Professional Documents

Culture Documents

Wall Stress Procedure

Uploaded by

Phani Krishna BadipatiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wall Stress Procedure

Uploaded by

Phani Krishna BadipatiCopyright:

Available Formats

LARSEN & TOUBRO LIMITED

DATE

09.03.2010

CHECKED SHEET

CKSR

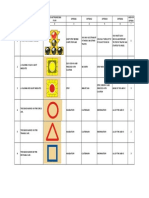

WALL ID : ELEVATION 1 GRIDS A-F

FLOOR ID : 1STFLOOR

TENS COMP TENS COMP TENS COMP TENS COMP

1 0 -3.73 0.89 -2.43 0 -7.92 0 -6.17

2 max 1.15 -3.2 1.24 -2.12 0 -5.95 0 -4.24

2 min 0 -3.01 0.47 -1.76 0 -6.72 0 -5.62

4 max 0.07 -3.46 0.9 -2.14 0.4 -5.84 0 -4.03

4 min 0 -3.02 0.53 -1.77 0 -6.83 0 -5.83

6 max 0.24 -3.5 1.43 -2.32 0 -6.37 0 -4.47

6 min 0 -3.34 0.46 -1.88 0 -7.34 0 -6.19

8 max 0.1 -3.82 1 -2.34 0.42 -6.24 0 -4.2

8 min 0 -3.36 0.54 -1.91 0 -7.47 0 -6.46

10 max 1.12 -2.21 1.7 -1.48 0.62 -3.63 0 -2.54

10 min 0 -2.31 0.16 -1.13 0 -4.69 0 -4.22

12 max 1.05 -2.53 0.73 -1.5 0.89 -3.5 0 -2.07

12 min 0 -2.33 0.24 -1.33 0 -4.73 0 -4.33

L/C 2max 8max 10max 1 12max 1 8 max 8min

Stress (N/mm

2

) 1.15 -3.82 1.7 -2.43 0.89 -7.92 0 -6.46

Average mesh size provided in the model = 600 mm x 600 mm

150 mm

S22 + S12 (N/sq.mm)

PIER

ADJACENT TO

OPENING PIER ADJACENT TO OPENING

EDRC B&F OC

O9021-C-TS-07-DC-0001

L/C

S11 + S12 (N/sq.mm)

Thickness of RC wall =

DOCUMENT NO.

DESIGNED

PROJECT:

TITLE : Block-C02 Design calculation for RC walls

Manabhavana Township at Bachupally for

APRSCL - PHASE - 1

Maximum stress values:

LARSEN & TOUBRO LIMITED

DATE

09.03.2010

CHECKED SHEET

CKSR

EDRC B&F OC

O9021-C-TS-07-DC-0001

DOCUMENT NO.

DESIGNED

PROJECT:

TITLE : Block-C02 Design calculation for RC walls

Manabhavana Township at Bachupally for

APRSCL - PHASE - 1

30 N/mm

2

415 N/mm

2

0.4 x fck

= 0.4 x 30 = 12 N/mm

2

=

Horizontal compressive stress in concrete (S11 + S12) (N/mm2) :

3.82 < 12 (N/mm

2

)

Minimum steel is sufficient

Therefore provide 8 mm # rod @ 250 mm c/c in 2 layers

402.12 mm

2

2.43 < 12 (N/mm

2

)

Minimum steel is sufficient

Therefore provide 8 mm # rod @ 250 mm c/c in 2 layers

402.12 mm

2

vertical compressive stress in concrete (S22 + S12) (N/mm2) :

7.92 < 12 (N/mm

2

)

Minimum steel is sufficient

Therefore provide 8 mm # rod @ 250 mm c/c in 2 layers

402.12 mm

2

6.46 < 12 (N/mm

2

)

Minimum steel is sufficient

Therefore provide 8 mm # rod @ 250 mm c/c in 2 layers

402.12 mm

2

Horizontal tensile stress in concrete (S11 + S12) N/mm

2

:

1.15

103.5 kN

477.77 mm

2

Force in plate element =

ADJACENT TO OPENING =

PIER =

PIER =

ADJACENT TO OPENING =

(Actual stress - Permissible stress) / 0.67 fy

Grade of steel =

Grade of concrete =

PIER =

Steel to be provided for compressive

stress

Steel required =

Steel provided =

Steel provided =

Steel provided =

Steel provided =

Permissible compressive stress in concrete =

The wall is designed as a column member in which the compressive strength of concrete should not

exceed 0.4 fck. (As per clause 39.3 - IS 456-2000)

LARSEN & TOUBRO LIMITED

DATE

09.03.2010

CHECKED SHEET

CKSR

EDRC B&F OC

O9021-C-TS-07-DC-0001

DOCUMENT NO.

