Professional Documents

Culture Documents

T500 Veeyes

Uploaded by

Timothy TaylorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T500 Veeyes

Uploaded by

Timothy TaylorCopyright:

Available Formats

Pag.

1 di 5

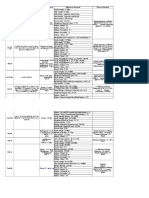

T-500

CARATTERISTICHE CHIMICHE, MECCANICHE E STATO DI FORNITURA DEI MATERIALI BFE

B.F.E.

CHEMICAL, MECHANICAL CHARACTERISTICS AND SUPPLY STATUS OF THE BFE MATERIALS

CHEMICAL COMPOSITION (maximun)

MECHANICAL PROPERTIES

MATERIAL

BFE

DESIGNATION

A105-LF2/BFE

A105-LF2-1.0460

ASTM /DIN

UNS/Other

nuova lega Riva

marzo 2008

nuova lega Riva

gennaio 2011

Form

Forging / Bar

Forging / Bar

A105N

A105-11a

K03504

Forging

SA105N

SA105 - 2011

K03504

Forging

A105-UOP

Forging for

ALK

A105-GS8

Forging

A105N DEGAS

LF1

LF2

LF2 60K

LF2N

LF3

C22.8

1.0460

P250GH

1.0566

TstE 355

1.0571

P355QH1

1.0619

GP240GH

1.0980

S420MC

Forging

A350- 12

LF1

A350 12

LF2 CL 1

A350 12

LF2 CL 1

A350-12

LF2 CL 1

A350-12

LF3 CL1

17243

C22.8

DIN EN10222-2

nat. attach.

DIN 17103

K03009

Forging

K03011

Forging

K03011

Forging

K03011

Forging

K32025

Forging

Forging / Bar

Forging / Bar

Forging

1.0566 equal to 1.0565

0,20

Plate

0,12

Forging

0,26

Forging

1.6368

WBL 377/3

06.2010

A29-12

4130

A29-12

4140

A182-12a

F1

DIN EN 10222-2

16Mo3

A182-12a

F11 Cl.2

A739-90a (2012)

B11

EN 10273

13CrMo4-5

A182-12a

F12 Cl.2

A182-12a

F22 Cl.3

A182-12a

F22 Cl.3

EN10028-2

10CrMo910

EN 10222-2

11CrMo910

A182-12a

F5

A182-12a

F5a

X12CrMo5 /

X16CrMo5-1

A182-12a

F9

Forging

F1

F11

B11

1.7335

F12

F22

F22 Mod

1.7380

1.7383

F5

F5a

1.7362 / 1.7366

F9

1.7386

A182-12a

F91

1.4903

X10CrMoVNb9-1

EN 10222-2 / WB511/2

F92

A182-12a

F92

1.4901

X10CrWMoVNb9-2

WB 552/2 12.2009

F6

(std. BFE)

F6 NM

AISI 410 cl.2

(steli)

AISI 410 cl.2

Cond 2

AISI 410 cl.2

(madrev.

AISI 416

(madrev. normali)

AISI 416

(madrev. Tempr)

AISI 422

(Condition HT)

D-2C

K03014

A182-12a

F6a CL 1

A182-12a

F6a CL 2

A182-12a

F6NM

A479-12

Type 410 CL 2

A479-12

Type 410 CL 2

A479-12

Type 410 CL 2

A582-12E1

S41600

A582-12E1

S41600

A565-10

S42200 - Gr616

A439-83 (2009)

D-2C

Forging

G41300

Forging

G41400

Forging

K12822

Forging

Forging

K11572

K11797

Forging

Bar

Forging

K11564

Forging

K21590

Forging

K21590

Forging

Forging

Forging

0,6

EN10028-2 /

EN 10222-2

Forging

0,10

0,15

K90941

Forging

0,15

Forging

0,15

0,08

0,12

0,08

0,12

0,07

0,13

0,07

0,13

0,30

0,60

0,30

0,60

0,30

0,60

0,30

0,60

0,30

0,60

0,30

0,60

0,30

0,60

Forging

0,020

0,015

0,025

0,025

0,025

0,025

0,010

0,015

0,020

0,035

0,020

0,035

0,020

0,035

0,020

0,035

Si

0,15

0,30

0,15

0,30

0,15

0,30

0,15

0,30

0,15

0,30

0,10

0,35

0,15

0,30

0,15

0,30

0,15

0,30

0,15

0,30

0,15

0,30

0,20

0,35

0,035

0,040

0,025

0,020

0,030

0,40

0,025

0,015

0,40

0,025

0,020

0,025

0,25

Forging

0,025

0,015

Forging

Forging

0,025

0,020

0,035

0,020

0,035

0,020

0,035

0,025

K42544

K92460

0,025

0,025

0,15

Forging

0,015

1,60

Forging

K90901

0,015

1,60

1,60

0,15

0,015

0,015

0,70

1,00

0,80

1,20

0,40

0,60

0,75

1,00

0,60

0,90

0,40

0,90

0,30

0,80

0,40

0,65

0,40

1,00

0,30

0,80

0,30

0,60

0,30

0,60

0,40

0,80

0,40

0,80

0,30

0,60

0,08

0,14

0,08

0,15

0,015

0,020

0,26

0,28

0,025

0,15

0,25

0,10

0,17

0,28

0,33

0,38

0,43

0,12

0,20

0,10

0,20

0,05

0,20

0,08

0,18

0,10

0,20

0,05

0,15

0,030

K41545

X12CrMo91

F91

F6

0,18

0,18

0,23

20MnMo35

1.5415

0,90

0,40

0,90

0,30

0,90

0,90

1,35

0,90

1,65

0,50

1,20

Forging

1.5421

4140

0,20

0,18

0,23

0,18

0,23

Casting

F60

(acc.carbonio)

