Professional Documents

Culture Documents

Presentation On DM Plant

Uploaded by

Venkat DoraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Presentation On DM Plant

Uploaded by

Venkat DoraCopyright:

Available Formats

DEMI NERALI SATI ON PLANT

PRESENTATI ON

ON

MGF ACF LBC DEGASSER

TOWER

WBA SBA MB

DM PLANT FLOW DIAGRAM

G.C.TANK-1 G.C.TANK-11 DM WATER.TANK

DM WATER

CONDENSATES FROM

1.All Paper Machines

2.New Fiber line

3.P.D.Plant

4.Coating Plant

5.Turbines etc.

Fresh water

6.Evaporator-3

300 m3

110 m3 100 m3

MGF: Multi gravel filter.

ACF: Activated carbon filter.

LBC : Layered bed cation.

WBA: Weak base anion.

SBA : Strong base anion.

MB : Mixed bed.

IMPORTANCE OF DIFFERENT UNITS

MGF : Contains gravels with different grade of pebbles. It

will remove suspended matter (TOTAL SUPENDED

SOLIDS).

ACF : Contains Activated Carbons AC is defined as highly

porous,carbonaceous material.The very large porosity

provides a large surface area,which results in exceptional

adsorptive properties.Works: Adsorbs Organic load &

Chlorine.

LBC: This is having Strong and Weak Cation resins.

( Indion-525 H= 2740 Lts and Indion-236 H=4160 Lts).Here

flow of water is from top to bottom and flow of regenerant is

from bottom to top.It absorbs hardness : Na,Ca & Mg.These

are exchanged with Hydrogen on the resin. In regeneration :

Na,Ca & Mg ions. are replaced by Hydrogen ions

Reactions: RESINS- H

+

ions + Water CaCl

2

,MgSo

4

,NaCl

RESINS-Ca +HCl , H

2

So

4

+ HCl

RESINS- H

+

ions +CaCl

2

,CaSo

4

(Drained during regeneration )

DEGASSER: Here Carbon dioxide is removed.

Reactions: Carbonic Acid + Air by blower

Carbon dioxide + Water

WBA : It is having weak anion resin.(Indion-850 Resin = 2350 Lts)

It will absorb all the Free mineral acidity in cation treated water.

FMA: Conversation of neutral salt (Chloride,Sulphate &

Nitrate ) to their respective mineral acids.

EMA: Equivalent mineral Acidity a measure of the neutral salts

(Chloride,Sulphate & Nitrate ) content of the water.

EMA-FMA = Sodium Slip

SBA: This is having Strong anion resins. ( Indion-FFIP = 5690

Lts).Here flow of water is from top to bottom and flow of

regenerant is from bottom to top.

It absorbs : Chloride,Sulphate,Nitrate and Silica

Reactions: RESINS- OH

-

ions + HCl,H

2

So

4,

RESINS-Cl, So

4

+ H

2

O

+ NaOH

RESINS- OH

-

ions + NaCl,Na

2

So

4

(Drained during regeneration )

MB: This the final polishing unit. It contains both cation and

anion resins ( Indion-FFIP=1210 Lts and Indion-225

H=2360 Lts) . If there is some traces of hardness and anions

leakages,then these are absorbs in MB.

Cation resins : are regenerated with HCl.

Anion resins : are regenerated with NaOH.

DM Water Parameters

1.pH = 6.8 to 7.2

2.Conductivity = 0.5 PPM ( Max)

3.Silica = 0.02 PPM ( Max)

4.Total Hardness = NiL

Boiler water parameters

1.pH = 8.7 to 9.5

2.Silica = 5 PPM (Max)

3.Total Dissolved Solid = 50 PPM(Max)

4.Total Hardness = NIL

Steam

1.pH = 8.5 to 9.0

2.Silica = 0.02 PPM (Max)

3.Total Dissolved Solid = 8 Micro Simens/Cm(Max)

4.Total Hardness = NIL

Return Condensate

1.pH = 8.5 to 9.0

2.Silica = 0.02 PPM (Max)

3.Conductivity = 8 PPM(Max)

4.Total Hardness = NIL

Return Condensate received at G.C.Tank

1. All Paper Machines ( 5 Nos)

2. PD Plant

3. Coating Plant

4. Fiber Line

5. TG Sets ( 3 Nos)

6. Evaporators ( 2 Nos)

7. Condensate from LFB-4

8. CFB-5 Feed Water Heater

CONDENSATE BALANCE

Total Feed water =DM Water ( Make up) + Return Condensate.

