Professional Documents

Culture Documents

Chapter - 3 Forced Convection

Uploaded by

Renu SekaranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter - 3 Forced Convection

Uploaded by

Renu SekaranCopyright:

Available Formats

BKF2422 HEAT TRANSFER

CHAPTER 3

Part 1

Principles of steady-state heat

transfer in convection

FORCED CONVECTION

TOPIC OUTCOMES

Define and differentiate between forced convection and

natural convection

Solve problems involve with forces convection inside pipe

Determine the heat transfer coefficient and solve problems

for heat transfer in system with fluid flow across plate, tube

cylinder, sphere and bank of tubes.

CONTENT

Forced Convection Heat Transfer Inside Pipe

For laminar flow inside pipe

For turbulent flow inside pipe

For transition flow inside pipe

Entrance-region effect on heat transfer coefficient

Liquid-metal heat transfer coefficient

Log mean Temperature Difference

Heat Transfer Outside Various Geometries In Forced Convection

Flow Parallel to Flat Plate

Flow Past Cylinder With Axis Perpendicular

Flow Past Single Sphere

Flow Past Banks of Tubes or Cylinders

Flow Past in Packed Beds

Natural convection

From planes and cylinders

In enclosed spaces

Boiling

Nucleate boiling

Film boiling

Condensation

Film-condensation coefficient for vertical surfaces

Film-condensation coefficient for horizontal cylinders

CONTENT

Convection: Heat transfer using movement of fluids.

Heat transfer is considered as convection with the presence of

bulk fluid motion. Fluid motion enhances heat transfer where

the higher the fluid velocity, the higher the rate of heat

transfer.

2 main classification of convective heat transfer;

1. Forced Convection : fluid flow by pressure differences, a

pump, a fan and so on

2. Natural Convection: motion of fluid results from the density

changes in heat transfer

CONVECTION HEAT TRANSFER

The rate of heat transfer :

T

w

= 80

o

C

T

o

= 30

o

C

q

q = Ah(T

w

T

o

)

The convection coefficient is

a measure of how effective

a fluid is at carrying heat to

and away from the surface.

h = heat transfer coefficient

(W/m

2

.K)

A= surface area (m

2

)

Fluid flow

CONVECTION HEAT TRANSFER

Metal wall

Warm fluid A

Cold fluid B

q

Turbulence absent

T2

T3

Turbulence region

T1

q = hA (T-Tw)

FKKSA

..

.

..

.

..

.

..

.

..

.

..

.

..

.

FORCED CONVECTION INSIDE PIPES

Forced convection fluid forced to flow by pressure differences

Types of fluid, laminar or turbulent

great effect on heat-transfer coefficient

More turbulent greater heat-transfer coefficient

Reynolds number, N

Re

N

Re

=

Dv

where

v = velocity of fluid (m/s)

= viscosity of fluid (Pa.s)

= density of fluid (kg/m

3

)

D = diameter of pipe (m)

FKKSA

..

.

..

.

..

.

..

.

..

.

..

.

..

.

FORCED CONVECTION

where

= viscosity of fluid (Pa.s)

= density of fluid (kg/m

3

)

k = thermal conductivity of fluid (W/m.K)

c

P

= heat capacity of fluid (J/kg.K)

h = heat transfer coefficient (W/m

2

.K)

D = diameter of pipe (m)

Prandtl number, N

Pr

Dimensionless numbers:

Nusselt number, N

Nu

k

c

c

k

N

P

P

Pr

= =

k

hD

N

Nu

=

FKKSA

..

.

..

.

..

.

..

.

..

.

..

.

..

.

LAMINAR FLOW INSIDE HORIZONTAL PIPE

where

D = inside diameter of pipe (m)

L = length of pipe (m)

b

= viscosity of fluid at bulk temperature (Pa.s)

w

= viscosity of fluid at wall temperature (Pa.s)

h

a

= average heat transfer coefficient (W/m

2

.K)

N

Nu

|

\

|

.

|

a

=

h

a

D

k

=1.86 N

Re

N

Pr

D

L

|

\

|

.

|

|

1

3

b

w

|

\

|

.

|

|

0.14

N

Re

< 2100 & N

Re

N

P r

> 100 :

L

D

All physical properties at except

w

2

bi

T

bo

T

mean b

T

|

.

|

\

|

+

=

q = h

a

AT

a

where

2

bo

T

w

T

bi

T

w

T

a

T

|

.

|

\

|

+

|

.

|

\

|

=

100

2100

Pr Re

Re

>

<

L

D

N N

N

Limitations

FKKSA

..

.

..

.

..

.

..

.

..

.

..

.

..

.

TURBULENT FLOW I NSI DE HORI ZONTAL PI PE

where

N

Nu

=

h

L

D

k

=0.027 N

Re

0.8

N

Pr

1

3

b

w

|

\

|

.

|

|

0.14

N

Re

> 6000 , 0.7 N

P r

16000 & > 60:

D

L

Rate of heat transfer is greater

c

P

= heat capacity of fluid (J/kg.K)

D = inside diameter of pipe (m)

k = thermal conductivity of fluid (W/m.K)

b

= viscosity of fluid at bulk average temperature (Pa.s)

h

L

= heat transfer coefficient based on the log mean driving force

T

lm

(W/m

2

.K)

w

= viscosity of fluid at wall temperature (Pa.s)

Many industrial heat transfer processes in the turbulent region

60

16000 7 . 0

6000

Pr

Re

>

s s

>

D

L

L

D

N

N

Limitations

FKKSA

..

.

..

.

..

.

..

.

..

.

..

.

..

.

