Professional Documents

Culture Documents

Cat® D11T Vs - Komatsu D475A-5

Uploaded by

Mónica Rada UrbinaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

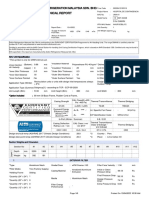

Cat® D11T Vs - Komatsu D475A-5

Uploaded by

Mónica Rada UrbinaCopyright:

Available Formats

Cat

Product Information

Competitive Bulletin

May 2012

Cat

D11T vs.

Komatsu D475A-5

For Dealer Sales Personnel

2 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Table of Contents

Introduction ..........................................................................................................................................................................3

Summary/Key Selling Points .............................................................................................................................................4

Features ...............................................................................................................................................................................10

Case and Frame ...........................................................................................................................................................10

Cooling System ...........................................................................................................................................................11

Engine ...........................................................................................................................................................................12

Torque Converter/Divider and Transmission .........................................................................................................17

Brakes and Steering Clutches ..................................................................................................................................19

Final Drives ..................................................................................................................................................................20

Undercarriage .............................................................................................................................................................21

Implement and Steering Controls ............................................................................................................................24

Operators Station .......................................................................................................................................................28

Blades ...........................................................................................................................................................................30

Rippers and Counterweights ....................................................................................................................................31

Monitoring System .....................................................................................................................................................33

Serviceability ..............................................................................................................................................................35

D11T Carrydozer ..........................................................................................................................................................37

D475A-5 Super Dozer..................................................................................................................................................38

Summary..............................................................................................................................................................................39

Technical Specifcations .................................................................................................................................................40

Notes ....................................................................................................................................................................................46

3 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Introduction

Cat

D11 track-type tractors have been working around the world proving themselves as highly productive,

reliable, and durable machines backed by world class support. The Cat D11T builds on that expectation for

performance, reliability, durability and operator comfort.

Since the D11N was introduced in 1987, it has become the standard of the industry for large construction

and mining tractors. The R series tractors built on that standard while meeting more stringent Tier 1 emissions

requirements. With changing times comes new opportunities. Caterpillar has taken every opportunity and

designed the new D11T with the next generation in mind. The new D11T and D11T Carrydozer (CD) will be

offered with two variations of the C32 engine with ACERT Technology. One will be U.S. EPA Tier 4 Final

certied and required for sale in the United States and Canada. The other will remain at 2006 U.S. EPA

Tier 2 equivalent emission levels for sales outside of the United States and Canada.

The D11T combines power and efciency with advanced technology for outstanding production at a

lower cost-per-yard. The durable construction of the D11T is well suited for tough working conditions.

Combined with the Cat C32 ACERT engine for superior performance, fuel economy and meeting

emissions targets, it keeps material moving with the lowest overall cost.

The Komatsu D475A-5, rst introduced in 2003 and updated in 2006 with a U.S. EPA Tier 2 engine,

is the primary competitor for the D11T. The D475A-5 is primarily used in mining and large-scale

heavy construction projects. The development of this tractor focused on operator comfort, sound levels,

and reduced maintenance and repair cost.

The main selling points of the D475A-5 are the lock up torque converter and low cab sound levels.

The low sound design focuses on sound absorbing fan blades, side enclosure with air duct, double hood,

and viscous cab mounts.

4 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Summary/Key Selling Points

The D11T frame is a fabrication featuring box section construction, and high strength steel castings in

high stress areas giving it higher strength and durability.

The D11T has outstanding durability due to frame design containing castings used in important stress

prone areas and component placement, such as the suspended undercarriage that raises the nal drives

above the ground.

The mainframe is built to withstand high impact loads induced by heavy dozing and ripping in hard

clays, shales, and rock.

The D11T has better ride quality, especially in reverse, than the D475A-5 due to its fully suspended

undercarriage and sprocket placement.

The elevated sprocket raises the sprocket above abrasive materials, extending sprocket life. Shock loads

from the blade are directly carried to the mainframe rather than through the nal drive cases. More track

is located aft of the sprocket for better balance and improvements to traction and otation while

counteracting front-end rise during heavy dozing and drawbar work.

D11T Featuring Elevated Sprocket Design

The D11T has a torque divider and a three-speed planetary transmission. The D475A-5 uses a lock-up

torque converter and a three-speed planetary transmission. The torque divider, offered by Caterpillar,

provides a more efcient power train system over a broader operating range than a torque converter

and does not require the operator to decide when to enable or disable lock-up capability.

The major power train components of the D11T are designed as separate modules that are easy to

remove. Komatsu uses a one-piece power module that is difcult to remove. The D475A-5 requires

pulling off the ROPS, cab, operator platform, and fuel tank to get the power module out.

Cat Modularity Komatsu Body and Frame

5 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Summary/Key Selling Points

The blade tag-link design of the D11T keeps the blade closer to the tractor, improving maneuverability,

tractor balance, blade penetration force, pryout force, and blade control.

D11T Tag-Link

The D11T has standard open labyrinth seal guards to protect the nal drive components when working

in applications where mud packing is common.

D11T Standard Open Labyrinth Seal Guards

6 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Summary/Key Selling Points

The D11T provides an ergonomically designed cab and electro-hydraulic controls, making the operator

more comfortable and efcient. With the updated cab interior there is more commonality across the

product line and is easier to clean. Also, the new Automatic Climate Control system automatically adjusts

the heating and air conditioning controls to maintain a consistent cab temperature throughout the day.

Suite of Electronics

Standard Automatic Blade Assist (ABA) allows the blade to pitch forward and backward

automatically through preset positions to improve productivity.

Autocarry (optional) provides automatic blade control (raise and lower only) during the carry

segment of the dozing cycle.

Terrain for Grading (optional) enables an electronic site plan to be sent to the machine from

the ofce in real-time, directing the operator where to cut and ll. Terrain for Grading provides

high precision management of dozing and grading applications for enhanced safety, productivity

and efciency.

Automatic Ripper Control (optional) reduces operator fatigue and decreases wear and tear on the

machine. This is done by monitoring the tractor speed with the new cab mounted Global Navigation

Satellite System (GNSS) to automatically adjust engine speed and ripper depth to minimize track slip.

D11T Terrain for Grading

The D11T features Finger Tip Controls (FTC) that require less effort and are more comfortable for long

periods of operation than the D475A-5 Palm Command Control System (PCCS).

D11T Finger Tip Control Steering D475A-5 PCCS Control Steering

7 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Summary/Key Selling Points

An integrated electronics suite provides building blocks for future machine control and management

strategies that are being developed today.

The D11T offers optional features including a hydraulically powered ladder that can be raised and

lowered for access to and from the operator station, rear platform that can be attached to the 1911 liter

(505 U.S. gallon) fuel tank, and spectator sound suppression for locations where sound levels are a concern.

Standard heavy duty guard rails are strategically placed on the edges of the fender platforms outside the cab.

Strategically placed heavy duty grab handles and non-slip steps and decking aid the operator getting

on and off the machine.