1. Make Up Water = 30 %

2. Return Condensate = 70 %

3. Steam Generated = 4051 M

3

/Day

4. Expected Condensate = 3195 M

3

/Day ( 68.28 % )

5. Actual Condensate received = 2888 M

3

/Day ( 82.40 % )

6. Deviation of Condensate = 307 M

3

/Day ( 14.13 % )

7. Make up Water = 1276 M

3

/Day ( 31.41% )

8. Total CBD/IBD = 41 M

3

/Day

9. Total Feed Water = 4092 M

3

/Day

2888

4092

1204

41

4051

% % % % % % % %

%

846 89 34 95 92 95 403 61 46 38 481 93 277 45 313 95 703 100

798 84 25 70 68 70 265 40 0 0 439 85 277 45 313 95 703 100

48 5 9 25 24 25 138 21 46 38.02 42 8 0 0 0 0 0 0

2888

DM Plant

CBD / IBD

G.C.Tanks

Boilers for

Steam

Generation

RETURN CONDENSATE

Pulp Mill

Causticizing

Plant

Evaporators

( I & III)

659 121 516

3) Deviation

Regenerat i on,

Cl O2 , SPRD et c

Paper

Machines

PD Plant

Coating

Plant

954 36 97

DAILY RETURN CONDENSATE BALANCE IN M

3

2) Actual

1) Expected

CFB

Internal

Turbines

Steam

Blow

LFB-4&5

329 703 15

Return Condensate

Steam Supplied 621

72

1204

1276

Boiler Water Treatment Chemical (Conditioning Chemical)

For Boiler water treatment the following Chemicals are used:

1. Indion-5203( Filming Amine): used as 8 PPM on Make up

Water.

2. Indion-5164(pH Booster): used as a Contingency

Chemical.Depending on the pH in Boiler water it is dosed as

1 to 2 PPM on Make up Water.

3. Hydrazine Hydrate: used as Passivation When Boilers are in

Ideal Conditions.

Cooling tower Treatment Chemical

There are 3 Nos of Cooling towers:

1. Three Cell Cooling tower

2. Four Cell Cooling tower

3. Single Cell Cooling tower

Following chemicals are used :

1. Anti scaling & Anticorrosion

2. Bio despersent

3. Biocides

4. Sulphuric Acid

Cooling tower Water

quality

pH = 7.8 to 8.0

COC = 3 to 5

12MW COOLING TOWER FILL DEPOSIT CLEANING

We are planning to remove the fill deposit with NALCO Chemicals :

1. Nalco 73550 : This is a Biodetergent . It will remove the deposits

through a combination of Chemical solubilization and Physical

scrubbing .

2. Nalco 90001 : Quaternary ammonium biocide.

3. Sodium Hypochlorite : As per the system requirement.

END OF THE PRESENTATION

You might also like

- DmwatersDocument70 pagesDmwatersSamay Desai100% (1)

- DM PlantDocument35 pagesDM PlantVuong BuiNo ratings yet

- DM PlantDocument25 pagesDM PlantAbdul BokhariNo ratings yet

- Demineralization and Condensate Polishing BasicsDocument16 pagesDemineralization and Condensate Polishing BasicsvenkeekuNo ratings yet

- DM Plant OperationDocument23 pagesDM Plant OperationKanaga Sundaram80% (5)

- Mixed BedDocument10 pagesMixed BedAbdulSalamathNo ratings yet

- DM PlantDocument21 pagesDM PlantAbdulSalamath100% (10)

- DM Water Cost Chemical Name Unit Consumption Rate AmountDocument3 pagesDM Water Cost Chemical Name Unit Consumption Rate AmountRamdas TaloleNo ratings yet

- Enhancing Throughput of Condensate Polishing UnitDocument5 pagesEnhancing Throughput of Condensate Polishing Unitprakash100% (2)

- DM Plant CommissioningDocument10 pagesDM Plant CommissioningSANTRANo ratings yet

- Boiler Water Treatment: Thermax Limited Chemical DivisionDocument53 pagesBoiler Water Treatment: Thermax Limited Chemical Divisionkcp1986100% (2)

