Professional Documents

Culture Documents

Ti e Protegol 32-55 MT Jan 08

Uploaded by

A MahmoodOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ti e Protegol 32-55 MT Jan 08

Uploaded by

A MahmoodCopyright:

Available Formats

Corrosion Protection Systems

P R O T E G O L

UR - Coating 32-55 MT

Solvent-free, airless spray able

two-component polyurethane coating compound

Date of issue 01/2008

TIB Chemicals AG | Muelheimer Strasse 16 -22 | 68219 Mannheim | P. O. Box 81 02 20 | 68202 Mannheim

Phone +49 621 8901-812 | Fax +49 621 8901-902 | info.protegol@tib-chemicals.com | www.tib-chemicals.com

This information is given to the best of our knowledge but without obligation. We are not liable for any wrong advice or any advice we may have failed to give.

This data sheet becomes invalid as soon as a new edition has been published. Please contact us for latest.

1/4

Description

Solvent-free two-component polyurethane coating

compound.

Meets DIN 30671 edition june 1992 Thermoset plastic

coatings for buried steel pipes as well as DIN 30677

Part 2 Sept. 1988 External corrosion protection for

buried valves; Heavy-duty thermoset plastics

coatings. The product is applied by airless hot-

spraying.

In comparison to PROTEGOL 32-55 the PROTEGOL

32-55 MT is used whenever a prolonged pot life is

necessary or, respectively, a prolonged curing time is

acceptable and also when a higher coating thickness

per operation is required.

Uses

Interior and exterior coating of

Pipes

Fittings

Valves

Containers / Tanks

Thrust bore pipes made of cast-iron and steel

Benefits

good corrosion protection

abrasion resistant

impact resistant

good chemical resistance

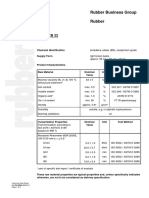

Product Data

The following data were determined at +20 C unless

otherwise stated:

Type internally plasticized two-component

material

Base PUR

Solvents None

Volume solids 100 %

Consistency

Comp. A Pasty

Comp. B Liquid

Density

Comp. A 1,7 g/cm

Comp. B 1,2 g/cm

Comp. A + B 1,6 g/cm

Mixing ratio

Comp. A : B 82 : 18 parts by weight

3,5 : 1 parts by volume approx. ***

Application method airless hot-spray system

Application thickness up to 2,5 mm per operation on vertical

surfaces

Minimum coating thickness 600 m

Pot life approx. 80 sec. at 60 C

Application temp. Substrate > 10 C

Comp. A 50 C - 80 C

Comp. B 40 C - 60 C

Curing time at 20 C at 90 C

touch dry after approx. 60 min. after 10 min. *

stackable after approx. 15

hours

after 60 min. *

Exposure to mech. and

chemical load

after 5 days

Temperature limits without

simultaneous mechanical

stress

- 30 C up to +80 C

up to 110 C for short-term periods

(without temperature gradient to the

substrate)

Shore D

according to DIN 53 505

75 3 **

Cleaning material Solvent B or Solvent G

Adhesion test

(Pull-off method)

according to EN 10 290

at 23 C

20,0 MPa

Cathodic Despondent

according to EN 10 290

after 28 d , at 23 C

4,3 mm

Specific electrical insulation

resistance

according to EN 10 290

after 100 d , at 23 C

( 1,3 ) 10

11

m

Corrosion Protection Systems

P R O T E G O L

UR - Coating 32-55 MT

Solvent-free, airless spray able

two-component polyurethane coating compound

Date of issue 01/2008

TIB Chemicals AG | Muelheimer Strasse 16 -22 | 68219 Mannheim | P. O. Box 81 02 20 | 68202 Mannheim

Phone +49 621 8901-812 | Fax +49 621 8901-902 | info.protegol@tib-chemicals.com | www.tib-chemicals.com

This information is given to the best of our knowledge but without obligation. We are not liable for any wrong advice or any advice we may have failed to give.

This data sheet becomes invalid as soon as a new edition has been published. Please contact us for latest.