TURBULENT FLOW I NSI DE HORI ZONTAL PI PE

where

D = inside diameter of pipe (m)

u = velocity of fluid (m/s)

h

L

=

3.52u

0.8

D

0.2

h

L

=1429 1+0.0146 T

o

C

|

\

|

.

|

u

0.8

D

0.2

h

L

=423

u

0.8

D

0.2

Air at 1 atm total pressure (N

Re

> 2100) :

Water at T = 4 to 105

o

C :

Organic liquids :

Flow inside helical coils :

H

coil

= h

straight pipes

+ (1 + 3.5D/D

coil

)

2100

Re

> N

Limitations

C T

o

105 to 4 =

Limitations

4

Re

10 > N

Limitations

EXAMPLE 4.5-1 Page 262: Heating of Air in

Turbulent Flow

Air at 206.8 kPa and an average of 477.6 K is being heated as

it flows through a tube of 25.4mm inside diameter at velocity

of 7.62 m/s. The heating medium of 488.7 K steam

condensing on the outside of the tube. Since the heat-transfer

coefficient of condensing steam is several thousand W/m

2

.K

and the resistance of the metal wall is very small, it will be

assumed that the surface wall temperature of the metal in

contact with the air is 488.7 K. Calculate the heat-transfer

coefficient for an L/D > 60 and also the heat-transfer flux q/A.

bo

T

K 7 . 488 Steam, =

w

T

steam o

h h =

L

mm 5.4 2

air

bi

T

kPa 8 . 206

m/s 62 . 7

K 6 . 477

=

=

=

P

v

T

ave

3

Pr

5

kg/m 74 . 0

W/m 03894 . 0

686 . 0

Pa.s 10 6 . 2

K 477.6 kPa, 101.32 at A.3, Appendix From

=

=

=

=

= = =

k

N

T T P

b

bm ave

Pa.s 10 64 . 2

K 7 . 88 4 at A.3, Appendix From

5

=

=

w

w

T

( )

3

kPa 8 . 206

2 1

1

2

1

2

1 2

kg/m 509 . 1

35 . 101

8 . 206

74 . 0

on depend is

, For

=

|

.

|

\

|

=

=

|

|

.

|

\

|

|

|

.

|

\

|

=

=

=

|

.

|

\

|

=

|

.

|

\

|

= =

T T

T

T

P

P

P & T

RT

PM

RT PM RT

V

m

PM

RT

M

m

PV nRT PV

) 6000 ( 10 122 . 1

10 6 . 2

) 509 . 1 )( 62 . 7 ( 10 4 . 25

4

5

3

Re

> =

=

=

u D

N

( ) ( )

.K W/m 2 . 63

0264 . 0

0260 . 0

686 . 0 10 122 . 1 027 . 0

03894 . 0

) 10 4 . 25 (

027 . 0

2

14 . 0

3

1

8 . 0

4

3

14 . 0

3

1

Pr

8 . 0

Re

=

|

.

|

\

|

=

|

|

.

|

\

|

= =

L

L

w

b L

Nu

h

h

N N

k

D h

N

( )

( )

2

W/m 1 . 701

6 . 477 7 . 488 2 . 63

=

=

=

bm w L

T T h

A

q

FKKSA

..

.

..

.

..

.

..

.

..

.

..

.

..

.

TRANSITION FLOW INSIDE A PIPE

2100 < N

Re

< 6000 :

where

G = mass velocity of fluid (kg/s.m

2

) = u

EXAMPLE 4.5-2 Page 264: Water Heated by

Steam and Trial and error Solution

Water is flowing in a horizontal 1-in schedule 40 steel

pipe at an average temperature of 65.6

o

C and a velocity of

2.44 m/s. it is being heated by condensing steam at

107.8

o

C on the outside of pipe wall. The steam side

coefficient has been estimated as h

o

= 10500 W/m

2

.K.

a) Calculate the convective coefficient hi for water inside

the pipe

b) Calculate the overall coefficient U

i

based on the inside

surface area

c) Calculate the heat-transfer rate q for 0.305m of pipe with

the water at an average temperature of 65.6

o

C

bo

T

C 8 . 107 Steam,

o

=

w

T

.K W/m 10500

2

=

o

h

m 305 . 0

mm 6.64 2

water

bi

T

m/s 44 . 2

C 6 . 65

o

=

=

v

T

bm

mm 3.4 3

3

Pr

3

o

kg/m 9 . 981

W/m 6629 . 0

72 . 2

Pa.s 10 432 . 0

C, 5 . 5 6 at A.3, Appendix From

=

=

=

=

=

k

N

T

b

bm

Pa.s 10 56 . 3 C 80 at

C 80 l, first tria for C 80 or 107.8 and 65.5 between way the

third one about as assumed be will and needed is metal inside of re temperatu The

4 o

o o

= =

=

w w

w

T

T

) 6000 ( 10 473 . 1

10 32 . 4

) 980 )( 44 . 2 ( 0266 . 0

5

4

Re

> =

=

=

u D

N

( ) ( )

.K W/m 13324

10 56 . 3

10 32 . 4

72 . 2 10 473 . 1 027 . 0

663 . 0

) 0266 . 0 (

027 . 0

2

14 . 0

4

4

3

1

8 . 0

5

14 . 0

3

1

Pr

8 . 0

Re

=

|

|

.

|

\

|

=

|

|

.

|

\

|

= =

L

L

w

b L

Nu

h

h

N N

k

D h

N

again. re temperatu for the make we assumption check the to have We

2

m 0255 . 0

) 305 . 0 )( 0266 . 0 (

=

=

=

t

t L D A

i i

2

m 032 . 0

) 305 . 0 )( 0334 . 0 (

=

=

=

t

t L D A

o o

: follow as are areas various The

002633 . 0

) 305 . 0 ( ) 45 ( 2

) 0266 . 0 / 0334 . 0 ln(

2

) ln(

1 / 2

= = =

t t kL

r r

R

pipe

002976 . 0

) 032 . 0 ( 10500

1 1

= = =

o o

o

A h

R

002943 . 0

) 0255 . 0 ( 13324

1 1

= = =

i i

i

A h

R

008552 . 0 = R

necessary. not is trial Second

C. 80 of estimate original the to close quite is C.This 1 . 80 5 . 14 5 . 65 T Hence,

C 14.5 K 5 . 14 ) 2 . 42 (

008852 . 0

002943 . 0

) 2 . 42 ( drop e Temperatur

is film water the across drop re temperatu The

C 42.2 65.6) (107.8 is difference re temperatu overall The

o o

w

o

o

= + =

= =

|

.

|

\

|

=

=

=

R

R

i

(b)

( )

.K W/m 4586

) 008552 . 0 ( 0255 . 0

1

1

2

=

=

=

=

=

R A

U

T T A U

R

T T

q

i

i

i o i i

i o

(c)

( )

W 4935

) 2 . 42 )( 0255 . 0 ( 4586

C 2 . 42 6 . 65 8 . 107

C, 65.6 of re temperatu average an at with water

o

o

=

=

=

= =

i o i i

i o

T T A U q

T T

FKKSA

..