D11T Rear Platform

D11T Hydraulically Powered Ladder D11T Raised Ladder with Rear Platform

8 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Summary/Key Selling Points

Multiple visibility package options enhance the operators visibility of their surroundings and provides

a broader view of the work area. The packages include a Work Area Vision System (WAVS) camera

system (single or dual) and mirrors inside and outside the cab.

D11T Dual Camera System D11T Camera View from Operators Station

D11T Carrydozer was developed from the standard D11T, but with the following modications:

Frame has been modied to provide durability and reliability in the carry dozer application.

Hydraulic specs are redened for optimal performance when using a Carrydozer blade.

Carrydozer blade is designed to carry material inside the blade curvature for maximum productivity.

Heavy single shank and multi shank rippers along with optional counterweight are available for rear

attachment.

The D11T offers safety and sustainability features including ecology drains, longer oil change interval

in certain applications, remanufactured parts and components for repair, extended life coolants,

SOS

SM

sampling ports, and sight gauges.

9 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Summary/Key Selling Points

D11T Ground Level Service Option

A standard ground level service center mounted on the rear attachment or ripper provides easy access to:

secondary engine shutoff, access lighting switch, fast fuel and optional high speed engine and power train

oil change.

The D11T is supported by the unmatched worldwide Cat dealer network of trained experts that will

keep the machine up and running, maximizing your equipment investment.

World class product support through the worldwide Cat dealer network offers many repair options

including piece parts, complete new components, complete remanufactured components, and dealer

exchange and rebuild.

Many Cat dealers offer extended warranty options, Maintenance and Repair Contracts (MARC),

and Customer Service Agreements (CSAs).

Caterpillar SOS

SM

Lab for Fluid Analysis Remanufactured Components and Parts

10 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

D11T Case and Frame

The D11T mainframe is built to absorb high impact

shock loads and twisting forces of severe dozing

and ripping. The full box section design keeps

components rigidly aligned. Heavy steel castings

provide a strengthened main case, equalizer bar

saddle, front cross member and mounting location

for the forged steel tag-link trunnion. Top and

bottom rails are made from continuous rolled sections

to eliminate welds and machining, which provide for

superior mainframe durability. Heavy steel hydraulic

tubing is pressed into the main case to minimize

external hoses and to ensure a leak-free drive train

oil system. Robotic welding in critical areas ensures

weld consistency and strength.

The pivot shaft and pinned equalizer bar maintain

track roller frame alignment. The equalizer bar is a

high strength steel forging. The case and frame features

a one-piece cast case with provisions for ripper and

ROPS mounting. It elevates the nal drives well

above the ground level work area to protect them

from impact loads, abrasion and contaminants.

The power train oil reservoir is included in the

one-piece rear case casting. The heavy cast saddle is a

ribbed design that increases frame life. The front engine

and radiator guard mounts are heavy castings as well.

The frame design allows for easy servicing of the

transmission, bevel gears, steering clutches, brakes,

and nal drives. These components are accessible

directly from the rear or side of the tractor and do not

require any major component removal for access.

D475A-5 Case and Frame

The D475A-5 mainframe is a hull, fabricated plate

design. The fabricated plate design can experience

excess vibrations and/or early stress fractures.

The hull design reduces power train access.

To service the torque converter, transmission, bevel

gears, steering clutches, and brakes, they must be

raised vertically out of the frame. As a result,

the cab, ROPS, operator platform, and fuel tank

must be removed to service these components.

These components are combined into a single unit

that Komatsu calls a power module.

Features

11 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

D11T Cooling System

The D11T cooling system uses a two-piece radiator

built with rugged, highly efcient aluminum bar

plate cores. The aluminum bar plate construction

aids durability and allows for higher heat transfer

and superior corrosion resistance. The aluminum

bar plate radiator has 8.5 ns per inch density, with

(optional) 6 ns per inch for plugging applications.

The new air to hydraulic oil cooler reduces hydraulic

oil temperatures thus improving component life.

The core is built using the same rugged aluminum

bar plate design as the jacket water cooler.

The use of a hydraulically variable demand fan

provides engine cooling capability that is matched

to the ambient conditions. In cooler conditions,

the fan turns at a slower speed, reducing power

demands. This reduces fuel consumption in lower

load factor operations. Low speed fan operation also

reduces both operator and spectator sound levels.

The D11T also offers an optional hydraulic reversing

fan for automatic clean-out with ultra low fan speeds

for cold climate applications.

Another optional attachment for the D11T cooling

system is the Mesabi Radiator.

D475A-5 Cooling System

The D475A-5 features a one piece radiator with

one individual core. Komatsu does not offer optional

radiator packages to meet customer needs for

different application requirements.

The engine cooling system requires manual activation

and uses a hydraulically driven engine cooling fan

that is controlled depending on the hydraulic oil

and coolant temperature. Two modes are available;

reverse and reverse/clean-out to facilitate radiator

maintenance. It is unclear if these modes are

automatic on the D475A-5.

12 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

Cat C32 Engine

C32 Engine The D11T and D11T CD feature a

Cat C32 ACERT engine to deliver the performance

and efciency that customers demand. An engine

that meets U.S. EPA Tier 4 Final emissions

standards will be available for sales in the

United States and Canada.

Performing at full rated net power of 634 kW (850 hp)

at 1,800 rpm with a high torque rise of 21 percent,

the large 32.1 L (1,959 in

3

) displacement and high

torque rise allow the D11T to doze through tough

material. Matched with high efciency torque divider

and electronically controlled power shift transmission,

it will provide years of dependable service. For higher

altitude applications, the Cat C32 engine offers 22%

more altitude capability over the Komatsu engine.

The Cat C32 engine does not require derating up

to 3658 m (12,000 ft). With the Komatsu engine

no derating is required up to 2999 m (9,840 ft).

To improve high altitude performance above 3658 m

(12,000 ft), Caterpillar offers an optional arrangement

that uses a different impeller in the torque divider.

To best of our knowledge Komatsu has no optional

higher altitude arrangement.

ADEM A4 Engine Controller The ADEM A4

electronic control module manages fuel delivery and

air ow to get the best performance per liter (gallon)

of fuel used. It provides exible fuel mapping,

allowing the engine to respond quickly to varying

application needs.

MEUI Fuel System The Cat MEUI fuel system

is a eld-proven design, combining the technical

advancement of electronic control with the simplicity

of direct mechanically controlled unit fuel injection.

This system has a strong history of reliability and

design integrity. It excels in its ability to control

injection pressure over the entire engine operating

speed range.

This system electronically controls injection pressure

by monitoring the engine speed and load conditions.

In the MEUI fuel systems, a low-pressure fuel

transfer pump provides fuel to the injectors, which

then introduce highly pressurized fuel into the

combustion chamber with precise timing, duration,

and pressure. The injectors pressurize the fuel to

deliver very ne, atomized fuel particles into the

combustion chamber, thus producing a more

efcient burn. Combined with electronic control,

engines with ACERT Technology are producing

more work for a customers fuel dollar.

Overhead Cams Two, single (one per head)

overhead cams are driven by gears on the ywheel

end of the engine. Placing the cam gears at the

ywheel end signicantly reduces noise and vibration.

