Professional Documents

Culture Documents

Elastic Bending Radius Calculation of PIPELINES

Uploaded by

mailmaverick8167Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Elastic Bending Radius Calculation of PIPELINES

Uploaded by

mailmaverick8167Copyright:

Available Formats

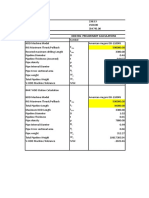

InputData:

PipelineDiameter D = 168.3 mm

DesignPressure P = 23.0 Mpa

InstallationTemperature T

i

= 21 DegC

Max.DesignTemperature(U/G) T2 = 85 DegC

Min.DesignTemperature(U/G) T1 = 4 DegC

SMYSoflinepipematerial S = 241 MPa

Youngsmodulusofpipe E = 207000 MPa

Steelexpansioncoefficient = 0.0000116 mm/m/

o

C

Poisson/sratio = 0.3

CorrosionAllowance CA = 3.0 mm

PipelineDeisgnfactor f = 0.72

Jointefficiencyfactor e = 1.0

Temperaturederatingfactor T = 1

Min.RequiredThickness(incl.CA) t

min

= 11.15 mm

Selectedwallthickness(incl.CA) t

s

= 14.27 mm

SelectedwallthicknesswithoutCA t = 11.27 mm

RestrainedPipeStressCalculation

Hoopstress S

h

= PD/2t

S

h

= 171.73469 MPa

LongitudinalStressduetoInternalPessure SP = Sh

SP = 51.520408 MPa

Thermalstress(Compressive) S

tc

= E(TiT2) = 153.6768 MPa

Thermalstress(Tensile) S

tt

= E(TiT1) = 40.8204 MPa

Longitudi.stress(fullyrestrained) S

LC

= (S

h

P)+E(T2Ti) = 109.06 Mpa

S

Lt

= S

h

P)+E(T1Ti) = 85.44 Mpa

Allowableequivalentstress S

AE

= 0.9xSxT

S

AE

= 216.9 MPa

BendingStressbasedonVonmisesEquivalentstressCriteria

S

eq

= (S

L

2

S

L

S

H

+S

H

2

) 0.9ST (AsperASMEB31.8/ASMEB31.4)

S

L

= {S

H

S

H

2

4(S

H

2

(0.9ST)

2

)]}/2

S

L1

= 243.75 Mpa

S

L2

= 72.01 Mpa

Max.valueofNetLongitudinalStress,S

L = 72.01 Mpa

AllowableBendingStressvalues

S

B1

= S

L

S

Lc

SB3 352.80

S

B1

= 37.04 Mpa

S

B2

= S

L

S

Lt

SB4 158.31

S

B2

= 157.45 Mpa

MaximumAllowableBendingStress |S

B

| = 37.044018 Mpa

MinimumAllowableElasticbendradius

AllowableBendingStress S

B

= 37.04 Mpa

Min.AllowableBendingRadius R = ED/2S

B

= 470.23 m = 2794 D

Value>0.9ST

Value<=0.9ST

You might also like

- Design of 610 mm MS Pumping MainDocument6 pagesDesign of 610 mm MS Pumping MainMathiTwadCNo ratings yet

- Hydraulic Design of Storm Sewers With Excel CourseDocument41 pagesHydraulic Design of Storm Sewers With Excel CourseRonal Salvatierra100% (1)

- Wall THK Calculation Asme b31.4Document7 pagesWall THK Calculation Asme b31.4Luis Jose Duran100% (1)

- Pipeline Anchor Length Calculation PDFDocument3 pagesPipeline Anchor Length Calculation PDFAlvin SmithNo ratings yet

- 24in Pipeline Buoyancy CalculationDocument1 page24in Pipeline Buoyancy CalculationAdaghara67% (3)

- Pipeline Anchor Length CalculationsDocument3 pagesPipeline Anchor Length Calculationslsatchithananthan100% (3)

- Cairn Energy India PTY Ltd BSPL Project - Barmer to Salaya Pipeline CALCULATIONDocument4 pagesCairn Energy India PTY Ltd BSPL Project - Barmer to Salaya Pipeline CALCULATIONschaali100% (5)

