Professional Documents

Culture Documents

Engr103 Presentation

Uploaded by

api-2541110830 ratings0% found this document useful (0 votes)

42 views51 pagesOriginal Title

engr103 presentation

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

42 views51 pagesEngr103 Presentation

Uploaded by

api-254111083Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 51

Solar-Powered Reverse Osmosis Water Purification System

Section 074 | Group 07

ENGR 103: Engineering Design Lab III

Maissoun Ksara

Lenora Dieyi

Colton Terrace

David Rowell

Hadi Almeer

Dr. Peter Herczfeld

Donald Bucci

1

Group Members Advisor

Fellow

1 Monday, June 2, 14

1. Problem Overview

2. Project Objective

3. Existing Solutions

4. Proposed Solution

5. Technical Activities

a. Schematic

b. Matching Inputs and Outputs

c. Technical Constraints

d. Solar Array Configuration

6. Results

7. Future Work

2

Outline

2 Monday, June 2, 14

Problem Overview

3

Certain regions in Africa do not have access to clean water

Nairobi, Kenya

Lack technological advancement and funds

Water: Most necessary element for survival

Average human needs 2.5 L of water per day for survival

Poor muscle tone, digestive complications, muscle soreness,

water-retention and nutrition problems

*http://www.ready.gov/water

*http://www.naturodoc.com/library/nutrition/water.htm

3 Monday, June 2, 14

4

Existing Solutions

Boiling Water

4 Monday, June 2, 14

5

Existing Solutions

Solar Water Disinfection (SODIS)

5 Monday, June 2, 14

6

Existing Solutions

Ceramic Filters

6 Monday, June 2, 14

7

Existing Solutions

Slow Sand and BioSand Filters

7 Monday, June 2, 14

8

Solar Energy

Project Objective

8 Monday, June 2, 14

9

Clean Water

Project Objective

9 Monday, June 2, 14

10

Clean Water

Project Objective

Sun: valuable and readily available resource

Capable of sustaining population with drinking water using

this clean, renewable source of energy

Targeted audience: a small village or household

10 Monday, June 2, 14

11

??

Proposed Solution

11 Monday, June 2, 14

12

Proposed Solution

?

Effective

12 Monday, June 2, 14

13

Proposed Solution

?

Effective Sustainable

13 Monday, June 2, 14

14

Proposed Solution

?

Effective Sustainable Renewable

14 Monday, June 2, 14

15

Proposed Solution

Reverse Osmosis

15 Monday, June 2, 14

16

Proposed Solution

How it works:

Applies pressure to force impure water through a

semipermeable membrane in the direction opposite to that of

normal osmosis

Uses a diaphragm pump - electric outlet

16 Monday, June 2, 14

17

Proposed Solution

How it works:

Applies pressure to force impure water through a

semipermeable membrane in the direction opposite to that of

normal osmosis

Uses a diaphragm pump - electric outlet

17 Monday, June 2, 14

18

Proposed Solution

Benefits:

Removes contaminants such as arsenic, nitrates, sodium,

copper, lead, fluoride

Pathogen-free water

Easily operated and time efficient

Sustainable

* http://www.freshwatersystems.com/images/RO-Flow-Chart.jpg

18 Monday, June 2, 14

19

Proposed Solution

Benefits:

Removes contaminants such as arsenic, nitrates, sodium,

copper, lead, fluoride

Pathogen-free water

Easily manageable

Inexpensive

Clean Water

* http://www.freshwatersystems.com/images/RO-Flow-Chart.jpg

19 Monday, June 2, 14

20

Proposed Solution

Reverse Osmosis System:

iSpring 75 GDP 5-Stage System

Filters 75 gallons of water per day

Problem:

Operates with a pump that uses electric outlet

Goal:

Use solar energy that is abundant in Kenya

Re-engineer the system to function with solar cells instead of

electricity

Match solar input with specifications of the pump to run the

system

20 Monday, June 2, 14

21

Proposed Solution

Reverse Osmosis System

+

Solar PV Cells

+

Solar Charge Controller

+

Battery

=

Solar-Powered

Reverse Osmosis

Water Purification System

21 Monday, June 2, 14

22

Technical Activities: Schematic

22 Monday, June 2, 14

23

Technical Activities: Schematic

23 Monday, June 2, 14

24

Technical Activities: Schematic

24 Monday, June 2, 14

25

Technical Activities: Schematic

25 Monday, June 2, 14

26

Technical Activities: Schematic

26 Monday, June 2, 14

27

Technical Activities: Schematic

27 Monday, June 2, 14

28

Technical Activities: Schematic

28 Monday, June 2, 14

29

Technical Activities: Schematic

Clean Water

29 Monday, June 2, 14

30

Technical Activities: Matching Inputs and Outputs

24 VDC 0.65 A 28 LPH

Diaphragm Pump Technical Specifications:

30 Monday, June 2, 14

31

Technical Activities: Matching Inputs and Outputs

24 VDC 0.65 A

28 LPH

x = 15.6 W

Diaphragm Pump Technical Specifications:

31 Monday, June 2, 14

32

Technical Activities: Matching Inputs and Outputs

24 VDC 0.65 A

28 LPH

x =

15.6 W x 14 hours ! 218 W!h or 0.218 kW!h

Therefore, an input of 218 W!h is required to function the pump

and run the system effectively

Requirement is easily obtained due to abundant solar radiation in

Kenya

Diaphragm Pump Technical Specifications:

32 Monday, June 2, 14

33

Technical Activities: Matching Inputs and Outputs

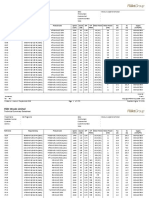

Table-1: Solar Radiation and Energy Data for Nairobi, Kenya

* http://rredc.nrel.gov/solar/calculators/pvwatts/version1/version1_index.html#map

33 Monday, June 2, 14

34

Technical Activities: Matching Inputs and Outputs

Table-1: Solar Radiation and Energy Data for Nairobi, Kenya

* http://rredc.nrel.gov/solar/calculators/pvwatts/version1/version1_index.html#map

Peak Radiated Energy in January

Lowest Radiated Energy in June

34 Monday, June 2, 14

Average solar radiation per year in Kenya is 5.08 kWh/m^2/day

Total solar energy emitted for a year is 1311 kWh

Peak energy is 131 kW!h in January; lowest is in June

35

Technical Activities: Matching Inputs and Outputs

86 kW!h

35 Monday, June 2, 14

36

Technical Activities: Matching Inputs and Outputs

Average solar radiation per year in Kenya is 5.08 kWh/m^2/day

Total solar energy emitted for a year is 1311 kWh

Peak energy is 131 kW!h in January; lowest is in June

30 days

= 2.87 kW!h per day

86 kW!h

36 Monday, June 2, 14

86 kW!h

37

Technical Activities: Matching Inputs and Outputs

30 days

= 2.87 kW!h per day

2.87 kW!h

Average solar radiation per year in Kenya is 5.08 kWh/m^2/day

Total solar energy emitted for a year is 1311 kWh

Peak energy is 131 kW!h in January; lowest is in June

0.218 kW!h

"

The pump requirement is easily fulfilled in Nairobi

37 Monday, June 2, 14

38

Technical Activities: Technical Constraints

Budget - $300

Limited ability to design working prototype

Attempted to conceive the least expensive system that would still

function effectively

This would alter the way solar array is configured

38 Monday, June 2, 14

39

Technical Activities: Solar Array Configuration

With respect to budget, least expensive solar panel would function

with the system is 20 W

LiteFuze 20W Mono-crystalline Solar Panel

Solar Panel:

* http://www.nairobi.climatemps.com/sunlight.php

**http://www.amazon.com/LiteFuze-Mono-crystalline-Solar-Panel-Watt/dp/B0079OA7SK

Maximum Power (Pmax): 20W

Voltage at Pmax (Vmp) 17.4V, Current

at Pmax (Imp) 1.15A

Open Circuit Voltage (Voc): 21.6V, Short

Circuit Current (Isc): 1.27A

Weight 5.51 lbs, Size: 24.21" x 11.22" x 1"

Durable Heavy Duty Long Lasting

Frame**

39 Monday, June 2, 14

40

Technical Activities: Solar Array Configuration

Duration:

Average of 12 daylight hours annually in Kenya*

1.55 worst-weather multiplier is used as a safety factor***

12 hours

1.55

=

7.742 sunshine hours

With respect to budget, least expensive solar panel would function

with the system is 20 W

LiteFuze 20W Mono-crystalline Solar Panel

Solar Panel:

* http://www.nairobi.climatemps.com/sunlight.php

**http://www.amazon.com/LiteFuze-Mono-crystalline-Solar-Panel-Watt/dp/B0079OA7SK

*** http://www.batterystuff.com/kb/tools/solar-calculator.html

40 Monday, June 2, 14

41

Technical Activities: Solar Array Configuration

Average Solar Input:

Two 20 W solar panels are connected in series to result in a 40 W

solar array

40 W

7.742 hours

x

310 W!h or 0.310 kW!h !

41 Monday, June 2, 14

42

Technical Activities: Solar Array Configuration

Average Solar Input:

Two 20 W solar panels are connected in series to result in a 40 W

solar array

40 W

7.742 hours

x

310 W!h or 0.310 kW!h !

A 40 W array is sufficient to provide an input greater than the

requirement

0.310 kW!h 0.218 kW!h >

Least expensive method given the budget constraints

42 Monday, June 2, 14

43

Technical Activities: Solar Array Configuration

* http://www.samlexamerica.com/products/ProductDetail.aspx?pid=157

Charge Controller:

SOLSUM 6.6 F Solar Charge Controller 12V/24V, 6 Amps*

Prevents overcharging and protects the system from over-voltage

Observe the state of charge of the battery bank

43 Monday, June 2, 14

44

Technical Activities: Solar Array Configuration

Charge Controller:

* http://www.samlexamerica.com/products/ProductDetail.aspx?pid=157

** http://www.altestore.com/howto/Solar-Electric-Power/Design-&-Components/Sizing-PWM-Solar-Charge-Controllers/a91/

SOLSUM 6.6 F Solar Charge Controller 12V/24V, 6 Amps*

Prevents overcharging and protects the system from over-voltage

Observe the state of charge of the battery bank

Sizing:

Short circuit current (Isc) of array : 1.27 A

Number of panels: 2

Caution multiplier: 1.56**

1.27 A x 2 ! x 1.56 3.96 A

The model is able to sustain the current

44 Monday, June 2, 14

45

Technical Activities: Solar Array Configuration

Battery:

Pump voltage requirement is 24 V

Used during dark hours i.e no sunshine available

Stores energy and runs the pump for half a day

This means battery would need to match similar input

Two 12 V batteries connected in series would provide the

necessary voltage requirement*

12V, 18 AH, UB12180

Length 7.13in,Width: 3.01in,Height: 6.57in

Absorbed glass mat technology (AGM)

Used in exit lighting & other equipment

Weight of 12 lbs

*http://www.amazon.com/UPG-UBCD5745-Sealed-Lead-Batteries/dp/B001DL7D1O

45 Monday, June 2, 14

46

Results

Initial objective of the project was to design a full, working solar

powered water purification system

All the calculations and data required to build the system were

acquired

Unfortunately objective was not entirely achieved due to the high

cost of materials - the project cost is $489

System is effective, sustainable, and manageable; however, it is

expensive and not as efficient as other methods

Only purifies fresh water with a TDS lower than 1,000

Reverse Osmosis is often used on a larger scale

On a scale size of this project, efficiency is low

46 Monday, June 2, 14

47

Results

http://www.wsc.com.mt/content/reverse-osmosis-plants

Pembroke - Reverse Osmosis Plant

Nominal Capacity : 54,000m3/day

Number of Trains : 6 " 4,400m3/day - 6 " 4,600m3/day

Configuration : Single Pass

Recovery : 45 per cent

Operating Pressure : 83 Bar (1200 PSI)

Feed Intake : Beach Wells

Feed TDS : 39,000 mg/I

Feed Temperature : 19C

Ghar Lapsi - Reverse Osmosis Plant

Nominal Capacity : 24,000m3/day

Number of Trains : 12 " 2,000m3/day

Configuration : Single Pass

Recovery : 33 per cent

Operating Pressure : 69 Bar (1000 PSI)

Feed Intake : Beach Wells

Feed TDS : 39,000 mg/I

Feed Temperature : 19 - 25 C

47 Monday, June 2, 14

Future Work

Research ways to decrease the cost of solar power

Abacus Solar reports that the best way to decrease the

cost of solar energy is to expand the market for it

Market for it would most likely expand and the cost of

producing solar power would decrease

This project can be improved by scaling the system up

or down, depending on regional needs

Utilize larger and more powerful solar cells

48 Monday, June 2, 14

Future Work

Can be modified to purify brackish water and desalinate

salt water

The pressure can be increased either by the addition of

more pumps to the system or the installation of a stronger

pump, as a huge higher PSI would be required for the

purification of brackish water

The most significant part of this project is to find possible

methods of funding the distribution of this system, as it

proves to be very costly.