To reduce wear, two pendulum shock absorbers are

mounted at the front of the camshafts. These features

contribute to the long-life and durability of this engine.

Component Life Oil-cooled pistons and full-length

water cooled cylinder liners provide maximum heat

transfer, and utilize additional coolant passages to

provide maximum cooling to the engine. Through-

hardened crankshaft journals and steel-backed,

copper-lead bearings, help assure reliable performance

in the toughest applications.

Fuel Heater (optional) The optional fuel heater

uses the temperature of the engine return fuel to

warm the cold fuel coming directly from the tank.

The heater is strategically placed directly at the fuel

tank and ahead of any lters in order to minimize the

risk of fuel gelling. Temperature regulators built into

the fuel heater ensure that the heat exchange only

occurs at cold fuel temperatures. The fuel heater

option allows an easier transition to winter blended

fuels during season changes.

13 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

Air-to-Air Aftercooling Air-to-air aftercooling on

the D11T cools hot, compressed air coming out of

the turbocharger which provides cooler and denser

air into the air intake system. Bringing more cool air

into the engine increases power generation and lowers

emissions. In addition, the aftercooler, along with

the tight-tolerance combustion chamber components,

maximizes fuel efciency.

Steel Spacer Located between the block and head

to eliminate the need for block counterbores, and

extend block life.

Service Engine enclosures provide easy access to

maintenance points within the engine compartment.

Easier maintenance and repair is available through

monitoring of key functions and logging of critical

indicators. Electronic diagnostic access is possible

with a single tool, the Caterpillar Electronic

Technician (ET).

ET is a personal computer-based service tool that allows

the technician access to service all ECMs. ET offers

ash programming and histogram capabilities, and

saves machine systems status data.

14 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

The information below only refers to the

C32 engine that meets U.S. EPA Tier 4 Final

emission standards.

The C32 ACERT engine meeting U.S. EPA Tier 4

Final emission standards will continue to be counted

on to work productively and economically in tough

applications. It delivers the power and torque needed

for optimal performance.

High Efficiency Turbocharger A new high

efciency turbocharger with a simple design and

fewer moving parts enhances reliability. It delivers

variable boost, dependable performance and long

service life in the most demanding applications.

Emissions Reduction Technologies To meet U.S. EPA

Tier 4 Final emissions standards, Cat emissions

reduction components have been designed to match

application needs. D11T and D11T CD system

components include:

Cat NOx Reduction System The Cat NOx Reduction

System captures and cools a small quantity of

exhaust gas, then routes it into the combustion chamber

where it drives down combustion temperatures and

reduces NOx emissions. The result of more than

a decade of Caterpillar engineering research into

this technology, the Cat NOx Reduction System is

designed to be the most reliable system of its type.

Diesel Oxidation Catalyst (DOC)

The DOC uses oxidation, a chemical process,

to condition exhaust gases to meet regulatory

requirements.

The DOC does not require maintenance because

it is a ow-through device and the particulate

matter does not get trapped in the component.

DOC only Muffer

Integral

Mounting

Cradle

Aftertreatment will consist of Cat Clean Emission

Module (DOC + mufer). A Diesel Particulate Filter

(DPF) is not required, so the D11T does not have a

Cat Regeneration System.

MEUI-C Fuel System Developed from the eld

proven MEUI-A system while increasing fuel

efciency and further NOx reduction.

EUI injector platform retained

Precise multiple injection capability

Injection pressure 30,000 psi

15 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

Ultra Low Sulfur Diesel (ULSD) Fuel and

Low Ash Oil

ULSD fuel ( 15 ppm or mg/kg) sulfur is required

Cat ECF-3 spec (API CJ-4 and ACEA E9)

low ash oil is required

U.S. EPA Tier 4 Testing and Validation The testing

and validation program of Cat Tier 4 engines is the

largest in Caterpillar history. This industry-leading

engine validation program will ensure that all new

Cat engines deliver reliable performance from the

rst day on the job.

Multi-segment, multi-phase validation of prototype,

pilot and support machines was conducted in a wide

variety of the most demanding applications.

Developed a new manufacturing plant process

designed to improve production and quality.

Advanced power system simulators provide

extensive modeling, analysis and testing.

Next generation simulation techniques enhance

cooling system design, increase electronics

capabilities and optimize power train integration.

16 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

Komatsu SAA 12V 140E-3 Engine

The D475A-5 uses a Komatsu SAA 12V 140E-3

diesel engine, with net power of 641 kW (860 hp)

at 2,000 rpm with fan fully engaged. The SAA 12V

140E-3 engine has a bore of 140 mm (5.51 in) and

a stroke of 165 mm (6.5 in). It uses a direct injection

fuel system with an all-speed electronic governor.

The engine has no derating up to 2999 m (9,840 ft).

The intake air system is turbocharged and uses

air-to-air after cooler.

The SAA 12V 140E-3 engine is also used in

HD785-7 off-highway truck, PC2000-8 shovel,

and WA800 and WA900 wheel loaders.

The engine is emissions certied for Tier 2 EPA.

The Cat C32 engine with a displacement of 32.1 L

(1,959 in

3

) has a 5.3% displacement advantage

over the Komatsu SAA 12V 140E-3 engine which

has a displacement of only 30.48 L (1,860 in

3

).

The larger displacement and high torque rise of

the C32 allow the D11T to doze through tough

material more efciently.

17 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

D11T Torque Divider and Transmission

The D11T is equipped with a single stage torque

converter with an output torque divider that sends

75 percent of engine torque through the converter

and 25 percent through a direct drive shaft for greater

driveline efciency and higher torque multiplication.

The torque converter shields the driveline from

sudden torque shocks and vibration. Using a torque

divider provides higher efciency than a normal

torque converter and it does not require the operator

to select the operating mode. The Komatsu uses a

lock-up clutch which requires the operator to choose

when to enable or disable the lock-up capability.

The planetary power shift transmission has three

speeds forward and three speeds reverse, utilizing

large diameter, high-capacity, oil-cooled clutches.

Some of the features of the transmission include:

Modulation system permits fast speed and

direction changes.

Modular transmission and bevel gear slide

into rear case for servicing ease, even with

ripper installed.

Oil-to-water cooler for maximum cooling capacity.

Forced oil ow lubricates and cools clutch packs

to provide maximum clutch life.

Controlled throttle shifting regulates engine

speed during directional shifts for smoother

operation and longer component life.

Electronic Long Range Transmission (ELRT)

controlled throttle provides smoother shifting

and reduces shock loads on the components.

This feature provides auto-shift capability that

allows the operator to go from rst forward

to second reverse just by making a directional

change. The operator can override the auto-shift

feature at any time.

The D11T electronic transmission control system

is equipped with auto downshift. This feature

adds value by enhancing safety and productivity

during the dozing cycle. If the torque converter

speed ratio drops to a specied threshold, this

function automatically downshifts the transmission.

However, manual upshift is still available. After a

manual upshift is made, the auto downshift is prevented

for 2 seconds. This function works in forward and

reverse gears. Auto downshift switch has no function

unless the switch functions is enabled by the

operator in Advisor.

