Professional Documents

Culture Documents

Optimizing Quality by Design in Bulk Powder & Solid Dosage: Smt. Bhoyar College of Pharmacy, Kamtee

Uploaded by

Free Escort ServiceOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Optimizing Quality by Design in Bulk Powder & Solid Dosage: Smt. Bhoyar College of Pharmacy, Kamtee

Uploaded by

Free Escort ServiceCopyright:

Available Formats

OPTIMIZING QUALITY BY DESIGN IN BULK POWDER & SOLID

DOSAGE

SMT.KISHORITAI BHOYAR COLLEGE OF PHARMACY,KAMTEE

INTRODUCTION

Pharmaceutical QBD is a systematic scientific risk based approach to

pharmaceutical development that begins with predefined objective

that address product & process understanding & process control.

Applying QBD principles leads to greater process understanding

facilitates regulatory approval & streamlines post approval changes.

Main step of a QBD process critical quality attributes (CQA).CQA are

defined based on the target drug profile these are quality characteristic of a

drug. ( eg. purity, crystalline form, particle size)

RISK ASSESSMENT

During the development phase for CQR, on analysis of the potential

critical process parameter & potential critical material attribute is

conducted.

Figure 1: An overview of Hoviones quality-by-design approach. CQA is

critical quality attribute, PAT is process analytical technology, NOR is

normal operating range, FMEA is failure mode effect analysis. All Figures are

courtesy of the authors.

Criticality analysis

By knowing the feasible operating region & after evaluating the equipment /procedure at the

manufacturing scale & the practical NOR, a final criticality analysis takes place to identify

parameter/material attributes that will require tight monitoring or control.

Process control strategy

Once the criticility around a process

Figure 2: Risk assessment. Decomposing the process in main steps for a

more structured criticality assessment (illustrative example for the bulk

powder manufacturing process). CQA is critical quality attribute, p is

potential.

You might also like

- Quality by DesignDocument10 pagesQuality by DesignMd UmarNo ratings yet

- Pharmaceutical QBD (Final)Document41 pagesPharmaceutical QBD (Final)Tahsin AhmedNo ratings yet

- Quality by Design Process Analytical Technology: (QBD) & (PAT)Document45 pagesQuality by Design Process Analytical Technology: (QBD) & (PAT)Sharon DsouzaNo ratings yet

- QbD and Formulation Optimization Using Design of ExperimentsDocument63 pagesQbD and Formulation Optimization Using Design of ExperimentsJOHNNYNo ratings yet

- 01-How-to-identify-CQA-CPP-CMA-Final Imp PDFDocument40 pages01-How-to-identify-CQA-CPP-CMA-Final Imp PDFmarwa100% (1)

- How To Identify Critical Quality Attributes and Critical Process ParametersDocument40 pagesHow To Identify Critical Quality Attributes and Critical Process ParametersNicolas Mateo Gonzalez LopezNo ratings yet

- Critical Quality Attributes Critical Process ParametersDocument40 pagesCritical Quality Attributes Critical Process ParametersSergiu LungNo ratings yet

- FDA How Identify QCA CPPDocument40 pagesFDA How Identify QCA CPPgrandcrisNo ratings yet

- Qa&Qmc Unit 1 Part IV QBDDocument17 pagesQa&Qmc Unit 1 Part IV QBDAbdul WashiqueNo ratings yet

- Quality by DesignDocument10 pagesQuality by DesignAnurag GuptaNo ratings yet

- Application of Quality by Design Approach For Development and Validation of Analytical RP-HPLC Method For Prasugrel HCL in Bulk and Tablet Dosage FormDocument10 pagesApplication of Quality by Design Approach For Development and Validation of Analytical RP-HPLC Method For Prasugrel HCL in Bulk and Tablet Dosage FormIjsrnet EditorialNo ratings yet

- Elements of Quality by Design (QBD)Document14 pagesElements of Quality by Design (QBD)MeetNo ratings yet

- Quality by Design (QBD)Document18 pagesQuality by Design (QBD)fjjfjfjfggjgkgkNo ratings yet

- Introduction To QBD FixDocument25 pagesIntroduction To QBD FixAdel ZilviaNo ratings yet

- QbD and Process Validation in Pharmaceutical DevelopmentDocument107 pagesQbD and Process Validation in Pharmaceutical Developmentitung23No ratings yet

- From QbT to QbD: A comparison of quality by test and quality by design approachesDocument3 pagesFrom QbT to QbD: A comparison of quality by test and quality by design approachesJuspidayantiNo ratings yet

- Rancang Formula Sediaan Salep 2Document27 pagesRancang Formula Sediaan Salep 2rizalNo ratings yet

- Program Pengembangan Produk FarmasiDocument25 pagesProgram Pengembangan Produk FarmasiRiriFakhriiNo ratings yet

- CALIDAD EN EL DISEÑO-QbDDocument24 pagesCALIDAD EN EL DISEÑO-QbDSilvia OrdazNo ratings yet

- Quality by Design Essentials in ManufacturingDocument4 pagesQuality by Design Essentials in ManufacturingPaulo LindgrenNo ratings yet