.

..

.

..

.

..

.

..

.

..

.

..

.

ENTRANCE-REGION EFFECT ON HEAT-

TRANSFER COEFFICIENT

At entrance, h =

0.7

L

L

D

1

h

h

|

|

.

|

\

|

+ =

|

|

.

|

\

|

+ =

L

D

6 1

h

h

L

2 < < 20

D

L

20 < < 60

D

L

h = average heat transfer coefficient for a tube of finite length L

h

L

= heat transfer coefficient for a very long tube

where

At L/D ~ 60, h = h

L

20 2 < <

D

L

Limitations

60 20 < <

D

L

Limitations

FKKSA

..

.

..

.

..

.

..

.

..

.

..

.

..

.

LI QUI D METAL HEAT-TRANSFER COEFFI CI ENT

N

Pe

= Peclet number = N

Re

N

Pr

where

Turbulent flow, N

Re

> 6000 :

0.4

Pe

N 625 0

k

D

L

h

Nu

N . = =

0.8

Pe

N 025 0 5.0

k

D

L

h

Nu

N . + = =

Constant wall temperature ( > 60, N

Pe

> 100 ) :

D

L

D

L

Uniform heat flux, 100 <

N

Pe

> 10

4

& > 60 :

4

Re

10 100

60

2100

< <

>

>

Pe

N

D

L

N

Limitations

100

60

>

>

Pe

N

D

L

Limitations

EXAMPLE 4.5-3 Page 266: Liquid-metal Heat

Transfer Inside a Tube

A liquid metal flows at a rate of 4.00kg/s through a tube

having an inside diameter of 0.05m. The liquid enters at 500K

and is heated to 505K in the tube. The tube wall is maintained

at a temperature of 30K above the fluid bulk temperature and

constant heat flux is maintained. Calculate the required tube

length. The average physical properties are as follows: = 7.1

x 10-4 Pa.s, = 7400 kg/m3, c

p

= 120 J/kg.K, k = 13 w/m.K

kg/s 4 = m

K 30 =

bm w

T T

metal liquid

K 500 =

bi

T

K 505 =

bo

T

? = L

m 05 . 0 =

i

D

3

4

kg/m 7400

W/m.K 13

kJ/kg.K 120

Pa.s 10 1 . 7

K, 5 . 502 at A.3, Appendix From

=

=

=

=

=

k

c

T

p

b

bm

K 5 . 502

2

505 500

2

=

+

=

+

=

bo bi

bmean

T T

T

w

T

bm

T

q

( ) ( ) | |

c or h

bi bo p bmean w

T T c m T T hA q

= =

L D A

i i

t =

K 30 =

bm w

T T

) 2000 ( 10 435 . 1

05 . 0

4

10 1 . 7

) 4 ( 05 . 0

5

2 4

Re

> =

|

.

|

\

|

=

=

x

A

m D

N

bm

T

w

T

4

2

i

x

D

A

t

=

) 10 100 ( 940

) 10 55 . 6 ( 10 435 . 1

4

3 5

Pr Re

< < =

=

=

Pe

Pe

N

N N N

3

4

Pr

10 55 . 6

13

) 10 1 . 7 ( 120

=

=

k

c

N

p

.K W/m 2512

) 940 ( 625 . 0

13

) 05 . 0 (

625 . 0

2

4 . 0

4 . 0

=

=

= =

i

i

Pe

i i

Nu

h

h

N

k

D h

N

( )

W 2400

) 500 505 )( 120 ( 4

=

=

=

bi bo p

T T c m q

( )

2

m 10 185 . 3

2400

) 30 ( 2512

2400

2

=

=

= =

i

i

bmean w i

i

A

A

A

T T h

A

q

m 203 . 0

) 05 . 0 ( 10 185 . 3

2

=

=

=

L

L

L D A

i i

t

t

bm o o bm i i

T A U T A U q A = A =

( ) ( ) ( ) ( )

ci co

c

p hi ho

h

p

T T c m T T c m q = =

|

|

.

|

\

|

A

A

A A

=

|

|

.

|

\

|

A

A

A A

= A

1

2

1 2

2

1

2 1

ln ln

T

T

T T

T

T

T T

T

lm

flow rent countercur

flow parallel

ho

T

hi

T

hi

T

ho

T

co

T

co

T

ci

T

ci

T

1

T A

1

T A

2

T A

2

T A

hi

T

hi

T

ho

T

ho

T

ci

T

ci

T

co

T

co

T

|

.

|

\

|

+

= A =

2

bo bi

w i ai a a

T T

T A h T A h q

(

(

(

(

(

|

|

.

|

\

|

A

A

A A

= A =

2

1

2 1

ln

T

T

T T

A h T A h q

i ai lm a

EXAMPLE 4.5-4 Page 268: Heat Transfer Area and

Log Mean Temperature Difference

A heavy hydrocarbon oil which has a c

pm

= 2.30kJ/kg is

being cooled in a heat exchanger from 371.9 K to 349.7 K

and flows inside the tube at a rate of 3630 kg/h. A flow of

1450kg water/h enters at 288.6K for cooling and lows

outside the tube.

a) Calculate the water outlet temperature and heat-transfer

area if the overall U

i

= 340 W/m2.K and the streams are

countercurrent

b) Repeat for parallel flow

flow rent countercur (a)

1

T A

2

T A

hi

T = K 1 . 397

K 7 . 349 =

ho

T

K 6 . 288 =

ci

T

co

T

kg/h 3630 oil, = m

kg/h 1450 water, = m

( ) ( )

| |

W 51490

3600 / ) 7 . 349 9 . 371 )( 3 . 2 ( 3630

=

=

=

hi ho

h

p

T T c m q

( )

( )

?