DESIGNED

PROJECT:

TITLE : Block-C02 Design calculation for RC walls

Manabhavana Township at Bachupally for

APRSCL - PHASE - 1

Therefore provide 8 mm # rod @ 150 mm c/c in 2 layers

670.21 mm

2

Hence ok

Steel provided =

LARSEN & TOUBRO LIMITED

DATE

09.03.2010

CHECKED SHEET

CKSR

EDRC B&F OC

O9021-C-TS-07-DC-0001

DOCUMENT NO.

DESIGNED

PROJECT:

TITLE : Block-C02 Design calculation for RC walls

Manabhavana Township at Bachupally for

APRSCL - PHASE - 1

1.7

153 kN

706.27 mm

2

Therefore provide 8 mm # rod @ 100 mm c/c in 2 layers

1005.31 mm

2

Hence ok

Vertical tensile stress in concrete (S22 + S12) (N/mm

2

) :

0.89

80.1 kN

369.75 mm

2

Therefore provide 8 mm # rod @ 200 mm c/c in 2 layers

502.65 mm

2

Hence ok

0

0 kN

0.00 mm

2

Therefore provide 10 mm # rod @ 125 mm c/c in 2 layers

1256.64 mm

2

Hence ok

Force in plate element =

Steel required =

Force in plate element =

Steel required =

ADJACENT TO OPENING =

PIER =

ADJACENT TO OPENING =

Force in plate element =

Steel required =

Steel provided =

Steel provided =

Steel provided =

LARSEN & TOUBRO LIMITED

DATE

09.03.2010

CHECKED SHEET

CKSR

EDRC B&F OC

O9021-C-TS-07-DC-0001

DOCUMENT NO.

DESIGNED

PROJECT:

TITLE : Block-C02 Design calculation for RC walls

Manabhavana Township at Bachupally for

APRSCL - PHASE - 1

Design of spandrels:

WALL ID : ELEVATION 1 GRIDS A-F

FLOOR ID :

TENS COMP TENS COMP

1 0.70 -0.49 0.00 -1.83

2 max 0.90 -0.53 0.00 -1.47

2 min 0.2 -0.82 0 -1.85

4 max 0.73 -0.23 0 -1.15

4 min 0.38 0.59 0 -1.78

6 max 1.04 -0.6 0 -1.59

6 min 0.17 -0.96 0 -2.11

8 max 0.82 -0.24 0 -1.19

8 min 0.38 -0.67 0 -1.97

10 max 0.8 -0.5 0 -0.97

10 min 0 -0.79 0 -1.6

12 max 0.58 -0.13 0 -0.56

12 min 0.14 -0.5 0 -1.34

L/C 6max 6min 4 min 6min

Stress (N/mm

2

) 1.04 -0.96 0 -2.11

Maximum mesh size provided in the model = 900 mm x 800 mm

150 mm

L/C

Stress in plates for spandrel design

S11 + S12 (N/sq.mm) S22 + S12 (N/sq.mm)

Maximum stress values:

Thickness of RC wall =

LARSEN & TOUBRO LIMITED

DATE

09.03.2010

CHECKED SHEET

CKSR

EDRC B&F OC

O9021-C-TS-07-DC-0001

DOCUMENT NO.

DESIGNED

PROJECT:

TITLE : Block-C02 Design calculation for RC walls

Manabhavana Township at Bachupally for

APRSCL - PHASE - 1

30 N/mm

2

415 N/mm

2

0.4 x fck

= 0.4 x 25 = 12 N/mm

2

=

Horizontal compressive stress in concrete (S11 + S12) (N/mm2) :

0.96 < 12 (N/mm

2

)

Minimum steel is sufficient

Therefore provide 8 mm # rod @ 250 mm c/c in 2 layers

402.12

Hence ok

vertical compressive stress in concrete (S22 + S12) (N/mm2) :

2.11 < 12 (N/mm

2

)

Minimum steel is sufficient

Therefore provide 8 mm # rod @ 250 mm c/c in 2 layers

402.12

Hence ok

Horizontal tensile stress in concrete (S11 + S12) N/mm

2

:

1.04

124.8 kN

345.66 mm

2

Therefore provide 8 mm # rod @ 175 mm c/c in 2 layers

574.46

Hence ok

Vertical tensile stress in concrete (S22 + S12) (N/mm

2

) :

0 (

v

)

Maximum compressive stress =

The compressive strength in the concrete should not exceed 0.4 fck. (As per clause 14.2.2 - IS 456-2000)

Grade of concrete =

Steel provided =

Grade of steel =

Permissible compressive stress in concrete =

Note: If compressive stress of concrete exceeds the permissible limit, then steel is to be provided for

remaining stress

Steel to be provided for compressive

stress

(Actual stress - Permissible stress) / 0.67 fy

Force in plate element =

Steel provided =

Steel provided =

Maximum compressive stress =

Maximum tensile stress =

Steel required =

Maximum tensile stress =

LARSEN & TOUBRO LIMITED

DATE

09.03.2010

CHECKED SHEET

CKSR

EDRC B&F OC

O9021-C-TS-07-DC-0001

DOCUMENT NO.

