Professional Documents

Culture Documents

Data Sheet: Description

Uploaded by

EDUARDOOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet: Description

Uploaded by

EDUARDOCopyright:

Available Formats

Rev: 0

1 Rev DESCRIPTION

2 Code: ASME VIII DIV 1 Top head 2:1 S.E./Torispherical/Hemisperical

3 Service: Bottom head 2:1 S.E./Torispherical/Hemisperical

4 Cone

5 DESIGN DATA APPURTENANCES

6 Pressure Design kPag

7 Opp kPag

8 Vac mmHg

9 Test kPag

10 Temperature Design C

11 Opp C

12 MDMT C

13 Design liquid level (from BTL) m

14 Fluid

15 Specific Gravity

16 Vapour pressure

17 Corrosion allowance - shell mm FOUNDATION DETAILS ( By Vendor )

18 - heads mm Overturning Moment @ Base kNm

19 Corrosive Constituents Shear Force @ Base kN

20 Joint efficiency Shell Anchor Bolt Allow. Stress Mpa

21 Head No. of bolts

22 Supports Legs Platform Load kN

23 Internals Base ring: OD mm

24 ID mm

25 Diameter - shell mm PCD mm

26 Height (shell, tan/tan) mm Thk mm

27 Nominal Capacity m

3

Chair height mm

28 Working Capacity m

3

29 PWHT INSULATION

30 Test Fluid Material

31 Wind design Thickness mm

32 Earthquake design Ins. Supports

33 SPARES MASS (Estimated) ( By Vendor )

34 5% bolting Empty (excl int.) kg

35 Gaskets: 1 for all blanked nozzles and manholes Internals kg

36 Opp kg

37 Test kg

38

39

38

39 MATERIAL OF CONSTRUCTION

40 Shell Stiffeners

41 Top head Internals - plate

42 Bottom head Internals - pipe

43 Supports Insul. Support rings

44 Nozzles - plate Clips., Misc. steel

45 Nozzles - pipe Bolts / studs - Internal

46 Flanges - forging Bolts / studs - External

47 Flanges - plate Nuts - Internal

48 Nozzle reinforcement Nuts - External

49 Lining Thk (mm) Gaskets By Vendor

50

51

DATE BY CHK'D APP'D

Plant/Area: Equip. No:

Client:

DATA SHEET

Project: VESSELS

REVISION LOG

REV: DESCRIPTION

ADL Doc. No: ENG-DAT-000106

WO #: Equip. Name:

Agitator

Packing

Baffles

Vortex Breaker

Lifting Lugs

Trunions

Grounding Lugs

Trays

Downcomers

Distributor

Stilling Wells

Packing Supports

Packing/Bed Limiter

Pipe Support Brackets

Pipe Supports

Platform Brackets

Ladder Brackets

Platforms

Handrails

Ladders

Other:

Source Doc: DS.131.0042M.CAL.R00 1 of 6

Rev: 0

Plant/Area: Equip. No:

Client:

DATA SHEET

Project: VESSELS

ADL Doc. No: ENG-DAT-000106

WO #: Equip. Name:

1 Rev TESTING PAINTING

2 Hydrotest (shop) Shell/heads Surface prep

3 X-ray Primer

4 Impact Testing Vendor to Advise Final

5 Bottom: Surface prep

6 Primer

7 Final

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

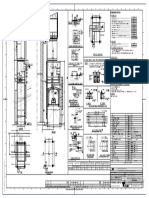

34 SKETCH IS AN EXAMPLE - ALTERNATE SKETCHES MAY BE SELECTED OR MODIFIED FROM ATTACHED PAGES

35

36 NOZZLE SCHEDULE

37 Mark Size Designation/service Rat/type Facing Proj Ext Proj Int Remarks

38 N1

39 N2

38 N3

39 N4

40 N5

41 N6

42 M1

43 M2

44 D1

45 V1

46 L1

47 L2

EL. -x.xx m (Tan line)

Demister Pad

L1A

L1B

L2A

L2B

N1 N2

N5A N5B

N3

V1 N6

D1

N

M1

EL. 0.00 m (Tan line)

EL. x.xx m (Tan line)

ID = xxx mm

Yes No

None Spot Full

Source Doc: DS.131.0042M.CAL.R00 2 of 6

Rev: 0

Plant/Area: Equip. No:

Client:

DATA SHEET

Project: VESSELS

ADL Doc. No: ENG-DAT-000106

WO #: Equip. Name:

1 Rev Nozzle loads (process nozzles only)

2 Fr (kN) Fc (kN) Fl (kN) Mt (kNm) Mc (kNm) Ml (kNm) Remarks

3 NPS 50 2"

4 NPS 80 3"

5 NPS 100 4"

6 NPS 150 6"

7 NPS 200 8"

8 NPS 250 10"

9 NPS 300 12"

10 NPS 350 14"

11 NPS 400 16"

12 NPS 450 18"

13 NPS 500 20"

14 NPS 600 24"

15 NPS 750 30"

16 AGITATOR

17 Note: Adequate nozzle compensation to be added for nozzle loads.

18 NOTES:

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

38

39

40

41

42

43

44

45

46

47

48

49

50

51

Source Doc: DS.131.0042M.CAL.R00 3 of 6

SKETCHES

HLL

Page 4

PARTS

NOZZLES INTERNALS

Vortex Breaker

Nx

Lxx

Mx

Dx

Nx

L2B

Nx

Mx

Nx

Demister Pad

Nx

Nx

Nx

Nx

Nx

Dx

Nx

Heating Coil

Mx

Mx

Page 5

PARTS

SUPPORTS MISC

EL. x.xx m (Tan line)

Page 6

You might also like

- Storage Tanks CalculationsDocument21 pagesStorage Tanks Calculationsjimallen21288% (26)

- Moldavite Ukazka PDFDocument15 pagesMoldavite Ukazka PDFNeven Žižić100% (1)

- CycloneDocument1 pageCycloneEDUARDO100% (1)

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Document12 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Document12 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDONo ratings yet

- 830 CB 120 M07 - Rev0Document1 page830 CB 120 M07 - Rev0EDUARDONo ratings yet

- T316Document5 pagesT316ANKIT SHARMA100% (1)

- AWS D1.1 Short Code Tests #3Document4 pagesAWS D1.1 Short Code Tests #3Malcolm DiamondNo ratings yet

- Gear CalculationDocument58 pagesGear CalculationSachin KubasadNo ratings yet

- Data Sheet: Hydraulic Power UnitDocument3 pagesData Sheet: Hydraulic Power UnitEDUARDONo ratings yet

- 4 KL Reactor Data SheetDocument4 pages4 KL Reactor Data Sheetpankil patelNo ratings yet

- Datasheet Phe OnwjDocument1 pageDatasheet Phe OnwjMamank Ira Sudrajat100% (1)

- E-03.0) General Static-Mixing Customer Specification QuestionnaireDocument2 pagesE-03.0) General Static-Mixing Customer Specification QuestionnaireimyourscinNo ratings yet

- Control Valve Sizing: Unit L m3/d 1800 1.03 Bar 8.2 Bar 7.2 Bar 1 °C 120 Bar in 3 in 4Document4 pagesControl Valve Sizing: Unit L m3/d 1800 1.03 Bar 8.2 Bar 7.2 Bar 1 °C 120 Bar in 3 in 4ghandri1986No ratings yet

- Pressure Vessel: General DescriptionDocument4 pagesPressure Vessel: General DescriptionTiny Tấn MinhNo ratings yet

- Transmission Insulator SpecificationDocument0 pagesTransmission Insulator Specificationrenjithas2005No ratings yet

- Sample8 DrawingDocument1 pageSample8 DrawingRam Kumar NNo ratings yet

- Mechanical Data Sheet Pressure Vessel: GeneralDocument2 pagesMechanical Data Sheet Pressure Vessel: GeneralEDUARDONo ratings yet

- Analyzer Sample Systems Ver HappenDocument12 pagesAnalyzer Sample Systems Ver HappenIñaki Eseberri100% (1)

- Steam BoilerDocument10 pagesSteam BoilerEDUARDONo ratings yet

- ZAU 256 MS 2105 00003 0001 A01 Datasheet For Produced Water Storage Vessel (V 8421)Document6 pagesZAU 256 MS 2105 00003 0001 A01 Datasheet For Produced Water Storage Vessel (V 8421)Vijayaraj KumarNo ratings yet

- Durban Classic Cover + Caposide in One Side (Shougang Project)Document4 pagesDurban Classic Cover + Caposide in One Side (Shougang Project)EDUARDONo ratings yet

- Hid Ro CycloneDocument1 pageHid Ro CycloneEDUARDONo ratings yet

- Mechanical Data Sheet Tanks: DescriptionDocument2 pagesMechanical Data Sheet Tanks: DescriptionEDUARDONo ratings yet