2/4

Thermal Aging

(Adhesion test)

according to EN 10 290

after 100 d at 100 C

20 MPa

Flexibility

according to EN 10 290

at 23 C

fulfils requirements

Elongation

according to EN 10 290

17,0 %

Impact resistance

according to EN 10 290

at 23 C

test voltage = 18 kV

impact (max.) = 10. J

* after the coating has cooled down below 30 C

** after the coating has fully reacted and cured

*** The volumetric mixing ratio was determined

on processing conditions

Colours

Light ivory approx. RAL 1015

Capri blue approx. RAL 5019

Reseda green approx. RAL 6011

Feh grey approx. RAL 7000

Achat grey approx. RAL 7038

Graphite black approx. RAL 9011

and others on request

Coverage

Approx. 1,6 kg / mm dft. / m (theoretical value)

Packaging

Comp. A and Comp. B in 30 ltr. non-returnable drums

Comp. A and Comp. B in 200 ltr. non-returnable drums

Comp. A in 1000 ltr. non-returnable or returnable bulk

container

Storage

In a cool and dry place, approx. 12 months in tightly

closed original packs.

When stored below 0C Comp. B may partly

crystallize. In this case warm up to approx. 25 C in an

oven or by oil bath (do not use water bath as Comp. B

is sensitive to moisture!) in order to redissolve the

crystals. Comp. B with crystals should on no account

be used since the presence of crystals results in the

spraying equipment becoming blocked up as well as

interfering with the curing process.

Storage and Transport Data

Flash point RID/ADR ICAO/IATA-DGR

PROTEGOL

32-55 MT

Comp. A > 100 C

Comp. B > 220 C

Solvent B appr. 28 C cl. 3/fig. 31 c cl. 3/ UN 1263/ III

Solvent G appr. 7 C cl. 3/fig. 5 b cl. 3/UN 1263/III

Application

Substrate

The steel surfaces to be coated must be dry, clean,

free from dust, have a good key and be free from all

matter acting as release agents (e.g. oil, grease, old

paint etc.). In order to obtain the necessary conditions

suitable substrate preparation methods such as

blasting must be used.

Steel surfaces must be abrasive blast clean to

nearwhite (degree of cleanliness according to DIN

55928 at least Sa 2 ). The first coating must be

applied immediately after blast cleaning. Later

application of the base coat is only permissible if the

original degree of cleanliness has been maintained.

The constructional design of steel and iron shall

comply to DIN 28051 and DIN 28053 or to VDI

guideline 2532.

The surface profile shall range between 50 and 70 m.

The blasting material shall be angled shot.

Corrosion Protection Systems

P R O T E G O L

UR - Coating 32-55 MT

Solvent-free, airless spray able

two-component polyurethane coating compound

Date of issue 01/2008

TIB Chemicals AG | Muelheimer Strasse 16 -22 | 68219 Mannheim | P. O. Box 81 02 20 | 68202 Mannheim

Phone +49 621 8901-812 | Fax +49 621 8901-902 | info.protegol@tib-chemicals.com | www.tib-chemicals.com

This information is given to the best of our knowledge but without obligation. We are not liable for any wrong advice or any advice we may have failed to give.

This data sheet becomes invalid as soon as a new edition has been published. Please contact us for latest.

3/4

Coating

Ensure that the temperature of the substrate is at least

3 C above the dew point to avoid condensation. The

dew point can be determined with a suitable dew point

mirror.

PROTEGOL 32-55MT is only applied by using a two

component airless hot spray system.

It is possible to use a fixed or variable metering

system. For these systems the manufacturer of the

equipment should guarantee a dosage accuracy with a

maximum deviation of +/- 5% of component B relating

to the fixed component A.

For control and monitoring of this accurate dosage we

recommend to measure the gravimetric mixing ratio of

the unit, the usage of an automatic pressure control

unit and the usage of a fluid control system.

Alternatively we recommend an analysis of the

nitrogen content of a fully cured foil of coating in our

laboratory.

At 20 C the coating is tack-free after 60 minutes and

after 15 hours (depending on the weight of the coated

objects) it allows for stacking.

Holiday tests can be carried out after approx. 4 hours.