DESIGNED

PROJECT:

TITLE : Block-C02 Design calculation for RC walls

Manabhavana Township at Bachupally for

APRSCL - PHASE - 1

0 kN

c =

V / bd = 0.000

Hence OK

Therefore provide the nominal steel of Y8 @ 250 c/c as shear reinforcement

Force in plate element =

LARSEN & TOUBRO LIMITED

DATE

09.03.2010

CHECKED SHEET

WALL ID : ELEVATION 4 GRIDS A-F

FLOOR ID : 1STFLOOR

TENS COMP TENS COMP TENS COMP TENS COMP

1 0 -1.95 1.51 -2.03 0 -8.84 0 -2.84

2 max 0.3 -1.59 1.41 -1.3 0 -6.8 0 -1.87

2 min 0 -1.52 1.01 -1.94 0 -7.34 0 -2.97

4 max 0 -1.55 1.34 -1.55 0 -7.31 0 -2.01

4 min 0 -1.56 0.53 -1.77 0 -7.98 0 -3.33

6 max 0.35 -1.72 1.61 -1.35 0 -4.25 0 -1.23

6 min 0 -1.64 1.07 -2.15 0 -5.77 0 -2.36

8 max 0 -1.67 1.48 -1.66 0 -6.71 0 -2.02

8 min 0 -1.69 1.16 -1.84 0 -8.58 0 -2.88

10 max 0.41 -1.05 1.15 -0.65 0 -4.25 0 -1.23

10 min 0 -1.03 0.54 -1.49 0 -5.77 0 -2.36

12 max 0.06 -1 0.95 -0.96 0 -3.65 0 -1.13

12 min 0 -1.02 0.64 -1.14 0 -5.52 0 -1.89

L/C 10max 1 6max 6min 12max 1 8 max 4min

Stress (N/mm

2

) 0.41 -1.95 1.61 -2.15 0 -8.84 0 -3.33

Average mesh size provided in the model = 600 mm x 600 mm

150 mm

EDRC B&F OC

PROJECT:

Manabhavana Township at Bachupally for

APRSCL - PHASE - 1

DOCUMENT NO.

O9021-C-TS-07-DC-0001

TITLE : Block-C02 Design calculation for RC walls

DESIGNED

L/C

S11 + S12 (N/sq.mm) S22 + S12 (N/sq.mm)

PIER

ADJACENT TO

OPENING PIER ADJACENT TO OPENING

Maximum stress values:

Thickness of RC wall =

The wall is designed as a column member in which the compressive strength of concrete should not

exceed 0.4 fck. (As per clause 39.3 - IS 456-2000)

LARSEN & TOUBRO LIMITED

DATE

09.03.2010

CHECKED SHEET

EDRC B&F OC

PROJECT:

Manabhavana Township at Bachupally for

APRSCL - PHASE - 1

DOCUMENT NO.

O9021-C-TS-07-DC-0001

TITLE : Block-C02 Design calculation for RC walls

DESIGNED

30 N/mm

2

415 N/mm

2

0.4 x fck

= 0.4 x 30 = 12 N/mm

2

=

Horizontal compressive stress in concrete (S11 + S12) (N/mm2) :

1.95 < 12 (N/mm

2

)

Minimum steel is sufficient

Therefore provide 8 mm # rod @ 250 mm c/c in 2 layers

402.12 mm

2

2.15 < 12 (N/mm

2

)

Minimum steel is sufficient

Therefore provide 8 mm # rod @ 250 mm c/c in 2 layers

402.12 mm

2

vertical compressive stress in concrete (S22 + S12) (N/mm2) :

8.84 < 12 (N/mm

2

)

Minimum steel is sufficient

Therefore provide 8 mm # rod @ 250 mm c/c in 2 layers

402.12 mm

2

3.33 < 12 (N/mm

2

)

Minimum steel is sufficient

Therefore provide 8 mm # rod @ 250 mm c/c in 2 layers

402.12 mm

2

Horizontal tensile stress in concrete (S11 + S12) N/mm

2

:

0.41

36.9 kN

170.34 mm

2

Therefore provide 8 mm # rod @ 150 mm c/c in 2 layers

670.21 mm

2

Grade of concrete =

Grade of steel =

Permissible compressive stress in concrete =

Steel to be provided for compressive

stress

(Actual stress - Permissible stress) / 0.67 fy

PIER =

Steel provided =

ADJACENT TO OPENING =

Steel provided =

PIER =

Steel provided =

ADJACENT TO OPENING =

Steel provided =

PIER =

Force in plate element =

Steel required =

Steel provided =

LARSEN & TOUBRO LIMITED

DATE

09.03.2010

CHECKED SHEET

EDRC B&F OC

PROJECT:

Manabhavana Township at Bachupally for

APRSCL - PHASE - 1

DOCUMENT NO.

O9021-C-TS-07-DC-0001

TITLE : Block-C02 Design calculation for RC walls

DESIGNED

Hence ok

1.61

144.9 kN

668.88 mm

2

Therefore provide 8 mm # rod @ 100 mm c/c in 2 layers

1005.31 mm

2

Hence ok

Vertical tensile stress in concrete (S22 + S12) (N/mm

2

) :

0

0 kN

0.00 mm

2

Therefore provide 8 mm # rod @ 200 mm c/c in 2 layers

502.65 mm

2

Hence ok

0

0 kN

0.00 mm

2

Therefore provide 10 mm # rod @ 125 mm c/c in 2 layers

1256.64 mm

2

Hence ok

Design of spandrels:

WALL ID : ELEVATION 1 GRIDS A-F

FLOOR ID :

TENS COMP TENS COMP

1 1.21 -1.61 0.00 -6.97

ADJACENT TO OPENING =

Force in plate element =

Steel required =

Steel provided =

PIER =

Force in plate element =

Steel required =

Steel provided =

ADJACENT TO OPENING =

Force in plate element =

Steel required =

Steel provided =

L/C

Stress in plates for spandrel design

S11 + S12 (N/sq.mm) S22 + S12 (N/sq.mm)

LARSEN & TOUBRO LIMITED

DATE

09.03.2010

CHECKED SHEET

EDRC B&F OC

PROJECT:

Manabhavana Township at Bachupally for

APRSCL - PHASE - 1

DOCUMENT NO.

O9021-C-TS-07-DC-0001

TITLE : Block-C02 Design calculation for RC walls

DESIGNED

2 max 1.13 -1.34 0.00 -4.8

2 min 0 -1.47 0 -6.79

4 max 1.18 -1.39 0 -5.14

4 min 0 -1.45 0 -7.61

6 max 1.25 -1.47 0 -2.97

6 min 0 -1.64 0 -5.42

8 max 1.31 -1.52 0 -4.99

8 min 0 -1.61 0 -7.12

10 max 0.83 -0.91 0 -2.97

10 min 0 -1.13 0 -5.42

12 max 0.89 -0.97 0 -2.58

12 min 0 -1.1 0 -4.77

L/C 6max 6min 4 min 4min

Stress (N/mm

2

) 1.31 -1.64 0 -7.61

Maximum mesh size provided in the model = 900 mm x 800 mm

150 mm

30 N/mm

2

415 N/mm

2

0.4 x fck

= 0.4 x 25 = 12 N/mm

2

=

Maximum stress values:

Thickness of RC wall =

The compressive strength in the concrete should not exceed 0.4 fck. (As per clause 14.2.2 - IS 456-2000)

Grade of concrete =

Grade of steel =

Permissible compressive stress in concrete =

Note: If compressive stress of concrete exceeds the permissible limit, then steel is to be provided for

remaining stress

Steel to be provided for compressive

stress

(Actual stress - Permissible stress) / 0.67 fy

LARSEN & TOUBRO LIMITED

DATE

09.03.2010

CHECKED SHEET

EDRC B&F OC

PROJECT:

Manabhavana Township at Bachupally for

APRSCL - PHASE - 1

DOCUMENT NO.