- Water TreatmentDocument27 pagesWater TreatmentArya Singh Rathod100% (1)

- Deminerlise PlantDocument34 pagesDeminerlise PlantSyed Safiur Rahman100% (1)

- DM PlantDocument40 pagesDM PlantPrabhat Jha100% (1)

- Dmplant Operation& OptimisationDocument46 pagesDmplant Operation& Optimisationapi-1977578388% (8)

- DM PlantDocument13 pagesDM PlantAjay Kasture100% (3)

- DM Plant GuideDocument6 pagesDM Plant Guidepremrrs60% (15)

- DM PlantDocument2 pagesDM PlantDarakhshan Sheikh100% (1)

- DM Plant Manual-10 KLDDocument5 pagesDM Plant Manual-10 KLDenqNo ratings yet

- O & M ManualDocument39 pagesO & M ManualAjith KumarNo ratings yet

- WTPDocument33 pagesWTPSam100% (2)

- DM PlantDocument40 pagesDM PlantArunkumar ChandaranNo ratings yet

- DM Plant Design CalculationDocument6 pagesDM Plant Design CalculationGoutham Naveen0% (5)

- Thermal Power Plant Water ChemistryDocument33 pagesThermal Power Plant Water ChemistryNAITIK100% (4)

- Sop WTP CombinedDocument17 pagesSop WTP CombinedsiccppNo ratings yet

- DM Plant CulationDocument2 pagesDM Plant CulationMukesh KumarNo ratings yet

- Mixed BedDocument10 pagesMixed BedMayette Rose Sarroza100% (1)

- DM Manual DoshionDocument111 pagesDM Manual Doshionace-winnie67% (3)

- Process of de Mineralization PlantDocument13 pagesProcess of de Mineralization Plantmoinulriad100% (4)

- Water Treatment PlantDocument27 pagesWater Treatment PlantAshwani Dogra100% (5)

- DM Plant Design CalculationDocument10 pagesDM Plant Design CalculationLutfur RahmanNo ratings yet

- Water Treatment - Overview Ion ExchangeDocument9 pagesWater Treatment - Overview Ion ExchangeAliAliNo ratings yet

- 20 KLD STP - Offer - MBBRDocument10 pages20 KLD STP - Offer - MBBRHarish Kumar MahavarNo ratings yet

- Simulation Mixed BedDocument13 pagesSimulation Mixed BedarufatoNo ratings yet

- Mixed Beds Regeneration - 45-D01129-EnDocument7 pagesMixed Beds Regeneration - 45-D01129-EnDFMNo ratings yet

- RODM PresentationDocument67 pagesRODM PresentationSekharNo ratings yet

- Welcome To: Cooling Water Treatment in Power Plants Recent Trends & Case StudyDocument17 pagesWelcome To: Cooling Water Treatment in Power Plants Recent Trends & Case StudyrpshvjuNo ratings yet

- CPU FinalDocument23 pagesCPU Finalmkgchem0% (1)

- Specification For Water Softening Plant and Online Self Cleaning FilterDocument16 pagesSpecification For Water Softening Plant and Online Self Cleaning Filterkatepol8264100% (1)

- Design Calculation For Softener UnitDocument12 pagesDesign Calculation For Softener Unitaraikun74775% (8)

- Cooling Water Treatment Chlorination WorkoutDocument3 pagesCooling Water Treatment Chlorination WorkoutMohsin ModiNo ratings yet

- DM PlantDocument30 pagesDM Plantapi-19775783No ratings yet

- Acw and CW Cooling Water SystemDocument31 pagesAcw and CW Cooling Water SystemPrudhvi RajNo ratings yet

- Demineralisation Plant: BY RAVIKUMAR G/ CM/Chemical Tps I ExpansionDocument37 pagesDemineralisation Plant: BY RAVIKUMAR G/ CM/Chemical Tps I Expansionarul mNo ratings yet

- DM Plant Design CalculationDocument10 pagesDM Plant Design CalculationD Nageswara Rao100% (4)

- Co-Ordinated and Congruent Phosphate Treatment of Boiler WaterDocument3 pagesCo-Ordinated and Congruent Phosphate Treatment of Boiler WaterRavi Shankar0% (1)