4130

0,85

1,05

0,60

0,90

0,85

1,05

0,85

1,05

See notes

0,18

85

0,85

0,25

1,05

0,16

0,85

0,20

1,05

0,60

0,22

1,35

0,18

0,85

0,22

1,05

0,18

0,85

0,22

1,05

0,85

0,180,22

1,05

EN10213-2

K03014

Mn

0,16

0,20

0,16

0,20

0,18

0,20

0,18

0,22

EN10222-4

1.0571

EN 10149-2

S420MC

A694-08

F42

A694-08

F60

F42

0,025

0,025

0,025

0,025

0,025

0,016

0,025

0,025

0,035

0,040

0,045

0,045

0,025

0,015

0,040

0,030

0,10

0,50

0,10

0,50

0,60

Cu

Ni

Cr

Mo

0,25

0,25

0,20

0,12

0,025

0,25

0,25

0,20

0,12

0,020

0,40

0,40

0,30

0,12

0,08

0,01

0,40

0,40

0,30

0,12

0,08

0,01

0,02

0,02

0,12

0,08

0,01

See notes See notes See notes See notes

85

85

85

85

0,40

0,40

0,040

0,10

0,35

0,040

0,040

0,50

0,006

0,006

0,30

0,12

0,025

0,02

0,12

0,08

0,02

0,40

0,40

0,30

0,12

0,08

0,01

0,40

0,40

0,30

0,12

0,08

0,01

0,40

0,40

0,30

0,12

0,08

0,01

0,40

3,30

3,70

0,30

0,12

0,03

0,30

0,30

0,20

0,30

0,08

0,02

0,02

0,06

0,30

0,30

0,08

0,10

0,30

0,12

0,03

1,00

1,30

0,30

0,30

0,20

0,20

0,30

0,50

0,30

0,50

0,030

0,030

0,50

0,50

0,040

0,030

0,50

0,50

0,020

0,005

0,030

0,030

0,035

0,035

0,020

0,010

0,30

0,30

0,40

0,30

0,30

0,020

0,005

0,020

0,010

0,50

0,40

0,020

0,010

0,50

0,40

1,00

0,040

0,030

1,00

0,50

S41000

Forging

0,15

S41000

Forging

0,15

1,00

0,040

0,030

1,00

0,50

S41500

Forging

0,05

0,50

1,00

0,030

0,030

0,60

3,5

5,5

S41000

Bars

0,15

1,00

0,040

0,030

1,00

S41000

Bars

0,15

1,00

0,040

0,030

1,00

S41000

Bars

0,15

1,00

0,040

0,030

1,00

Bars

0,15

1,25

0,060

0,15

1,00

Bars

0,15

1,25

0,060

0,15

1,00

S42200

Bars

0,20

0,25

F43002

Bars

2,90

0,50

1,00

1,80

2,40

0,50

1,00

3,00

0,30

0,80

1,10

0,80

1,10

0,50

S41600

0,03

Notes

1 - 18

47

1 - 18

47-82

1 - 18

47

1 - 18

47

85

1 - 18

89-90

1 - 18

31-47

1 18

47

1 18

47

1 18

47

1-18

47

0,02

18

0,010

82

0,05

0,05

19-8693

86

86A

0,09

0,15

69

69

0,50

S41600

0,03

> 0,015

0,20

0,015

0,40

0,015

0,050

0,015

0,050

0,10

0,40

0,010

0,025

0,30

0,02

0,30

0,025

0,08

0,30

0,20

0,020

0,50

1,00

0,25

1,00

0,20

0,50

0,20

0,50

0,01

0,20

0,50

1,00

0,50

0,80

0,040

0,010

0,020

0,30

0,30

0,35

0,020

0,035

0,25

0,35

0,01

0,02

0,40

0,50

0,80

0,040

Nb/Cb

0,25

0,50

0,025

Ti

0,40

0,15

0,35

0,15

0,35

0,15

0,25

0,25

0,50

0,15

0,35

0,15

0,35

0,15

0,35

0,035

0,025

0,30

Al

0,50

1,00

21,00

24,00

0,30

1,00

1,50

1,00

1,50

0,70

1,15

0,80

1,25

2,00

2,50

2,00

2,50

2,00

2,50

2,00

2,50

4,00

6,00

4,00

6,00

4,00

6,00

8,00

10,00

8,00

10,00

8,00

9,50

8,00

9,50

8,50

9,50

8,50

9,50

11,50

13,50

11,50

13,50

11,5

14,0

11,50

13,50

11,50

13,50

11,50

13,50

12,00

14,00

12,00

14,00

11,00

12,5

0,50

0,40

0,60

0,25

0,50

0,15

0,25

0,15

0,25

0,44

0,65

0,25

0,35

0,44

0,65

0,45

0,65

0,40

0,60

0,44

0,65

0,87

1,13

0,87

1,13

0,90

1,10

0,90

1,10

0,44

0,65

0,44

0,65

0,45

0,65

0,90

1,10

0,90

1,10

0,85

1,05

0,85

1,05

0,30

0,60

0,30

0,60

Rev. 29

(minimum)

Hardness

NACE

MR

Yeld p.

N/mm2

Tensile

N/mm2

Elong %

Reduct %

Hardness

ASTM

HB

250

485655

22

30

137187

187 HBW

250

485540

25

30

137187

187 HBW

250

485655

22

30

137187

187 HBW

250

485655

22

30

137187

187 HBW

250

485655

22

30

137187

187 HBW

250

485655

22

30

137187

187 HBW

01-03 or

01-75

MR

250

485655

22

30

137187

187 HBW

205

415585

25

38

137187

22 HRC

250

485655

22

30

197 max

22 HRC

414

485655

22

30

137187

22 HRC

250

485655

22

30

137187

22 HRC

260

485655

22

35

197 max

22 HRC

240

410540

25

187 max.

250

410540

25

187 max.

23L

21T

21L

19T

335

490630

315

470630

240

420

22

420

480620

16

290

415

20

415

515

20

430

580740

20

187 max.

Notch

impact

See note

N53

See note

N53

27J min

-29C

27J min

-29C

See note

N53

See note

N53

See note

N53

14/18J

-29C

20/27J

- 50C

20/27J

- 50C

30/40J

-50C

16/20J

-101C

27J min

-29C

27J min

-29C

27/19J

-50C

27/20

-50C

27J miin

-10C

22 HRC

22 HRC

68/54J

-50C

Heat treatment

according to ASTM

Normalizing at 843927 C

Normalizing at 843927 C

Normalizing at 843927 C

Normalizing at 843927 C

Normalizing and Tempered at

590C min,

Quench in water at 930C

Tempered at 640670 C

Normalizing at 843927 C

Quench in oil at 860C

Tempered at 640C

Normalizing at 890950C

Normalizing at 890950C

Quench in water at 930C

Tempered at 640C

Quench in water at 860-940C

Tempered at 600-700 C

Normalizing at 890950C

Quench in water at 930C

Tempered at 640C

Quench in water at 930C

Tempered at 640C

Post Weld Heat Treatment Acc.

To ASME B31.3 (for effective

temperature and time see

spicific WPS-PQR)

If required or Thk > 20 mm

593649Cx1hr min(+1hr/in.)

If required or Thk > 20 mm

593649Cx1hr min(+1hr/in.)

If required or Thk > 20 mm

Normalizing at 910 C

593649Cx1hr min(+1hr/in.)

If required or Thk > 20 mm

Normalizing at 910 C

593649Cx1hr min(+1hr/in.)

If required or Thk > 20 mm

593649Cx1hr min(+1hr/in.)

If required or Thk > 20 mm

Normalizing at 910 C

593649Cx1hr min(+1hr/in.)

If required or Thk > 20 mm

Normalizing at 910 C

593649Cx1hr min(+1hr/in.)

If required or Thk > 20 mm

593649Cx1hr min(+1hr/in.)

Quench in water at 880C

If required or Thk > 20 mm

Tempering at 640C

593649Cx1hr min(+1hr/in.)

Quench in water at 930C

If required or Thk > 20 mm

Tempering at 580C

593649Cx1hr min(+1hr/in.)

If required or Thk > 20 mm

Normalizing at 910 C

593649C x 1hr min (+ 1 hr/in.)

Quench in oil at 860C

If required or Thk > 20 mm

1Temp. at 670C 2Temp.at

593635Cx1hr min(+1hr/in.)

If required or Thk > 20 mm

Normalizing at 910 C

593649Cx1hr min(+1hr/in.)

If required or Thk > 20 mm

Normalizing at 910 C

593649Cx1hr min(+1hr/in.)

Quench in water at 930C

If required or Thk > 20 mm

593649Cx1hr min(+1hr/in.)

Tempered at 640C

Quench in water at 860-940C

If required or Thk > 20 mm

Tempered at 600-700 C

593649Cx1hr min(+1hr/in.)

If required or Thk > 20 mm

Normalizing at 910 C

593649Cx1hr min(+1hr/in.)

Effective Heat Treatment

temperature after forging

Quench in water at 930C

Tempered at 640C

Quench in water at 930C

Tempered at 640C

If required or Thk > 20 mm

593649Cx1hr min(+1hr/in.)

If required or Thk > 20 mm

593649Cx1hr min(+1hr/in.)

Normalizing at 900C min,

Tempered at 620C min,

Quench 840860C

Tempered 550670C

Quench 840860C

Tempered 550670C

Normalizing at 920C min,

Tempering at 640C min.

530620C x 1hr min (+ 1 hr/in.)

593718C x 1hr min (+1 hr/in.)

0,02

0,015

0,050

0,015

0,03

190240

HV10

acc, to 75K acc, to 75K acc, to 75K acc, to 75K

517

655

17

35

acc, to 75K acc, to 75K acc, to 75K acc, to 75K

517

655

17

35

0,02

0,01

0,010

0,02

0,18

0,25

0,18

0,25

0,15

0,25

0,15

0,25

0,01

0,02

0,01

0,040

0,02

0,01

0,02

0,01

0,06

0,10

0,06

0,10

0,04

0,09

0,04

0,09

Min. 197

225 HBW

Min. 197

225 HBW

30

143192

225 HBW

143207

225 HBW

275

485

20

87

285

440570

23l

21t

83

275

485

20

30

18

45

310

483

655

102

280

440590

22L

20T

102

275

485

20

30

143207

83

310

515

20

30

156207

83

94

L&T

415535

L&T

586670

18

225 HBW

235 HBW

220 max

20L

22T

20L

20T

102

300

480630

102

310

520670

275

485

20

35

143217

235 HBW

450

620

22

50

187248

235 HBW

390

590740

17

380

585

20

102

49

415

620

20

20

175220

40

179217

235 HBW

40

190248

248 HBW

95

450

630

730

100

440

620

20

45

269 max

248 HBW

100

440

620850

20

45

269 max

248 HBW

275

485

18

35

143207

22 HRC

0,50

1,00

39J at 0C Normalizing at 880-960C min,

48J at

Tempered at 580-680C min,

27J min

Quench 840860C

-46C

Tempered 550670C

27J min

Quench 840860C

-46C

Tempered 550670C

27J min

Normalizing at 900C min,

-18C

Tempered at 620C min,

L 50min

Austenitizing 890-960C

T 34min

Tempering 620-700 C

27J min.

