesFixed Base Plate Design - Arhmaheshbandham100% (1)

- Connection v1.3Document14 pagesConnection v1.3Trần Minh ChiếnNo ratings yet

- Base Plate p1Document128 pagesBase Plate p1Pranav PrabhakarNo ratings yet

- Aisc Chevron BraceDocument42 pagesAisc Chevron Bracegvlanusha100% (1)

- Wind Loads Calculations by ASCE7 05 For Any BuildingDocument13 pagesWind Loads Calculations by ASCE7 05 For Any BuildingDaren ModestoNo ratings yet

- CIRCBASE STEEL COLUMN ANALYSISDocument9 pagesCIRCBASE STEEL COLUMN ANALYSISjigarshah21No ratings yet

- BASEPLT9Document5 pagesBASEPLT9Bunkun15No ratings yet

- TCC21 Subframe AnalysisDocument1 pageTCC21 Subframe AnalysisMario Sajulga Dela CuadraNo ratings yet

- Analysis: (Table 2.1)Document5 pagesAnalysis: (Table 2.1)Mario Sajulga Dela CuadraNo ratings yet

- Uls Analysis: Spreadsheets To EC2Document8 pagesUls Analysis: Spreadsheets To EC2Mario Sajulga Dela CuadraNo ratings yet

- Spreadsheets To EC2: B E B EDocument1 pageSpreadsheets To EC2: B E B EMario Sajulga Dela CuadraNo ratings yet

- Rigorous One-Way SlabsDocument1 pageRigorous One-Way SlabsMario Sajulga Dela CuadraNo ratings yet

- Supports From Grid To GridDocument1 pageSupports From Grid To GridMario Sajulga Dela CuadraNo ratings yet

- Spreadsheets To BS 8110: The Concrete CentreDocument1 pageSpreadsheets To BS 8110: The Concrete CentreMario Sajulga Dela CuadraNo ratings yet

- Prestressed/Post-Tensioned Concrete Section (Aci 318-08)Document1 pagePrestressed/Post-Tensioned Concrete Section (Aci 318-08)Mario Sajulga Dela CuadraNo ratings yet

- Floor BeamDocument2 pagesFloor BeamMario Sajulga Dela CuadraNo ratings yet

- TCC63 Core Wall DesignDocument12 pagesTCC63 Core Wall DesignMario Sajulga Dela CuadraNo ratings yet

- Spreadsheets To BS 8110: Post-Tensioned Analysis & Design To Bs 8110:2005 - General DataDocument1 pageSpreadsheets To BS 8110: Post-Tensioned Analysis & Design To Bs 8110:2005 - General DataMario Sajulga Dela CuadraNo ratings yet

- Spreadsheets To BS 8110: D&D: Main Beam Grids C To H: From Grid 1 To 3Document6 pagesSpreadsheets To BS 8110: D&D: Main Beam Grids C To H: From Grid 1 To 3Mario Sajulga Dela CuadraNo ratings yet

- Spreadsheets To BS 8110: The Concrete CentreDocument1 pageSpreadsheets To BS 8110: The Concrete CentreMario Sajulga Dela CuadraNo ratings yet

- RCC43 Wide Beams (A & D)Document1 pageRCC43 Wide Beams (A & D)Mario Sajulga Dela CuadraNo ratings yet

- Sub FrameDocument1 pageSub FrameMario Sajulga Dela CuadraNo ratings yet

- Spreadsheets To BS 8110 The Concrete Centre: Advisory Group 3rd Floor Slab RMW 51 CHG - R68 1 5aDocument1 pageSpreadsheets To BS 8110 The Concrete Centre: Advisory Group 3rd Floor Slab RMW 51 CHG - R68 1 5aMario Sajulga Dela CuadraNo ratings yet

- Continuous BeamsDocument1 pageContinuous BeamsMario Sajulga Dela CuadraNo ratings yet

- RCC81 Foundation PadsDocument1 pageRCC81 Foundation PadsMario Sajulga Dela CuadraNo ratings yet

- Spreadsheets To BS 8110: The Concrete CentreDocument1 pageSpreadsheets To BS 8110: The Concrete CentreMario Sajulga Dela CuadraNo ratings yet

- Phonics Book1 PDFDocument38 pagesPhonics Book1 PDFMario Sajulga Dela Cuadra100% (1)

- Sub FrameDocument1 pageSub FrameMario Sajulga Dela CuadraNo ratings yet

- Spreadsheets To BS 8110: Post-Tensioned Analysis & Design To Bs 8110:2005 - General DataDocument1 pageSpreadsheets To BS 8110: Post-Tensioned Analysis & Design To Bs 8110:2005 - General DataMario Sajulga Dela CuadraNo ratings yet

- MainDocument1 pageMainMario Sajulga Dela CuadraNo ratings yet

- Spreadsheets To BS 8110: Advisory Group Beam C1-2, Level 3Document1 pageSpreadsheets To BS 8110: Advisory Group Beam C1-2, Level 3Mario Sajulga Dela CuadraNo ratings yet

- Spreadsheets To BS 8110 The Concrete Centre: Advisory Group Columns at A1, A2 Etc RMW 124 CHG R68Document1 pageSpreadsheets To BS 8110 The Concrete Centre: Advisory Group Columns at A1, A2 Etc RMW 124 CHG R68Mario Sajulga Dela CuadraNo ratings yet

