Professional Documents

Culture Documents

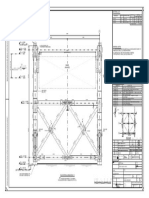

A307 T-1022 8005 TN REV1 Part15 Part4

Uploaded by

Vuong BuiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A307 T-1022 8005 TN REV1 Part15 Part4

Uploaded by

Vuong BuiCopyright:

Available Formats

Page 2028 of 2791

TPI SEPARATOR

MATERIAL OF CONSTRUCTION

SEPARATOR TANK

RCC EL / CSEP (NOTE-1)

PLATES

FRP (OLEOPHILIC)

PLATE FRAME MSEP

SUPPORT FRAMEWORK CSEP

FLOW DISTRIBUTION BAFFLES

CSEP / FRP

WEIRS CSEP

OIL DISCHARGE PIPING (AS PER ENGINEERING SPECS)

HANDRAILS

(AS PER ENGINEERING SPECS)

CHEQUERED PLATES/GRATINGS FOR WALKWAY

(AS PER ENGINEERING SPECS)

NUTS AND BOLTS SS-316

OIL SKIMMER ASSEMBLY

CSEP

COVERS

REQUIRED (NOTE-)

SLUDGE DRAW OFF PIPING CSEP

BOLTING ! FI"ING SS-316

LIFTING DEVICES (NOTE-2)

TYPE OF LIFTING DEVICE SPREADER BAR

CAPACITY (MINIMUM) #$% TIMES TOTAL WEIGHT/PACK

TOTAL WEIGHT/PACK

NOTE-1

SKIMMING & SLUDGE WITHDRAWL ARRANGEMENT

TYPE OF SKIMMER

DIA OF SKIMMER (&&)

(1% && MIN$)

MAKE PROPOSED/SELECRED AS PER APPROVED VENDOR LIST

BACK UP TECHNOLOGY NOTE-1

SOURCE OF PROCUREMENT

NOTE-1

NOTES:

1 DATA TO BE FURNISHED/CONFIRMED BY THE BIDDER$

#

3

' SLOTTED PIPE SKIMMER SHALL BO OPERABLE FROM PLATFORM LEVEL$

6

(

SLOTTED PIPE (ROTATABLE TYPE

WITH RACK ! PINION )BEVEL

GEAR* ARRANGEMENT ! HAND

WHEEL)