18 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

D475A-5 Torque Converter and Transmission

The D475A-5 features an automatic lockup torque

converter system. The lockup mode, when selected

by the operator, allows the system to automatically

engage the torque converter lockup clutch. Locking up

the torque converter transmits all the engine power

directly to the transmission resulting in increased

efciency. This is only when clutch is locked up.

When heavy loads are applied to the tractor the clutch

will unlock resulting in lower efciency operation.

Best productivity in dozing applications is achieved

by loading the blade to the point that ground speed

is 1.4 to 1.6 mph. This maximizes productivity by

minimizing reverse time. At these speeds it is not

uncommon to see the D475 running with an unlocked

torque converter. This reduces overall efciency

and productivity.

The Komatsu TORQFLOW transmission consists

of a water-cooled, 3-element, 1-stage, 1-phase torque

converter with lockup clutch and planetary gear sets.

The multiple-disc clutch transmission is hydraulically

actuated and force-lubricated for heat dissipation.

The D475A-5 utilizes a new power train electronic

control system. The controller registers the amount

of operator control (movements of lever and operation

of switches) along with machine condition signals

from each sensor to accurately calculate the control

of the torque converter and transmission to optimize

machine operation.

This tractor has an Electronic Controlled Modulation

Valve (ECMV) controlled transmission. This allows

for automatic adjustments of each clutch engagement

depending on travel conditions such as gear speed,

rpm, and shifting pattern. This feature is designed

to provide shockless and smooth clutch engagement;

while improving component reliability, component

life and operator ride comfort.

19 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

D11T Brakes and Steering Clutches

The D11T features high capacity brakes (high power

dissipation) that are hydraulically released, spring

applied, and have computerized electronic control

for excellent brake modulation while providing

safe and reliable braking performance. Thick, large

diameter plates and disks provide high torque capacity

and service life. The brake housing has cast-in ribs

for more durability. A single pedal simultaneously

applies brakes to both tracks for fast stops.

The parking brake is electronically controlled.

The D11T features standard oil cooled, wet steering

clutches. Both the clutches and brakes are serviceable

from the side of the tractor.

D475A-5 Brakes and Steering Clutches

The D475A-5 features an Electronic Controlled

Modulation Valve (ECMV) system that provides

sensors to monitor the machine operating conditions

and electronically control the steering clutches

and wet, multi-disc brakes. Depending on the

conditions the ECMV controller adjusts every

clutch engagement automatically.

The ECMV sensors monitor application parameters

such as size of load during dozing, and incline angle

of slope and load provides smooth and easy operation

by reducing counter steering on downhill travel.

When dozing and turning, ECMV automatically

controls stroke ratio of steering clutches and brakes

depending on degree of load.

Wet steering clutches are standard on the D475A-5.

Interconnected control of steering clutch and brake

reduces the load on the transmission during forward

and reverse directional changes, resulting in the

improved durability and reduced component

maintenance cost. Serviceability of the Komatsu

torque converter, bevel gear, transmission, steering

clutches and brakes is adversely affected by the

design of the tractor. All of these components

are combined into a single unit called a power

module which is housed inside the hull style frame.

Access to these components requires the ROPS,

Cab, Platform, and fuel tank to be removed.

On the D11T/D11T CD all components mentioned

above can be removed without removal of the ROPS,

Cab, Platform, and fuel tank. Repairs should be

faster and easier on a Cat D11T/D11T CD.

20 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

D11T Final Drives

The D11T features an elevated sprocket with large,

strong nal drives for durability and long service

life. Double reduction planetary gears, with tapered

roller bearings, spread torque loads for increased life.

Gears and planet carriers are sized for high loads,

while the axle and spline are larger for higher torque.

The support hub is made of a high strength casting

for increased life and is large and strong at the inboard

bearing to accommodate higher drawbar pull.

The hub spline improves fatigue life and the sprocket

bearings are designed for increased load capacity.

The elevated nal drives are protected from ground

and implement induced impact loads, extending

power train life. Open Labyrinth Seals are standard.

This seal minimizes wet material entry into the nal

drives and is ideal for mud-packing applications.

The new seal provides replaceable seal wear surfaces

and is retrotable to earlier tractor models.

Sprockets have four bolt-on, replaceable rim

segments with more bolts to resist high impact loads.

Abrasion-resistant steel increases the sprocket

segments wear life.

D475A-5 Final Drives

The D475A-5 double-reduction nal drive consists

of spur and planetary gear sets. Segmented sprocket

teeth are bolt-on for easy replacement.

The oval track design places the nal drives at

ground level exposing these components to additional

impact loads that can result in decreased life of the

nal drive components. It also allows impact loads

to be passed into the power module which could

result in a decrease in service life.

21 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

D11T Undercarriage

Caterpillar developed the elevated sprocket to deliver

the benets of suspended undercarriage. This design

transfers implement shock loads to the mainframe,

so nal drives, axles, and steering components are

isolated from harsh impact loads commonly seen in

large track-type tractor applications.

The elevated sprocket also keeps nal drives and

sprocket teeth away from abrasive materials and

moisture, resulting in longer nal drive and seal life.

Because more track is located to the rear of the roller

frame, the elevated sprocket improves traction and

otation. It also counteracts front-end rise during

heavy dozing and drawbar applications.

The suspended undercarriage has a low center of

gravity and wide track gauge. When working in

uneven or rocky conditions, the bogie system keeps

more track on the ground for increased stability.

The suspended design makes tractors more stable in

rocky conditions because the track readily adjusts to

match the ground contour; the more track in contact

with the ground, the greater the machine stability.

With 4444 mm (14 ft 7 in) of track on the ground,

the D11T delivers exceptional balance.

The elevated sprocket and suspended undercarriage

work together to reduce shock loads to tractor

components, increasing traction and giving the

operator a smoother ride. These benets translate

into higher production and longer component life.

To increase strength, durability, and reliability, the

undercarriage has large idler caps and roller caps

with an abutment joint and three-bolt mounting.

Optional attachment idler guards further improve

undercarriage wear life in some applications.

These guards bridge the gap between the track roller

frame and the idler, and substantially reduce the ow

of abrasive material into the track chain. The guards

steel-reinforced rubber construction allows them to

follow the oscillation of the idler, while still being

durable for long life. Guards are recommended for

high abrasion, low impact applications.

The D11T offers optional carrier rollers, and the

base tractor is equipped with carrier roller mounts

for more exibility as job conditions change.

Previously, mounts had to be welded to the roller

frame before a carrier roller could be added.

The new, integrated mounts minimize the time

needed to recongure the tractor.

The end pin bearings in the equalizer bars benet

from remotely greased bearings to maximize service

life and eliminate daily maintenance. This design

provides impact resistance as well as a service point

that is easy to access. The center pin bearing is made

with oil-impregnated powdered metal for longer life.

The pivot shaft and pinned equalizer bar eliminate

diagonal braces, which improves ground clearance

and track oscillation, increasing traction in all

underfoot conditions.

22 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

A special coating on the track bushing provides an

abrasion- and corrosion-resistant protective layer

on the end of the bushing. The coating improves

track sealability. In addition, 75W140 synthetic

oil reduces pin galling and increases seal life.