Normalized at 900C min

Tempered at 620C min,

-29C

27J min.

Normalized at 900C min

Tempered at 620C min,

-29C

27J min.

Normalized at 890950C

Tempered at 630740C ,

-29C

27J min.

Normalized at 900C min

Tempered at 620C min,

-29C

27J min.

Normalized at 900C min

Tempered at 675C min,

-29C

L&T100/80

Quench and

Tempered at 710 C min.

-36C

Normalized at 900960C min,

27J min.

Tempered at 650750C min,

-29C

L:40-60J

Normalized at 900980C min,

Tempered at 670770C min,

T:27-50

Normalizing at 955C min,

27J min.

Tempered at 677C min,

-29C

27J min.

Normalizing at 955C min,

Tempered at 677C min,

-29C

27J min.

Normalized at 9551000C

Tempered

at 700760C

-29C

27J min.

Normalized at 955C min

Tempered at 677C min,

-29C

27 min.

-18C

27J min.

Normalized at 10401080C

Tempered at 730800C

-29C

68 min L&T. Normalized at 10401090C

Tempered at 730C min,

-29C

Normalized at 10401080C

27J min.

Tempered at 730800C

-29C

27J min.

Normalized at 10401090C

Tempered at 740780C

-29C

0,20

0,30

104

593718C x 1hr min (+1 hr/in.)

593718C x 1hr min (+1 hr/in.)

Normalizing at 970C

Tempering at 680C

Normalizing at 970C

Tempering at 680C

Normalizing at 940C

Tempering at 740C

Normalizing at 970C

Tempering at 680C

Normalizing at 970C

Tempering at 680C

Quench at 950C OIL

Tempering at 720C

Normalizing at 960C

Tempering at 680C

Normalizing at 960C

Tempering at 680C

Normalizing at 970C min.

Tempered at 680C min.

Normalizing at 970C min.

Tempered at 680C min.

Normalizing at 970C

Tempering at 720C

Normalizing at 970C

Tempering at 760C

704746C x 2hr min (+1 hr/in.)

704746C x 2hr min (+1 hr/in.)

600-700C x 2hr min (+1 hr/in.)

600-700C x 2hr min (+1 hr/in.)

704760C x 2hr min (+1 hr/in.)

704760C x 2hr min (+1 hr/in.)

700750C x 2hr min (+1 hr/in.)

700750C x 2hr min (+1 hr/in.)

704760C x 2hr min (+1 hr/in.)

704760C x 2hr min (+1 hr/in.)

704760C x 2hr min (+1 hr/in.)

704760C x 2hr min (+1 hr/in.)

704760C x 2hr min (+1 hr/in.)

Normalizing at 1040C

Tempering at 780C

732774C x 3hr min (+1 hr/in.)

See note 98

740760C x 3hr min (+1 hr/in.)

Normalizing at 1040C

Tempering at 780C

Normalizing at 1040C

Tempering at 760C

Stabilize annealing 760C min,

Stabilize annealing 760C min,

704780C x 3hr min (+1 hr/in.)

740770C x 3hr min (+1 hr/in.)

732788C x 2hr min (+1 hr/in.)

380

585

18

35

167229

22 HRC

Stabilize annealing 760C min,

Stabilize annealing 760C min.

732788C x 2hr min (+1 hr/in.)

620

790

15

45

max. 295

22 HRC

Stabilize annealing 760C min.

Normilizing 1020C. +

Tempering 600C + Tempering

732788C x 2hr min (+1 hr/in.)

585

760

15

45

max. 269

22 HRC

Condition 1 Tempered at

675760C

732788C x 2hr min (+1 hr/in.)

585

760

15

45

max. 269

Condition 2 Quenched

732788C x 2hr min (+1 hr/in.)

585

760

15

45

350370

See note 96

See note 96

350370

See note 96

See note 96

302352

Quench in air or oil and temper

at 620C min for 2 h min

732788C x 2hr min (+1 hr/in.)

Annealed

Not Applicable

230260

0,90

1,25

704746C x 2hr min (+1 hr/in.)

704746C x 2hr min (+1 hr/in.)

760

965

13

193

400

20

30

Not Applicable

Not Applicable

22 HRC

121171

Data stampa 24/06/2014Ora 12:05Doc valido 24 ore da data stampa; dopo da considerarsi COPIA NON CONTROLLATA Date printed 24/06/2014Time 12:05 Document is valid for 24 hours from the date printed; afterwards it must be considered an UNVERIFIED COPY

Not Applicable

Pag. 2 di 5

T-500

CARATTERISTICHE CHIMICHE, MECCANICHE E STATO DI FORNITURA DEI MATERIALI BFE

B.F.E.

CHEMICAL, MECHANICAL CHARACTERISTICS AND SUPPLY STATUS OF THE BFE MATERIALS

CHEMICAL COMPOSITION (maximun)

MECHANICAL PROPERTIES

MATERIAL

BFE

DESIGNATION

AISI 420

AISI 430

1.4104

AISI 431

ASTM /DIN

A276-10

Type 420

A479-12

Type 430

A479-12

F316-L 60K

Max 80mm

1.4404

EN 10088-3

F304L

1.4301

1.4307

F304H

304L BARRA

304H BARRA

F321

F321 H

321 H BARRA

1.4541

F347 H

347 H

BARRA

1.4550

309

F310H

F310 MoLn

F316L

F316H

316L BARRA

316H BARRA

F 316-L U.G.

1.4571

(F316Ti)

1.4580

(F316 Cb)