- Gfts Tank Model 140 17.5 Ø42.69 M, Nominal Volume 6170 M : ConfidentialDocument3 pagesGfts Tank Model 140 17.5 Ø42.69 M, Nominal Volume 6170 M : ConfidentialFathurrachman RachmanNo ratings yet

- Silencer Data Sheet ReviewDocument2 pagesSilencer Data Sheet ReviewEDUARDONo ratings yet

- 820 CB 120G WM25 - Rev0Document1 page820 CB 120G WM25 - Rev0EDUARDONo ratings yet

- Evapco Evaporative Condenser Engineering ManualDocument32 pagesEvapco Evaporative Condenser Engineering Manualrodolfocv923590% (1)

- RNZ Integrated (M) SDN BHD: Calculation SheetDocument14 pagesRNZ Integrated (M) SDN BHD: Calculation SheetNhantran VanNo ratings yet

- JSW Steel Dust Extraction System ISO Format DesignDocument1 pageJSW Steel Dust Extraction System ISO Format DesignHemant PatilNo ratings yet

- Pipe Bends Specification PDFDocument4 pagesPipe Bends Specification PDFToniNo ratings yet

- Axial ThrustDocument2 pagesAxial ThrustGerman ToledoNo ratings yet

- HRD Hot Water Pump P001Document6 pagesHRD Hot Water Pump P001nguyenquoc1988No ratings yet

- Titanium Bellows Design CalculationsDocument8 pagesTitanium Bellows Design CalculationsNamıkNo ratings yet

- Gas Scrubbers: DescriptionDocument14 pagesGas Scrubbers: DescriptionPitiporn HasuankwanNo ratings yet

- XTR 0107 Rev1Document6 pagesXTR 0107 Rev1anand shekhawatNo ratings yet

- Heat Exchanger Ball Cleaning Package Data SheetDocument2 pagesHeat Exchanger Ball Cleaning Package Data SheetEDUARDONo ratings yet

- Sewage Treatment PlantDocument2 pagesSewage Treatment PlantEDUARDONo ratings yet

- PIPE THICKNESS CALCULATIONDocument11 pagesPIPE THICKNESS CALCULATIONvazzoleralex6884100% (1)

- FLANGE DN800 PN40Document35 pagesFLANGE DN800 PN40fsalminNo ratings yet

- Mechanical Design SpreadsheetDocument1 pageMechanical Design SpreadsheetHoney TiwariNo ratings yet

- Reff: A Text Book of Machine Design - Chapter 10, RS. KHURMIDocument5 pagesReff: A Text Book of Machine Design - Chapter 10, RS. KHURMIAsep MulyadiNo ratings yet

- Sewage Treatment Tank MixerDocument1 pageSewage Treatment Tank MixerEDUARDONo ratings yet

- Data Sheet For T-8101.RevCDocument5 pagesData Sheet For T-8101.RevCSuresh SjNo ratings yet

- Calculation Cover Sheet: ClientDocument8 pagesCalculation Cover Sheet: Clientanamaria ursuNo ratings yet

- Plate Exchanger Performance and Design DataDocument2 pagesPlate Exchanger Performance and Design DataEDUARDONo ratings yet

- 5720 D E DWG 0201 - RevADocument4 pages5720 D E DWG 0201 - RevAEDUARDONo ratings yet

- Model Designation KEE-1-2Document10 pagesModel Designation KEE-1-2Wahyu ANo ratings yet

- L028 Me Dat 01 00122 001 00Document8 pagesL028 Me Dat 01 00122 001 00sivasan10006098No ratings yet

- S.no Description Data For ApprovalDocument2 pagesS.no Description Data For ApprovalVenkatNo ratings yet

- Data Sheet: Operating ConditionsDocument2 pagesData Sheet: Operating ConditionsEDUARDONo ratings yet

- G+1 Residential Building Architectural DrawingsDocument36 pagesG+1 Residential Building Architectural DrawingsTokio87No ratings yet

- 820 CB 120G WM26 - Rev0Document1 page820 CB 120G WM26 - Rev0EDUARDONo ratings yet

- Heater DataDocument2 pagesHeater DataEDUARDONo ratings yet

- Data Sheet: Description Unit Design DataDocument1 pageData Sheet: Description Unit Design DataEDUARDONo ratings yet