APPROACH ROAD SUITABLE FOR TYRE MOUNTED CRANE SHALL BE PROVIDED FROM MAIN

PLANT ROADS TO ACCESS TPI UNIT$

THE PLATE PACK AREA SHALL BE DESIGNED TO REMOVE FREE OIL OF GLOBULE SI+E 6%

MICRON AND ABOVE,

THE UNIT SHALL BE COVERED AND PROVIDED WITH VENTS$ COVERS SHALL NE

REMOVABLE TYPE (EPO"Y PAINTED MS CHEQUERED PLATES WITH AIR TIGHT GASKETS)$

VENTS SHALL NE CONNECTED TO VOC HANDLING SYSTEM$

OIL SKIMMING ! SLOP COLLECTION SYSTEM TO BE DESIGNED FOR MA"IMUM OIL

CONCENTRATION$

ARRANGEMENT OF HEATING COIL SHALL BE SUCH THAT IT DOES NOT HINDER REMOVING

OF PLATE PACKS$

1

1

Page 2029 of 2791

Page 2030 of 2791

Page 2031 of 2791

Page 2032 of 2791

Page 2033 of 2791

Page 2034 of 2791

Page 2035 of 2791

Page 2036 of 2791

Page 2037 of 2791

Page 2038 of 2791

2

Page 2039 of 2791

Page 2040 of 2791

Page 2041 of 2791

Page 2042 of 2791

Page 2043 of 2791

Page 2044 of 2791

Page 2045 of 2791

Page 2046 of 2791

Page 2047 of 2791

Page 2048 of 2791

Page 2049 of 2791

Page 2050 of 2791

Page 2051 of 2791

Page 2052 of 2791

Page 2053 of 2791

TREATED WATER TANK

PROJECT : IREP CLIENT : BPCL-KR JOB NO. : A307

UNIT NO. : IUE ITEM NO. : IUE-T-106

PROCESS DATA

FLUID HANDLED

TREATED WATER

AMBIENT

INFLUENT FLOW (m3/hr) (DESIGN) 1400

PRESENCE OF CORROSIVE/TOIC COMPONENTS NO

EFFECTIVE CAPACIT! OF "#$% (m3) 1000

RESIDENCE TIME (PEA&) 4' MINUTES

AN! BAFFLE ARRANGEMENT RE(UIRED (!ES/NO) NO

T!PE OF SUMP (OPEN/COVERED) OPEN

UNIT SPECIFICATION

SHAPE RECTANGULAR

OVERALL SI)E AS PER SBR SI)ING

LI(UID DEPTH (m) 4*+

FREE BOARD (m) (MIN*) 0*+ (m,$,m-m)

TOTAL HEIGHT (m) +

EFFECTIVE LI(UID STORAGE VOLUME (m3) 1000

COVER NO

VENT (NOS* AND DIA) NO

H!DRO INSULATION (!ES/NO) NO

T!PE OF H!DRO INSULATION

N*A*

FLAME ARRESTOR RE(UIRED NO

LEVEL INDICATION RE(UIRED (!ES / NO) !ES

LEVEL TRANSMITTER (!ES / NO) !ES

LEVEL SWITCHES (!ES / NO) NO

LEVEL TRANSMITTER / SWITCH PLATFORM (!ES/NO) !ES

LEVEL ALARM (!ES/NO) !ES

MATERIAL OF CONSTRUCTION

TAN& RCC

PAINTING/LINING EPO! LINED

UNIT : EFFLUENT TREATMENT

PLANT SERVICE . TO HOLD / TRANSFER TREATED WATER FROM SBR UNIT OUTLET

INFLUENT TEMPERATURE (

0

C)

1

1

Page 2054 of 2791

You might also like

- TA2860 RHI SI ZZ DR N 3002 Temporary UtilitiesDocument1 pageTA2860 RHI SI ZZ DR N 3002 Temporary UtilitiesBack To SumateraNo ratings yet

- Paf002 V0006 Me DRG 0009 - B - ADocument1 pagePaf002 V0006 Me DRG 0009 - B - Asareluis2727No ratings yet

- Application - Bespoke - Non Technical SummaryDocument7 pagesApplication - Bespoke - Non Technical SummaryOsama AbbasNo ratings yet

- TII-HZI-50021275 - 0.0 - TII 15.02.08 Identification and Marking EIC ComponentsDocument11 pagesTII-HZI-50021275 - 0.0 - TII 15.02.08 Identification and Marking EIC ComponentsBorn ToSinNo ratings yet

- Siemens AGDocument6 pagesSiemens AGS Rao CheepuriNo ratings yet

- Ekpsip E4 C1 9808 We 01Document1 pageEkpsip E4 C1 9808 We 01S Rao CheepuriNo ratings yet

- AL MARAI HADCO ETP - Process Description and SeqDocument43 pagesAL MARAI HADCO ETP - Process Description and SeqHumaid ShaikhNo ratings yet

- Pts 0800 - A (Process Description)Document6 pagesPts 0800 - A (Process Description)ingegnere1234No ratings yet

- 2021 BinNova Microfiltration General PresentationDocument19 pages2021 BinNova Microfiltration General PresentationФейсал УджхихNo ratings yet

- QIPP-MPN013-M00-2302 Piping Tie-In Point List Rev.0Document4 pagesQIPP-MPN013-M00-2302 Piping Tie-In Point List Rev.0Ganesh R NairNo ratings yet

- Concept Dewatering, Hydrotest Water and Land Release Management Plan (DHWLRMP)Document23 pagesConcept Dewatering, Hydrotest Water and Land Release Management Plan (DHWLRMP)nodyyy100% (1)

- Safety Data Sheet: 1 IdentificationDocument10 pagesSafety Data Sheet: 1 IdentificationLokesh HNo ratings yet

- Ipp-Gsf-Civ-Gen-005 - 1 of 10 - Rev e PDFDocument1 pageIpp-Gsf-Civ-Gen-005 - 1 of 10 - Rev e PDFYosuaNo ratings yet

