Professional Documents

Culture Documents

B0054832-4 Erection Arrangement DRB-XCL PC Fired Burner C.C.W

Uploaded by

Nanang Cesc UttaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B0054832-4 Erection Arrangement DRB-XCL PC Fired Burner C.C.W

Uploaded by

Nanang Cesc UttaCopyright:

Available Formats

686 REF TYP

2'-3"

4

2

5

R

E

F

T

Y

P

1

'-4

3

/

4

"

305

1'-0"

4

3

2

1

'-5

"

1

5

5

6

'

2

5

'

1

5

3

0

'

2

3

5

5

'

3642'

8

10

3

4

6

'

1

4

3

0

'

2

5

165

6 1/2"

2286 INSIDEWINDBOX

7'-6"

5

0

8

T

O

C

O

A

L

E

L

B

O

W

1

'-8

"

438 I.D.

1'-5 1/4"

533

1'-9"

127

5"

546 B.C.

1'-9 1/2"

27

W.P. W.P.

<10V @25 MA AC

MOUNT

SCANNER

VOLTAGEDROP . . . . . . . <8V @25 MA DC

HANDLE

VANEPULL

OUTERAIR

HANDLE

VANEPULL

RATCHETDRIVE

AIRZONEDISK

INNERAIR

MOUNT

SCANNER

J UNCTION BOX

10

THERMOCOUPLE

IGNITOR

CFSOIL

DOOR

NE18

G1 &

9

EXCITER

2.5 MA @121-250 VAC/ DC

ENERGY

B&WHIGH

OBSERVATION

IGNITOR

UNIT#1R.W. - 1E-2, 1E-4, 1E-6, 1E-7

THISBURNERARRANGEMENTFORBURNERS:

(NE10 & NE12)

UNIT#2R.W. - 2E-2, 2E-4, 2E-6, 2E-7

CONNECTION

AIRMONITOR

LOWPRESSURE

FRONTVIEW

CONNECTION

AIRMONITOR

HIGHPRESSURE

GENERALNOTES:

G1. ELECTRICAL REQUIREMENTSFORHIGHENERGY SPARK IGNITOR:

85-250 VAC, 50-60 HZ, 1 PHASE, 100VA

G2. SEAL AIRREQUIREMENTS:

G3. AIRREQUIREMENTSFOROIL IGNITORDRIVECYLINDER:

80-120 PSIG: .087 CF PERSTROKE

5.6-8.4 KG/CM

2

: , .0025 M

3

PERSTROKE

G4. AIRREQUIREMENTSFOROIL IGNITORPROBEDRIVE

CYLINDER:

80-120 PSIG: .017 CF PERSTROKE

5.6-8.4 KG/CM

2

: , .0025 M

3

PERSTROKE

G5. ELECTRICAL DATA FOROIL IGNITORPROXIMITY SWITCH:

VOLTAGERANGE. . . . . . 20-250 VAC/DC

LOAC CURRENT. . . . . . . .2-25 MA

LEAKAGECURRENT. . . . .1.7 MA @120 VAC/DC

32

H

H

G

G

F

F

E E

D

D

C

C

B

B

A

A

DWD

UNIT#1 USERDEFINED FIELD UNIT#2

ORIG CONTRACTNO

PROJ ECTNO

563-0061-39-53

0635-212G

6

3/ 1/ 2010

NOs. 32-34. REVISED CUSTOMERTITLE BLOCK. CAI/ DAS

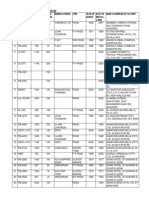

ITEM NO QTY. DESCRIPTION DRAWING NUMBER

4

PARTNUMBER

1

FLANGESEGMENT

1 ASSEMBLY BURNERELEMENTC.C.W. B0054847 6420888

2 1 ASSEMBLY SLIP SEAL 2729173C 2729173

3 2 RETAINERBAR 2345650A 2345650

4 1 17 1/4"CONICAL DIFFUSER(SILICON CARBIDE) 2135985C 2135985

5 1 17 1/4"DEFLECTOR(SILICON CARBIDE) 2343811D 2343811

MATCHPAINTLINEOF COAL NOZZLEWITHMOUNTING PLATE.

SEEGENERAL ARRANGEMENTFORCORRECTORIENTATION. FORALIGNMENT

DIFFUSER(INSIDENOZZLE) IN LINEWITHCENTERLINEOF COAL ELBOWINLET.

IN COAL ELBOW. ERECTORTO ROTATECENTERLINEOF DEFLECTORAND

NE10. ERECTORTO ROTATENOZZLEIF NECESSARY TO LINEUP WITHBOLTHOLES

NE9. FORWELDING CERAMIC LINED COMPONENTS, SEEDRAWING 275065A.

ISCOMPLETE.