The tension applied may be up to 10.000 volt per mm

coating thickness.

A post-heating up to 50 C by gas filled or infra-red

heaters will accelerate curing to such a degree that

after the coated objects have cooled to < 30 C holiday

tests can be carried out.

Relative humidity during application of the coating

must be < 80 %. (In case the relative humidity is

higher, then please ask for our special technical

advice.)

Waiting periods

The waiting periods between coatings depend on

temperature. Subsequent coatings may be applied

after 10 minutes. If, for technical reasons, several

coating operations with prolonged waiting periods

between applications are necessary the substrate

must always be dry, free of oil, grease and dust.

Between operations, the temperature of the substrate

shall be at least 3 C above the dew point to avoid

condensation. Each layer can be over coated without

mechanical roughening when the waiting period does

not exceed 3 days (storage at room temperature).

Maintenance of tools

Immediately after use all instruments should be

cleaned with Solvent B or G.

Health and Safety

Although PROTEGOL

32-55 MT is solvent-free it

may, if processed at elevated temperatures, develop

vapours which may cause irritation to the skin. It must

be ensured by suitable measures, such as continuous

ventilation, mechanical extraction or respiratory pro-

tection that such vapours and any mist eventually

forming during the spraying process are not inhaled.

Therefore we recommend to wear a filter or fresh air

masks.

The unprotected skin should not be allowed to come in

contact with Component B. If any of the material has

accidentally splashed onto the skin, the affected area

should immediately be washed thoroughly with warm

soapy water or better with warm non-alcaline cleaners

(e.g. Lutrol E 400, BASF). Clean again thoroughly with

soap.

When using PROTEGOL

32-55 MT all safety precau-

tions applicable to handling polyurethane resins and

their hardeners must be observed. They are listed in

the Merkblatt fr den Umgang mit Isocyanaten

(Instructions for handling isocyanates) which is

available on request.

Corrosion Protection Systems

P R O T E G O L

UR - Coating 32-55 MT

Solvent-free, airless spray able

two-component polyurethane coating compound

Date of issue 01/2008

TIB Chemicals AG | Muelheimer Strasse 16 -22 | 68219 Mannheim | P. O. Box 81 02 20 | 68202 Mannheim

Phone +49 621 8901-812 | Fax +49 621 8901-902 | info.protegol@tib-chemicals.com | www.tib-chemicals.com

This information is given to the best of our knowledge but without obligation. We are not liable for any wrong advice or any advice we may have failed to give.

This data sheet becomes invalid as soon as a new edition has been published. Please contact us for latest.

4/4

In addition, the health and safety precautions being

effective in the respective country should be observed.

According to the regulations on dangerous substances

component B of PROTEGOL 32-55 MT as well as

solvents B and G are liable to danger identification.

You might also like

- Santoprene Blow Molding Guide EnpdfDocument23 pagesSantoprene Blow Molding Guide EnpdfNikhil AherNo ratings yet

- A 269 - 04 Qti2oqDocument6 pagesA 269 - 04 Qti2oqfekihassan100% (1)

- Astm D 1148Document4 pagesAstm D 1148arthymanicNo ratings yet

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data SheetajuhaseenNo ratings yet

- Uk BS 5852Document22 pagesUk BS 5852irwanchemNo ratings yet

- Molybdate and Borate Complexes For Enhanced Cable Compound Fire Performance Technical PaperDocument7 pagesMolybdate and Borate Complexes For Enhanced Cable Compound Fire Performance Technical PapernilayNo ratings yet

- Unibar Shopprimer LV: BarilDocument2 pagesUnibar Shopprimer LV: BarilFlori SmăduNo ratings yet

- Zinc Flake Coating Ex GeometDocument7 pagesZinc Flake Coating Ex GeometRoter DiamNo ratings yet

- ASTM D 3188 - 00 Rubber-Evaluation of IIR (Isobutene-Isoprene Rubber)Document4 pagesASTM D 3188 - 00 Rubber-Evaluation of IIR (Isobutene-Isoprene Rubber)alin2005No ratings yet

- Kevlar Cut Protection TestingDocument6 pagesKevlar Cut Protection Testingalvares90No ratings yet