- TR2212 Rev.5Document35 pagesTR2212 Rev.5Maffone NumerounoNo ratings yet

- Safety Data Sheet: 1 IdentificationDocument10 pagesSafety Data Sheet: 1 IdentificationLokesh H0% (1)

- Safety Data Sheet for Arizona Test DustDocument6 pagesSafety Data Sheet for Arizona Test DustHerry KurniawanNo ratings yet

- CNG Facility Process NarrativeDocument4 pagesCNG Facility Process NarrativeArnel MorenoNo ratings yet

- 01.01. 1000437900 1000437897 - 1.2Document4 pages01.01. 1000437900 1000437897 - 1.2Javier Ordoñez BarrigaNo ratings yet

- Specification 01286 SPE EPC 302 210 0001 IFB0-01Document27 pagesSpecification 01286 SPE EPC 302 210 0001 IFB0-01minakirolosNo ratings yet

- 0127-Tp-01ab - Sample Tie in PackageDocument11 pages0127-Tp-01ab - Sample Tie in Packagemengelito almonteNo ratings yet

- Ref.04 - OS00002 - E - BW31.ZA3.UM01&EZ18023 - EN - R0Document1 pageRef.04 - OS00002 - E - BW31.ZA3.UM01&EZ18023 - EN - R0IliyanPetrovNo ratings yet

- 2924-G000-13517-DWG-0008 - 0.0 - Standard Drawing For Floor and JoistDocument3 pages2924-G000-13517-DWG-0008 - 0.0 - Standard Drawing For Floor and JoistGeta Oisis Arya PutraNo ratings yet

- Tubing Cable Tray Layout - Rev2Document6 pagesTubing Cable Tray Layout - Rev2BumiLangitNo ratings yet

- Cascade BrochureDocument2 pagesCascade BrochureEzequiel FavelukesNo ratings yet

- B 001032 OHI CW 131 PA 004 - A SDW of DMGF 131 Form Work Layout Wall Pour 03 Section A A View 1Document3 pagesB 001032 OHI CW 131 PA 004 - A SDW of DMGF 131 Form Work Layout Wall Pour 03 Section A A View 1Babin Saseendran100% (1)

- Annexure 2 - Requisition For Pipe 4inch & AboveDocument11 pagesAnnexure 2 - Requisition For Pipe 4inch & Abovefrankz89No ratings yet

- Approved Subcontractor ListDocument189 pagesApproved Subcontractor ListTuan DauNo ratings yet

- VNM GENR ITM PCD CHV 0000 00004 00 H03 Document Transmital ProcedureDocument9 pagesVNM GENR ITM PCD CHV 0000 00004 00 H03 Document Transmital ProcedureHuynh Khuong DuyNo ratings yet

- Electrical Documentation For Level SwitchDocument7 pagesElectrical Documentation For Level SwitchsatfasNo ratings yet

- Volume 1 - General - V1-CH02-Introduction and Numbering Rev1Document16 pagesVolume 1 - General - V1-CH02-Introduction and Numbering Rev1MohamedNo ratings yet

- Training Presentasjon v8 PDFDocument60 pagesTraining Presentasjon v8 PDFAdetu DanielNo ratings yet

- Plano IN 60 KVDocument18 pagesPlano IN 60 KVHamylto PamoNo ratings yet

- Permanent Part Marking SpecificationDocument2 pagesPermanent Part Marking SpecificationCareyNo ratings yet

- 2012 ModelS LHD ReleaseDocument112 pages2012 ModelS LHD ReleaseBilly Hagler100% (2)

- Potence Controls PVT Limited Company ProfileDocument52 pagesPotence Controls PVT Limited Company ProfileAmit KamtheNo ratings yet

- GE Oil & Gas PO Copy For Arexons MotorsilDocument1 pageGE Oil & Gas PO Copy For Arexons MotorsilProject Sales CorpNo ratings yet

- Topside Termination With Flexible BullnoseDocument1 pageTopside Termination With Flexible BullnoseSuperCrack5No ratings yet

- DS951 C13 A30 UL - Concise protection and fault deviceDocument3 pagesDS951 C13 A30 UL - Concise protection and fault deviceȘtefanConstantinNo ratings yet