O9021-C-TS-07-DC-0001

TITLE : Block-C02 Design calculation for RC walls

DESIGNED

Horizontal compressive stress in concrete (S11 + S12) (N/mm2) :

1.64 < 12 (N/mm

2

)

Minimum steel is sufficient

Therefore provide 8 mm # rod @ 250 mm c/c in 2 layers

402.12

Hence ok

vertical compressive stress in concrete (S22 + S12) (N/mm2) :

7.61 < 12 (N/mm

2

)

Minimum steel is sufficient

Therefore provide 8 mm # rod @ 250 mm c/c in 2 layers

402.12

Hence ok

Horizontal tensile stress in concrete (S11 + S12) N/mm

2

:

1.31

157.2 kN

435.40 mm

2

Therefore provide 8 mm # rod @ 175 mm c/c in 2 layers

574.46

Hence ok

Vertical tensile stress in concrete (S22 + S12) (N/mm

2

) :

0 (

v

)

0 kN

c =

V / bd = 0.000

Hence OK

Therefore provide the nominal steel of Y8 @ 250 c/c as shear reinforcement

Maximum compressive stress =

Steel provided =

Steel provided =

Maximum tensile stress =

Force in plate element =

Maximum compressive stress =

Steel provided =

Maximum tensile stress =

Force in plate element =

Steel required =

You might also like

- PE Civil Engineering - Structural Exam SpecsDocument6 pagesPE Civil Engineering - Structural Exam SpecsCristina Garzozi100% (1)

- Pipe Rack Design Philosophy GuideDocument8 pagesPipe Rack Design Philosophy Guidegk80823100% (1)

- Outstanding of Amee EnterpriseDocument1 pageOutstanding of Amee EnterprisePhani Krishna BadipatiNo ratings yet

- 3.0-Load Data Summary For Cpau 11-IfcDocument33 pages3.0-Load Data Summary For Cpau 11-IfcPhani Krishna BadipatiNo ratings yet

- Column Design ExcelDocument10 pagesColumn Design ExcelPhani Krishna Badipati100% (1)

- Ew15 Module 2 MassDocument17 pagesEw15 Module 2 MassPhani Krishna BadipatiNo ratings yet

- Learning Licence Test Road-signs-EnglishDocument15 pagesLearning Licence Test Road-signs-Englishu2mailrahulNo ratings yet

- Account Ledger of Amee EnterDocument5 pagesAccount Ledger of Amee EnterPhani Krishna BadipatiNo ratings yet

- Shiv Shakti HotalDocument4 pagesShiv Shakti HotalPhani Krishna BadipatiNo ratings yet

- Civil & Building Design SpecificationDocument200 pagesCivil & Building Design SpecificationPhani Krishna Badipati100% (2)

- Netbill 14 04 16Document1 pageNetbill 14 04 16Phani Krishna BadipatiNo ratings yet

- Civil Design HelpDocument4 pagesCivil Design HelpRanjan ParajuliNo ratings yet

- Phani PanDocument2 pagesPhani PanPhani Krishna BadipatiNo ratings yet

- Learning Licence Test Road-signs-EnglishDocument15 pagesLearning Licence Test Road-signs-Englishu2mailrahulNo ratings yet

- Combined Footing DesignDocument5 pagesCombined Footing DesignRana ImranNo ratings yet

- Shree Balaji Test House Pvt. Ltd. Geotechnical ReportDocument64 pagesShree Balaji Test House Pvt. Ltd. Geotechnical ReportPhani Krishna BadipatiNo ratings yet

- M.tech - Marks ListshDocument2 pagesM.tech - Marks ListshPhani Krishna BadipatiNo ratings yet

- Pipe Rack Support Structures CommentsDocument2 pagesPipe Rack Support Structures CommentsPhani Krishna BadipatiNo ratings yet

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document2 pagesIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Phani Krishna BadipatiNo ratings yet

- HelloDocument1 pageHelloPhani Krishna BadipatiNo ratings yet

- Moral Din Fight With Idiot FoxDocument1 pageMoral Din Fight With Idiot FoxPhani Krishna BadipatiNo ratings yet

- Combined Footing DesignDocument5 pagesCombined Footing DesignRana ImranNo ratings yet

- Goin Towards MoralDocument1 pageGoin Towards MoralPhani Krishna BadipatiNo ratings yet

- 4Document1 page4Phani Krishna BadipatiNo ratings yet

- I Want A Book: in Steel StructuresDocument1 pageI Want A Book: in Steel StructuresPhani Krishna BadipatiNo ratings yet

- Structural Design Bolted Welded ConnectionsDocument52 pagesStructural Design Bolted Welded ConnectionsBergadamusNo ratings yet

- HowruDocument1 pageHowruPhani Krishna BadipatiNo ratings yet

- I Came To Nellore: Ie Was Good Place To StayDocument1 pageI Came To Nellore: Ie Was Good Place To StayPhani Krishna BadipatiNo ratings yet

- New Microsoft Office PowerPoint PresentationDocument1 pageNew Microsoft Office PowerPoint PresentationGbsReddyNo ratings yet

- I Want A Book: in Steel StructuresDocument1 pageI Want A Book: in Steel StructuresPhani Krishna BadipatiNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)