- Construction Manual For CERARL PDFDocument8 pagesConstruction Manual For CERARL PDFAyyoubNo ratings yet

- Greblon e GBDocument8 pagesGreblon e GBbelcoooNo ratings yet

- Durock Cement Board Msds en 14090001Document9 pagesDurock Cement Board Msds en 14090001joelbeckerNo ratings yet

- ESCRDocument3 pagesESCRAvelino Sobrevega Pinuela Jr.No ratings yet

- Ti e Protegol 32-55 H Nov 07Document3 pagesTi e Protegol 32-55 H Nov 07A MahmoodNo ratings yet

- Ti - e - Protegol 130 HT L - Jan 08Document3 pagesTi - e - Protegol 130 HT L - Jan 08A MahmoodNo ratings yet

- Ti e Protegol 130 HT Nov 07Document3 pagesTi e Protegol 130 HT Nov 07A MahmoodNo ratings yet

- PUF - Voracor CD 1786 Polyol With CD345 TDS PDFDocument2 pagesPUF - Voracor CD 1786 Polyol With CD345 TDS PDFRajendra Kumar SharmaNo ratings yet

- D 6463 - 99 Rdy0njmDocument4 pagesD 6463 - 99 Rdy0njmMarceloNo ratings yet

- Gloss MeterDocument2 pagesGloss Meterravi00098No ratings yet

- Nitoprime 31Document2 pagesNitoprime 31Balasubramanian AnanthNo ratings yet

- PA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66Document2 pagesPA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66watnaNo ratings yet

- Understanding UL 94 Certifications and LimitationsDocument2 pagesUnderstanding UL 94 Certifications and LimitationsLakshmi PrasannaNo ratings yet

- Din 4 MM Standard and Dip CupsDocument7 pagesDin 4 MM Standard and Dip CupsDmitry_ucpNo ratings yet

- SoniCell ASTM E85 Fire TestDocument10 pagesSoniCell ASTM E85 Fire TestAvs CrNo ratings yet

- ASTEM D955 00 - Standard Test Method of Measuring Shrinkage From Mold Dimensions of Thermoplastics PDFDocument5 pagesASTEM D955 00 - Standard Test Method of Measuring Shrinkage From Mold Dimensions of Thermoplastics PDFAndre Rodriguez SpirimNo ratings yet

- Final1 Additive StandardsDocument16 pagesFinal1 Additive StandardsmohammedNo ratings yet

- Exxelor PE1040 DatasheetDocument2 pagesExxelor PE1040 DatasheetmaheshgupteNo ratings yet

- Test Method: Renault Automobiles Standardisation DQSC - S / Department 00621 Section Normes Et Cahiers Des ChargesDocument9 pagesTest Method: Renault Automobiles Standardisation DQSC - S / Department 00621 Section Normes Et Cahiers Des Chargesclaudio5475No ratings yet

- HDPE Smooth Geomembrane Technical Data SheetDocument1 pageHDPE Smooth Geomembrane Technical Data SheetAgun GunawanNo ratings yet

- C240Document4 pagesC240BeymerBustamanteMejía100% (1)

- POLYPOXY-NF Technical Data SheetDocument2 pagesPOLYPOXY-NF Technical Data SheetCommando crawlerNo ratings yet

- Synthetic Bioplastics From Cassava SkinDocument20 pagesSynthetic Bioplastics From Cassava SkinlisaNo ratings yet

- National Guard Epoxy Red Oxide PrimerDocument3 pagesNational Guard Epoxy Red Oxide PrimerCyril J PadiyathNo ratings yet

- PMMA Test MethodDocument8 pagesPMMA Test MethodFirman MuttaqinNo ratings yet

- D 3194 - 17Document3 pagesD 3194 - 17Salma Farooq100% (1)

- Der 671 Solid EpoxyDocument3 pagesDer 671 Solid Epoxyvanhung680% (1)