NE8. ERECTORTO INSUREPROPERDISK MOVEMENTAFTERBURNERINSTALLATION

THEERECTORUNLESSOTHERWISESPECIFIED.

NE7. THEFIELD INSTALLED INSULATION AND LAGGING ISTHERESPONSIBILITY OF

PACKING IN PLACE.

INSTALL ROPEPACKING AND BEND SLIP SEAL TABSOVERTO HOLD

THEN COMPLETETHEWELDING OF THESLIP SEAL TO THEFRONTPLATE.

ALL SUPPORTBRACKETSMUSTBECARRYING THELOAD OF THEBURNER.

POSSIBLEWITHOUTINFRINGING ON THE13 [1/2"] +6 [1/4"] -0"GAP TOLERANCE.

NE6. BURNERSARETO BEASLEVEL AND PERPENDICULARTO THEWALL TUBESAS

BURNERWEIGHTON SLIP SEAL.)

AIRSLEEVEWITHRESPECTTO THETHROATOPENING. (DO NOTSUPPORT

+/- 1/8". SLIP SEAL WILL SERVEASA GUIDEFORPOSITIONING THEBURNER

NE5. TACK WELD SLIP SEAL TO FRONTPLATECONCENTRIC WITHTHROATOPENING

DIMENSIONSATSUPPORTBRACKETS.

BEFOREWELDING SUPPORTCHANNELS, ERECTORTO INSURECLEARANCE

CENTERLINEOF BURNERAND RESTING ON SUPPORTCHANNELSIN WINDBOX.

NE4. SUPPORTCHANNELSTO BEPARALLEL TO TUBEWALL, PERPENDICULARTO

SLEEVESUPPORTBARS.)

(DO NOTLIFTBURNERBY AIR LUG ON COVERPLATEAND AIRSLEEVE.

NE3. TO AVOID DAMAGETO BURNERS, USE38 [1 1/2"] DIA HOLESPROVIDED IN LIFTING

NE2. DISSIMILARWELD SST TO CARBON. SEEFIELD WELD SCHEDULEDRAWING.

COVERPLATE.

TO INSURECLEARANCETHRUAIRVANES. THEN WELD LIGHTERPIPEAT

TUBEWALL. TACK WELD LIGHTERASSEMBLY THEN STROKEAIRCYLINDER

NE17. INSUREPROPERLOCATION FROM LIGHTERSHIELD TO CENTERLINEOF

REVERSETHISPROCEDURETO ATTAIN THEFULLY CLOSED POSITION.

E) EXTEND RATCHETJ ACKBACK TO MECHANICALLY OPENED POSITION.

D) RETIGHTEN U-BOLTS

C) RETRACTRATCHETJ ACK 102 [4"]

NE16 CONTINUED:

B) LOOSEN U-BOLTS

A) ASSURETHATRATCHETJ ACK ISMECHANICALLY OPEN

POSITION YOUMUST:

CLOSED TO 102 [4"] FROM FULLY OPENED. TO ACHIEVETHEFULLY OPENED

RATCHETJ ACK WILL ALLOWFOR203 [8"] OF TRAVEL: FROM FULLY

FULLY CLOSED POSITION. IN IT'SCURRENTPOSITION THE

NE16. BURNERSARESHIPPED WITHTHERATCHETJ ACK DRIVESIN THE

FORLIFTING BURNER.)

AFTERINSTALLATION ISCOMPLETE. (DO NOTUSETHESEMEMBERS

NE15. ERECTORTO REMOVEALL SUPPORTMEMBERSPAINTED YELLOW

ELBOWCOVER 3/4"DIA BOLT& NUT 100 14.8

16 & 18 1"DIA BOLT& NUT 245 33.9

17 3/ 8"SCREW 15 2

FIND NO. DESCRIPTION FT-LBS KG/M

NE14. TORQUEREQUIREMENTS:

BURNERELEMENTASSEMBLY: 1590 KG [3503 LBS.]

NE13. ESTIMATED WEIGHTS:

ERECTION NOTES:

BY MANUFACTURING.

BY BURNERNUMBERAND NOZZLESROTATED TO THEIRAPPROXIMATELOCATIONS

BURNERNUMBERPERTHEGENERAL ARRANGEMENTS. BURNERSARESTENCILED

NE12. ERECTORMUSTINSERTBURNERSIN THEIRAPPROPRIATELOCATIONSBY

FILL HOLESIN COAL NOZZLEFORDEFLECTORRETAINERBARSWITHRTV SEALER.

NE11. APPLY RTV SEALERTO LEADING EDGEOF DEFLECTORAND COAL NOZZLE.

GOOD INDUSTRY PRACTICE.

NE1. UNLESSOTHERWISENOTED: ALL NPP TO NPP WELDSSHALL CONFORM TO

c) ALL REMAINING BOLTS.

a) FOUR(4) CORNERBOLTSFORFLANGES#1.

b) FOUR(4) CORNERBOLTSFORFLANGES#2.