This exclusive technology reduces unscheduled

track maintenance and improves machine reliability.

The D11T features the Cat Sleeve Bearing Track that

is a patented design proven in a series of eld tests

to extend track life. Because it extends undercarriage

life, the need for service before normal bushing

turn time is also reduced which in turn reduces

maintenance costs as well as unscheduled downtime.

Sleeve Bearing Track eliminates galling between

pin and bushing, increases track re-seal point from

4,000 to 6,000 hours, and a separate post-turn track

seal provides sealability after bushing turn.

Positive pin retention prevents track link assembly

end-play generation while providing additional

benets that include preventing link movement

on pin, improved oil retention (sealability), and

consistent seal face contact on the bushing.

Changes to the geometry of the D11T master link

provides improved resistance to cracking through

a larger radius in the end serrations, increasing

service life.

Standard shoe size is 710 mm (28 in). Shoes are

available in additional sizes: 810 mm (32 in),

and 915 mm (36 in). Abrasion resistant material,

trapezoidal holes, and tall tough steel links for

highly abrasive, high wear applications are also

available as options.

The D11T elevated sprocket design provides improved

operator comfort resulting in higher productivity.

This is because when an obstacle is encountered on

the return portion of a dozing cycle by the D11T the

rst thing to encounter the obstacle is the track with

an idler supporting it. The obstacle can cause the

rear idler to experience up to 107 mm (4.2 in) of

upward travel as it oscillates. This idler movement

allows the D11T to build a ramp to smoothly climb

over and then envelop the obstacle reducing the

shock loads experienced by machine and operator.

The reduced shock loads provides an improvement

in machine life and keeps the operator comfortable

allowing them to maintain the highest level of

production possible. This is only possible with a

machine that has a fully suspended undercarriage.

Cat elevated sprocket machines are the only

Large Track-Type Tractors that can offer this capability.

D475A-5 Undercarriage

The Komatsu K-Bogie undercarriage System has the

current features:

Effective length of track on ground is consistent.

Shoe slippage is minimized therefore, high

traction is obtained.

Oscillating front idler.

K-bogies oscillate with two fulcrums, and

track roller vertical travel is greatly increased.

Because track and rollers are always in contact

with track link, impact loading to undercarriage

components is reduced and durability of

components is improved.

23 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

Undercarriage life is improved due to better

control of track chain alignment with track rollers.

Vibration and shock is reduced when traveling

over rough terrain.

Standard shoe size is 710 mm (28 in). Shoes are

available in additional sizes: 810 mm (32 in) and

910 mm (36 in).

The oval track undercarriage places the nal drive

close to the ground on the D475A-5. This provides

reduced ride comfort for the operator resulting in

decreased productivity. The rst thing to reach an

obstacle during the return part of the dozing cycle

is a track supported by a rigidly mounted sprocket

attached to the nal drive. With the nal drive close

to the ground, there is no ramp for the tractor to

transition over the obstacle resulting in the tractor

jumping over the obstacle. This produces a

signicant shock load into the tractor that must be

absorbed by both machine and operator. Over the

course of a long day these shock loads add up and

can cause an operator to reduce travel speeds to

provide a better ride for improved comfort which

lowers machine productivity.

24 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

Implement and Steering Controls

Reduced operator fatigue for increased performance.

D11T Dozer Control Joystick

Dozer Control Joystick A low-effort electronic

dozer control handle gives the operator control of all

dozer functions with one hand. Fore/aft movement

of the joystick lowers and raises the blade. Left/right

movement directionally tilts the blade. Blade response

and blade oat can be set/adjusted using the

Advisor Panel.

The thumb lever at the top of the handle and the

trigger switch controls blade pitch fore and aft.

The two thumb buttons to the left of the implement

control provide control over the semi-automated

blade pitch functions that Dual Tilt provides.

Blade pitch for load, carry and spread segments

can be preset on Advisor and controlled by one

button. The other button is used for the optional

Autocarry feature.

Lower-Raise Pushing joystick forward will

lower the blade. When joystick is released,

it will return to the hold position. Pulling back

on joystick will raise the blade. When joystick

is released, it will return to the hold position.

Float Pushing joystick fully forward will

move the blade control to oat. When joystick is

released, it will return to the hold position while

staying in oat function. The oat function will

be deactivated through a dozer lift command.

Tilt Pulling joystick to the left will lower the

left side of the blade. Pulling joystick to the

right will lower the right side of the blade.

Pitch Rolling the thumb lever to the left will

pitch the top of the blade towards the machine.

Rolling the thumb lever to the right will pitch

the top of the blade away from the machine.

The trigger switch will do the same.

Automated Blade Assist Controls A semi-automatic

dozer control that makes use of preset blade pitch

positions. This increases efciency while reducing

operator workload. It can be controlled with the

two thumb buttons on the dozer control or the push

button key pad.

D11T Electronic Ripper Control

Electronic Ripper Control A rigidly mounted

handgrip provides rm support for the operator even

when ripping in the roughest terrain. The low effort

thumb lever controls raising and lowering.

The nger lever controls shank-in and shank-out

positioning. The programmable Auto Stow feature

automatically raises the ripper to the full up position.

Programmable options are to full lift, full lift and

shank-in, or full lift and shank-out.

25 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

Automatic Ripper Control (optional) Automatic

ripper control is a new feature that reduces operator

fatigue and decreases wear and tear on the machine.

This is done by monitoring the tractor speed with

the new cab mounted Global Navigation Satellite

System (GNSS) to automatically adjust engine

speed and ripper depth to minimize track slip.

Performance Monitor The monitoring system

collects machine data and provides real-time feedback

on machine productivity to optimize performance.

Finger Tip Controls (FTC) Clustered for easy, one-

handed operation to the operators left. They control

steering, machine direction and gear selection.

Enhanced Auto Shift (EAS) A new standard

feature for the D11T and D11T CD is Enhanced

Auto Shift (EAS). EAS improves fuel efciency by

automatically selecting the optimal reverse gear and

engine speed combination based upon power train

load and desired ground speed. This feature functions

similar to an automatic transmission when traveling

in reverse. The operator can set a desired track speed

in reverse by using the upshift and downshift buttons

while using EAS, and the machine will automatically

adjust the gear and engine speed to maintain this

desired track speed. Once the track speed is set in

automatic mode no operator intervention is needed.

Autoshift This feature boosts productivity and reduces

operator fatigue by automating the transmission

settings to best match the job conditions. Autoshift

mode enables the operator to preset a forward or

reverse gear for directional changes. When activated

with the switch on the right console, an icon on the

front instrument cluster lights up. A directional shift

to the forward position will automatically shift to

either rst or second gear, based on the operators

preference. A directional shift to the reverse position

will go to the mode set up by the operator.

Modes available are:

1. 1F Auto

2. 2F Auto

3. 1F 2R

4. 2F 2R

5. 2F 1R

6. Off Manual Mode

The top banner on the Advisor screen will show

forward gear selected on the left side, center will

show reverse gear selected or reverse speed if

EAS is active.