- Ich Q8Document23 pagesIch Q8kennylee0001No ratings yet

- TB - 2012 - 8 Quality by DesignDocument4 pagesTB - 2012 - 8 Quality by DesignHéctor Fabio Leyton ArcosNo ratings yet

- A Roadmap For Implementing QRM Principles in Drug Substance ManufacturingDocument7 pagesA Roadmap For Implementing QRM Principles in Drug Substance ManufacturingAYMEN GOODKidNo ratings yet

- Topical Generic Development-Part IIDocument11 pagesTopical Generic Development-Part IIharshitNo ratings yet

- Determination of Critical Quality Attributes For Monoclonal AntibodiesDocument15 pagesDetermination of Critical Quality Attributes For Monoclonal AntibodiesSuneal VemuriNo ratings yet

- What is Quality by Design (QbDDocument25 pagesWhat is Quality by Design (QbDmanipallavanNo ratings yet

- 21st Century CGMPDocument13 pages21st Century CGMPVidya PasalkarNo ratings yet

- 2.seamless Integration Daniel NilssonDocument20 pages2.seamless Integration Daniel Nilssonleon tagoreNo ratings yet

- QbD approach for developing quality pharmaceuticalsDocument7 pagesQbD approach for developing quality pharmaceuticalsVitalis MbuyaNo ratings yet

- Keep On Rising Toward Quality by DesignDocument25 pagesKeep On Rising Toward Quality by Designkunal royNo ratings yet

- A Quantitative Approach For PharmaceuticDocument8 pagesA Quantitative Approach For PharmaceuticHalil İbrahim ÖzdemirNo ratings yet

- The New Quality Paradigm in Ich q8 q9 q10 q11Document30 pagesThe New Quality Paradigm in Ich q8 q9 q10 q11ishtidu34No ratings yet

- Fda'S Question-Based Review (QBR) : A Risk-Based Pharmaceutical Quality Assessment ToolDocument50 pagesFda'S Question-Based Review (QBR) : A Risk-Based Pharmaceutical Quality Assessment Toollalooprasad15No ratings yet

- M4 - Lesson 5 - Quality by DesignDocument2 pagesM4 - Lesson 5 - Quality by DesignWilliam DC RiveraNo ratings yet

- QBD Application in Pharm Industry PDFDocument83 pagesQBD Application in Pharm Industry PDFSetyo Budiarto100% (1)

- 2006 09 FDA - Ind Statistics SlidesDocument36 pages2006 09 FDA - Ind Statistics SlidesSudhagarNo ratings yet

- What Is Quality by DesignDocument16 pagesWhat Is Quality by Designnoned273No ratings yet

- Indonesia's Perspective on Pharmaceutical Validation RequirementsDocument23 pagesIndonesia's Perspective on Pharmaceutical Validation RequirementsChusnul HudaNo ratings yet

- Analysis of Wet Granulation Process With Plackett-Burman Design Ñ Case StudyDocument9 pagesAnalysis of Wet Granulation Process With Plackett-Burman Design Ñ Case StudyAnnwary SiregarNo ratings yet

- Quality by Design (QBD) OverviewDocument22 pagesQuality by Design (QBD) Overviewlouish9175841No ratings yet

- Review On Implementation of Quality by DesignDocument5 pagesReview On Implementation of Quality by DesignInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Quality by Design (QBD)Document25 pagesQuality by Design (QBD)Khrisna Whaty SilalahiNo ratings yet

- WC 500115824Document19 pagesWC 500115824louish9175841No ratings yet

- ICH Quality Implementation Working Group Points To Consider: ICH-Endorsed Guide For ICH Q8/Q9/Q10 ImplementationDocument12 pagesICH Quality Implementation Working Group Points To Consider: ICH-Endorsed Guide For ICH Q8/Q9/Q10 ImplementationChrist BudionoNo ratings yet

- Jurnal Internasional CpobDocument11 pagesJurnal Internasional CpobkhanNo ratings yet

- Nadia Belu, Agnieszka Misztal and Laurentiu Mihai IonescuDocument6 pagesNadia Belu, Agnieszka Misztal and Laurentiu Mihai IonescuArunakshi SurajNo ratings yet

- Guidance For Industry: Process ValidationDocument18 pagesGuidance For Industry: Process ValidationBruno DebonnetNo ratings yet

- Regulatory - Perspective QBD PDFDocument35 pagesRegulatory - Perspective QBD PDFrihabNo ratings yet

- White PaperDocument32 pagesWhite PaperAndroid modded gamesNo ratings yet

- "Current Approach of Quality by Design" An OverviewDocument11 pages"Current Approach of Quality by Design" An OverviewResearch ParkNo ratings yet

- Pharmaceutics 13 00919 v2Document45 pagesPharmaceutics 13 00919 v24n4n4sNo ratings yet

- Quality by Design JournalDocument6 pagesQuality by Design JournalMiftahul ChairadNo ratings yet

- QbD: Understanding Quality by DesignDocument33 pagesQbD: Understanding Quality by DesignmudrikaNo ratings yet