NE28. FIELD PROCEDUREFORREMOVAL AND INSTALLATION OF COAL ELBOWCOVER:

INDICATESBURNERTERMINAL

SYMBOL:

C) REBOLTFLANGESSEQUENTIALLY ASFOLLOWS:

B) CLEAN FLANGESAND APPLY HIGHTEMPERATURERTV.

A) UNBOLTAND REMOVECOVER.

T

NE27. TRIM VANEASNEEDED TO MAINTAIN TOLERANCES.

PRIORTO INSERTING THECOAL NOZZLEINTO THEBURNER.

WELDING INSTRUCTIONSFORCERAMIC COMPONENTS. . . . . . . . 275065A

R

FIELD WELD SCHEDULE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B0054841

ERECTION ARRANGEMENTDIFFERENTIAL PRESSUREGAGE. . . . . .B0054842

ARRANGEMENTRECOMMENDED SPAREPARTS. . . . . . . . . . . . . . .B0054840

ERECTION ARRANGEMENTTHERMOCOUPLES. . . . . . . . . . . . . . . . B0054839

ERECTION ARRANGEMENTSECTIONS& VIEWS2 . . . . . . . . . . . . . . B0054838

ERECTION ARRANGEMENTSECTIONS& VIEWS1 . . . . . . . . . . . . . . B0054837

GENERAL ARRANGEMENTREARWALL . . . . . . . . . . . . . . . . . . . . . . B0054793

GENERAL ARRANGEMENTFRONTWALL . . . . . . . . . . . . . . . . . . . . . B0054792

REFERENCEDRAWINGS:

THECOAL NOZZLETHERMOCOUPLESARETO BEINSTALLED ON THECOAL NOZZLE

SEEBURNERGENERAL ARRANGEMENTDRAWINGSFORCORRECTORIENTATIONS.

MOUNTING HOLESAREINLINEWITHTHECENTERLINEOF THECOAL ELBOWINLET.

NE26. ORIENTATECOAL NOZZLESO THECENTERLINEBETWEEN THEDEFLECTOR

BEFLUSHWITHCLAMPSWHEN PROBETIP ISFLUSHWITHOIL IGNITORSHIELD.

NE22. ERECTORTO FILEMARK SPARK TCD WITH(4) 6 [1/4"] INCREMENTS. FIRSTMARK TO

OBJ ECTS, ANY IMPACTCAN DAMAGETHECERAMIC.

D) CARESHOULD BETAKEN TO AVOID CONTACTWITHANY OTHER

CERAMIC PARTFORLIFTING.

C) DO NOTUSEA CABLEORCHAIN THROUGHORAROUND ANY

B) FORPARTSWITHOUTLIFTING LUGS, USENYLON SLING FORLIFTING.

A) ALWAYSUSELIFTING LUGS, IF PROVIDED, TO LIFTPART.

TO AVOID BREAKING, CRACKING AND CHIPPING:

CERAMIC ISA VERY BRITTLEPRODUCTAND REQUIRESSPECIAL HANDLING

NE21. GENERAL HANDLING FORCERAMIC COMPONENTS:

THREADS. (NO ADJ USTMENTSTO BEMADEBY TWISTING HOSE.)

NE20. TO PREVENTDAMAGETO HOSE, ALL ADJ USTMENTSMUSTBEMADEIN PIPE

TWISTING HOSEDURING INSTALLATION.

TWISTING. NO TORSIONAL FORCESMAY BEAPPLIED TO HOSEBY

PARALLEL TO THEVERTICAL CENTERLINEOF BURNERTO PREVENT

NE19. LOOP OF HOSETO BEINSTALLED IN A VERTICAL POSITION AND

HIGHENERGY EXCITERON WINDBOXCASING.

NE18. LOCATEHIGHENERGY EXCITERWITHIN 3048 [10'-0"] OF LIGHTER. DO NOTMOUNT

2763817A 2763817

7 1 DIFFUSERMOUNTING BRACKET 299350B 2174414

8 1 GASKET 356104C 4688613

9 1 EXCITERHIGHENERGY 348822C 4688147

REVISIONS

REV DESCRIPTION DATE APPROVED

1 ADDED CUSTOMERTITLEBLOCK. CAI/ DAS 2/ 2/ 2009 DWD

2

ADDED ITEM NO. 27-30. UPDATED GRAPHICSIN FRONTVIEW

AND SECTION A-A. ADDED SECTION AB-AB. REVISED NE14.

ADDED NE26-28. REVISED CUSTOMERTITLEBLOCK FROM YYY

TO BNR. CAI/ DAS

6/ 2/ 2009 DWD

3

REVISED DRAWING REVISION NUMBERSIN TITLE BLOCK.