.K W/m 340

kJ/kg.K 187 . 4

kJ/kg.K 3 . 2

2

=

=

=

=

i

i

water

p

oil

p

A

U

c

c

( ) ( )

K 1 . 319

) 6 . 288 )( 187 . 4 ( 1450 51490

=

=

=

co

co

ci co

c

p

T

T

T T c m q

K 9 . 56

8 . 52

1 . 61

ln

8 . 52 1 . 61

ln

2

1

2 1

=

|

.

|

\

|

=

|

|

.

|

\

|

A

A

A A

= A

T

T

T T

T

lm

2

m 66 . 2

) 9 . 56 ( 340 51490

=

=

A =

i

i

lm i i

A

A

T A U q

K 1 . 61 6 . 288 7 . 349

K 8 . 52 1 . 319 9 . 371

2

1

= = A

= = A

T

T

flow parallel (b)

K 3 . 83 6 . 288 9 . 371

K 6 . 30 1 . 319 7 . 349

2

1

= = A

= = A

T

T

K 7 . 52

6 . 30

3 . 83

ln

6 . 30 3 . 83

ln

2

1

2 1

=

|

.

|

\

|

=

|

|

.

|

\

|

A

A

A A

= A

T

T

T T

T

lm

2

m 87 . 2

) 7 . 52 ( 340 51490

=

=

A =

i

i

lm i i

A

A

T A U q

forces. driving perature larger tem

gives ws counterflo because occurs This w. counterflo for than area larger a is This

EXAMPLE 4.5-5 Page 269 : Laminar Heat

Transfer and Trial and Error

A hydrocarbon oil at 150

o

F enters inside a pipe with an

inside diameter of 0.0303 ft and a length of 15 ft with a

flow rate of 80 Ibm/h. The inside pipe surface is assumed

constant at 350

o

F since steam is condensing outside the

pipe wall and has a very large heat-transfer coefficient.

The properties of the oil are c

pm

= 0.5 btu/Ibm.

o

F and k

m

=

0.083 btu/h.ft.

o

F. The viscosity of the oil varies with

temperature as follows: 150

o

F, 6.50 cp; 200

o

F, 5.05 cp;

250

o

F, 3.80 cp; 300

o

F, 2.82 cp; 350

o

F, 1.95cp. Predict the

heat-transfer coefficient and the oil outlet temperature, T

bo

Ibm/h 80 = m

F 350

o

=

w

T

oil

F 150

o

=

bi

T

? =

bo

T

ft 15

ft 0303 . 0

4

2

D

A

x

t

=

( )

F btu/h.ft. 083 . 0

F btu/Ibm. 5 . 0

o

o

=

=

m

oil

p

k

c

Ib/ft.h 23 . 12

cp 1

Ib/ft.h 2.4191

5.05cp

F 200

2

150 250

F 250 if value Assume

o

o

=

|

|

.

|

\

|

=

=

+

=

=

bmean

bo

T

T

) 2100 ( 5 . 275

0303 . 0

4

23 . 12

) 80 ( 0303 . 0

2

Re

< =

|

.

|

\

|

=

=

t

x

A

m D

N

7 . 73

083 . 0

) 23 . 12 ( 5 . 0

Pr

=

=

=

k

c

N

p

41

15

0303 . 0

) 7 . 73 ( 5 . 275

Pr Re

=

|

.

|

\

|

=

L

D

N N

( )

F . btu/h.ft 1 . 20

4191 . 2 95 . 1

23 . 12

41 86 . 1

083 . 0

) 0303 . 0 (

86 . 1

o 2

14 . 0

3

1

14 . 0

3

1

Pr Re

=

|

.

|

\

|

=

|

|

.

|

\

|

|

.

|

\

|

= =

h

h

L

D

N N

k

hD

N

w

b

Nu

again. re temperatu for the make we assumption check the to have We

( ) ( ) 150 ) 5 . 0 ( 0 . 80 = =

bo bi bo pm

T T T c m q

a a

T A h q A =

bo

bo bo bi

w a

T

T T T

T T 5 . 0 275

2

150

350

2

=

|

.

|

\

|

+

=

+

= A

( )

( )

F 255

5 . 0 275 150 ) 5 . 0 ( 0 . 80

o

=

=

A = =

bo

bo bo

a a bi bo pm

T

T T

T A h T T c m q

correct. is F 255 of perature outlet tem the Hence, l. first tria

for 5.05 with compared cp 5.0 is viscosity new The F. 202.5 or 255)/2 (150 be would boil the of

rature bulk tempe mean the trial, second For the F. 250 of value assumed n the higher tha is This

o

1

o

o

=

+

T

) 2100 ( 5 . 275

0303 . 0

4

23 . 12

) 80 ( 0303 . 0

2

Re

< =

|

.

|

\

|

=

=

t

x

A

m D

N

7 . 73

083 . 0

) 23 . 12 ( 5 . 0

Pr

=

=

=

k

c

N

p

41

15

0303 . 0

) 7 . 73 ( 5 . 275

Pr Re

=

|

.

|

\

|

=

L

D

N N

( )

F . btu/h.ft 1 . 20

4191 . 2 95 . 1

23 . 12

41 86 . 1

083 . 0

) 0303 . 0 (

86 . 1

o 2

14 . 0

3

1

14 . 0

3

1

Pr Re

=

|

.

|

\

|

=

|

|

.

|

\

|

|

.

|

\

|

= =

h

h

L

D

N N

k

hD

N

w

b

Nu

again. re temperatu for the make we assumption check the to have We

( ) ( ) 150 ) 5 . 0 ( 0 . 80 = =

bo bi bo pm

T T T c m q

a a

T A h q A =

bo

bo bo bi

w a

T

T T T

T T 5 . 0 275

2

150

350

2

=

|

.

|

\

| +

=

+

= A

( )

( )