- Ion Exchange Design - Hand Calculation: Brian Windsor (Purolite International LTD)Document43 pagesIon Exchange Design - Hand Calculation: Brian Windsor (Purolite International LTD)Octiva100% (4)

- SOP For Calculating OBR Due To Ionic LoadDocument1 pageSOP For Calculating OBR Due To Ionic LoadsoumitrabanNo ratings yet

- Industrial Water Demineralization Systems: An Introduction ToDocument39 pagesIndustrial Water Demineralization Systems: An Introduction ToMd Ashif khanNo ratings yet

- A Practical Guide To Investigate Problems On Polishing Mixed Bed PDFDocument5 pagesA Practical Guide To Investigate Problems On Polishing Mixed Bed PDFengp1922100% (7)

- Cooling Water Chemistry: Specific Skills Training by Laeeq Ahmad RumiDocument31 pagesCooling Water Chemistry: Specific Skills Training by Laeeq Ahmad RumiIqbalAwais100% (1)

- Boiler Water TreatmentDocument22 pagesBoiler Water TreatmentTarun Patel100% (1)

- An Overview of Demineralisation Plant in Thermal Power StationDocument37 pagesAn Overview of Demineralisation Plant in Thermal Power StationAnirban Pal80% (5)

- Softner Plant 25 KLDocument8 pagesSoftner Plant 25 KLWatermax TechnologiesNo ratings yet

- FALLSEM2022-23 BCHY101L TH VL2022230105172 Reference Material I 20-12-2022 Module-7-Water Softening MethodsDocument81 pagesFALLSEM2022-23 BCHY101L TH VL2022230105172 Reference Material I 20-12-2022 Module-7-Water Softening MethodsVenkat BalajiNo ratings yet

- WATERDocument47 pagesWATERTarun NairNo ratings yet

- Caco Mgco MG (OH)Document28 pagesCaco Mgco MG (OH)Shivam KumarNo ratings yet

- 1st Presentation On Chemistry of Water TreatmentDocument7 pages1st Presentation On Chemistry of Water TreatmentAnonymous RsTfwYVcNo ratings yet

- Application Guide Purolite Water Softening Resin - 01 07 2014 - AC PDFDocument8 pagesApplication Guide Purolite Water Softening Resin - 01 07 2014 - AC PDFAbhisek BhattacharyaNo ratings yet

- Application Guide Purolite Water Softening Resin - 01 07 2014 - AC PDFDocument8 pagesApplication Guide Purolite Water Softening Resin - 01 07 2014 - AC PDFsundarNo ratings yet

- Store and Spares Cost 30.09.14Document1 pageStore and Spares Cost 30.09.14Venkat DoraNo ratings yet

- Boe Exam Notification Odisha 2014Document10 pagesBoe Exam Notification Odisha 2014Venkat DoraNo ratings yet

- Thermax IR-CFBCDocument28 pagesThermax IR-CFBCVenkat Dora100% (2)

- Boiler Operation Engineers Rules 2011Document21 pagesBoiler Operation Engineers Rules 2011Sun100% (1)

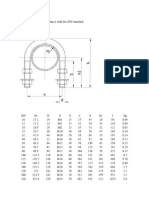

- Pipe Support Standard SpecDocument13 pagesPipe Support Standard SpecVenkat DoraNo ratings yet

- Asme Specifications SA36 ToSA423Document4 pagesAsme Specifications SA36 ToSA423Venkat Dora100% (1)

- Steam Turbines - TurbotechDocument29 pagesSteam Turbines - TurbotechArjun PatelNo ratings yet

- Cooling Tower Side Stream FiltrationDocument6 pagesCooling Tower Side Stream FiltrationVenkat DoraNo ratings yet

- Poultry Waste 1Document4 pagesPoultry Waste 1Venkat DoraNo ratings yet

- Asme Specifications SA36 ToSA423Document4 pagesAsme Specifications SA36 ToSA423nadhabindhu0% (1)

- ITR Ack 2010 11Document1 pageITR Ack 2010 11Kiran Avinash Priti MhatreNo ratings yet

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Standard Penetration TestDocument8 pagesStandard Penetration TestRodneyXerri100% (1)

- Indian Industrial Policy Since 1956Document12 pagesIndian Industrial Policy Since 1956Akash BadoniNo ratings yet