DAS

6/ 16/ 2009 DWD

4

CHG'D DESC AND P/ N FORITEM NO. 9. ADDED ITEM

0458702 WASHERPLN 3/8"TYPEB(W) F844 4 15

4591668 PACKING ROUND ROPEFIBERFRAX2300 5/8" 31 FT 14

0330146 SEALER, RED SILICONERUBBER .5 TUBE 13

4678009 C6 X10.5 X1'-4"LG. A36 4 12

4539895 162770A BURNERSUPPORTBRACKETRETAINER

5CM WC ABOVEFURNACE

2"WC ABOVEFURNACE

/ HR

3

17 NM

10 SCFM

OIL IGNITORCONN. b

5CM WC ABOVEWINDBOX

2"WC ABOVEWINDBOX

/ HR

3

8.5NM

5 SCFM

OIL IGNITORCONN. a

PRESSURE FLOW DESCRIPTION

4 11

6419310 2269078E IGNITORCFSOIL R.H. "L =10'-0""LS"=8'-0 5/16" 1 10

ITEM NO QTY. DESCRIPTION DRAWING NUMBER PARTNUMBER

16 16 NUTHEX1"A563B(GR5) 4685586

17 4 SCREWCAP HEX3/8"-16UNC-2A X1 1/4"A307A 8004289

18 16 BOLTHEX1"X3 1/4"LG. A449TP1 (GR5) 4695347

19 2 ASSEMBLY FLEXIBLEHOSE3/8"X50"LG 6253420

20 2 TEETHRD 1/2"3000#STL 3017087

21 2 BSHG HEXHD SCRD 1/2"X3/8"SA105 0350068

22 2 PLUG THRD SQHG 1/4"3000#STL 3026365

23 2 BSHG HEXHD SCRD 1/2"X1/4"STL 3014711

24 2 BALL VALVE1/2"SHARPE54574N 4688127

25 2 NIPPLE1/2"X3"LG TBENPTSA106B 2235574

27 1 ASSEMBLY 17 1/4"I.D. CERAMIC LINED COAL ELBOW B0054931 6436045

28 1 ASSEMBLY 16 1/2"CERAMIC LINED COAL NOZZLE B0054911 6425470

29 1 ASSEMBLY MOUNTING PLATE B0054905 6425088

30 1 COAL NOZZLEMOUNTING PLATE B0054895 6423304

32 1 ASSEMBLY CABLE15'-0" 4688148

33 1 HIGHENERGY SPARK ROD PL-12"=9'-11 9/16" 188723B 2226783

34 1 HIGHENERGY SPARK PROBETIP 188722B 8804376

OPERATION, ANDFOR SOLICITING BIDS FOR THE ERECTION OF, THE EQUIPMENT DISCLOSEDHEREIN.

8 7 6 5 4 3 2 1

A

J

I

H

G

F

E

D

C

B

J

I

H

G

F

E

D

C

B

A

1 2 3 4 5 6 7 8

B 0 0 5 4 8 3 2

- DO NOTSCALE-

N O

D W G

J 44-Customer.slddrt

11/2"=1'-0"

NO

YES

YES

563-0060-39-53

REV

J

DWG NO COA PROJ ECTNO

DISTMFG

DISTEREC

DISTCUST

SCALE

DATE

CHKD

APPVD

DWN

USERDEFINED FIELD

B0054832.slddrw

DRB-XCL PC FIRED

ERECTION ARRANGEMENT

C.C.W.

4 B0054832 AC5100 0635-212F

BURNER

USEDIMENSIONSONLY

ORIG CONTRACTNO

12/11/08

D.W.DOWDELL

D.A.SMITH

C.A.IAFANO

TYPE PROJ ECT

Babcock & Wilcox Power Generation Group, Inc.

2008 BABCOCK &WILCOX POWER GENERATION GROUP, INC. ALL RIGHTS RESERVED.

THIS DRAWING IS THE PROPERTY OF BABCOCK &WILCOX POWER GENERATION GROUP, INC. (B&WPGG) ANDITS USE IS

GOVERNEDBY THE TERMS ANDCONDITIONS OF THE CONTRACT FOR WHICH IT WAS CREATED. B&WPGG GRANTS A

NON-EXCLUSIVE LICENSE TO USE, REPRODUCE ANDDISTRIBUTE THIS DRAWING SOLELY FOR THE MAINTENANCE, REPAIR AND

20 SOUTH VAN BUREN AVENUE, BARBERTON, OHIO

VIEWK

VIEWL

T

STRADDLE

27

ON 76 [3"] CENTERS

NE3

NE3

2 1

7

NE14 8

SECTION A-A

5

4

IN

W

IN

D

B

O

X

16

2 1/2"O.D. TUBES

30 29

(16) 7/8"DIA THRU

18

CL

FLANGE#1

1'-9 1/2"B.C.