F 255

5 . 0 275 150 ) 5 . 0 ( 0 . 80

o

=

=

A = =

bo

bo bo

a a bi bo pm

T

T T

T A h T T c m q

correct. is F 255 of perature outlet tem the Hence, l. first tria

for 5.05 with compared cp 5.0 is viscosity new The F. 202.5 or 255)/2 (150 be would boil the of

rature bulk tempe mean the trial, second For the F. 250 of value assumed n the higher tha is This

o

1

o

o

=

+

T

3

1

Pr Re

N CN N

m

Nu

=

( ) 1 - 4.6 table from m & C

( )

re temperatu fluid bulk average the and re temperatu or wall surface the is where

, 2 / re, temperatu film at the evaluated are properties fluid The

b w

b w f

T T

T T T + =

3

1

Pr

5 . 0

Re

664 . 0 N N N

Nu

=

7 . 0

10 3

Pr

5

Re

>

<

N

N

3

1

Pr

8 . 0

Re

0366 . 0 N N N

Nu

=

7 . 0

10 3

Pr

5

Re

>

>

N

N

Limitations

Limitations

EXAMPLE 4.6-1 Page: 272 Cooling a Copper Fin

A smooth, flat, thin fin of copper extending out from a

tube is 50 mm by 51 mm square. Its temperature is

approximately uniform at 82.2

o

C. Cooling air at 15.6

o

C

and 1 atm abs flows parallel to the fin at a velocity of

12.2 m/s.

a) For laminar flow, calculate the heat-transfer coefficient,

h

b) If the leading edge of the fin is rough so that all of the

boundary layer o film next to the fin is rough so that alls

o the boundary layer or film next to the fin is completely

turbulent, calculate h

mm 1 5

mm 1 5

q

C 2 . 82

o

=

w

T

C 6 . 15

o

=

bi

T

m/s 2 . 12 air, = v

atm 1 = P

C 49 C 9 . 48

2

6 . 15 2 . 82

2

o o

~ =

+

=

+

=

b w

f

T T

T

3

Pr

5

o

kg/m 097 . 1

W/m.K 028 . 0

704 . 0

Pa.s 10 95 . 1

C, 49 at A.3, Appendix From

=

=

=

=

=

k

N

T

b

f

) 10 3 ( 10 49 . 3

10 95 . 1

) 097 . 1 )( 2 . 12 ( 10 51

5 4

5

3

Re

< =

=

=

u L

N

.K W/m 7 . 60

) 704 . 0 ( ) 10 49 . 3 ( 664 . 0

028 . 0

) 10 51 (

664 . 0

2

3

1

5 . 0 4

3

3

1

Pr

5 . 0

Re

=

=

= =

h

h

N N

k

hL

N

Nu

( )

( )

W 51 . 10

6 . 15 2 . 82 ) 10 51 ( 7 . 60

6

=

=

=

bm w

T T hA q

3

1

Pr

5 . 0

Re

60 . 0 2 N N N

Nu

+ =

400 to 6 . 0

0000 7 to 1

Pr

Re

=

=

N

N

Limitations

EXAMPLE 4.6-2 Cooling of a Sphere

Using same condition as Example 4.6-1, where air at 1 atm

abs pressure and 15.6

o

C is flowing at velocity of 12.2 m/s,

predict the average heat-transfer coefficient for air flowing

by a sphere having a diameter of 51mm and an average

surface temperature of 82.2

o

C. Compare this with the value

of h = 77.2 W/m

2

.K for the flat plate in turbulent flow.

mm 1 5

C 2 . 82

o

=

w

T

3

Pr

5

o

kg/m 097 . 1

W/m.K 028 . 0

704 . 0

Pa.s 10 95 . 1

C, 49 at A.3, Appendix From

=

=

=

=

=

k

N

T

b

f

C 49 C 9 . 48

2

6 . 15 2 . 82

2

o o

~ =

+

=

+

=

b w

f

T T

T

.K W/m 56.1

) 704 . 0 ( ) 10 49 . 3 ( 60 . 0 2

028 . 0

) 10 51 (

60 . 0 2

2

3

1

5 . 0 4

3

3

1

Pr

5 . 0

Re

=

+ =

+ = =

h

h

N N

k

hD

N

Nu

) 10 3 ( 10 49 . 3

10 95 . 1

) 097 . 1 )( 2 . 12 ( 10 51

5 4

5

3

Re

< =

=

=

u L

N

EXAMPLE 4.6-3 Page 273: Heating Air by a Bank of

Tubes

Air at 15.6

o

C and 1 atm abs flows across a bank of tubes

containing four transverse rows in the direction of flow and 10

rows normal to the flow at a velocity of 7.62 m/s as the air

approaches the bank of tubes. The tube surfaces are maintained

at 57.2

o

C. The outside diameter of the tubes is 25.4mm and the

tubes are in-line to the flow. The spacing S

n

of the tubes normal

to the flow is 38.1mm and also S

p

is 38.1mm parallel to the

flow. For a 0.305m length of the tube bank, calculate the heat-

transfer rate

mm 1 . 38 =

n

S

mm 1 . 38 =

p

S

mm 4 . 25 = D

C 2 . 57

o

=

w

T

1

2

3

9

10

C 6 . 15

o

=

bi

T

m/s 6 . 7 air, = v

atm 1 = P

C 7 . 37

2

3 . 18 2 . 57

2

o

=

+

=

+

=

b w

f

T T

T

3

Pr

5

o

kg/m 137 . 1

W/m.K 027 . 0

705 . 0

Pa.s 10 904 . 1

C, 7 . 37 at A.3, Appendix From

=

=

=

=

=

k

N

T

b

f

2 3 4

) 10 3 ( 10 47 . 3

10 90 . 1

) 137 . 1 )( 86 . 22 ( 02547 . 0

5 4

5

max

Re

< =

=

=

u L

N

m/s 86 . 22

47 . 25 1 . 38

1 . 38

6 . 7

max

=

|

.