- Sub FrameDocument1 pageSub FrameMario Sajulga Dela CuadraNo ratings yet

- BS 8110 solid slab design parametersDocument1 pageBS 8110 solid slab design parametersMario Sajulga Dela CuadraNo ratings yet

- TCC22 FE AssistantDocument3 pagesTCC22 FE AssistantMario Sajulga Dela CuadraNo ratings yet

- SlabDocument1 pageSlabMario Sajulga Dela CuadraNo ratings yet

- Sample Header: Engineering With The SpreadsheetDocument1 pageSample Header: Engineering With The SpreadsheetMario Sajulga Dela CuadraNo ratings yet

- Grade 9 ICT Network Configuration GuideDocument15 pagesGrade 9 ICT Network Configuration GuideMark Anthony Nieva RafalloNo ratings yet

- II B.Tech II Semester Regular Examinations, Apr/May 2007 Chemical Engineering Thermodynamics-IDocument7 pagesII B.Tech II Semester Regular Examinations, Apr/May 2007 Chemical Engineering Thermodynamics-IrajaraghuramvarmaNo ratings yet

- Ee-316 - Circuit Theory LabDocument47 pagesEe-316 - Circuit Theory LabsureshhasiniNo ratings yet

- Basic Functions of A Computer SystemDocument3 pagesBasic Functions of A Computer SystemAlanlovely Arazaampong AmosNo ratings yet

- Online School Management System Integrated With Accounting Management SystemDocument24 pagesOnline School Management System Integrated With Accounting Management SystemKIRUTHIKA SNo ratings yet

- Nokia 7368 ISAM ONT G-010G-A For Optical LAN Data Sheet enDocument3 pagesNokia 7368 ISAM ONT G-010G-A For Optical LAN Data Sheet enMirado AndriamihasinoroNo ratings yet

- Kurzweil MicropianoDocument24 pagesKurzweil Micropianoestereo8No ratings yet

- Insulation ProductsDocument1 pageInsulation ProductsDygoPalNo ratings yet

- Cisco CCIE CCNP RS Study Flashcards Ver 49Document102 pagesCisco CCIE CCNP RS Study Flashcards Ver 49niboozNo ratings yet

- Rfid Based Attendance SystemDocument16 pagesRfid Based Attendance Systemhim chauNo ratings yet

- Mistika SGCDocument17 pagesMistika SGCflameadgNo ratings yet

- Schools Division of Pasay City outlines 5S workplace organizationDocument9 pagesSchools Division of Pasay City outlines 5S workplace organizationJhaexelle allenah AlfonsoNo ratings yet

- Culata JD 6466Document4 pagesCulata JD 6466TECNOTRAC AldanaNo ratings yet

- Numeric To Numeric Encryption of Databases Using 3kDES AlgorithmDocument5 pagesNumeric To Numeric Encryption of Databases Using 3kDES AlgorithmSwathi VasudevanNo ratings yet

- Hospital Building Civil ProjectDocument128 pagesHospital Building Civil ProjectArun Ragu100% (6)

- Code of Conduct at Pizza HutDocument2 pagesCode of Conduct at Pizza HutAdeel Chaudhary0% (1)

- 1100cc Engine Parts CatalogueDocument39 pages1100cc Engine Parts CatalogueSimon placenciaNo ratings yet

- Sch40 80 ASTM A53Document2 pagesSch40 80 ASTM A53Keshia Murillo PinnockNo ratings yet

- Precast Concrete Septic Tank 5000dsDocument1 pagePrecast Concrete Septic Tank 5000dsMarco Vega TaipeNo ratings yet

- DBX DriveRack PA 2 BrochureDocument2 pagesDBX DriveRack PA 2 BrochureSound Technology LtdNo ratings yet

- Look at The Picture Carefully. Rearrange The Words To Form Correct SentencesDocument6 pagesLook at The Picture Carefully. Rearrange The Words To Form Correct SentencesAdy PutraNo ratings yet

- How To Use AZUpDocument1 pageHow To Use AZUpjovicasNo ratings yet

- June 2014 Draft for Public ReviewDocument59 pagesJune 2014 Draft for Public ReviewRomel Vargas Sánchez0% (1)

- Leadership Learnings From Chhatrapati SHDocument5 pagesLeadership Learnings From Chhatrapati SHSagar RautNo ratings yet

- AKA DP Close Bus Ring SolutionsDocument2 pagesAKA DP Close Bus Ring Solutionssun qiNo ratings yet

- PDF 7758Document2 pagesPDF 7758José Antônio CardosoNo ratings yet

- DYNAenergetics 2.875 PA Auto-Vent Firing Head Field Assembly ProcedureDocument7 pagesDYNAenergetics 2.875 PA Auto-Vent Firing Head Field Assembly ProceduremahsaNo ratings yet

- KQ2H M1 InchDocument5 pagesKQ2H M1 Inch林林爸爸No ratings yet

- Language As IdeologyDocument26 pagesLanguage As IdeologyAlcione Gonçalves Campos100% (2)

- Acha Teff ThresherDocument62 pagesAcha Teff ThresherTANKO BAKO100% (2)