F316L Mo2,5

1.4432

1.4435

1.4408

F317L

317L BARRA

1.4438

A182-12a

F316H

A479-12

316 316L

A479-12

316H

A182-12a

F316 Mod

EN 10222-5

X6CrNiMoTi17122

DIN EN 10088-1/3

X6CrNiMoNb17-12A182-12a

F316-L Mo2,5

EN 10088-3

X2CrNiMo17-12-3

DIN EN 10088-1/3

X2CrNiMo 18-14-3

EN10213:2007

GX5CrNiMo 19-11-2

A182-12a

F317 - F317L

A479-12

317 317L

17440

X2CrNiMo 18 16 4

F51/F60

A479-12

F51/F60

A182-12a

F51/F60

1.4462

X2CrNiMoN22-5-3

F53

F55

1.4410

F44

F44

F62

F62

A182-12a

F53

A182-12a F55

ZERON 100

EN 10222-5

X2CrNiMoN25-7-4

A182-12a

F44

A479-12

A 182-12a

F62

A479-12

F62

A182-12a

F904L

Form

Mn

Si

S42000

Bars

>0,15

1,00

0,040

0,030

1,00

S43000

Bars

0,12

1,00

0,040

0,030

1,00

Bars

0,10

0,17

1,50

0,060

0,15

0,35

1,00

X12CrMoS 17

17440

X10Cr13

A182-12a

F304-F304L

EN 10088-3

X5CrNi18-10

EN 10088-3

X2CrNi10-9

A182-12a

F304H

A479-12

304 304L

A479-12

304H

A182-12a

F321

A182-12a

F321 F321H

A479-12

321 321H

EN 10088-3

X6CrNiTi1810

A182-12a

F347 F347H

A479-12

347 347H

17440

X6CrNiNb1810

A276-10

S30900

A182-12a

F310H

A182-12a

F310 MoLn

A182-12a

F316 F316L

A182-12a

F316 F316L

1.4006

UNS/Other

S43100

S30403

Bars

0,20

1,00

0,040

0,030

1,00

Forging / Bars

0,08

0,15

1,50

0,04

0,030

1,00

0,75

Forging

0,030

2,00

0,045

0,030

1,00

Forging

0,070

2,00

0,045

0,030

1,00

Forging

0,030

2,00

0,045

0,030

1,00

Forging

0,04

0,10

2,00

0,045

0,030

1,00

S30403

Bars

0,030

2,00

0,045

0,030

1,00

S30409

Bars

0,04

0,10

2,00

0,045

0,030

1,00

S32100

Forging

0,08

2,00

0,045

0,030

1,00

2,00

0,045

0,030

1,00

2,00

0,045

0,03

1,00

2,00

0,045

0,030

1,00

S32109

Forging

S32109

Bars

Forging

S34709

Forging

S34709

Bars

0,04

0,08

0,04

0,08

0,08

0,04

0,08

0,04

0,08

2,00

0,045

0,030

1,00

2,00

0,045

0,030

1,00

0,08

2,00

0,045

0,015

1,00

Bars

0,20

2,00

0,045

0,030

1,00

S31009

Forging

0,04

0,10

2,00

0,045

0,030

1,00

S31050

Forging

0,030

2,00

0,030

0,015

0,40

Forging

0,030

2,00

0,045

0,030

1,00

Forging

0,030

2,00

0,045

0,030

1,00

Forging

0,030

2,00

0,045

0,030

1,00

S31690

Forging

0,04

0,10

2,00

0,045

0,030

1,00

S31603

Bars

0,030

2,00

0,045

0,030

1,00

Forging

S31603

equal to 1.4404

X2CrNiMo17-12-2

S31603

equal to 1.4404

X2CrNiMo17-12-2

equal to F316-L

X2CrNiMo17-12-2

S31609

Bars

0,04

0,10

2,00

0,045

0,030

1,00

Forging

0,020

2,00

0,015

0,010

1,00

Forging

0,080

2,00

0,045

0,030

1,00

Forging/Bars

0,080

2,00

0,045

0,015

1,00

Forging

0,030

2,00

0,045

0,030

1,00

Forging

0,030

2,00

0,045

0,030

1,00

Forging/Bars

0,030

2,00

0,045

0,03

1,00

Forging/Bars

0,07

1,50

0,040

0,03

1,50

S31703

Forging

0,030

2,00

0,045

0,030

1,00

S31703

Bars

0,08

2,00

0,045

0,030

1,00

Forging

0,030

2,00

0,045

0,030

1,00

Bars

0,030

2,00

0,030

0,020

1,00

Forging

0,030

2,00

0,030

0,020

1,00

S31803 /

S32205

S31803 /

S32205

0,50

Forging / Bars

0,030

2,00

0,035

0,015

1,00

S32750

Forging

0,030

1,20

0,035

0,020

0,80

0,50

S32760

Forging

0,030

1,00

0,030

0,010

1,00

0,50

1,00

Forging

0,030

2,00

0,035

0,015

1,00

0,50

1,00

0,50

1,00

S31254

Forging

0,020

1,00

0,030

0,010

0,80

S31254

Bars

0,020

1,00

0,030

0,010

0,80

N08367

Forging

0,030

2,00

0,040

0,030

1,00

0,75

N08367

Bars

0,030

2,00

0,040

0,030

1,00

0,75

Forging

0,020

2,00

0,040

0,030

1,00

1,00

2,00

Forging

0,020

2,00

0,030

0,010

0,70

1,202,00

N08028

Pipe

0,030

2,50

0,030

0,030

1,00

B649-06 (2011)

N08925

Forging

0,020

1,00

0,045

0,030

0,50

N08925 BARRA

B649-06 (2011)

N08925

Bars

0,020

1,00

0,045

0,030

0,50

N08926 BARRA

B649-06 (2011)

N08926

Bars

0,020

2,00

0,030

0,010

0,50

Monel 400

B564-11

N04400

Forging

0,30

2,00

0,024

0,50

2.4360

DIN 17743

Forging

0,15

2,00

0,02

0,50

Monel 400 HH

Half Hard

B564-11

Bars

0,30

2,00

0,024

0,50

F904L

1.4539

Sew 400

Sanicro 28

Alloy 28

CRONIFER

WP1925

B668-05 (2010)

N08904

SEW 400

N04400

Ni

1,25

2,50

S30409

S30900

Cu

0,60

1,40

0,80

1,50

0,80

1,50

0,50

1,50

28,00

34,00

28,00

34,00

28,00

34,00

8,00

11,00

8,00

10,50

8,00

10,50

8,00

11,00

8,00

12,00

8,00

10,50

9,00

12,00

9,00

12,00

9,00

12,00

9,00

12,00

9,00

13,00

9,00

12,00

9,00

12,00

12,00

15,00

19,00

22,00

21,00

23,00

10,00

14,00

10,00

14,00

10,00

13,00

10,00

14,00

10,00

14,00

10,00

14,00

13,00

15,00

10,50

13,50

10,50

13,50

10,00

15,00

10,5

13,0

12,5

15,0

9,00

12,00

11,00

15,00

11,00

15,00

11,00

15,00

4,50

6,50

4,50

6,50

4,50

6,50

6,00

8,00

6,00

8,00

6,00

8,00

17,50

18,50

17,50

18,50

23,50

25,50

23,50

25,50

23,0

28,0

24,00

26,00

30,00

34,00

24,00

26,00

24,00

26,00

24,00

26,00

63,00

min

63,00

min

63,00

min

Cr

12,00

14,00

16,00

18,00

15,5

17,5

15,0

17,0

11,50

13,50

18,00

20,00

17,50

19,50

17,50

19,50

18,00

20,00

18,00

20,00

18,00

20,00

17,00

19,00

17,00

19,00

17,00

19,00

17,00

19,00

17,00

20,00

17,00

19,00

17,00

19,00

22,00

24,00

24,00

26,00

24,00

26,00

16,00

18,00

16,00

18,00

16,50

18,50

16,00

18,00

16,00

18,00

16,00

18,00

17,00

18,50

16,50

18,50

16,50

18,50

16,00

18,00

16,5

18,5

17,0

19,0

18,00

20,00

18,00

20,00

18,00

20,00

18,00

20,00

22,00

23,00

22,00

23,00

21,00

23,00

24,00

26,00

24,00

26,00

24,00

26,00

19,50

20,50

19,50

20,50

20,00

22,00

20,00

22,00

19,0

23,0

19,00

21,00

26,00

28,00

19,00

21,00

19,00

21,00

19,00

21,00

Mo

Al

Ti

Nb/Cb

Rev. 29

(minimum)

Hardness

NACE

MR

Tensile

N/mm2

Elong %

Reduct %

Hardness

ASTM

HB

275

485

20

45

192

450

640840

11

230

277

Annealed

250

450650

20

200 max

Normalized at 980C min,

Tempered at 760C min,

20

205

515

30

20

190

500700

45

20

175

500700

45

205

515

30

50

22 HRC

205

515

30

40

22 HRC

205

515

30

40

22 HRC

205

515

30

50

22 HRC

205

515

30

50

22 HRC

205

515

30

40

22 HRC

200

500730

40

Notes

01-03 or

01-75

MR

Notch

impact

241

0,20

0,60

20

5xC

0,70

4xC

0,70

4x(C+N)

0,70

5xC

0,70

35

215 max

215 max

515

30

50

22 HRC

205

515

30

40

22 HRC

205

510740

40

310

620

30

91

20

64

65

5xC

0,70

40

205

515

30

50

255

540

25

40

205

515

35

50

414

586

18

35

200

500-700

40

205

515

30

50

22 HRC

205

515

35

60

22 HRC

22 HRC

22 HRC

235 max

215

205

515

30

40

190

485

30

50

210

510710

45

200

510740

35

20

91

205

515

35

20

200

500700

40

215

20

235

500700

40

215

210

440640

30

(10xC)

1,00

12

51

12

51

12

51

37

48

25

48

N 0,20

0,35

13

32- 48

13

32

22 HRC

215

50

22 HRC

205

515

30

50

22 HRC

205

515

30

50

22 HRC

195

490690

35

450

655

25

450

655

25

290 max

45

28 HRC

28 HRC

450

650880

25

270 max

550

800

25

310 max

550

750895

25

45

500

8001000

30

25

32 HRC

32 HRC

290 max

300

650

35

50

35 HRC

305

655

35

50

35 HRC

44

310

655

30

50

44

310

655

30

Not Applicable

Annealed

Not Applicable

27J min,

-196C

27J min,

-196C

27 J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min

-196C

27J min

-196C

60J min

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

35/45 J

-50C

35/45 J

-50C

45/35

-50C

45/35

-50C

45/35

-50C

L200J+20C

27J min,

-50C

27J min,

-50C

241

Not Applicable

Solubilized 10001100C min

Solubilized 1060C min

Not Applicable

Solubilized 10001100C min

Solubilized 1060C min

Not Applicable

Solubilized 1040C min

Solubilized 1060C min

Not Applicable

Solubilized 1040C min

Not Applicable

Solubilized 1040C min

Not Applicable

Solubilized 1095C min

Stabilizing at 815870C

Solubilized 1095C min

Stabilizing at 815870C

Solubilized 1095C min

Stabilizing at 815870C

Solubilized 1100C min

Stabilizing at 870C

Solubilized 1100C min

Stabilizing at 870C

Solubilized 10201100C

Solubilized 1060C min

Not Applicable

Solubilized 1095C

Stabilizing at 815870C

Solubilized 1095C

Stabilizing at 815870C

Solubilized 1100C

Stabilizing at 870C

Not Applicable

Solubilized 10201100C

Solubilized 1060C min

Not Applicable

Solubilized 1040C min

Solubilized 1060C min

Not Applicable

Not Applicable

Not Applicable

Not Applicable

Not Applicable

Solubilized 1040C

Not Applicable

Solubilized 1060C min.