|

\

|

=

D S

vS

v

n

n

620 . 0 , 278 . 0 5 . 1 line, In

251) (pg 2 - 4.6 Table From

= = = = m c

D

S

D

S

p

n

.K W/m 8 . 171

) 705 . 0 ( ) 10 47 . 3 ( 278 . 0

027 . 0

) 0254 . 0 (

2

3

1

620 . 0 4

3

1

Pr Re

=

=

= =

h

h

N cN

k

hD

N

m

Nu

3 - 4.6 Table in given as

0.9, by multiplied be must the direction, e transvers in the rows 4 only For rows. 10 for is This h h

.K W/m 62 . 154 ) 8 . 171 ( 9 . 0

2

= = h

2

m 973 . 0 ) 305 . 0 )( 0254 . 0 ( 40 40 = = = t tDL A

kg/s 084 . 1 ) 1162 . 0 )( 224 . 1 ( 6 . 7 ) 3600 ( = = =

t

A v m

2

m 1162 . 0 ) 305 . 0 )( 0381 . 0 ( 10 10 = = = L S A

n t

( )

C 20

) 6 . 15 )( 10 0048 . 1 ( 084 . 1

2

6 . 15

2 . 57 ) 973 . 0 ( 62 . 154

2

o

3

=

= |

.

|

\

| +

= |

.

|

\

| +

=

bo

bo

bo

bi bo p

bi bo

w

T

T

T

T T c m

T T

T hA q

C 17.8 or 20)/2 (15.6 be would use be to average new the made, be to ware trial second If

o

+

b

T

35 . 0

Re

Re

3

2

3023 . 0 876 . 2

'

N

N k

c

c

h

f

p

p

+ =

|

|

.

|

\

|

u

c

0000 1 to 10

Gases

Re

= N

Limitations

Note : All properties are at T

bmean

, except for those with

subscript f

You might also like

- Double Pipe Heat Exchanger: Experiment 9Document6 pagesDouble Pipe Heat Exchanger: Experiment 9Jelain HumarangNo ratings yet

- Condensation and BoilingDocument14 pagesCondensation and BoilingCrislyn Akilit Bayawa100% (1)

- Tutorial Slides - Internal Forced Convection & Natural ConvectionDocument31 pagesTutorial Slides - Internal Forced Convection & Natural ConvectionVivaan Sharma75% (4)

- AssigDocument2 pagesAssigZakwan0% (1)

- Volumetric Properties of Pure FluidsDocument40 pagesVolumetric Properties of Pure FluidsAleem Ahmed100% (1)

- Practice Problems in Absorption and HumidificationDocument4 pagesPractice Problems in Absorption and HumidificationJenna BraszNo ratings yet

- Thermo Heat EffectsDocument61 pagesThermo Heat Effectsafri riandraNo ratings yet

- Week 1Document35 pagesWeek 1FAizNo ratings yet

- Lecture Notes 3Document70 pagesLecture Notes 3joshuaNo ratings yet

- CH E Problem 3Document3 pagesCH E Problem 3Brayan AguilarNo ratings yet

- Solution Thermodynamics Theory-Ch 11Document50 pagesSolution Thermodynamics Theory-Ch 11Donni Azhar100% (2)

- Separation Processes: Worksheet #3: Multicomponent DistillationDocument5 pagesSeparation Processes: Worksheet #3: Multicomponent DistillationPatricia DavidNo ratings yet

- Multi Stage VapourDocument20 pagesMulti Stage VapourMazhar UddeenNo ratings yet

- Tuto Chap 3Document3 pagesTuto Chap 3Zakiyah Mohamed Razi50% (2)

- Chapter 4 (Heat Effects)Document67 pagesChapter 4 (Heat Effects)yohannes lemiNo ratings yet

- Try MeDocument9 pagesTry MeKrizzete HernandezNo ratings yet

- Radiation Heat TransferDocument20 pagesRadiation Heat TransferMc Jason LaureteNo ratings yet

- Humidification and Dehumidification DEHUMIDIFCATION Is The Process in Which The Moisture or Water Vapor or TheDocument7 pagesHumidification and Dehumidification DEHUMIDIFCATION Is The Process in Which The Moisture or Water Vapor or TheAwi ButuanNo ratings yet

- CHAPTER 03 - 2nd Part - Properties of Pure Fluids-May20Document49 pagesCHAPTER 03 - 2nd Part - Properties of Pure Fluids-May20Scorpion Royal100% (1)

- Convective Mass TransferDocument46 pagesConvective Mass TransferSandra Enn BahintingNo ratings yet

- APT300S Tutorial - RefrigerationDocument2 pagesAPT300S Tutorial - Refrigerationcarleston thurgood0% (1)

- Quiz Ert 216 Heat and Mass Transfer - AnswerDocument3 pagesQuiz Ert 216 Heat and Mass Transfer - AnswerMohammed Al MurisiNo ratings yet

- Cooling and Humidification HandoutDocument57 pagesCooling and Humidification HandoutTony Msipa50% (2)

- Convection&RadiationDocument40 pagesConvection&RadiationdesdainedmanNo ratings yet

- Solid Fuels Group 7 & 8Document91 pagesSolid Fuels Group 7 & 8Jowel MercadoNo ratings yet

- Heat Transfer Joeffrey Bardon (7!18!19)Document3 pagesHeat Transfer Joeffrey Bardon (7!18!19)pamiNo ratings yet

- 01 - Introduction To Transport PhenomenaDocument22 pages01 - Introduction To Transport PhenomenaClaire dela CruzNo ratings yet

- ConvectionDocument37 pagesConvectionCarlos Peralta0% (1)

- Practical Conduction Heat TransferDocument14 pagesPractical Conduction Heat TransfertskNo ratings yet

- Thermodynamics ProblemsDocument1 pageThermodynamics ProblemsTots HolaresNo ratings yet

- Pressure Drop and Friction Factor in Turbulent FlowDocument35 pagesPressure Drop and Friction Factor in Turbulent FlowBrian CbtngnNo ratings yet

- Humidification and Drying ProblemsDocument2 pagesHumidification and Drying ProblemsKuo SarongNo ratings yet

- HumidificationDocument26 pagesHumidificationOky TresiaNo ratings yet

- Problem 2.4 SeborgDocument2 pagesProblem 2.4 SeborgJacky Lou Cabalejo100% (3)