- Quality Risk ManagementDocument29 pagesQuality Risk ManagementmmmmmNo ratings yet

- Reporting Cpps To Fda20 22 FDA 1018Document2 pagesReporting Cpps To Fda20 22 FDA 1018Akhmad Rafi'iNo ratings yet

- M4 - Lesson 2 - Process DesignDocument2 pagesM4 - Lesson 2 - Process DesignWilliam DC RiveraNo ratings yet

- A Case For Stage 3 Continued Process VerificationDocument9 pagesA Case For Stage 3 Continued Process VerificationPatricia Joyce Malabanan SunglaoNo ratings yet

- ICH Quality Guidelines: An Implementation GuideFrom EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleNo ratings yet

- Pharmaceutical Quality by Design: A Practical ApproachFrom EverandPharmaceutical Quality by Design: A Practical ApproachWalkiria S. SchlindweinNo ratings yet

- Mechanism For The Ability of 5Document2 pagesMechanism For The Ability of 5Free Escort ServiceNo ratings yet

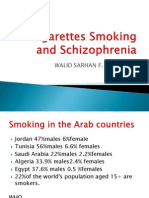

- Walid Sarhan F. R. C. PsychDocument46 pagesWalid Sarhan F. R. C. PsychFree Escort ServiceNo ratings yet

- My Resume in Word Format1679Document11 pagesMy Resume in Word Format1679Free Escort ServiceNo ratings yet

- The Worldwide Impacts of SchizophreniaDocument10 pagesThe Worldwide Impacts of SchizophreniaMadusha PereraNo ratings yet

- Students Prayer For Exam 2014Document2 pagesStudents Prayer For Exam 2014Free Escort ServiceNo ratings yet

- Nutraceuticals: Let Food Be Your MedicineDocument32 pagesNutraceuticals: Let Food Be Your MedicineFree Escort ServiceNo ratings yet

- Students Prayer For Exam 2014Document2 pagesStudents Prayer For Exam 2014Free Escort ServiceNo ratings yet

- SchizEdDay Freudenreich - PpsDocument29 pagesSchizEdDay Freudenreich - PpsFree Escort ServiceNo ratings yet

- Pharmacological Treatment SchizDocument54 pagesPharmacological Treatment SchizFree Escort ServiceNo ratings yet

- ValidityDocument3 pagesValidityFree Escort ServiceNo ratings yet

- Inflammation in Schizophrenia and DepressionDocument9 pagesInflammation in Schizophrenia and DepressionFree Escort ServiceNo ratings yet

- Role of Nutraceuticals in Health Promotion: Swati Chaturvedi, P. K. Sharma, Vipin Kumar Garg, Mayank BansalDocument7 pagesRole of Nutraceuticals in Health Promotion: Swati Chaturvedi, P. K. Sharma, Vipin Kumar Garg, Mayank BansalFree Escort ServiceNo ratings yet

- Shubh AmDocument1 pageShubh AmFree Escort ServiceNo ratings yet

- Reliablity Validity of Research Tools 1Document19 pagesReliablity Validity of Research Tools 1Free Escort Service100% (1)

- Presentation 2Document29 pagesPresentation 2Free Escort ServiceNo ratings yet

- EulaDocument3 pagesEulaBrandon YorkNo ratings yet

- Reliability and ValidityDocument15 pagesReliability and Validityapi-260339450No ratings yet

- New Pharmacological Approaches To The Treatment of SchizophreniaDocument1 pageNew Pharmacological Approaches To The Treatment of SchizophreniaFree Escort ServiceNo ratings yet

- Reliablity Validity of Research Tools 1Document19 pagesReliablity Validity of Research Tools 1Free Escort Service100% (1)

- ResumeDocument3 pagesResumeFree Escort ServiceNo ratings yet

- HerbaceutclDocument1 pageHerbaceutclFree Escort ServiceNo ratings yet

- MBKDocument12 pagesMBKFree Escort ServiceNo ratings yet

- QBD Definition AnvvvvDocument4 pagesQBD Definition AnvvvvFree Escort ServiceNo ratings yet

- Nutraceutical Role in Health CareDocument1 pageNutraceutical Role in Health CareFree Escort ServiceNo ratings yet

- Quality Is Built in by Design, Not Tested inDocument1 pageQuality Is Built in by Design, Not Tested inFree Escort ServiceNo ratings yet

- ABSTRACT (QBD: A Holistic Concept of Building Quality in Pharmaceuticals)Document1 pageABSTRACT (QBD: A Holistic Concept of Building Quality in Pharmaceuticals)Free Escort ServiceNo ratings yet

- 2415 14725 4 PBDocument13 pages2415 14725 4 PBFree Escort ServiceNo ratings yet

- Quality by Design On PharmacovigilanceDocument1 pageQuality by Design On PharmacovigilanceFree Escort ServiceNo ratings yet

- M.Pharm Dissertation Protocol: Formulation and Evaluation of Antihypertensive Orodispersible TabletsDocument7 pagesM.Pharm Dissertation Protocol: Formulation and Evaluation of Antihypertensive Orodispersible TabletsFree Escort ServiceNo ratings yet