- HWTT Seawater Desalination Technology DevelopmentDocument33 pagesHWTT Seawater Desalination Technology DevelopmentGoedarz KarimiNo ratings yet

- Sub Control System: Doc. No.: 80040532 - 3.0Document197 pagesSub Control System: Doc. No.: 80040532 - 3.0TuấnNo ratings yet

- PHR-ICM-DTL-105253 Piping and Instrument Diagrams, Process Flow Diagrams, and Material Flow DiagramsDocument54 pagesPHR-ICM-DTL-105253 Piping and Instrument Diagrams, Process Flow Diagrams, and Material Flow Diagramsmashari budiNo ratings yet

- Millport Coastal Flood Protection Scheme: Environmental StatementDocument49 pagesMillport Coastal Flood Protection Scheme: Environmental StatementCory WashingtonNo ratings yet

- Cdoo 01 95 23012 0001 H01 - Hoja - de - Util PDFDocument1 pageCdoo 01 95 23012 0001 H01 - Hoja - de - Util PDFsgtNo ratings yet

- (SA05C1-WV00-S-0013) Cartridge Filter Dimensional Drawing - REVD (AA)Document5 pages(SA05C1-WV00-S-0013) Cartridge Filter Dimensional Drawing - REVD (AA)ABAID ULLAHNo ratings yet

- 4.03B - Single Line Diagram SVC CajamarcaDocument4 pages4.03B - Single Line Diagram SVC CajamarcaFebo MccdNo ratings yet

- Kta Tb-Pac03-C01-002 Rev G VDRLDocument28 pagesKta Tb-Pac03-C01-002 Rev G VDRLLê Đức ThiệnNo ratings yet

- Performance of Reinforced Thermosetting Resin Pipe Systems in Desalination Applications: A Long-Term Solution To Corrosion - The Arabian Gulf ExampleDocument6 pagesPerformance of Reinforced Thermosetting Resin Pipe Systems in Desalination Applications: A Long-Term Solution To Corrosion - The Arabian Gulf ExamplejatecconsultNo ratings yet

- Desalter DrumDocument4 pagesDesalter DrumHsein WangNo ratings yet

- Drawing Harmonic FilterDocument1 pageDrawing Harmonic Filtercr4ck3rjackNo ratings yet

- MiniVac OIM ManualDocument10 pagesMiniVac OIM ManualGiorgiana RosuNo ratings yet

- QIPP MPN013 M00 2203 - A - Status2Document5 pagesQIPP MPN013 M00 2203 - A - Status2Ganesh R NairNo ratings yet

- TII-HZI-50021280 - 2.2 - TII 16.03 Steel Structures, Platforms, Stairs, RailingsDocument24 pagesTII-HZI-50021280 - 2.2 - TII 16.03 Steel Structures, Platforms, Stairs, RailingsBorn ToSinNo ratings yet

- BOP - DCS IO List Rev 2.4 (27.01.2014)Document566 pagesBOP - DCS IO List Rev 2.4 (27.01.2014)vinospaceshuttleNo ratings yet

- COMPRESSED AIR SYSTEM DESCRIPTION 压缩空气Document20 pagesCOMPRESSED AIR SYSTEM DESCRIPTION 压缩空气کالرو تحریک اتحادNo ratings yet

- 9504A-9504B Pump Skid As Build Drawing PDFDocument2 pages9504A-9504B Pump Skid As Build Drawing PDFnull nullNo ratings yet

- CNG Storage Equipment for Lampung Peaker Power PlantDocument3 pagesCNG Storage Equipment for Lampung Peaker Power PlantAde Okta YurwendraNo ratings yet

- Instructions FOR Supplier Documentation: Document No.: Winz-Pm-Dc-0001Document17 pagesInstructions FOR Supplier Documentation: Document No.: Winz-Pm-Dc-0001Anil JaxNo ratings yet

- List of Finished PlansDocument8 pagesList of Finished PlansKunal JhinganNo ratings yet

- 82848211-TREX-05106 Equipmenl Alerl ReviewDocument10 pages82848211-TREX-05106 Equipmenl Alerl ReviewHKHKBOOKSNo ratings yet