- Heat and Mass Transfer (NPTEL) PDFDocument569 pagesHeat and Mass Transfer (NPTEL) PDFArnab Midya83% (12)

- Heat Transfer Coefficient PDFDocument57 pagesHeat Transfer Coefficient PDFAnmol Preet SinghNo ratings yet

- P P P P: ( (P - P) / P) % 0.665 % We Can Neglect The K.E. Term in This ProblemDocument3 pagesP P P P: ( (P - P) / P) % 0.665 % We Can Neglect The K.E. Term in This ProblemAramNawzad100% (1)

- NonNewtonian NumericalDocument14 pagesNonNewtonian Numericaldr_drk4503100% (1)

- Simulation of Double-Effect Evaporator For Concentrating Orange JuiceDocument23 pagesSimulation of Double-Effect Evaporator For Concentrating Orange JuicethanhndbNo ratings yet

- Heat Transfer by ConvectionDocument61 pagesHeat Transfer by ConvectionJason Yap Han YuenNo ratings yet

- Forstudents Mar4Document4 pagesForstudents Mar4RawlinsonNo ratings yet

- Drying ProblemDocument5 pagesDrying ProblemStephanie Torrecampo Delima100% (2)

- HT304 - Draft Report PDFDocument7 pagesHT304 - Draft Report PDFshashiNo ratings yet

- Edinburgh EH14 4AS, United Kingdom Produced by Heriot-Watt University, 2018Document119 pagesEdinburgh EH14 4AS, United Kingdom Produced by Heriot-Watt University, 2018LydsNo ratings yet

- First Law of ThermodynamicsDocument64 pagesFirst Law of ThermodynamicsAnonymous fU6NLw3No ratings yet

- M.E LAB 3 Experiment 4 Heat Losses From PipesDocument14 pagesM.E LAB 3 Experiment 4 Heat Losses From PipesDrw ArcyNo ratings yet

- Tutorial 5Document3 pagesTutorial 5pleco4meNo ratings yet

- Heat Transfer in Natural ConvectionDocument4 pagesHeat Transfer in Natural ConvectionkoushikaerosNo ratings yet

- Experiment 14 - Heat Conduction Study BenchDocument11 pagesExperiment 14 - Heat Conduction Study Bencheven leeNo ratings yet

- 3 - Shell Momentum Balances and Velocity Distribution in Laminar FlowDocument15 pages3 - Shell Momentum Balances and Velocity Distribution in Laminar FlowPatricia de LeonNo ratings yet

- DRYINGDocument14 pagesDRYINGKaia MacNo ratings yet

- 07 - Steam Generator FamiliarizationDocument6 pages07 - Steam Generator FamiliarizationJoren HuernoNo ratings yet

- Heat Transfer in Agitated VesselDocument4 pagesHeat Transfer in Agitated Vesselshaz_don100% (2)

- Design of Shell and Tube Heat ExchangerDocument42 pagesDesign of Shell and Tube Heat Exchanger3004 Divya Dharshini. MNo ratings yet

- Heat Chap08 053Document10 pagesHeat Chap08 053Kerem GönceNo ratings yet

- Where, The Temperature Ratio, Capacity Ratio, R A Value of 0.8 Is Generally Not AcceptedDocument43 pagesWhere, The Temperature Ratio, Capacity Ratio, R A Value of 0.8 Is Generally Not AcceptedAditya DeokarNo ratings yet

- 11B - Chapter 11, Secs 11.4 - 11.7 BlackDocument15 pages11B - Chapter 11, Secs 11.4 - 11.7 BlackrajindoNo ratings yet

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocument2 pagesDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateAbhishek SinglaNo ratings yet

- Heat Transfer UNIT-8 Heat Exchangers:: Problem 50Document8 pagesHeat Transfer UNIT-8 Heat Exchangers:: Problem 50Miguel Angel Carranza OlveraNo ratings yet

- Science Form 1Document15 pagesScience Form 1Renu SekaranNo ratings yet

- For Section A, Write Your Answer in The Answer Sheet Provided in Page 12Document12 pagesFor Section A, Write Your Answer in The Answer Sheet Provided in Page 12Renu SekaranNo ratings yet

- Cell As A Unit of LifeDocument40 pagesCell As A Unit of LifeRenu SekaranNo ratings yet

- Lesson Plan (Subject: SCIENCE)Document3 pagesLesson Plan (Subject: SCIENCE)Renu SekaranNo ratings yet

- Wesley Methodist School Klang MONTHLY TEST 1 (2019) Chemistry Form 4 Total: 50 MarksDocument8 pagesWesley Methodist School Klang MONTHLY TEST 1 (2019) Chemistry Form 4 Total: 50 MarksRenu SekaranNo ratings yet

- Lesson Plan Format 27-1Document4 pagesLesson Plan Format 27-1Renu SekaranNo ratings yet

- Lesson Plan Format 24-2 (Opal)Document3 pagesLesson Plan Format 24-2 (Opal)Renu SekaranNo ratings yet

- Intensive 4 Page 2Document1 pageIntensive 4 Page 2Renu SekaranNo ratings yet

- Lesson Plan (Subject: SCIENCE)Document2 pagesLesson Plan (Subject: SCIENCE)Renu SekaranNo ratings yet

- Lesson Plan Format 27-1 (Opal)Document4 pagesLesson Plan Format 27-1 (Opal)Renu SekaranNo ratings yet

- E E:sl: Et Isl If:: I Ii:i I Il", 3:p:r I Et:sfDocument1 pageE E:sl: Et Isl If:: I Ii:i I Il", 3:p:r I Et:sfRenu SekaranNo ratings yet

- Intensive 4 Page 4Document1 pageIntensive 4 Page 4Renu SekaranNo ratings yet

- 1 PGDIPEDU (UAB) MyVLE Practicum SlideDocument17 pages1 PGDIPEDU (UAB) MyVLE Practicum SlideRenu SekaranNo ratings yet

- MODE 2: For Student-Teacher With Less Than One: 1 Observation by Co-TeacherDocument4 pagesMODE 2: For Student-Teacher With Less Than One: 1 Observation by Co-TeacherRenu SekaranNo ratings yet