Not Applicable

Solubilized 1040C min

Solubilized 1060C min

Not Applicable

Solubilized 1040C min

Solubilized 1060C min

Not Applicable

Solubilized 1040C min

Solubilized 1060C min

Not Applicable

Solubilized 1040C min

Solubilized 1060C min

Solubilized 1040C min

Not Applicable

Not Applicable

Not Applicable

Solubilized 1040C min

Solubilized 1040C min

Solubilized 1060C min

Not Applicable

Solubilized 10401080C min

Solubilized 1060C min

Not Applicable

Solubilized 10201120C min

Solubilized 1100C

Not Applicable

Solubilized 1040C min

Solubilized 1060C min

Not Applicable

Solution Annealing 1020

1120C

Solution Annealing 1020

1120C

Solution Annealing

10801150C

Solubilized 1040C

Not Applicable

Solubilized 1040C

Not Applicable

Solubilized 1040C min

Solubilized 1060C min

Not Applicable

Not Applicable

Solubilized 1040C min

Not Applicable

Solubilized 1040C min

Not Applicable

Not Applicable

Solubilized 1020C min,

Solubilized 1020C min

Solubilized 1060C min

Not Applicable

Solubilized 1040C min,

Solubilized 1060C min

Not Applicable

Solubilized 1025C min

Solubilized 1060C min

Not Applicable

Solubilized 11001140C

Solubilized 1100C min

Not Applicable

Solubilized 10401120C

Solubilized 1100C min

Not Applicable

Solubilized 1150C min.

Solubilized 1180C min.

Not Applicable

Solubilized 1150C min.

Not Applicable

Solubilized 1105C min.

Not Applicable

Solubilized 1105C min.

Not Applicable

Solubilized 10501150C

Not Applicable

Annelaed

Not Applicable

215

490

35

255

540740

40

85/55T

69

214

500

40

300

600

40

Solubilized 1180C

300

600

40

Solubilized 1180C

3

7

3

7

3

7

Not Applicable

Solubilized 1060C min

20

35 HRC

Not Applicable

Solubilized 1040C min

43

28A

Post Weld Heat Treatment Acc.

To ASME B31.3 (for effective

temperature and time see

spicific WPS-PQR)

Annealed

27J min,

-50C

24

33

24

33

0,3

50

205

20

91

20

91

Effective Heat Treatment

temperature after forging

Not Applicable

30

76

0,50

235 HBW

22

10C

1,00

2,00

3,00

2,00

3,00

2,00

3,00

2,00

2,50

2,00

3,00

2,00

3,00

2,00

3,00

1,90

2,60

2,00

2,50

2,00

2,50

2,50

3,00

2,50

3,00

2,50

3,00

2,00

2,50

3,00

4,00

3,00

4,00

3,00

4,00

3,00

3,50

3,00

3,50

2,50

3,50

3,00

5,00

3,00

4,00

3,00

4,50

6,00

6,50

6,00

6,50

6,00

7,00

6,00

7,00

4,0

5,0

4,00

5,00

3,00

4,00

6,00

7,00

6,00

7,00

6,00

7,00

Heat treatment

according to ASTM

Yeld p.

N/mm2

Solubilized 10801140C

Not Applicable

Solubilized 1180C

Not Applicable

Not Applicable

Solubilized 1180C

Not Applicable

295

650

35

172

483

35

35 HRC

Crystall Annealing 950C

Crystall Annealing 950C

Not Applicable

172

483

35

35 HRC

Crystall Annealing 950C

Crystall Annealing 950C

Not Applicable

300

550

25

195222

Data stampa 24/06/2014Ora 12:05Doc valido 24 ore da data stampa; dopo da considerarsi COPIA NON CONTROLLATA Date printed 24/06/2014Time 12:05 Document is valid for 24 hours from the date printed; afterwards it must be considered an UNVERIFIED COPY

see note 99

Not Applicable

Pag. 3 di 5

T-500

CARATTERISTICHE CHIMICHE, MECCANICHE E STATO DI FORNITURA DEI MATERIALI BFE

B.F.E.

CHEMICAL, MECHANICAL CHARACTERISTICS AND SUPPLY STATUS OF THE BFE MATERIALS

CHEMICAL COMPOSITION (maximun)

MECHANICAL PROPERTIES

MATERIAL

BFE

DESIGNATION

ASTM /DIN

UNS/Other

Form

Mn

MONEL

K500

Inconel 600

2.4816

Inconel 600

BARRA

B865-04 (2010)

NiCu30Al

N05500

Forging

0,18

1,50

B564-11

N06600

Forging

0,15

1,00

0,015

0,50

0,50

B166-11

N06600

Bars

0,15

1,00

0,015

0,50

0,50

Inconel 601

B166-11

N06601

Bars

0,10

1,00

0,015

0,50

1,00

Inconel 625

B564-11

N06625

Forging

0,10

0,50

0,015

0,015

0,50

Inconel 625

BARRA

Alloy 718

API 6A

B446-03 (R2008)e1

N06625

Bars

0,10

0,50

0,015

0,015

0,50

20 ed. 2010

N07718

Bars

0,045

0,35

0,010

0,010

0,35

0,23

Inconel 718

B637-12e1

N07718

Bars

0,08

0,35

0,015

0,015

0,35

0,30

Incoloy 800

B564-11

N08800

Forging

0,10

1,50

0,015

1,00

0,75

Incoloy 800

BARRA

B408-06 (R2011)

N08800

Bars

0,10

1,50

0,015

1,00

0,75

Incoloy 800H

B564-11

N08810

Forging

1,50

0,015

1,00

0,75

Incoloy 800H

BARRA

B408-06 (R2011)

N08810

Bars

1,50

0,015

1,00

0,75

Incoloy 800HT

B564-11

N08811

Forging

1,50

0,015

1,00

0,75

Incoloy 800HT

BARRA

B408-06 (R2011)

N08811

Bars

1,50

0,015

1,00

Incoloy 825

B564-11

N08825

Forging

0,05

1,00

0,030

0,50

B425-11

N08825

Bars

0,05

1,00

0,030

0,50

A564-10

S17400

Bars

0,07

1,00

0,03

1,00

Incoloy 825

BARRA

17-4-PH

Type 630 cond. H1150

17-4-PH

Type 630 cond. H1150D

Alloy 20

Alloy 20

BARRA

Alloy 20

BILLETTE

Titanium

F2

Titanium

GR.5 BARRA

Titanium

GR.2 BARRA

0,05

0,10

0,05

0,10

0,06

0,10

0,06

0,10

0,04

Si

Cu

Ni

0,010

0,50

27,00

33,00

63,00

min

72,00

min

72,00

min

58,00

63,00

58,00

min

58,00

min

50,00

55,00

50,0

55,0

30,00

35,00

30,00

35,00

30,00

35,00

30,00

35,00

30,00

35,00

30,00

35,00

38,00

46,00

38,00

46,00

3,00

5,00

3,00

5,00

32,00

38,00

32,00

38,00

32,00

38,00

S17400

Bars (NACE)

0,07

1,00

0,04

0,03

1,00

B462-10e1

N08020

Forging

0,07

2,00

0,045

0,035

1,00

B473-07

N08020

Bars

0,07

2,00

0,045

0,035

1,00

B472-10

N08020

Billet

0,07

2,00

0,045

0,035

1,00

A564-10

e1

e1

R50400

Forging

0,08

B348-11

R56400

Bars

0,08

B348-11

R50400

Bars

0,08

Hastelloy B

B335-03 (2013)

N10001

Bars

0,05

1,00

0,040

0,030

1,00

Hastelloy B2

B335-03 (2013)