- HDD Calculation (Template)Document4 pagesHDD Calculation (Template)bebas_amarah87% (15)

- API RP 1102 SpreadsheetDocument6 pagesAPI RP 1102 Spreadsheetm_michael_cNo ratings yet

- Buried Pipe Design (Flexible) 1Document9 pagesBuried Pipe Design (Flexible) 1Ah Leng Lau100% (2)

- Wall Thickness Calculation ASME B31!8!2007Document1 pageWall Thickness Calculation ASME B31!8!2007shafeeqm3086No ratings yet

- Buried PipeDocument11 pagesBuried PipePrashant Agrawal100% (4)

- Pipeline Stability Calculation of 24 Oil EmptyDocument4 pagesPipeline Stability Calculation of 24 Oil Emptybaghelrohit80% (5)

- Underground Pipe THK CalDocument12 pagesUnderground Pipe THK Calmkchy12100% (3)

- Wall Thickness Calculation of 36in Gas PipelineDocument1 pageWall Thickness Calculation of 36in Gas PipelineLU1228100% (3)

- Upheaval Buckling CalculationDocument6 pagesUpheaval Buckling Calculationheldermanuel100100% (2)

- HDD Crossing Calculation 2Document26 pagesHDD Crossing Calculation 2Denstar Ricardo Silalahi93% (29)

- Laying 30Document13 pagesLaying 30Ashok SwamiNo ratings yet

- Lifting Lug Material and Stress CheckDocument1 pageLifting Lug Material and Stress Checkveeru2906No ratings yet

- Pipeline Design Calculations PDFDocument21 pagesPipeline Design Calculations PDFjimallen21281% (21)

- Thickness CalculationsDocument6 pagesThickness Calculationsvijayunity100% (1)

- Centrifugal Pump SelectionDocument25 pagesCentrifugal Pump SelectionAbhay Sisodia100% (1)

- Wall Thickness Calculation Verification under StressDocument1 pageWall Thickness Calculation Verification under StresshhgjdfNo ratings yet

- Permissible Elastic Bend Limit Calculations for PipelinesDocument4 pagesPermissible Elastic Bend Limit Calculations for Pipelinesheldermanuel100No ratings yet

- Mathcad - KpeterDocument4 pagesMathcad - KpeterMahmoud Samir100% (1)

- ONSHORE PIPELINE LOWERING CALCULATIONDocument5 pagesONSHORE PIPELINE LOWERING CALCULATIONRagh88% (16)

- HDPE Pipe InformationDocument24 pagesHDPE Pipe InformationTylerNo ratings yet

- Virtual Anchor Length - KBRDocument22 pagesVirtual Anchor Length - KBRSammar Adhikari100% (2)

- Pipeline Sesmic CalculationDocument4 pagesPipeline Sesmic Calculationbaghelrohit100% (3)

- Is 9523 Ductile Iron FittingsDocument32 pagesIs 9523 Ductile Iron FittingsKathiravan Manimegalai100% (2)

- Natural Bend Radius Cal Rev. C PDFDocument3 pagesNatural Bend Radius Cal Rev. C PDFhamid sobirin100% (2)

- Design of Piping Systems by Tengku SyahdilanDocument115 pagesDesign of Piping Systems by Tengku SyahdilanRagerishcire KanaalaqNo ratings yet

- Calculating Minimum Bending Radius for Subsea PipelinesDocument4 pagesCalculating Minimum Bending Radius for Subsea PipelinesPugel YeremiasNo ratings yet

- HDD design calculations for 18Document23 pagesHDD design calculations for 18Binay Kumar100% (1)

- HDD DesignDocument7 pagesHDD Designanon_824061466No ratings yet

- HDD Design and MethodologyDocument14 pagesHDD Design and MethodologyVipin Gupta100% (4)

- HDD Installation CalculationsDocument4 pagesHDD Installation Calculationslive4sankar100% (1)