- Intensive 3 Page 2Document1 pageIntensive 3 Page 2Renu SekaranNo ratings yet

- Form 2 - Page 1Document1 pageForm 2 - Page 1Renu SekaranNo ratings yet

- Form 1 Assessment OCTOBER 2015 Form 1 Science: (Duration: 25 Minutes)Document8 pagesForm 1 Assessment OCTOBER 2015 Form 1 Science: (Duration: 25 Minutes)Renu SekaranNo ratings yet

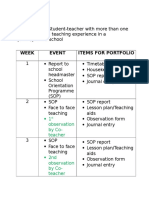

- MODE 1: For Student-Teacher With More Than One: 1 Observation by Co-TeacherDocument4 pagesMODE 1: For Student-Teacher With More Than One: 1 Observation by Co-TeacherRenu SekaranNo ratings yet

- Chapter 2b Molecular Diffusion in LiquidDocument12 pagesChapter 2b Molecular Diffusion in LiquidRenu SekaranNo ratings yet

- Lennox - High Wall Mini Split INVERTER 18 SEERDocument4 pagesLennox - High Wall Mini Split INVERTER 18 SEERWalter BernalNo ratings yet

- M.4-2-201a - Hotel Mechanical Services Chilled Water System Schematic DiagramDocument1 pageM.4-2-201a - Hotel Mechanical Services Chilled Water System Schematic Diagramdiki anggriawanNo ratings yet

- Thermodynamics 2 Quiz #5 - T01: Name: ID #: ProblemDocument2 pagesThermodynamics 2 Quiz #5 - T01: Name: ID #: ProblemPolyanaNo ratings yet

- Heat Transfer Introduction: February 2018Document63 pagesHeat Transfer Introduction: February 2018abdelrhmanNo ratings yet

- AC07 - 4x2 Merged MergedDocument4 pagesAC07 - 4x2 Merged MergedHaris YusoffNo ratings yet

- College: Multiple Pass and Cross Flow Heat ExchangersDocument5 pagesCollege: Multiple Pass and Cross Flow Heat Exchangersggy34No ratings yet

- Energise 2020 - Jupiter Hospital Case StudyDocument7 pagesEnergise 2020 - Jupiter Hospital Case StudySujoy DeNo ratings yet

- Problem: A.) B.) A.) B.) C.)Document1 pageProblem: A.) B.) A.) B.) C.)jose friasNo ratings yet

- 27 TDP Cat Int PriceDocument12 pages27 TDP Cat Int Pricespotty81100% (3)

- Air Cooling Effect of Fins in MotorcycleDocument7 pagesAir Cooling Effect of Fins in Motorcyclestorage spaceNo ratings yet

- Final Year Project Report-Ground Source Cooling SystemDocument24 pagesFinal Year Project Report-Ground Source Cooling SystemAmanpreet Singh93% (28)

- 10Document66 pages10Praveen100% (1)

- HMT Module V Class NoteDocument20 pagesHMT Module V Class NoteJithosh BabuNo ratings yet

- Thermodynamics An Engineering Approach ED8 - IQ2001 - StuDocu6565 PDFDocument1 pageThermodynamics An Engineering Approach ED8 - IQ2001 - StuDocu6565 PDFBrandom Antonio Cervantes SacachipanaNo ratings yet

- Earth Air Tunnel Heat ExchangerDocument21 pagesEarth Air Tunnel Heat ExchangerRatan Ng100% (1)

- Understand Hvac DesignDocument14 pagesUnderstand Hvac DesignahmaborashedNo ratings yet

- Napitupulu 2020 IOP Conf. Ser. Mater. Sci. Eng. 725 012004Document7 pagesNapitupulu 2020 IOP Conf. Ser. Mater. Sci. Eng. 725 012004هادی طاهریNo ratings yet

- He SelectionDocument7 pagesHe SelectionKaizerNo ratings yet

- Faculty Development Programme On Recent Trends in Thermo-Fluids Engineering (RTTFE 2018)Document42 pagesFaculty Development Programme On Recent Trends in Thermo-Fluids Engineering (RTTFE 2018)Minhaz SixNo ratings yet

- ANSI - ASHRAE - IESNA Standard 90.1-1999 With 90.1-2001 Highlights (PDFDrive)Document193 pagesANSI - ASHRAE - IESNA Standard 90.1-1999 With 90.1-2001 Highlights (PDFDrive)Roubio MohamedNo ratings yet

- Fdocuments - in 1 Introduction To Heat TransferDocument12 pagesFdocuments - in 1 Introduction To Heat TransferShafqat HussainNo ratings yet

- Exp 4 Combined Convection and RadiationDocument3 pagesExp 4 Combined Convection and RadiationHaitham S Khouri50% (2)

- Cálculo de Carga Térmica Tienda de SouvenirDocument8 pagesCálculo de Carga Térmica Tienda de SouvenirIvan HernándezNo ratings yet

- Dose Measurements and Calculation PDFDocument19 pagesDose Measurements and Calculation PDFAlshuqaiq LaboratoryNo ratings yet

- 9.0 Coldstorage Principle of PsychrometricsDocument90 pages9.0 Coldstorage Principle of PsychrometricsSweekar KhadkaNo ratings yet

- Optimal Shell and Tube Heat Exchangers Design: September 2011Document31 pagesOptimal Shell and Tube Heat Exchangers Design: September 2011jeremytoh89No ratings yet

- 303-03A Engine Cooling - 1.5L EcoBoostDocument71 pages303-03A Engine Cooling - 1.5L EcoBoostMohamed AdelNo ratings yet

- Refrigeration and Air Conditioning - 220308 - 155054Document13 pagesRefrigeration and Air Conditioning - 220308 - 155054Dhruvi PadmaniNo ratings yet

- Science10 ActivityDocument12 pagesScience10 ActivityTitanium NohorNo ratings yet

- Transfer of Thermal Energy: ConductionDocument10 pagesTransfer of Thermal Energy: ConductionmelissaNo ratings yet