N10665

Bars

0,02

1,00

0,040

0,030

0,10

Hastelloy

C276

Hastelloy

C

Hastelloy C22

WPHC22

Hastelloy C4

WPHC4

C95200 - 9A

C95400 - 9C

C95500 - 9D

C63200

C95800

B381-10

B574-10

N10276

Bars

0,01

1,00

0,040

0,030

0,08

N10002

Bars

0,08

1,00

0,040

0,030

1,00

B366-10a

N06022

Bars

0,015

0,50

0,02

0,02

0,08

B366-10a

N06455

Bars

0,015

1,00

0,040

0,030

0,08

C95200

Casting

Bars

C95400

Casting

0,50

C95500

Casting

3,50

C63200

Bars

C95800

Casting

1,20

2,00

0,80

1,50

0,10

0,10

B61-08

C92200

Bars

0,05

0,05

0,005

B62

B62-09

C83600

Bars

0,05

0,08

0,005

S66286

Bolting

1,00

XM-19

Nitronic 50

A453-12

Gr. 660 Class A

A638-10

Gr. 660 Type 1

AWS 5.21

ER Co Cr A

AWS 5.21

ER Co Cr B

AWS 5.21

ER Co Cr E

A479-12

XM-19

Alloy 3005

B209-10

Gr. 660

Stellite Gr6

Stellite Gr12

Stellite Gr21

S66286

R30006

R30012

R30021

Bars

HF overlay

38 45 HRC

HF overlay

3447 HRC

HF overlay

2035 HRC

S20910

Bars

A93005

Plate

Sheet

Remain

der

Remain

der

Remain

der

Remain

der

Remain

der

Remain

der

86

min

83,00

min

78,00

min

B61

Gr. 660

Rem.

79,00

min

86,00

90,00

84,00

86,00

24,00

27,00

24,00

27,00

0,04

0,03

1,00

2,00

3,00

1,00

2,00

3,00

1,50

1,50

1,50

4,00

11,50

13,50

1,00

0,30

Tensile

N/mm2

Elong %

4

5

200

550

30

0,40

2,50

3,50

2,50

3,50

0,40

0,40

0,40

0,60

0,20

0,80

0,15

0,60

0,15

0,60

0,15

0,60

0,15

0,60

0,15

0,60

0,15

0,60

0,80

1,15

0,65

1,15

0,15

0,60

0,15

0,60

0,15

0,60

0,15

0,60

0,15

0,60

0,15

0,60

0,60

1,20

0,60

1,20

0,20

0,20

552

30

35 HRC

550

30

35 HRC

205

550

30

414

827

30

26,00

30,00

26,00

30,00

15,00

17,00

15,00

17,00

12,50

14,50

14,00

17,00

13,50

16,00

13,50

16,00

26,0

32,0

26,00

32,00

25,00

30,00

20,50

23,50

0,10

1,00

1,50

1,00

1,50

Effective Heat Treatment

temperature after forging

Post Weld Heat Treatment Acc.

To ASME B31.3 (for effective

temperature and time see

spicific WPS-PQR)

Solubilized at 1050C

Solubilized at 1060C

Not Applicable

Crystall Annealing 970C

Crystall Annealing 970C

Crystall Annealing 970C

414

827

30

827 - 1000

1034

20

35

32-40 HRC

1034

1275

12

15

331 min

207

517

30

35 HRC

35 HRC

27J min,

-46C

35 HRC

35 HRC

Solubilized 1180C

Solubilized 1180C

205

515

30

172

448

30

Solubilized 1180C

170

450

30

Solubilized 1180C

172

448

30

Solubilized 11501200C

11

11

14

103

14

101

15

69

15

69

15

69

170

450

30

241

586

30

241

586

30

725

930

16

Not Applicable

Solubilized at 1180C

Crystall Annealing 871C

-60C

68J / 61J

Not Applicable

Not Applicable

See note 107

Not Applicable

Solubilized at 1180C

Not Applicable

Not Applicable

Solubilized at 1180C

35 HRC

50

28 HRC min

Solubilized at 1180C

Not Applicable

Solubilized at 1180C

Not Applicable

Not Applicable

Crystall Annealing 950C

Not Applicable

Hardening 620C x 4hr Air cool

Not Applicable

Hardening 620C x 4hr Air cool

+ Hardening 620C x 4hr Air

24-33 HRC

Not Applicable

Not Applicable

Solubilized 11501200C

Solubilized 1180C

Not Applicable

See note 97

Solubilized 1180C

35 HRC

Not Applicable

Not Applicable

Crystall Annealing 700800C

35 HRC

725

860

16

50

241

551

30

50

32 HRC

241

551

30

50

32 HRC

Crystall Annealing 950C

Not Applicable

32 HRC

Hot worked

Not Applicable

100 HRBS

Stabilize annealing 660C min

24-33 HRC

29 HRC Tiranteria

-196C

27J min

Crystall Annealing 950C

Not Applicable

Crystall Annealing 950C

275

345

20

30

42

828

895

10

25

Stabilize annealing 660C min

Not Applicable

36

275

345

20

30

Stabilize annealing 660C min

Not Applicable

39

315

690

30

Solubilized 1100C

Not Applicable

40

350

760

40

Solubilized 1100C

Not Applicable

0,35

41

283

690

40

0,35

71

72

71

92

0,20

0,40

0,35

0,7 max

0,10

0,50

0,10

0,50

0,35

0,35

1,90

2,35

1,90

2,35

35 HRC

Stabilize annealing 660C min

Not Applicable

36

5,50

6,75

Not Applicable

Solubilized 1220C

Solubilized 1220C

Not Applicable

Solubilized 1220C

Solubilized 1220C

Not Applicable

310

655

30

Not Applicable

80

276

690

40

Not Applicable

84

170

450

20

110

46

205

515

12

150

46

275

620

190

275

620

15

240

585

15

50

110

235

24

105

95

205

20

70

585

895

15

18

70

585

895

15

18

1,00

58

1,00

61

4,50

7,00

1,50

3,00

27J min,

-46C

Heat treatment

according to ASTM

9

28

9

28

Remainde

r

Remainde

r

Remainde

r

MR

Notch

impact

35 HRC

240

2,00

3,00

2,00

3,00

2,00

3,00

01-03 or

01-75

241

26

27

26-27

34

54

55

10

55D

0,40

Hardness

ASTM

HB

8

1,00

1,70

8,00

10,00

8,00

10,00

2,80

3,30

2,80

3,30

Reduct %

Hardness

NACE

MR

0,005

2,00

0,60

Yeld p.

N/mm2

1,00

0,08

0,030

0,35

0,85

Notes

0,005

0,91,4

0,045

2,30

3,15

Nb/Cb

1,00

0,03

4,00

6,00

1,00

1,50

14,50

16,50

14,50

16,50

20,00

22,50

14,00

18,00

Ti

28C

55C

66-6768

0,04

1,00

1,00

1,00

Al

8,5

9,5

10,0

11,50

10,00

11,50

8,70

9,50

8,50

9,50

2,00

0,06

See note

n52

See note

n28B

4,00

4,80

See note

n67

0,08

1,20

1,70

0,15

0,45

14,00

17,00

14,00

17,00

21,00

25,00

20,00

23,00

20,00

23,00

17,00

21,00

17,00

21,00

19,00

23,00

19,00

23,00

19,00

23,00

19,00

23,00

19,00

23,00

19,00

23,00

19,50

23,50

19,50

23,50

15,00

17,50

15,00

17,50

19,00

21,00

19,00

21,00

19,00

21,00

Mo

3,50

4,50

SAE HS-1086

B148-97(R2009)

C95200

B148-97(R2009)

C95400

B148-97(R2009)

C95500

B150-12

C63200

B148-97 (R2009)

C95800

0,75

1,50

3,00

1,50

3,00

3,00

5,00

3,00

5,00

3,00

4,00

3,00

4,00

3,00

4,00

Cr

Rev. 29

(minimum)

Not Applicable

Quench at 890C min,

and Tempered at 640C min

Quench at 920C min,

and Tempered at 540C min

Quench at 850C min,

and Tempered at 700C min

Quench at 890C min,

and Tempered at 640C min

Quench in water at 890C min

Tempering at 640C min

Quench at 920C min,

and Tempered at 540C min

Not Applicable

Not Applicable

Not Applicable

Quench in water at 890C min

Tempering at 640C min

Not Applicable

Not Applicable

Not Applicable

248341

44/32J

-196C + LE

248

Acc, To Table 4 ASTM A453

Not Applicable

Acc, To Table 3 ASTM A638

Not Applicable

38 45

HRC

Not Applicable

56

0,10

0,30

0,10

0,30

Remainde

r

0,10

74

106

380

690

35

55

293 max

Not applicable - Material for nameplate

Data stampa 24/06/2014Ora 12:05Doc valido 24 ore da data stampa; dopo da considerarsi COPIA NON CONTROLLATA Date printed 24/06/2014Time 12:05 Document is valid for 24 hours from the date printed; afterwards it must be considered an UNVERIFIED COPY

Solution Annealing 1040C min

Solution Annealing 1080C

Not Applicable

Not Applicable

Not Applicable

Not Applicable

Pag. 4 di 5

T-500

CARATTERISTICHE CHIMICHE, MECCANICHE E STATO DI FORNITURA DEI MATERIALI BFE

B.F.E.