26 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

Terrain for Grading (optional) Provides high precision

management of dozing and grading applications for

enhanced safety, productivity and efciency. The system

enables an electronic site plan to be sent to the machine

from the ofce in real-time, directing the operator

where to cut and ll. A graphical map of the design

plan and a view of the machines horizontal and vertical

position simplify operation and enhance production.

GNSS technology (centimeter-level) and in-cab

computing capabilities combine for precise grade

control. Ideal applications include roads, leach pads,

dump areas, and reclamation sites.

Autocarry (optional) Autocarry provides automatic

blade control during the carry segment of the dozing

cycle by measuring ground speed and track slip

with a robust GNSS cab mounted receiver. It will

automatically raise and lower the blade to optimize

machine productivity by maintaining a desired blade

load on the tractor. It is intended to enhance the

operators productivity in high production earthmoving

with carry distances over 30.5 m (100 ft).

D475A-5 Blade and Ripper Controls

D475A-5 Steering Control

D475A-5 Implement and Steering Controls

The D475A-5 is equipped with PCCS (Palm Command

Control System) that provides the machine control

systems. The palm command electronic controlled

travel joystick presents the operator with ne control,

but the position for the hand may be uncomfortable

to some operators for extended operating periods.

27 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

Gear shifting is done with thumb push buttons and

preset travel speed selection function is standard to

enable the operator to select forward and backward

travel speed among three preset patterns and

manual shift.

The auto-shift down function provides a controller

that monitors the engine speed, travel gear, and

travel speed. When a load is applied and the machine

travel speed is reduced and the controller automatically

shifts down.

The blade control joystick has PCC (Proportional

Pressure Control) valve and a similar type joystick

as the travel control joystick. The ripper control

lever is adjustable.

Komatsu does not offer a machine control solution like

Caterpillars Enhanced Auto Shift (EAS). EAS which

is standard on the D11T and D11T CD improves fuel

efciency by automatically selecting the optimal

reverse gear and engine speed combination based

upon power train load and desired ground speed.

28 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

D11T Operators Station

Wide Panoramic View The operator station offers

an exceptional viewing area. A large view hole in

the single-shank ripper frame provides a view of the

ripper tip. The tapered hood, notched fuel tank, and

narrow ripper carriage gives the operator a clear line

of sight to front and rear work areas. The laminated

glass door windows provide an excellent view to the

blade end bits.

The D11T has many features to increase operator

comfort such as Finger Tip Control (FTC) steering,

adjustable armrests and Cat Monitoring Display

System. The combination dash mounted instrument

cluster and the right console mounted Advisor

Monitoring System provide key machine operating

information and give the operator and service

technician insight into the machines operation and

maintenance needs. The monitoring system display

is illuminated for excellent visibility in low light and

is glare resistant for easier viewing in bright light.

The list of standard convenience features includes a

radio-ready cab, rearview mirror, air suspension seat,

76 mm (3 in) retractable seatbelt, foot rests, built-in

storage space with tie-downs, rst aid kit or other

personal items, cup holder, inside door releases,

power point plug-in and intermittent low and

high speed window wipers. Other features include:

Automatic Climate Control system Automatically

adjusts the heating and air conditioning controls to

maintain a consistent cab temperature throughout

the day. Conveniently located air circulation

vents evenly distribute airow within the cab.

Controls are located in the headliner and are

easily accessible from the operator seat.

Fuse Panel and Diagnostic Access The electrical

service compartment features a single location

fuse panel that includes a diagnostic port for the

Cat ET to connect for rapid machine diagnostics.

Comfortable Operation Standard isolation-

mounted cab reduces noise and vibration.

The cab is pre-wired for a 12-volt or 24-volt

radio, equipped with two speakers, and antenna

and a radio mount recess in the headliner. Other

features include IPOD/MP3 player ready.

Cat

Comfort Series Seat The Cat Comfort

Series Seat has eight adjustment controls

for optimal support and comfort. The thick

contoured seat cushion with adjustable 10-degree

to 15-degree tilt angle and rolled-down front

edge put less pressure on operators thighs.

Seat side bolsters restrain side-to-side movement,

especially when working on steep grades or side

slopes. Seat material contains special backing,

which is fused, not sewn, to the underside of the

fabric. The seat and suspension are designed

for 10,000-hour life. An optional heated

and ventilated seat is available for increased

operator comfort.

29 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

Visibility Arrangements (optional) The visibility

arrangements are offered with one or two cameras.

These arrangements include a camera system

and mirrors to enhance the operators visibility

of his surroundings and provide a better view of

his work tool. Mirrors are mounted to the right

and left lift cylinders. The camera system includes

a 179 mm (7 in) color display mounted to the

front dash and a 115 degree horizontal camera

mounted on the top of the ROPS. The one camera

system provides rearview visibility; the two camera

system provides additional visibility to the

ripper when using the optional larger fuel tank.

Operators Arrangement (optional) Modies

operator controls and platform to allow operator

to sit at the highest and most rearward position

and easily reach the pedals. This optional

attachment is designed to improve the visibility

for shorter operators.

Enhanced Glass with Precleaner (optional)

Two enhanced glass options are available.

Dual pane glass includes a powered precleaner

to help improve the cab air quality in debris and

dusty applications. 40 psi (275 kPa) glass is

designed to withstand external pressures up to

40 psi (275 kPa) and includes an air precleaner

with dual rear window wipers.

All of these features provide the D11T an industry

leading operator environment that provides high

productivity, efciency, and comfort.

D475A-5 Operators Station

The D475A-5 provides a new hexagonal design cab

with large tinted glass windows. The cab is mounted

using a hyper-viscous cab mounts providing shock

and vibration absorption. The operator can adjust the

seat 15 degrees to the right for improved visibility

and is tiltable for downhill dozing. The armrests are

independently adjustable to allow for individual

operator preference. The height of the blade control

armrest is adjustable in three stages. The transmission

and steering controls move with the seat.

The D475A-5 is equipped with an automatic

air conditioner. Once the operator sets a desired

temperature in the cab, the computer keeps that

temperature automatically, detecting changes of

the inside and outside temperatures and sunlight.

The cab features an insulated double oor, thicker

glass in the door and increased pressurization from

improved window seals.

Machine control buttons and interface on the console

are not within comfortable reach of the operator.

The joystick steering control increases arm movements

required for machine steering input.

Standard features include air conditioner with heater

and defroster, air-suspension seat with tilt adjustment,

double door wiper, lighting system, rearview mirror,

radio with AM/FM cassette, 76 mm (3 in) retractable

seat belt, hot and cool storage box, and sun visor.

30 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

D11T Blades

The D11T offers ve types of blades; high-capacity

universal blade (U), semi-universal blade (SU),

reclamation blade, three coal blade sizes ranging from

64 m

3

(83 yd

3

) to 75 m

3

(98 yd

3

), and a Carrydozer

blade. Additionally, the standard abrasion feature of

the SU blade and U blade extend blade life in

more severe applications. Abrasion blades are equipped

with rock guards, wear plates and extended wear life

cutting edges and end bits.