- 196217564-Selection of Main CB and Branch CBDocument41 pages196217564-Selection of Main CB and Branch CBVuong BuiNo ratings yet

- FaultDocument12 pagesFaultVuong BuiNo ratings yet

- Stpdesigns 120227072137 Phpapp01Document42 pagesStpdesigns 120227072137 Phpapp01Vuong BuiNo ratings yet

- Division 05 Ladder Platform +++++++PDFDocument16 pagesDivision 05 Ladder Platform +++++++PDFVuong BuiNo ratings yet

- Swimming Pool CalculationDocument3 pagesSwimming Pool CalculationVuong BuiNo ratings yet

- Apx BDocument7 pagesApx BVuong BuiNo ratings yet

- 2012 ISPSC AmendmentsDocument16 pages2012 ISPSC AmendmentsVuong BuiNo ratings yet

- Spa and Swimming Pool Code 2012Document100 pagesSpa and Swimming Pool Code 2012Kevin Christian Fagara100% (3)

- Invitation To Tender Swimming Pool (2013!02!13)Document24 pagesInvitation To Tender Swimming Pool (2013!02!13)Vuong Bui100% (1)

- Weftec SDC 2011 Acton Wastewater Treatment Plant Expansion Team University of Guelph Full PDFDocument100 pagesWeftec SDC 2011 Acton Wastewater Treatment Plant Expansion Team University of Guelph Full PDFVuong BuiNo ratings yet

- Line Sizing Criteria As Per Different StandardsDocument4 pagesLine Sizing Criteria As Per Different StandardsVuong BuiNo ratings yet

- Kwinana Combined Cycle Power PlantDocument38 pagesKwinana Combined Cycle Power PlantVuong BuiNo ratings yet

- Apx ADocument8 pagesApx AVuong BuiNo ratings yet

- Util PSDesignSpreadsheet3!20!09Document16 pagesUtil PSDesignSpreadsheet3!20!09Vuong BuiNo ratings yet

- GWS 1 02 Procedure R7Document11 pagesGWS 1 02 Procedure R7Vuong BuiNo ratings yet

- Water Treatment Plant Evaluation and Selection ProcessDocument86 pagesWater Treatment Plant Evaluation and Selection ProcessVuong BuiNo ratings yet

- Vessels - Flash Drums, Surge Tanks and AccumulatorsDocument2 pagesVessels - Flash Drums, Surge Tanks and AccumulatorsVuong Bui100% (1)

- DM PlantDocument35 pagesDM PlantVuong BuiNo ratings yet

- TIDEL Wastewater Vendor Name - Part 1B - Technical SpecificationDocument37 pagesTIDEL Wastewater Vendor Name - Part 1B - Technical SpecificationVuong Bui100% (1)

- ADA326907 (1) - Wastewater Treatment OM SpecsDocument276 pagesADA326907 (1) - Wastewater Treatment OM SpecsVuong Bui100% (2)

- Vessels - Flash Drums, Surge Tanks and AccumulatorsDocument2 pagesVessels - Flash Drums, Surge Tanks and AccumulatorsVuong Bui100% (1)

- Wws Ten State Standards Waste WaterDocument102 pagesWws Ten State Standards Waste WaterLauren BowenNo ratings yet

- Chemical Engineering Equipment Types, Descriptions, Design, Selection-IndexDocument2 pagesChemical Engineering Equipment Types, Descriptions, Design, Selection-IndexVuong BuiNo ratings yet

- Selection of Materials For Chemical Engineering EquipmentDocument4 pagesSelection of Materials For Chemical Engineering EquipmentVuong BuiNo ratings yet

- Heat Exchangers IndexDocument3 pagesHeat Exchangers IndexVuong BuiNo ratings yet

- Pump and Line Calculation Sheet: REV Date BY Apvd REV Date BY Apvd AddressDocument1 pagePump and Line Calculation Sheet: REV Date BY Apvd REV Date BY Apvd AddressVuong BuiNo ratings yet

- CONSIDERED in The REVIEW of Wastewater Treatment Facilities - Policy 96-1Document98 pagesCONSIDERED in The REVIEW of Wastewater Treatment Facilities - Policy 96-1Vuong BuiNo ratings yet