CHEMICAL, MECHANICAL CHARACTERISTICS AND SUPPLY STATUS OF THE BFE MATERIALS

CHEMICAL COMPOSITION (maximun)

MECHANICAL PROPERTIES

MATERIAL

BFE

DESIGNATION

A106 Gr. B

A106 Gr. C

GR.6

P1

P11

P22

P5

P9

P91

TP304

TP304H

TP304L

TP316

TP316H

TP316L

TP317

TP321

TP347

WCB

LCB

LCC

WC6

WC9

D1-Q2

C5

C12

C12A

CY-40

ASTM /DIN

A106-11

Gr. B (Std. BFE)

A106-11

Gr. C

A333/A333M-11

Grade 6

A335/A335M-11

P1

A335/A335M-11

P11

A335/A335M-11

P22

A335/A335M-11

P5

A335/A335M-11

P9

A335/A335M-11

P91

A312/A312M-13b

TP904

A312/A312M-13b

TP304H

A312/A312M-13b

TP304L

A312/A312M-13b

TP316

A312/A312M-13b

TP316H

A312/A312M-13b

TP316L

A312/A312M-13b

TP317

A312/A312M-13b

TP321

A312/A312M-13b

TP347

A216-12

WCB

A352-06 (2012)

LCB

A352-06 (2012)

LCC

A217-12

WC6

A217-12

WC9

A757-10

D1Q2

A217-12

C5

A217-12

C12

A217-12

C12A

A494-12

UNS/Other

Form

K03006

Pipe

0,22

Pipe

0,35

K03006

Pipe

0,30

K11522

Pipe

0,10

0,20

0,05

0,15

0,05

0,15

N-7M

A494-12

0,025

0,10 min

0,025

0,025

0,10

0,50

0,50

1,00

S30400

Pipe

0,08

2,00

0,045

0,030

1,00

S30409

Pipe

0,04

0,10

2,00

0,045

0,030

1,00

S30403

Pipe

0,035

2,00

0,045

0,030

1,00

S31600

Pipe

0,08

2,00

0,045

0,030

1,00

S31609

Pipe

0,04

0,10

2,00

0,045

0,030

1,00

S31603

Pipe

0,035

2,00

0,045

0,030

1,00

S31700

Pipe

0,08

2,00

0,045

0,030

1,00

S32100

Pipe

0,08

2,00

0,045

0,030

1,00

S34700

Pipe

0,08

2,00

0,045

0,030

1,00

J03002

Casting

Similar to A105

0,30

1,00

0,040

0,045

0,60

0,30

1,00

0,040

0,045

0,25

1,20

0,040

0,05

0,20

0,05

0,18

0,040

0,08

0,12

0,50

0,80

0,40

0,70

0,40

0,80

0,40

0,70

0,35

0,65

0,30

0,60

0,40

1,50

J03003

J02505

J12072

J21890

J22092

J82090

J82090

J84090

N06040

Casting

Similar to LF2

Casting

Similar to LF2

Casting

Similar to F11

Casting

Similar to F22

Casting

Similar to F22

Casting

Similar to F5

Casting

Similar to F9

Casting

Similar to F91

Casting

Similar to Inc600

Casting

Similar to HastB

Casting

Sim.to Hast C276

0,15

0,20

0,20

0,20

0,10

min

0,10

min

A494-12

N26625

A494-12

N26455

CA15

A217-12

J91150

CK-3MCuN

A351-12b

J93254

e1

J92205

GR 5A

e1

A995-12

J93404

GR 6A

A995-12e1

J93380

CN7M

A351-12b

N08007

Casting

Sim. to Hast C4

Casting

Sim. to 410

Casting

Similar to F44

Casting

Similar to F51

Casting

Similar to F53

Casting

Similar to F55

Casting

Similar to alloy20

0,15

0,08

47

0,44

0,65

0,44

0,65

0,87

1,13

0,45

0,65

0,90

1,10

0,85

1,05

415

22

275

485

20

240

415

22

205

380

30

205

415

30

205

415

30

205

415

30

205

415

30

415

585

20

205

515

35

205

515

35

170

485

35

205

515

35

205

515

35

170

485

35

205

515

35

205

515

35

205

515

35

0,20

0,03

240

450620

24

35

0,045

0,60

0,30

0,50

0,50

0,20

0,03

275

485655

22

35

0,045

0,60

0,50

20

35

0,60

0,50

0,50

275

485655

20

35

0,025

0,025

0,60

0,50

0,50

0,03

78

88

78

88

75

88

78

88

78

88

485655

0,045

0,45

0,65

0,90

1,20

0,90

1,20

0,45

0,65

0,90

1,20

0,85

1,05

275

0,040

1,00

1,50

2,00

2,75

2,00

2,75

4,00

6,50

8,00

10,00

8,00

9,50

14,0

17,00

515

655860

18

35

0,04

0,045

0,75

0,50

0,50

0,035

0,035

1,00

0,50

0,50

0,025

0,010

0,20

0,50

0,030

0,03

3,00

0,12

1,00

0,040

0,03

1,00

0,12

1,00

0,040

0,03

1,00

0,08

1,50

0,040

0,040

1,50

0,03

1,50

0,040

0,040

1,50

0,08

1,50

0,040

0,040

2,00

0,07

1,00

0,040

0,03

1,00

0,40

Remain

der

Remain

der

Remain

der

8,00

12,00

8,00

11,00

9,00

12,00

9,00

13,00

9,00

12,00

Remain

der

Remain

der

Remain

der

0,06

1,00

0,015

0,015

1,00

0,02

1,00

0,03

0,03

0,80

0,15

1,00

0,040

0,040

1,50

0,025

1,20

0,030

0,010

1,00

0,50

1,00

0,030

1,50

0,040

0,020

1,00

1,00

0,03

1,50

0,030

0,025

1,00

0,03

1,00

0,030

0,025

1,00

0,07

1,50

0,040

0,040

1,50

1,00

0,50

1,00

3,00

4,00

17,50

19,50

4,50

6,50

6,00

8,00

6,50

8,50

27,50

30,50

1,00

15,50

17,50

17,00

21,00

18,00

21,00

18,00

21,00

17,00

21,00

18,00

21,00

1,00

20,00

23,00

15,00

17,50

11,50

14,00

19,50

20,50

21,00

23,50

24,00

26,00

24,00

26,00

19,00

22,00

0,02

0,01

0,06

0,10

49

2,00

3,00

2,00

3,00

2,00

3,00

3,00

4,00

5xC

0,70

20

10C

1,00

415

620795

18

35

415

620795

18

35

49

415

585760

18

45

59

195

485

30

60

275

525

62

63

275

495

0,50

205

485

35

0,50

240

530

35

26,00

30,00

16,00

18,00

0,06

0,18

0,25

0,03

0,02

0,01

0,060

0,10

0,20

0,60

0,20

0,40

2,00

3,00

2,00

3,00

0,50

30,00

33,00

8,00

10,00

15,00

17,50

205

485

30

205

485

30

205

485

30

61

275

525

20

57

275

485

25

5

79

275

495

20

450

620

795

18

260

550

35

415

620

25

8xC

1,00

3,154,50

0,50

6,00

7,00

2,50

3,50

4,00

5,00

3,00

4,00

2,00

3,00

55A

55B

81

48

25

48

515

700

18

450

700

25

170

425

35

MR

Notch

impact

Heat treatment

according to ASTM

Effective Heat Treatment

temperature after forging

Hot finish

Hot finish

0,50

0,18

0,25

01-03 or

01-75

22 HRC

0,50

0,40

Hardness

ASTM

HB

Hardness

NACE

MR

190 HBW

0,30

2,00

Casting

Similar to Inc625

0,40

240

Reduct %

0,60

2,00

Casting

0,40

Elong %

35

0,040

Similar to F347

0,40

1

47

1

47

Tensile

N/mm2

22

0,040

Sim. to Hast B2

0,08

Yeld p.