All D11T blades feature a strong box-section design

that resists twisting and cracking. Blades are made of

high tensile strength steel that stands up to the most

severe applications. Heavy moldboard construction

and hardened bolt-on cutting edges and end bits add

strength and durability. Cutting edges are made of

DH-2 steel. End bits are made of DH-3 steel

to provide maximum service life in tough materials.

The standard dual tilt feature improves load control

and allows the operator to optimize the blade pitch

angle for each portion of the dozing cycle, while a

single lever controls all blade movements, including

the optional dual tilt. Standard ABA allows the blade

pitch for load, carry, and spread to be preset.

The tag-link blade mounting brings the blade closer

to the machine for excellent maneuverability, machine

balance, and blade penetration. The tag-link also

eliminates the need for diagonal bracing because

it transfers side loads to the main frame instead of

the dozer pusharms. The design has fewer parts for

reduced wear and lower maintenance costs, and it

provides solid lateral stability and better cylinder

positioning for constant pryout independent of blade

height. In addition, having the blade closer to the

front of the machine provides more precise dozing

and load control.

D475A-5 Blades

The D475A-5 has three blade options: semi-universal

dozer, universal dozer, and coal. A super (carry)

dozer option is also available. The front and sides

of the blade use high-tensile strength steel.

The standard dual tilt feature gives twice the dozer

tilt angle and tilt speed compared to a conventional

single tilt system.

31 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

D11T Rippers and Counterweights

The D11T has optional single and multi-shank rippers

available. Rippers are made to penetrate tough

material fast and rip thoroughly for use in a variety

of materials. The standard ripper hydraulic lines are

Cat XT-3 ES hose for durability and reliability.

The (optional) Automatic Ripper Control is a new

feature that reduces operator fatigue and decreases

wear and tear on the machine. This is done by

monitoring the tractor speed with the new cab

mounted Global Navigation Satellite System

(GNSS) to automatically adjust engine speed

and ripper depth to minimize track slip.

Enhanced visibility to the tip is made possible

by the machines slotted fuel tank and large view

hole in the ripper frame. Increased strength and

productivity is realized from its large, one-piece

shank. Superior ripper carriage design features heat

treated spacer bars in the shank pocket for increased

shank life. And the ripper frame design is streamlined

and narrow for minimum clogging and slab retention.

The operator can adjust the single shank ripper depth

from the seat using a standard single-shank

hydraulic pin puller.

The multi-shank ripper tailors the tractor to the material

by using one, two or three shanks. Hydraulic pitch

adjustment cylinders vary the shank angle to get the

best penetration so the material is lifted and shattered.

On the standard D11T, Caterpillar offers the

following ripper options:

1. Single-shank standard ripper

2. Single-shank Carrydozer ripper

3. Multi-shank standard ripper

4. Multi-shank leach pad ripper

Standard and deep shanks are both available for

both Single-shank standard rippers and Single-shank

Carrydozer rippers on the standard D11T.

A Carrydozer ripper option is available for extreme

ripping applications or when rear machine weight

is needed for balance.

On the D11T Carrydozer Caterpillar offers the

following ripper options:

1. Single-shank Carrydozer ripper

2. Multi-shank Carrydozer ripper

Standard and deep shanks are both available

on the Single-shank Carrydozer ripper.

An optional leach pad ripper is available for lighter

duty ripping to a depth of 3.35 m (11 ft).

A centralized, ground access system for lubricating

single-shank and multi-shank rippers is available

as a custom attachment. The single location system

allows access to all grease ttings without the use

of a ladder or other climbing device.

32 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

If the tractor is not equipped with a ripper, an optional

rear counterweight provides proper tractor balance

to maximize dozing production.

D475A-5 Rippers and Counterweights

The D475A-5 has optional single and multi-shank

rippers available. The variable giant ripper is a

parallelogram single shank ripper with a variable

ripping angle and an adjustable depth in four stages

by a hydraulically controlled pin puller. The multi-

shank ripper is a three shank ripper with a hydraulically

controlled parallelogram where the ripping angle is

variable and has a two stage adjustable depth.

The track shoe slip control system constantly

controls engine power output with the decelerator

while ripping.

A counterweight is available as an optional

attachment.

33 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

D11T Monitoring System

Cat Monitoring Display System The combination

dash mounted instrument cluster and the right console

mounted Advisor Monitoring System provide key

machine operating information and give the operator

and service technician insight into the machines

operation and maintenance needs. The monitoring

system includes:

Alert indicators

Digital display features transmission gear,

track speed (ground speed if Global Navigation

Satellite System (GNSS) equipped), and service

hour meter

Five gauges (hydraulic oil temperature, engine

coolant temperature, fuel level, torque converter

oil temperature and engine speed)

Self tests at every start

Fault codes for easier troubleshooting

The track odometer system records total forward

and reverse distances, total fuel consumption

and other operating parameters

Menus to create/set operator proles

(machine congurations)

Support 27 languages

Machine parameter status screens

Limp home mode support available for certain

implement and steering system faults that allows

limited machine controls

The monitoring system display, with easy-to-read

gauges, indicators and warning lamps, keeps the

operator aware of machine conditions. The monitoring

system display is illuminated for excellent visibility

in low light and is glare resistant for easier viewing

in bright light.

VIMS 3G Enables your equipment to provide

detailed, up-to-the-minute data about its own

health and working conditions by monitoring key

temperatures, pressures, and more. The system gathers

historical trends, histograms, events and more for

off-board analysis. Additional subscription required.

Cat Product Link (optional) This option, standard

in most regions of the world, allows the customer

or dealer to obtain machine diagnostics and location

information remotely through satellite technology.

Product Link provides updates on service meter hours,

fuel burn, machine condition and machine location,

as well as integrated mapping/route planning and all

logged diagnostic codes. Note: Product Link

licensing not available in all areas.

34 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

D475A-5 Monitoring System

Monitor with Self-Diagnostic Function If the monitor

nds abnormalities, the corresponding warning lamp

blinks and warning buzzer sounds. When abnormalities

occur during operation, user code and service meter

are displayed alternately. When a high importance

user code is displayed, a caution lamp blinks and

warning buzzer sounds to prevent the development

of serious problems.

VHMS (Vehicle Health Monitoring System)

Monitors the condition of various components on the

machine. Self-diagnostic function alerts the operator

when it nds abnormalities. When abnormalities

occur during operation, service meter and user code

are displayed. Orbcomm is paired with VHMS to send

data through a network of satellites that allow the

VHMS data to be displayed using a secure website.

This process is supported by the Komatsu distributors,

factory and design team.

35 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

D11T Serviceability

The D11T features sight gages, convenient lter

locations, improved access to oil and coolant SOS

SM

sampling ports, and engine compartment mounted

work lamps making daily and periodic service faster

and easier. When equipped with a dozer and a ripper,

there are only 18 lube points.

Engine Oil Filters Engine oil lters are located

on the engine for easy servicing access and minimal

downtime. Service time is reduced with the high

speed oil change system.

Major components such as the engine, transmission,

brakes, and nal drives are designed as modules and

most can be removed without disturbing or removing

other components such as the cab. This means less

service time and more productivity.