- Power Calculation For AgitatorDocument12 pagesPower Calculation For AgitatorDeepikaNo ratings yet

- Dual Plate Check ValveDocument38 pagesDual Plate Check ValveVikas Kumar PathakNo ratings yet

- Pressure Vessels (Project Standards and Specifications) : Page: 1 of 21Document6 pagesPressure Vessels (Project Standards and Specifications) : Page: 1 of 21Tafe AdamuNo ratings yet

- Mixer design parametersDocument2 pagesMixer design parametersEDUARDONo ratings yet

- A11Document1 pageA11liviu_dovaNo ratings yet

- Plant Engineers Fan Design ReferenceDocument23 pagesPlant Engineers Fan Design ReferenceKumaran GopalNo ratings yet

- BN MLS 21 PTSC 307526Document1 pageBN MLS 21 PTSC 307526mailmaverick8167No ratings yet

- 62577A Calculation of Orifice Coefficient Si UnitsDocument18 pages62577A Calculation of Orifice Coefficient Si UnitsUary Buza RegioNo ratings yet

- PlateDocument3 pagesPlateAdnan RanaNo ratings yet

- Carbon Steel and Alloy Steel FastenersDocument2 pagesCarbon Steel and Alloy Steel FastenersagnisivadasanNo ratings yet

- Yanbu: Export Refinery ProjectDocument8 pagesYanbu: Export Refinery ProjectJanakiraman MalligaNo ratings yet

- BELT CONVEYOR DESIGN EXAMPLEDocument10 pagesBELT CONVEYOR DESIGN EXAMPLESergio DiazNo ratings yet

- Cahpter 5 Special SteelDocument50 pagesCahpter 5 Special SteelhealgoseNo ratings yet

- Yanbu: Export Refinery ProjectDocument8 pagesYanbu: Export Refinery ProjectJanakiraman MalligaNo ratings yet

- Project: Date Jobno: Designed ACTIVITY: Utility Pipe/ Valve Workshop Checked SheetDocument36 pagesProject: Date Jobno: Designed ACTIVITY: Utility Pipe/ Valve Workshop Checked SheetGeorge Georgian100% (1)

- Technical Data: 150x125 CNHA 5 18.5Document5 pagesTechnical Data: 150x125 CNHA 5 18.5سمير البسيونىNo ratings yet

- PMS Rev 0Document36 pagesPMS Rev 0rami ghorbelNo ratings yet

- PSHL - Electrical PD DischargeDocument1 pagePSHL - Electrical PD DischargeMuhammad Ibad AlamNo ratings yet

- Ga Drawing With Bom and GTP of Indoor Type DB Panel Electronics LabDocument1 pageGa Drawing With Bom and GTP of Indoor Type DB Panel Electronics LabHytech Pvt. Ltd.No ratings yet

- 15 of 18 CTC Civil Engineering Design BasisDocument65 pages15 of 18 CTC Civil Engineering Design BasisRomoex R RockNo ratings yet

- Knife Gate Valves PDFDocument2 pagesKnife Gate Valves PDFashish_pradhan75No ratings yet

- Pressure Drop AND HEADDocument2 pagesPressure Drop AND HEADHoney TiwariNo ratings yet

- Junction Box DatasheetDocument1 pageJunction Box DatasheetNilesh ChavanNo ratings yet

- Mechanical Data Sheet Tanks: DescriptionDocument3 pagesMechanical Data Sheet Tanks: DescriptionEDUARDONo ratings yet

- MIS-M-DS-04052 50m3 Treated Water Tank Data Sheet (T-04320) - CDocument2 pagesMIS-M-DS-04052 50m3 Treated Water Tank Data Sheet (T-04320) - Chappale2002No ratings yet

- Dry CobbingDocument1 pageDry CobbingEDUARDONo ratings yet

- 830 CB 120 M06 - Rev0Document1 page830 CB 120 M06 - Rev0EDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit PlantDocument10 pagesMine Operation Expansion Project and Benefit PlantEDUARDONo ratings yet

- 5921 D E DWG 0205 - RevADocument6 pages5921 D E DWG 0205 - RevAEDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.09.2014Document14 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.09.2014EDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Document14 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit PlantDocument10 pagesMine Operation Expansion Project and Benefit PlantEDUARDONo ratings yet

- 5921 D E DWG 0205 - RevADocument6 pages5921 D E DWG 0205 - RevAEDUARDONo ratings yet