N/mm2

485655

0,010

0,040

N30007

0,15

Notes

250

0,025

0,020

0,040

Casting

0,40

Nb/Cb

1

77

0,025

0,25

1,00

0,20

0,50

1,50

Similar to F316L

0,40

Ti

0,03

0,50

1,50

J92710

0,40

Al

0,20

0,50

0,025

0,08

Casting

0,50

0,025

0,025

0,03

Similar to F316

Mo

0,50

0,025

Casting

Similar to F304H

J92900

Cr

0,30

0,025

J92600

J92800

Ni

8,0

11,0

8,0

11,0

8,0

13,0

11,0

14,0

11,0

14,0

10,0

14,0

11,0

14,0

9,0

12,0

9,0

13,0

0,025

Casting

Similar to F304L

Casting

Cu

1,00

1,50

1,90

2,60

4,00

6,00

8,00

10,00

8,00

9,50

18,0

20,0

18,0

20,0

18,0

20,0

16,0

18,0

16,0

18,0

16,0

18,0

18,0

20,0

17,0

19,0

17,0

19,0

J92700

CW-2M

A995-12

0,035

0,025

0,15

CW-6MC

GR 4A

0,035

0,08

0,12

Pipe

N30012

CF-8C

0,035

Pipe

Pipe

N30002

CF-3M

0,035

Pipe

K21590

K41545

A494-12

CF-8M

Si

K91560

Pipe

A494-12

CF8

S50400

K11597

N-12MV

A351-12b

CF3

A351-12b

CF8

A351-12b

CF8M

A351-12b

CF3M

A351-12b

CF8C

0,29

1,06

0,29

1,06

0,29

1,06

0,30

0,80

0,30

0,60

0,30

0,60

0,30

0,60

0,30

0,60

0,30

0,60

CW-12MW

CF3

Mn

Rev. 29

(minimum)

30

187 HBW

167-229

271

22 HRC

20/27

- 50C

27 min.

-29C

27 min.

-29C

27 min.

-29C

27 min.

-29C

27 min.

-29C

27 min.

-29C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27/20

-29C

16/20

-46C

16/20

-46C

27/20

-29C

27/20

-29C

27/20

-29C

27/20

-29C

27 min.

-29C

27 min.

-29C

27J min,

-46C

45/35

-46C

27J min,

-46C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-196C

27J min,

-46C

27J min,

-46C

27J min,

-46C

27/20

-29C

27J min,

-46C

45J/35J

-46C

45J/35J

-46C

45J/35J

-46C

27J min,

-46C

Data stampa 24/06/2014Ora 12:05Doc valido 24 ore da data stampa; dopo da considerarsi COPIA NON CONTROLLATA Date printed 24/06/2014Time 12:05 Document is valid for 24 hours from the date printed; afterwards it must be considered an UNVERIFIED COPY

Post Weld Heat Treatment Acc.

To ASME B31.3 (for effective

temperature and time see

spicific WPS-PQR)

If required or Thk > 20 mm

593649Cx1hr min(+1hr/in.)

If required or Thk > 20 mm

593649Cx1hr min(+1hr/in.)

If required or Thk > 20 mm

593649Cx1hr min(+1hr/in.)

Normalizing at 845945 C

Normalizing at 845945 C

Normalized at 955C min

Tempered at 650C min,

Normalized at 955C min

Tempered at 650C min,

Normalizing at 955C min,

Tempered at 675C min,

Normalizing at 955C min,

Tempered at 675C min,

Normalizing at 955C min,

Tempered at 675C min,

Normalized at 10401080C

Tempered at 730800C

Normalized at 955C min

Tempered at 650C min,

Normalized at 955C min

Tempered at 650C min,

Normalizing at 970C min.

Tempered at 680C min.

Normalizing at 970C min.

Tempered at 680C min.

Normalizing at 970C min.

Tempered at 680C min.

Normalizing at 1040C

Tempering at 780C

Solubilized 1040C min

Solubilized 1040C min

Not Applicable

Solubilized 1040C min

Solubilized 1040C min

Not Applicable

Solubilized 1040C min

Solubilized 1040C min

Not Applicable

Solubilized 1040C min

Solubilized 1040C min

Not Applicable

Solubilized 1040C min

Solubilized 1040C min

Not Applicable

Solubilized 1040C min

Solubilized 1040C min

Not Applicable

Solubilized 1040C min

Solubilized 1040C min

Not Applicable

Solubilized 1040C min

Solubilized 1040C min

Not Applicable

Solubilized 1040C min

Solubilized 1040C min

704760C x 2hr min (+1 hr/in.)

704760C x 2hr min (+1 hr/in.)

704760C x 3hr min (+1 hr/in.)

Not Applicable

704746C x 2hr min (+1 hr/in.)

704760C x 2hr min (+1 hr/in.)

Quench in water at 930C

Tempering at 680C

704760C x 2hr min (+1 hr/in.)

704760C x 2hr min (+1 hr/in.)

704760C x 2hr min (+1 hr/in.)

704760C x 3hr min (+1 hr/in.)

Quench at 1040C min,

Not Applicable

Quench at 1095C min,

Solubilized 1175C min,

704760C x 2hr min (+1 hr/in.)

If required or Thk > 20 mm

593649C x 1hr min (+ 1 hr/in.)

If required or Thk > 20 mm

593649C x 1hr min (+ 1 hr/in.)

If required or Thk > 20 mm

593649C x 1hr min (+ 1 hr/in.)

Normalized 920C min,

Normalized and Tempered at

590C min,

Normalized and Tempered at

590C min,

Normalized and Tempered at

595C min,

Normalized and Tempered at

675C min,

Quench,

and Tempered at 595C min

Normalized and Tempered at

675C min,

Normalized and Tempered at

675C min,

Normalized at 10401080C

Tempered at 730800C

593718C x 1hr min (+1 hr/in.)

704746C x 2hr min (+1 hr/in.)

Not Applicable

Solubilized 1220C

Not Applicable

Solubilized at 1040C min,

Not Applicable

Solubilized at 1040C min,

Not Applicable

Solubilized at 1040C min,

Not Applicable

Solubilized at 1040C min,

Not Applicable

Solubilized at 1065C min,

Not Applicable

Quench at 1095C min,

Not Applicable

Solubilized 1175C min,

Solubilized 1220C

Not Applicable

Stabilize annealing 760C min.

732788C x 2hr min (+1 hr/in.)

Quench at 1175C min,

Stabilize annealing 760C min,

Not Applicable

Solubilized at 1150C min,

Not Applicable

Solubilized 1120C min

Not Applicable

Solubilized 1120C min

Not Applicable

Solubilized 1100C min

Not Applicable

Solubilized 1120C min

Not Applicable

Pag. 5 di 5

T-500

CARATTERISTICHE CHIMICHE, MECCANICHE E STATO DI FORNITURA DEI MATERIALI BFE

B.F.E.

CHEMICAL, MECHANICAL CHARACTERISTICS AND SUPPLY STATUS OF THE BFE MATERIALS

CHEMICAL COMPOSITION (maximun)

MECHANICAL PROPERTIES

MATERIAL

BFE

DESIGNATION

ASTM /DIN

UNS/Other

Form

Mn

Si

Cu

Ni

Cr

Mo

Al

Ti

Nb/Cb

Notes

Yeld p.

N/mm2

Tensile

N/mm2

Elong %

Reduct %

Rev. 29

(minimum)

Hardness

ASTM

HB

Hardness

MR

NACE

01-03 or

01-75

MR

Notch

impact

Heat treatment

according to ASTM

Effective Heat Treatment

temperature after forging

Post Weld Heat Treatment Acc.

To ASME B31.3 (for effective

temperature and time see

spicific WPS-PQR)

NOTES:

C

Min.average of three specimens / min. of one

specimen

29

10xC < Nb+Ta

56

W = 0,5 max / Fe = 3 max / Co = rem

Other elements = 0,5 max

87

Cr+Cu+Mo 0.50 max.

Longitudinal

30

(8xC) < Cb < 1,10%

57

Fe = 5.0 max

88

W = 0.10 max