NE14 & NE28

FLANGE#2

NE14 & NE28

FLANGE#2

NE14 & NE28

LIFTING LUG

IN

L

E

T

F

L

A

N

G

E

28

EQ SPC'D ON

8 [5/16]

NE9,

NE10

& NE27

1

3

9

7

D

IA

O

P

E

N

IN

G

4

'-7

"

9

1

4

REF

3

'-0

"

I.D

. T

H

R

O

A

T

1/4"

6

1/4"

4

'-5

"

IN

S

ID

E

1

3

4

6

6

610 O.D.

2'-0"

1'-3"

381

1

'-4

1

/

2

"

I.D

.

4

1

9

368 REF

1'-2 1/2"

AB

AB

J

J

EMPLOYERS DOCUMENT REVIEWANDSTATUS

LOG

IN

DATE 08/09/09 REVIEW BY REVISION STATUS DISTRIBUTION 1

COMM NO : 0315 MECHANICA

L

A : ACCEPTED X CONTRACTOR X

LOG

OUT

DATE 16/10/09 ELECTRICAL B : ACCEPTED AS NOTED RECORD 1

COMM NO: 0236 I &C C : NOT ACCEPTED PIKITRING J BN 1

RELEASEDBY : DATE: 16/10/09 SUPPORT I : INFORMATION ONLY PROJ ECT 1

Owner :

PT. PLN (PERSERO)

SURALAYA STEAM POWER PLANT UNIT 1- 4 ( 4 X 400 MW)

LOT 1 : BOILER UNIT 1 & 2

REHABILITATION PROJECT Contract No. 255.PJ/041/DIR/2008

PT PLN (PERSERO) JASA ENJINIRING

DRAWING TITLE :

PLN DRAWINGNo. REV

0 1 0 4 1 L 1 - 0 2 - M - 5 1 - H J A - 0 0 9

Contractor :

MARUBENI CORPORATION

Revision History

Rev. Rev. Date Created by Checked

by

Approved by Description

01 2/03/2009 C.A. IAFANO D. SMITH D.W. DOWDELL ADDEDCUSTOMER TITLE BLOCK.

02 6/02/09 C.A. IAFANO D. SMITH D.W. DOWDELL ADDEDCOAL NOZZLE ANDRELATEDPARTS.

03 6/16/2009 D.SMITH D.SMITH D.W.DOWDELL REVISEDDRAWINGREVISION NUMBERS

04 3/1/2010 C.A.IAFANO D.SMITH D.W.DOWDELL CHGDDESC ANDP/NFOR ITEM9. ADDEDITEMS

32-34. REVISEDCUSTOMER TITLE BLOCK.

Contractors (Partner, Subcontractor)

Babcock&WilcoxPower GenerationGroup

Scale

1 1/2"=1-0

Contractors Document/ Drawing No

SRLSPP12-1-255-BNR-A-007-04

Responsible dept.

ISP

Created by

C.A. IAFANO

Checkedby

D.A. SMITH

Approvedby

D.W. DOWDELL

Size

J

Originator

B&W

Document Title(Subtitle)

ERECTION ARRANGEMENT

DRB-XCL PC FIRED

BURNER

C.C.W.

DocumentType

For FINAL

Identification number

B0054832

Rev.

04

Date

3/1/2010

Sheet

1/1

You might also like

- Oxygen Sensor Simulator - JumperDocument7 pagesOxygen Sensor Simulator - JumperBrianssrt4100% (2)

- Business PlanDocument25 pagesBusiness PlanMahesan SinthujanNo ratings yet

- Steam Network - Spirax Sarco - Submittal PDFDocument388 pagesSteam Network - Spirax Sarco - Submittal PDFRamy MahmoudNo ratings yet

- Boiler OfferDocument10 pagesBoiler OfferManohar PandianNo ratings yet

- 65 Twin Reverb ManualDocument9 pages65 Twin Reverb ManualGerardo PaesanoNo ratings yet

- Boiler: Heat Sources Materials Energy Boiler EfficiencyDocument10 pagesBoiler: Heat Sources Materials Energy Boiler EfficiencyrpercorNo ratings yet

- Reeving Information Grove CranesDocument19 pagesReeving Information Grove CranesLouisAucamp100% (2)

- COATING PROCEDURES AT A GLANCEDocument10 pagesCOATING PROCEDURES AT A GLANCENanang Cesc Utta100% (1)

- Bill of Quantities of M. S. Pipe Fittings (O-14027)Document4 pagesBill of Quantities of M. S. Pipe Fittings (O-14027)Tanmoy DuttaNo ratings yet

- MCQ ControllerDocument3 pagesMCQ ControllerHemanth AmuruNo ratings yet

- Welding defects, causes and correction explainedDocument3 pagesWelding defects, causes and correction explainedBinh Pham100% (2)

- p345 Technical ManualDocument1 pagep345 Technical ManualabhayambujNo ratings yet