49 Monday, June 2, 14

50

Thank you

Q & A

50 Monday, June 2, 14

References

51 Monday, June 2, 14

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CH 34Document8 pagesCH 34Qassem MohaidatNo ratings yet

- TechnicalArticle Solar PDFDocument191 pagesTechnicalArticle Solar PDFjbb_sitNo ratings yet

- SSS 7 Edition MANUAL The Analysis and Designs of Linear Circuit PDFDocument987 pagesSSS 7 Edition MANUAL The Analysis and Designs of Linear Circuit PDFEngr Azeem Awan100% (3)

- R&D ZE InglesDocument4 pagesR&D ZE Inglesoscarin071No ratings yet

- Load Duration CurveDocument27 pagesLoad Duration CurveJeff Fauni100% (2)

- Important Essays Outlines: Democracy in PakistanDocument56 pagesImportant Essays Outlines: Democracy in PakistanYasir MasoodNo ratings yet

- Es Electrical Formulas Chart PDFDocument1 pageEs Electrical Formulas Chart PDFAhmed GhreebNo ratings yet

- Low Head Hydropower From Wastewater PDFDocument8 pagesLow Head Hydropower From Wastewater PDFमनीष कश्यप100% (1)

- CEEW CG HighlightsDocument4 pagesCEEW CG HighlightsPrabir Kumar ChatterjeeNo ratings yet

- (Catalog Reciprocating Engine) MTU 252 - BookletEdition1-2020Document24 pages(Catalog Reciprocating Engine) MTU 252 - BookletEdition1-2020ppourmoghaddamNo ratings yet

- Free Samples Recruitment Theory Theory Basic Circuits Network TheoremsDocument25 pagesFree Samples Recruitment Theory Theory Basic Circuits Network TheoremsGrand Theft AutoNo ratings yet

- 2.PSOC - Load Frequency ControlDocument78 pages2.PSOC - Load Frequency ControlAjay BalarNo ratings yet

- Question Phase 3Document115 pagesQuestion Phase 3Noel Capillan OcapNo ratings yet

- Eyb 2021Document157 pagesEyb 2021Sajid AliNo ratings yet

- Denim Factory Setup: A Plant Layout AssignmentDocument55 pagesDenim Factory Setup: A Plant Layout Assignmenttanya gupta100% (1)

- Nuclear Power FundamentalsDocument12 pagesNuclear Power FundamentalsBijuNo ratings yet

- EE 204-Exam II-181 - ver1-KEY PDFDocument11 pagesEE 204-Exam II-181 - ver1-KEY PDFAyJam AdjNo ratings yet

- Conversion Tools FormulaDocument76 pagesConversion Tools Formulasunil suryavanshiNo ratings yet

- Physics For Future Presidents LectureDocument41 pagesPhysics For Future Presidents LectureJohn CrawfordNo ratings yet

- 3 Domestic Electricity: Practice 3.1 (p.133)Document8 pages3 Domestic Electricity: Practice 3.1 (p.133)teresa tsoiNo ratings yet

- Ieep 111Document3 pagesIeep 111habib ahmedNo ratings yet

- DEM1499 - English Version PDFDocument20 pagesDEM1499 - English Version PDFMuhammad Abdur RosyidNo ratings yet

- Solar System PV Calculation and DesignDocument3 pagesSolar System PV Calculation and DesignMustafa TasciNo ratings yet

- A Review of Energy Storage TechnologiesDocument56 pagesA Review of Energy Storage TechnologiesShak GohirNo ratings yet

- Value of Lost LoadDocument7 pagesValue of Lost LoadLuis AntonioNo ratings yet

- Principles and Practice of Electrical EngineeringDocument422 pagesPrinciples and Practice of Electrical EngineeringSaiKishoreNo ratings yet

- 15 Sources and UsesDocument66 pages15 Sources and UsesNaga LakshmiNo ratings yet

- Properties of Substance 2TDocument2 pagesProperties of Substance 2Tjc casordNo ratings yet

- 04ElectrictyEx Live1659612447165Document28 pages04ElectrictyEx Live1659612447165Siddharth BhattNo ratings yet

- Fise Tehnice Ventilatoare 1 Mall TargovisteDocument370 pagesFise Tehnice Ventilatoare 1 Mall TargovisteConstantin294No ratings yet