- Cooling Tower CalculationsDocument4 pagesCooling Tower CalculationsDesiree MolinaNo ratings yet

- Paper - Diki Wahyudi - Politeknik Negeri BandungDocument6 pagesPaper - Diki Wahyudi - Politeknik Negeri BandungDiq TalkNo ratings yet

- AkzoNobel TB Aquatreat Biocides-1Document24 pagesAkzoNobel TB Aquatreat Biocides-1Sharon WilsonNo ratings yet

- Chiller Energy AuditDocument11 pagesChiller Energy AuditneezaNo ratings yet

- Water Cooling TowerDocument13 pagesWater Cooling TowerArlene Joy PasquinNo ratings yet

- KDocument12 pagesKAdrian Joshua BernagaNo ratings yet

- Lab Report 2 - Cooling TowerDocument14 pagesLab Report 2 - Cooling TowerSeng Kong0% (2)

- Condenser in Power PlantDocument20 pagesCondenser in Power PlantPrabir Kumar PatiNo ratings yet

- FXV Engr DataDocument6 pagesFXV Engr DataAmir AbbaszadehNo ratings yet

- Beaudrey - Debris Filter - PDocument2 pagesBeaudrey - Debris Filter - PGustavo AngelNo ratings yet

- CT06 Nozzle CT 24.02.Document2 pagesCT06 Nozzle CT 24.02.Emanuel LucaNo ratings yet

- Operations Manual-Ktps, Version02Document110 pagesOperations Manual-Ktps, Version02Ganesh DasaraNo ratings yet

- Training ReportDocument68 pagesTraining ReportSunny Dhir100% (3)

- Spray NozzlesDocument2 pagesSpray Nozzleseureka.nitishNo ratings yet

- Hvac-Dbr - R6Document29 pagesHvac-Dbr - R6adkNo ratings yet

- SpigDocument24 pagesSpigTamer Abd ElrasoulNo ratings yet

- MotivairDocument8 pagesMotivaircortezt0% (1)

- Design of An Enclosed Football StadiumDocument32 pagesDesign of An Enclosed Football StadiumHani100% (1)

- Evaporative Cooling Tower PDFDocument2 pagesEvaporative Cooling Tower PDFJennifer0% (1)

- Smartsense - Chiller Insights Report For York Chiller 1, SKF Technologies India PVT LTD, Jun 2020Document24 pagesSmartsense - Chiller Insights Report For York Chiller 1, SKF Technologies India PVT LTD, Jun 2020VamsiDeepakNo ratings yet

- Comparison of Different Cooling Tower by TechnologyDocument1 pageComparison of Different Cooling Tower by TechnologyANIMESH JAINNo ratings yet

- Risks Prioritization Using Fmea Method - A Case StudyDocument5 pagesRisks Prioritization Using Fmea Method - A Case StudyTony IsodjeNo ratings yet

- BAC Website CXVE EN 2021Document30 pagesBAC Website CXVE EN 2021Mahmoud AbubakrNo ratings yet

- Cooling Towers - Evaporation Loss and Makeup WaterDocument13 pagesCooling Towers - Evaporation Loss and Makeup WaterXplore EnggNo ratings yet

- Fuel Oil Pump Calculation 26-05-2017R4 PDFDocument19 pagesFuel Oil Pump Calculation 26-05-2017R4 PDFArdian20No ratings yet

- ASHRAE Terminology - Complete ListDocument382 pagesASHRAE Terminology - Complete ListJose Luis ZIMICNo ratings yet

- DM-HSD-GU44-LCWS2 - Technical Guidelines For Legionella Control in Water System - V3Document39 pagesDM-HSD-GU44-LCWS2 - Technical Guidelines For Legionella Control in Water System - V3Ahmad ABushamahNo ratings yet

- MXH-3668F-37 Installation ManualDocument25 pagesMXH-3668F-37 Installation ManualLuis Alberto Huamán MalcaNo ratings yet

- Dean Paul Cueto 2 0 0 6 - 1 8 3 0 8: Me 188: Powerplant EngineeringDocument40 pagesDean Paul Cueto 2 0 0 6 - 1 8 3 0 8: Me 188: Powerplant EngineeringDean Paul100% (1)

- 44 Uc Irvine's Combined Heat Power PlantDocument48 pages44 Uc Irvine's Combined Heat Power Plantparklane79No ratings yet