Ecology drains provide an environmentally responsible

and effective way to drain uids during service

intervals. They allow uids to be drained into an

approved container. Ecology drains are included

on the radiator, hydraulic tank, engine oil tank,

torque divider and transmission.

Fast Fuel System The fast fuel system, with positive

fuel shut-off to prevent fuel spillage, can reduce fuel

waste and decrease downtime.

Ground Level Service Options The ground level

service center mounted on the ripper cylinder

provides easy access to:

Secondary engine shutoff

Access lighting switch turns on the forward

ROPS lights to light the access path to the

machine. The lights will stay on until you start

the tractor or when a congurable timer expires

(10 minute default).

Delayed lighting turns on the forward

ROPS lights to light the path when getting

off the machine.

Fast fuel

High speed engine and power train oil change

(rear location is optional)

Ok-to-Start The new Ok-to-Start strategy provides

electronic uid level verication at startup on the

power train and engine oil systems. All information

is available via the Advisor Monitoring System

within the cab.

If equipped with a ripper, the D11T offers an

optional attachment that provides ground level

access to grease the ripper pins on the single

and multi-shank rippers.

An optional rear platform converts the top of the

optional high capacity fuel tank into an access platform

with slip resistant surfaces, handrails, and kick plates.

The 1911 liter (505 U.S. gallon) fuel tank with rear

walkway is offered to provide a means of easily

cleaning the rear cab window, repairing rear mounted

lights, and providing access to the fuel ller cap in

the event that the fast fuel ll system is not being used.

Genuine Cat Remanufactured parts are available

for drive train, engine, and hydraulic components.

These components have the same warranty and

reliability as new products at cost savings of 40 percent

to 70 percent. When parts are remanufactured, about

85 percent of the energy expended during the original

manufacturing process is preserved as a result.

Features

36 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Using remanufactured parts not only saves the

customer money, but also benets the environment.

Caterpillar offers many rebuild options when most

competitive models would require replacement,

Cat equipment can be rebuilt to deliver a cost effective

second life. The extensive Certied Rebuild programs

incorporate the very latest Cat technology and critical

engineering updates into the machine at a fraction of

the cost of buying new. Caterpillar quality standards

are just as stringent the second time around because

only trained dealer service professionals and only

Cat parts are used to complete a certied rebuild.

A Cat Certied Power Train Rebuild is also an

option for customers interested in restoring life only

to their machines power train components.

The Cat dealer network of trained experts will keep

you up and running, maximizing your equipment

investment. Nearly all D11T parts can be found at

Cat dealer parts counters. Part options offered

by the dealer include piece parts, complete new

components, reman complete components, and dealer

rebuild and exchange. Cat dealers use a worldwide

computer network to nd in-stock parts to minimize

machine downtime. This will shorten repair time and

lower costs.

D475A-5 Serviceability

The D475A-5 provides a centralized service station

where the transmission and torque converter oil

lters are both arranged next to the power train oil

level gauge.

The pressure checking ports for the power train

components are centralized to promote quick and

simple diagnosis.

The modular power train design provides power train

components that can be dismounted and mounted

without oil spillage. Despite benets of no oil

spillage, the cab must be removed to service the

torque converter and transmission components.

Service of the power module requires the cab, ROPS,

operator platform, and fuel tank be removed.

Wet disc brakes require less maintenance and

provide a long service life.

Dual insulated gull-wing engine side covers

facilitate engine maintenance and lter replacement.

Side covers are a thick one-piece structure with

bolt-on latches.

Features

37 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Features

D11T Carrydozer (CD)

The D11T and D11T Carrydozer (CD) are highly

effective mass dozing tools that are ideally suited

to job applications requiring long push distances.

The D11T CDs higher operating weight and unique

carrydozer blade allow it to excel.

The frame has been designed to provide additional

durability and reliability due to the high loads

associated with the carry dozer application.

The Carrydozer blade has a unique bucket shape

that allows it to carry several cubic yards of material

inside the blade curvature for maximum productivity.

This acts as a counterweight that allows the

Carrydozer to push more material per pass than

a standard D11T. This also increases the effective

weight of the tractor which enables pushing a larger

pile of material in front of the blade. The carrying/

pushing effects combine to signicantly increase

productivity by up to 15%. The blade features a

strong box section made of high-strength, low-alloy

steel to resist twisting and cracking, and additional

wear plating is not necessary. Standard rock guards

and deector shields on the back of the blade help

protect lift and tilt cylinders from spillover. The blade

capacity is 43.6 m (57 yd).

The Carrydozer will not be as effective as the

U or SU dozer in tightly packed or poorly shot

material. It is also more sensitive to carry-back in

sticky materials.

The standard shoe size has been increased from

710 mm (28 in) to 915 mm (36 in).

The implement hydraulic pump has been resized

to match the larger blade pitch cylinders and longer

pitch length resulting in faster blade pitch cycle

times for the Carrydozer blade.

Heavier Carrydozer single and multi shank rippers

are available as optional attachments. When a ripper

is not used, an extended rear counter weight is

required for optimum tractor balance.

The operating weight for the Carrydozer is 112 698 kg

(248,456 lb). The operating weight includes lubricant,

coolant, full fuel tank, hydraulic controls and uids,

910 mm (36 in) extreme service shoes, 11 carry dozer,

single-shank ripper (optional equipment) and operator.

38 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

D475A-5 Super Dozer

The D475A-5 Super Dozer is based off of the

standard D475A-5. The Super Dozer provides a

large capacity super dozer blade providing lower

dozing resistance and provides 15% more production.

The blade capacity is 45 m (58.9 yd).

The fast fuel has become standard and the standard

shoe size has been increased from 710 mm (28 in)

to 810 mm (32 in).

Optional rear attachments include a single variable

giant ripper and counterweight.

The operating weight for the Super Dozer is

113 200 kg (249, 560 lb). The operating weight

includes strengthened super dozer blade,

counterweight, steel cab, ROPS, operator,

standard equipment, rated capacity of lubricant,

coolant, and full fuel tank.

Features

39 May 2012 TEJB9684 Cat D11T vs. Komatsu D475A-5

Summary

Caterpillar listened to customers around the world and has continued to produce a machine with an excellent

reputation for reliability, durability, and productivity. Engineered for demanding work, the D11T is designed

to be productive in a variety of applications including heavy dozing, ripping, pushing scrapers and land

clearing. The D11T will keep material moving with the reliability and low operating costs that customers

have come to expect from Cat machines.

The Cat D11T machine durability is built on the foundation of a case and frame engineered with integrated

casting design. Ride quality from the suspended undercarriage and component placement provides an

environment for more productive operation. Modular design aids in the power train repairability, which is

a class ahead of the Komatsu D475A-5. The tag-link design provides solid lateral stability and better cylinder

positions for constant break out force, independent of blade height. The standard Enhanced Auto Shift,

Automatic Blade Assist, and optional Terrain for Grading and Autocarry technology offerings provide

operational efciency improvements resulting in lower cost per ton. Enhanced safety features from the

factory such as standard heavy duty guard rails, steps, handles and optional hydraulic ladder, rear platform,

and visibility arrangement provide additional benets to the customers. These attributes of the D11T and