- 3 6077 RTVDocument2 pages3 6077 RTVgkretroNo ratings yet

- 4.elastoseal P100Document2 pages4.elastoseal P100adchem123No ratings yet

- Ash Astm d5630Document1 pageAsh Astm d5630Kanwal NainNo ratings yet

- Tri-ACT® 1820: Safety Data SheetDocument13 pagesTri-ACT® 1820: Safety Data SheetEDUARDONo ratings yet

- Impact of Petroleum Jelly on Ageing of Telephone WireDocument6 pagesImpact of Petroleum Jelly on Ageing of Telephone WireNavneet SinghNo ratings yet

- Cuptor DO308Document38 pagesCuptor DO308Dumitru Marius0% (1)

- Warwick Halls Presentation Australian StandardDocument32 pagesWarwick Halls Presentation Australian StandardLakshmi KanthNo ratings yet

- Buna CB 22 Technical Data SheetDocument2 pagesBuna CB 22 Technical Data SheetTmac100% (1)

- CW February 2013Document60 pagesCW February 2013Clint FosterNo ratings yet

- D 6012 - 03 (2013)Document2 pagesD 6012 - 03 (2013)othmanNo ratings yet

- Renderoc La80Document4 pagesRenderoc La80talatzahoorNo ratings yet

- OH Determination For Polyether PolyolDocument4 pagesOH Determination For Polyether PolyolHoang Cong ThanhNo ratings yet

- Natural Foam Blowing AgentsDocument178 pagesNatural Foam Blowing AgentssohailNo ratings yet

- ISO - 8543 - EN - Method For Determination of Mass of Textile Floor CoveringDocument6 pagesISO - 8543 - EN - Method For Determination of Mass of Textile Floor CoveringibrahimNo ratings yet

- TDS Irganox B 215Document2 pagesTDS Irganox B 215Jorge David Rojas CardenasNo ratings yet

- Metal Bearing Waste Streams: Minimizing, Recycling and TreatmentFrom EverandMetal Bearing Waste Streams: Minimizing, Recycling and TreatmentNo ratings yet

- Overall Aspects of Non-Traditional Glasses: Synthesis, Properties and ApplicationsFrom EverandOverall Aspects of Non-Traditional Glasses: Synthesis, Properties and ApplicationsNo ratings yet

- Ti e Protegol 32-55 RRG Jan 08Document3 pagesTi e Protegol 32-55 RRG Jan 08A MahmoodNo ratings yet

- Ti e Protegol 32-55 R Nov 07Document4 pagesTi e Protegol 32-55 R Nov 07A MahmoodNo ratings yet

- Ti e Protegol 32-55 M Jul 08Document4 pagesTi e Protegol 32-55 M Jul 08A MahmoodNo ratings yet

- Ti e Protegol 32-55 RRM Nov 07Document4 pagesTi e Protegol 32-55 RRM Nov 07A MahmoodNo ratings yet

- Ti e Protegol 32-60 Apr08Document3 pagesTi e Protegol 32-60 Apr08A Mahmood100% (1)

- A 269 - 00 - Qti2os0wma - PDFDocument5 pagesA 269 - 00 - Qti2os0wma - PDFJose Oliveros ArdilaNo ratings yet

- A 270 - 01 Qti3mc0wmq - PDFDocument5 pagesA 270 - 01 Qti3mc0wmq - PDFsingaravelan narayanasamyNo ratings yet

- A 270 - 03 - Qti3mc0wmwDocument5 pagesA 270 - 03 - Qti3mc0wmwehsanNo ratings yet

- A 254 - 97 R02 Qti1na - PDFDocument4 pagesA 254 - 97 R02 Qti1na - PDFMan98No ratings yet

- A 234 - A 234M - 04 Qtiznc9bmjm0tq - PDFDocument8 pagesA 234 - A 234M - 04 Qtiznc9bmjm0tq - PDFLuis Daniel ContrerasNo ratings yet

- A 254 - 97Document4 pagesA 254 - 97Maicol K. Huamán TitoNo ratings yet

- A 53 - A 53m - 00 QtuzltawDocument7 pagesA 53 - A 53m - 00 QtuzltawPablo CzNo ratings yet

- A 234 - A 234M - 01 Qtiznc0wmq - PDFDocument8 pagesA 234 - A 234M - 01 Qtiznc0wmq - PDFLuis Daniel ContrerasNo ratings yet