- Sootblowers for Fired EquipmentDocument3 pagesSootblowers for Fired EquipmentGilvan SilvaNo ratings yet

- Damper TorqueDocument3 pagesDamper TorqueNguyễn LinhNo ratings yet

- Welding Defects Part 4Document56 pagesWelding Defects Part 4Nanang Cesc UttaNo ratings yet

- Boiler O&M - DESCONDocument218 pagesBoiler O&M - DESCONppraveenkumar79100% (1)

- 400kgs Steam Boiler Oil FiredDocument5 pages400kgs Steam Boiler Oil FiredManikandanNo ratings yet

- Stainless Steel ANSI Pipe Flanges - A Guide: 1. What Type of Flange Is Required?Document5 pagesStainless Steel ANSI Pipe Flanges - A Guide: 1. What Type of Flange Is Required?Utada HikaruNo ratings yet

- Innovation For Boiler TubeDocument2 pagesInnovation For Boiler TubemasgrahaNo ratings yet

- P&ID Cooling System (PHE 1 Set)Document1 pageP&ID Cooling System (PHE 1 Set)Moon JaehyunNo ratings yet

- BR BoilerHouseComponents enDocument28 pagesBR BoilerHouseComponents enJosé Pedro MagalhãesNo ratings yet

- FW Utility Boiler PDFDocument12 pagesFW Utility Boiler PDFChandan AulakhNo ratings yet

- Steam Boiler ProjectDocument32 pagesSteam Boiler ProjectSwastik BhokareNo ratings yet

- Mundra LPG Terminal Boiler SpecificationDocument17 pagesMundra LPG Terminal Boiler SpecificationjkNo ratings yet

- Natural Circulation in BoilerDocument9 pagesNatural Circulation in BoilerSajjad AhmedNo ratings yet

- Pioneer DVH 750AVDocument86 pagesPioneer DVH 750AVboroda2410100% (3)

- Burn Selection MatrixDocument1 pageBurn Selection MatrixsahasidNo ratings yet

- Tata Consulting Engineers Design Guide For Auxiliary Steam HeaderDocument10 pagesTata Consulting Engineers Design Guide For Auxiliary Steam HeadervijayanmksNo ratings yet

- Power plant condenser and pressure reducersDocument1 pagePower plant condenser and pressure reducersPrudhvi RajNo ratings yet

- P103e Gas Scrubbing PlantsDocument12 pagesP103e Gas Scrubbing PlantsAswad Ali100% (1)

- P02-S01 Rev 5 Sep 2021 Piping Material Specifications For Process FluidsDocument21 pagesP02-S01 Rev 5 Sep 2021 Piping Material Specifications For Process FluidsMohamed AdelNo ratings yet

- B0054827-4 Erection Arrangement DRB-XCL PC Fired Burner C.WDocument1 pageB0054827-4 Erection Arrangement DRB-XCL PC Fired Burner C.WNanang Cesc UttaNo ratings yet

- B0054833-4 Erection Arrangement DRB-XCL PC and Oil Fired Burner C.C.WDocument1 pageB0054833-4 Erection Arrangement DRB-XCL PC and Oil Fired Burner C.C.WNanang Cesc UttaNo ratings yet

- 1 - Transmittal No. R0051734-CTCDocument7 pages1 - Transmittal No. R0051734-CTCNanang Cesc UttaNo ratings yet

- DZL 4-1.25-AiiDocument10 pagesDZL 4-1.25-AiiSamulaNo ratings yet

- Research Study Diesel To BiomassDocument9 pagesResearch Study Diesel To BiomassDarrel MagnoNo ratings yet

- General Boiler Information on Low-Emission Firetube ModelsDocument10 pagesGeneral Boiler Information on Low-Emission Firetube Modelsnecio77No ratings yet

- Single Glue MachineDocument28 pagesSingle Glue MachineVivid Exim100% (1)

- D/LND Series Burners Installation, Operation, Service, and Parts Manual Table of ContentsDocument120 pagesD/LND Series Burners Installation, Operation, Service, and Parts Manual Table of ContentsRosanny Borges ChirinosNo ratings yet

- Economiser Coil - DrawingDocument1 pageEconomiser Coil - DrawingAnjaneya ReddyNo ratings yet

- EPRF Report Com Fulton Steam BoilersDocument13 pagesEPRF Report Com Fulton Steam BoilersBlackzero68No ratings yet

- Material Requisition xxxx-MR01/: SRU Thermal Reactor PACKAGE (4137.05-PK-311/321)Document28 pagesMaterial Requisition xxxx-MR01/: SRU Thermal Reactor PACKAGE (4137.05-PK-311/321)saptarshi jashNo ratings yet

- Miura Boilers Steam GeneratorsDocument2 pagesMiura Boilers Steam GeneratorsDhonyAhmedPradjoegoNo ratings yet