- Surge Analysis and The Wave Plan MethodDocument126 pagesSurge Analysis and The Wave Plan Methodmailmaverick8167No ratings yet

- Pipe wall thickness calculation sheet for high pressure natural gas lineDocument1 pagePipe wall thickness calculation sheet for high pressure natural gas lineAris KancilNo ratings yet

- HDD Design Calculation for Sonamura Pipeline ProjectDocument22 pagesHDD Design Calculation for Sonamura Pipeline ProjectAmit Shrivastava100% (6)

- Pipe Bend Againts Coating 3LPE AnalisisDocument25 pagesPipe Bend Againts Coating 3LPE Analisisraditia2205100% (1)

- Calculation For Reinforced PadDocument4 pagesCalculation For Reinforced Padjsridhar_34750% (2)

- HDD Design Calculation for Sonamura GGS Pipeline ProjectDocument22 pagesHDD Design Calculation for Sonamura GGS Pipeline ProjectPer Bagus HandokoNo ratings yet

- Super CalculationsDocument12 pagesSuper CalculationsCarlos Tijerina0% (1)

- HDD Capacity CalculationDocument2 pagesHDD Capacity CalculationUghojor ElohoNo ratings yet

- Pipe Insulation THK CalculationDocument3 pagesPipe Insulation THK Calculationnitin_bir67% (3)

- Pipe Lowering CalculationDocument8 pagesPipe Lowering CalculationMochamad Safarudin50% (4)

- Surge Tank Design Considerations ForDocument14 pagesSurge Tank Design Considerations ForPatricio Muñoz Proboste100% (1)

- Wall THK Calculation Asme B31.4Document7 pagesWall THK Calculation Asme B31.4ISRAEL PORTILLONo ratings yet

- Flow Control ValvesDocument24 pagesFlow Control Valvesmk_chandru100% (1)

- K-4b Perhitungan PipaDocument51 pagesK-4b Perhitungan PipaIndra MaulanaNo ratings yet

- Design of Pressure ComponentsDocument34 pagesDesign of Pressure ComponentsYFFernando100% (1)

- Wall THK Calculation Asme b31.4Document5 pagesWall THK Calculation Asme b31.4Dwi Hermawan100% (2)

- MJPN-PGAS-3514-PL-CA-001 (Calculation For Pipeline Free Span) Rev. B (REVIEW)Document11 pagesMJPN-PGAS-3514-PL-CA-001 (Calculation For Pipeline Free Span) Rev. B (REVIEW)frusdt100% (3)

- HDPE Pipe Calculation MethodsDocument7 pagesHDPE Pipe Calculation Methodssabahiraq100% (2)

- Crossing Calculation API RP1102 (TEMPLATE)Document1 pageCrossing Calculation API RP1102 (TEMPLATE)bebas_amarah100% (5)

- Upheval Bukling CalculationDocument2 pagesUpheval Bukling Calculationbaghelrohit100% (7)

- HDD CalculationDocument5 pagesHDD Calculationiwan100% (1)

- Formula Asme Sec. I Pg. 27Document2 pagesFormula Asme Sec. I Pg. 27Syarif Dwi PriyantoNo ratings yet

- From Table We KnowDocument5 pagesFrom Table We KnowTaha ZakiNo ratings yet

- Displacement Control STN 10iDocument2 pagesDisplacement Control STN 10itungNo ratings yet

- 02-04 Chap GereDocument12 pages02-04 Chap GereSri DNo ratings yet

- Properties of composite steel and brass shaftDocument3 pagesProperties of composite steel and brass shaftEnders Wil Ccencho TorresNo ratings yet

- Pipe Cap Thickness Calculation for ASME Section VIIIDocument9 pagesPipe Cap Thickness Calculation for ASME Section VIIILcm TnlNo ratings yet

- Solucionario Cap. 4 Mecánica de Materiales ChapraDocument12 pagesSolucionario Cap. 4 Mecánica de Materiales ChapraXavier Pacheco PaulinoNo ratings yet