- A 268 - A 268M - 03 Qti2oc0wmw - PDFDocument6 pagesA 268 - A 268M - 03 Qti2oc0wmw - PDFMan98No ratings yet

- Astm A0213 - 1 (En) PDFDocument13 pagesAstm A0213 - 1 (En) PDFRahul SamalaNo ratings yet

- A 268 - A 268M - 01 Qti2oc0wmq - PDFDocument6 pagesA 268 - A 268M - 01 Qti2oc0wmq - PDFMan98No ratings yet

- A 249 - A 249M - 04 Qti0os9bmjq5tq - PDFDocument10 pagesA 249 - A 249M - 04 Qti0os9bmjq5tq - PDFMan98No ratings yet

- A 249 - A 249M - 01 Qti0os0wmq - PDFDocument8 pagesA 249 - A 249M - 01 Qti0os0wmq - PDFMan98No ratings yet

- A 249 - A 249M - 03 Qti0os9bmjq5ts1sruq - PDFDocument11 pagesA 249 - A 249M - 03 Qti0os9bmjq5ts1sruq - PDFMan98No ratings yet

- A 250 - A 250M - 95 R01 Qti1mc9bmjuwts1sruq - PDFDocument7 pagesA 250 - A 250M - 95 R01 Qti1mc9bmjuwts1sruq - PDFMan98No ratings yet

- A 234 - A 234M - 00 Qtiznc0wma - PDFDocument8 pagesA 234 - A 234M - 00 Qtiznc0wma - PDFCherie JohnsonNo ratings yet

- A 250 - A 250M - 95 Qti1mc05nq - PDFDocument4 pagesA 250 - A 250M - 95 Qti1mc05nq - PDFMan98No ratings yet

- A 234 - A 234M - 03 Qtiznc9bmjm0ts1sruq - PDFDocument10 pagesA 234 - A 234M - 03 Qtiznc9bmjm0ts1sruq - PDFLuis Daniel ContrerasNo ratings yet

- A 250 - A 250M - 04 Qti1mc9bmjuwtq - PDFDocument4 pagesA 250 - A 250M - 04 Qti1mc9bmjuwtq - PDFMan98No ratings yet

- A 250 - A 250M - 95 R01 Qti1mc05nviwmq - PDFDocument4 pagesA 250 - A 250M - 95 R01 Qti1mc05nviwmq - PDFMan98No ratings yet

- A 234 - A 234M - 00 Qtiznc0wmee - PDFDocument8 pagesA 234 - A 234M - 00 Qtiznc0wmee - PDFLuis Daniel ContrerasNo ratings yet

- A 213 - A 213M - 03 Qtixmy0wm0i - PDFDocument12 pagesA 213 - A 213M - 03 Qtixmy0wm0i - PDFMan98No ratings yet

- A 213 - A 213M - 03 Qtixmy0wmw - PDFDocument10 pagesA 213 - A 213M - 03 Qtixmy0wmw - PDFMan98No ratings yet

- A 249 - A 249M - 98 Qti0os05oeux PDFDocument7 pagesA 249 - A 249M - 98 Qti0os05oeux PDFMan98No ratings yet

- A 249 - A 249M - 03 Qti0os0wmw - PDFDocument9 pagesA 249 - A 249M - 03 Qti0os0wmw - PDFMan98No ratings yet

- A 214 - A 214M - 96 Qtixnc05ng - PDFDocument2 pagesA 214 - A 214M - 96 Qtixnc05ng - PDFMan98No ratings yet

- A 213 - A 213M - 01 Qtixmy0wmqDocument8 pagesA 213 - A 213M - 01 Qtixmy0wmqfadjarNo ratings yet

- A 213 Â " A 213M Â " 03 - QTIXMY0WM0MDocument13 pagesA 213 Â " A 213M Â " 03 - QTIXMY0WM0MhNo ratings yet

- A 213 - A 213M - 01 Qtixmy0wmue - PDFDocument9 pagesA 213 - A 213M - 01 Qtixmy0wmue - PDFErolNo ratings yet