- Longitudinal Section B-B Transverse Section A-A: Welding Details Not To ScaleDocument1 pageLongitudinal Section B-B Transverse Section A-A: Welding Details Not To ScalebunkeringNo ratings yet

- Modulating Control (Operating Procedure)Document32 pagesModulating Control (Operating Procedure)goodgranitNo ratings yet

- Ygnis Ingl+ S Multiflam 170.1-200.1Document24 pagesYgnis Ingl+ S Multiflam 170.1-200.1DihorulNo ratings yet

- Project On Conservation of Steam in Electroplating in Hero CyclesDocument7 pagesProject On Conservation of Steam in Electroplating in Hero Cyclessharanjeet4uNo ratings yet

- O&Msec2 Heat & Material BalanceDocument8 pagesO&Msec2 Heat & Material Balanceugun87No ratings yet

- Boiler: Sabari Girish N Sr. Engineer (O)Document37 pagesBoiler: Sabari Girish N Sr. Engineer (O)Deepak SinghNo ratings yet

- 6 SS Direct Fired Air HeaterDocument1 page6 SS Direct Fired Air HeaterYhony Gamarra VargasNo ratings yet

- Instrumentation For Fired Heaters IP 15-1-1: ScopeDocument14 pagesInstrumentation For Fired Heaters IP 15-1-1: ScopeLuis Alonso Aguirre LopezNo ratings yet

- 2ND CLASS Boilers in Lahore CircleDocument14 pages2ND CLASS Boilers in Lahore CircleGoldenshakehandNo ratings yet

- Chap 14 PDFDocument22 pagesChap 14 PDFnelson escuderoNo ratings yet

- Boiler Comp. For 250bhpDocument2 pagesBoiler Comp. For 250bhpNewaz KabirNo ratings yet

- Bangladesh Datasheets January 2017 Wee ChieftainDocument1 pageBangladesh Datasheets January 2017 Wee ChieftainFAVIONo ratings yet

- TECOtubeexpanders BROCHUREDocument56 pagesTECOtubeexpanders BROCHUREMontajes Industriales EOS, MIESANo ratings yet

- Chap 28 PDFDocument30 pagesChap 28 PDFnelson escuderoNo ratings yet

- Tube Removal Catalog Web ELLIOTDocument24 pagesTube Removal Catalog Web ELLIOTJose Luis RattiaNo ratings yet

- 236-76-12 Welding Jiont Selections For Pipes & TubesDocument7 pages236-76-12 Welding Jiont Selections For Pipes & TubesJKKNo ratings yet

- General Overview Boilers and FlowDocument22 pagesGeneral Overview Boilers and FlowLiam MoylanNo ratings yet

- PVM Su 1322 H.1 PDFDocument22 pagesPVM Su 1322 H.1 PDFJEEVITHANo ratings yet

- Instruction Manual: Fully Automatic Thermic Fluid HeaterDocument15 pagesInstruction Manual: Fully Automatic Thermic Fluid HeaterSubrato SahaNo ratings yet

- SSGC New ConnectionDocument19 pagesSSGC New ConnectionmimranislamNo ratings yet

- 3s Steam BoilerDocument13 pages3s Steam BoilertahirNo ratings yet

- Document Submission Status: FOR APPROVAL: Vung Ang 1 Thermal Power Plant 2 X 600Mw Lot M4A Cooling Water System (Bop)Document10 pagesDocument Submission Status: FOR APPROVAL: Vung Ang 1 Thermal Power Plant 2 X 600Mw Lot M4A Cooling Water System (Bop)khang10182No ratings yet

- Instruction, Operation, and Maintenance Manual Fulton Oil Fired/Gas Fired Steam BoilersDocument63 pagesInstruction, Operation, and Maintenance Manual Fulton Oil Fired/Gas Fired Steam BoilersKarla Sofia Torres Wong100% (1)

- 8475PZ7Document8 pages8475PZ7caballero_tigreNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- B0054831-4 Erection Arrangement DRB-XCL PC Fired Burner C.C.WDocument1 pageB0054831-4 Erection Arrangement DRB-XCL PC Fired Burner C.C.WNanang Cesc UttaNo ratings yet

- Applying Asymptotic Expansion to Price Long-Term Currency OptionsDocument14 pagesApplying Asymptotic Expansion to Price Long-Term Currency OptionsNanang Cesc UttaNo ratings yet

- NEMA Premium Efficiency Electric Motor (600V or Less)Document12 pagesNEMA Premium Efficiency Electric Motor (600V or Less)Nanang Cesc Utta100% (1)

- Astm Specifications For Weld Fittings and FlangesDocument1 pageAstm Specifications For Weld Fittings and FlangesamitkumarkarmakarNo ratings yet