- Lecture # 16 (Thermal StressDocument11 pagesLecture # 16 (Thermal StressOs ,No ratings yet

- Calculo de Recipientes A PresionDocument2 pagesCalculo de Recipientes A PresionCesar Augusto Castellar OrtegaNo ratings yet

- Hdpe Rates Pe80Document1 pageHdpe Rates Pe80mailmaverick8167No ratings yet

- Hdpe Rates Pe100Document1 pageHdpe Rates Pe100mailmaverick8167No ratings yet

- Joint Efficiency Factors For Seam-Welded Factory-Made Pipeline BendsDocument18 pagesJoint Efficiency Factors For Seam-Welded Factory-Made Pipeline Bendsmailmaverick8167No ratings yet

- Properly Sizing Pumps and Pipes for Variable Viscosity Non-Newtonian FluidsDocument3 pagesProperly Sizing Pumps and Pipes for Variable Viscosity Non-Newtonian Fluidsmailmaverick8167No ratings yet

- Modeling A Pump Start-Up Transient Event in HAMMER - OpenFlowsDocument22 pagesModeling A Pump Start-Up Transient Event in HAMMER - OpenFlowsmailmaverick8167No ratings yet

- Effect of Hydraulic and Geometrical Properties On Stepped Cascade Aeration SystemDocument11 pagesEffect of Hydraulic and Geometrical Properties On Stepped Cascade Aeration Systemmailmaverick8167No ratings yet

- Air Valve Orifice SizeDocument1 pageAir Valve Orifice Sizemailmaverick8167No ratings yet

- By Dr. A Jon Kimerling, Professor Emeritus, Oregon State UniversityDocument3 pagesBy Dr. A Jon Kimerling, Professor Emeritus, Oregon State Universitymailmaverick8167No ratings yet

- Enhancement of Efficiency of Biogas Dige PDFDocument6 pagesEnhancement of Efficiency of Biogas Dige PDFmailmaverick8167No ratings yet

- The Secrets of Breakpoint ChlorinationDocument26 pagesThe Secrets of Breakpoint Chlorinationmailmaverick8167No ratings yet

- Modeling pump startup and shutdown transients in the same simulationDocument5 pagesModeling pump startup and shutdown transients in the same simulationmailmaverick8167No ratings yet

- Design of Surge Tank For Water Supply Systems Using The Impulse Response Method With The GA AlgorithmDocument8 pagesDesign of Surge Tank For Water Supply Systems Using The Impulse Response Method With The GA Algorithmmailmaverick8167No ratings yet

- Design of Surge Tank For Water Supply Systems Using The Impulse Response Method With The GA AlgorithmDocument8 pagesDesign of Surge Tank For Water Supply Systems Using The Impulse Response Method With The GA Algorithmmailmaverick8167No ratings yet

- 5822Document16 pages5822rambinodNo ratings yet

- Design of Surge Tank For Water Supply Systems Using The Impulse Response Method With The GA AlgorithmDocument8 pagesDesign of Surge Tank For Water Supply Systems Using The Impulse Response Method With The GA Algorithmmailmaverick8167No ratings yet

- Flow Control ValvesDocument6 pagesFlow Control Valvesmailmaverick8167100% (1)

- CHP Old Projects Pump DimensionsDocument2 pagesCHP Old Projects Pump Dimensionsmailmaverick8167No ratings yet

- Flow Control ValvesDocument6 pagesFlow Control Valvesmailmaverick8167100% (1)

- Siewtanyimboh Warm 2012 Epanet PDXDocument23 pagesSiewtanyimboh Warm 2012 Epanet PDXmailmaverick8167No ratings yet

- Computation of Afflux With Particular Reference To Widening of Bridges On A RoadwayDocument8 pagesComputation of Afflux With Particular Reference To Widening of Bridges On A Roadwaymailmaverick8167No ratings yet

- 12 Shibly RahmanDocument34 pages12 Shibly Rahmanmailmaverick8167No ratings yet

- PG 67 IS 456Document1 pagePG 67 IS 456mailmaverick8167No ratings yet