- 5921 D E DWG 0105 - RevADocument6 pages5921 D E DWG 0105 - RevAEDUARDONo ratings yet

- Sewage Treatment MenbraneDocument1 pageSewage Treatment MenbraneEDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Document14 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDONo ratings yet

- StrainerDocument3 pagesStrainerEDUARDONo ratings yet

- Schedule Levels - Major Projects: Core Scheduling Papers: #6Document5 pagesSchedule Levels - Major Projects: Core Scheduling Papers: #6EDUARDONo ratings yet

- Sewage Treatment FloculantDocument1 pageSewage Treatment FloculantEDUARDONo ratings yet

- Sewagw Treatment FilterDocument1 pageSewagw Treatment FilterEDUARDONo ratings yet

- Sewage Treatment Ultraviolet DeinfectionDocument1 pageSewage Treatment Ultraviolet DeinfectionEDUARDONo ratings yet

- Sewage Treatment EfluentDocument5 pagesSewage Treatment EfluentEDUARDONo ratings yet

- Separation CellDocument11 pagesSeparation CellEDUARDONo ratings yet

- 11 Chapter Reaction Kinetics Text Book Exercise PDFDocument14 pages11 Chapter Reaction Kinetics Text Book Exercise PDFBilal KhanNo ratings yet

- FastLUBE lubricants guide for anti-galling and corrosion protectionDocument1 pageFastLUBE lubricants guide for anti-galling and corrosion protectionneubofren600No ratings yet

- WRS 2008 CatalogDocument34 pagesWRS 2008 CatalogYimmy Alexander Parra MarulandaNo ratings yet

- Compatibility of Materials With Liquid Oxygen (Impact Sensitivity Threshold and Pass-Fail Techniques)Document12 pagesCompatibility of Materials With Liquid Oxygen (Impact Sensitivity Threshold and Pass-Fail Techniques)Ahmed AlzubaidiNo ratings yet

- Magnetic Field Effect on Weld PropertiesDocument54 pagesMagnetic Field Effect on Weld PropertiesSarthak sainiNo ratings yet

- Controlled Collapse of Liquid Marbles Using Laser IrradiationDocument41 pagesControlled Collapse of Liquid Marbles Using Laser IrradiationSarika SomanNo ratings yet

- Aapt United States Physics Team AIP 2010: Do Not Distribute This PageDocument15 pagesAapt United States Physics Team AIP 2010: Do Not Distribute This PagelagostinhaNo ratings yet

- Test # 12.1 Physics-Ii: Superb in EducationDocument8 pagesTest # 12.1 Physics-Ii: Superb in EducationKamran AliNo ratings yet

- Material BalancesDocument15 pagesMaterial BalancesHalil İbrahim ÖzdemirNo ratings yet

- PDFDocument76 pagesPDFRavishankarNo ratings yet

- A Facile Strategy To Simultaneously Improve The Mechanical and Fire SafetyDocument43 pagesA Facile Strategy To Simultaneously Improve The Mechanical and Fire SafetyTia Nico Rossi RossiNo ratings yet

- Chapter 1 (Semicon) FLOYDDocument2 pagesChapter 1 (Semicon) FLOYDanon_337840562No ratings yet

- Chemistry Five YearDocument9 pagesChemistry Five YeararslsaadNo ratings yet

- Points For PPT On AdmixturesDocument9 pagesPoints For PPT On AdmixturesAvinash MaratheNo ratings yet

- Material Compatibility Charts PDFDocument1 pageMaterial Compatibility Charts PDFAndres Camilo BenitezNo ratings yet

- Masatoshi Imada, Atsushi Fujimori and Yoshinori Tokura - Metal-Insulator TransitionsDocument225 pagesMasatoshi Imada, Atsushi Fujimori and Yoshinori Tokura - Metal-Insulator TransitionsPo48HSDNo ratings yet

- ASTM D88-07 (Reaprobada 2013) Visc SayboltDocument7 pagesASTM D88-07 (Reaprobada 2013) Visc SayboltAngel MurilloNo ratings yet

- U4 - WeldingDocument59 pagesU4 - WeldingAnonymous LM9RaUA4yNo ratings yet

- Gemstone: Gemology and Jewelry PortalDocument8 pagesGemstone: Gemology and Jewelry PortalNurzamzami IsmailNo ratings yet

- Laprak Distilasi UapDocument11 pagesLaprak Distilasi UapRetnani Arum PertiwiNo ratings yet