- AWWA D100-96 TocDocument4 pagesAWWA D100-96 TocNanang Cesc UttaNo ratings yet

- Astm Specifications For Weld Fittings and FlangesDocument1 pageAstm Specifications For Weld Fittings and FlangesamitkumarkarmakarNo ratings yet

- Performance of CFB ErectionDocument0 pagesPerformance of CFB ErectionNanang Cesc UttaNo ratings yet

- B0054829-4 Erection Arrangement DRB-XCL PC and Oil Fired Burner C.WDocument1 pageB0054829-4 Erection Arrangement DRB-XCL PC and Oil Fired Burner C.WNanang Cesc UttaNo ratings yet

- B0179073-3 Erection Arrangement Superheater Replacement Section B-B Unit 1 OnlyDocument1 pageB0179073-3 Erection Arrangement Superheater Replacement Section B-B Unit 1 OnlyNanang Cesc UttaNo ratings yet

- Performance of CFB ErectionDocument0 pagesPerformance of CFB ErectionNanang Cesc UttaNo ratings yet

- Draft Surat Undangan Untuk Depnaker EnglishDocument1 pageDraft Surat Undangan Untuk Depnaker EnglishNanang Cesc UttaNo ratings yet

- MTV - Demineralised and Potable Water Distribution SystemDocument7 pagesMTV - Demineralised and Potable Water Distribution SystemNanang Cesc UttaNo ratings yet

- Epizootic Rabbit ThyDocument13 pagesEpizootic Rabbit ThyNanang Cesc UttaNo ratings yet

- LZQJ ManualDocument54 pagesLZQJ Manualthomaswangkoro100% (3)

- Wireless Power Transmission Circuit and Its WorkingDocument12 pagesWireless Power Transmission Circuit and Its Workingfiledownload643No ratings yet

- DP LAN Realtek 15036 DriversDocument7,242 pagesDP LAN Realtek 15036 DriversJuan Carlos Gonzalez LNo ratings yet

- Rain AlarmDocument3 pagesRain AlarmNahithaNo ratings yet

- U18 Hall Sensor FanDocument6 pagesU18 Hall Sensor FanscribdxtestxNo ratings yet

- B2-50 SchematicDocument15 pagesB2-50 Schematicmuminpapa100% (1)

- Report 60335-2-2Document14 pagesReport 60335-2-2madeNo ratings yet

- Report For Neha Lem ArchitectureDocument17 pagesReport For Neha Lem ArchitecturewafasaNo ratings yet

- Introduction To Amplifier DesignDocument6 pagesIntroduction To Amplifier DesignJuanNo ratings yet

- Datasheet Transistor 2SK1284Document1 pageDatasheet Transistor 2SK1284Nayla AzzahraNo ratings yet

- IOM 88 Module BDocument65 pagesIOM 88 Module BandiNo ratings yet

- United States Patent: Hochberg Et AlDocument18 pagesUnited States Patent: Hochberg Et Alأبو محمدNo ratings yet

- MMRF1012NDocument18 pagesMMRF1012NandreasmonNo ratings yet

- Unisonic Technologies Co., LTD: 14.7A, 100V (D-S) N-CHANNEL Power MosfetDocument7 pagesUnisonic Technologies Co., LTD: 14.7A, 100V (D-S) N-CHANNEL Power MosfetCesar AzcargortaNo ratings yet

- Transactions On Electrical and Electronic MaterialsDocument8 pagesTransactions On Electrical and Electronic Materialsanil kawanNo ratings yet

- 5x5x5 Led CubeDocument2 pages5x5x5 Led CubeSandu PetrascoNo ratings yet

- Product CompatiblityDocument22 pagesProduct CompatiblityrahulchandokNo ratings yet

- Irf640n PDFDocument12 pagesIrf640n PDFLeonel Antonio100% (1)

- IES Electrical Engineering Previous Year Question Paper 2004 Paper 2Document16 pagesIES Electrical Engineering Previous Year Question Paper 2004 Paper 2Vamsi ManojNo ratings yet

- AT90USB1286Document39 pagesAT90USB1286Alan_88No ratings yet

- KBU10005 THRU KBU1010: Single Phase Silicon Bridge RectifierDocument2 pagesKBU10005 THRU KBU1010: Single Phase Silicon Bridge RectifierThomas ThomasNo ratings yet

- Cortex M0 M3Document5 pagesCortex M0 M3Panji Pakuan PahlawanNo ratings yet

- Synopsys VCS IP Block Verification Ieee 1149-1-2013Document2 pagesSynopsys VCS IP Block Verification Ieee 1149-1-2013Ki KiNo ratings yet

- TV camera tubes: Types and principles of operationDocument8 pagesTV camera tubes: Types and principles of operationnjarambaNo ratings yet

- Service Manual Supplement for Split Type Air ConditionersDocument54 pagesService Manual Supplement for Split Type Air ConditionerskarunvandnaNo ratings yet