- Cost Estimating For Chemical Engineering Plant Design-IndexDocument6 pagesCost Estimating For Chemical Engineering Plant Design-IndexVuong BuiNo ratings yet

- Phong Khach San - HotelListingsnear CGHRevisedDocument2 pagesPhong Khach San - HotelListingsnear CGHRevisedVuong BuiNo ratings yet

- Pumpcal Polyethylene-Pump Power CalculatorDocument21 pagesPumpcal Polyethylene-Pump Power CalculatorVuong BuiNo ratings yet

- Advances in Remediation-eBookDocument88 pagesAdvances in Remediation-eBookalinerlfNo ratings yet

- I) CentrifugesDocument46 pagesI) Centrifugesiahim87No ratings yet

- Mathcad - Ampacity CalculationDocument76 pagesMathcad - Ampacity CalculationAlex Ribeiro100% (4)

- Template Icme 13 PosterDocument1 pageTemplate Icme 13 PosterZulma Xiomara Rueda GarciaNo ratings yet

- Mini System LG-RAD-226B PDFDocument65 pagesMini System LG-RAD-226B PDFAndres Lecaro JarrinNo ratings yet

- A134 PDFDocument4 pagesA134 PDFJarbas MoraesNo ratings yet

- GPT 1-15 LineBackerDocument4 pagesGPT 1-15 LineBackerazadeazNo ratings yet

- Touch Panel Debug Info Register ValuesDocument17 pagesTouch Panel Debug Info Register ValuesAlghazyNo ratings yet

- VHF Low Loss Band-Pass Helical Filter For 145 MHZ - English NewDocument33 pagesVHF Low Loss Band-Pass Helical Filter For 145 MHZ - English NewSharbel AounNo ratings yet

- Search Engine Collocations Frequency PhrasesDocument2 pagesSearch Engine Collocations Frequency PhrasesDinda NoviarmachdaNo ratings yet

- Factors Affecting Purchase Intentions in Generation Z Towards Hipster Cafe in Kelantan LOCKEDDocument70 pagesFactors Affecting Purchase Intentions in Generation Z Towards Hipster Cafe in Kelantan LOCKEDlassan199358No ratings yet

- Human Plus Machine A New Era of Automation in ManufacturingDocument8 pagesHuman Plus Machine A New Era of Automation in ManufacturingDuarte CRosaNo ratings yet

- HT Series: 73-136Kw I Up To 12 Mppts Three PhaseDocument2 pagesHT Series: 73-136Kw I Up To 12 Mppts Three PhasesyamprasadNo ratings yet

- Kosice Schulze Bramey PDFDocument13 pagesKosice Schulze Bramey PDFandrel_fariasNo ratings yet

- Computer Science: FieldsDocument2 pagesComputer Science: FieldstdoraxNo ratings yet

- Difference Between AND: Shahirah Nadhirah Madihah Suhana AtiqahDocument11 pagesDifference Between AND: Shahirah Nadhirah Madihah Suhana AtiqahShahirah ZafirahNo ratings yet

- Current Developments in Lens DesignDocument12 pagesCurrent Developments in Lens DesignMahabub HossainNo ratings yet

- Data Visualization Q&A With Dona Wong, Author of The Wall Street Journal Guide To Information Graphics - Content Science ReviewDocument14 pagesData Visualization Q&A With Dona Wong, Author of The Wall Street Journal Guide To Information Graphics - Content Science ReviewSara GuimarãesNo ratings yet

- Auto Temp II Heat Pump: Programmable Thermostat For Single and Multistage Heat Pump SystemsDocument22 pagesAuto Temp II Heat Pump: Programmable Thermostat For Single and Multistage Heat Pump Systemswideband76No ratings yet

- Eurox Cross Flow ScrubberDocument8 pagesEurox Cross Flow ScrubberRobin LayogNo ratings yet

- OkDocument29 pagesOkgouthamlabsNo ratings yet

- Aikah ProfileDocument20 pagesAikah ProfileMohammad ZeeshanNo ratings yet

- Attachment To Division Memorandum No. - , S, 2020Document3 pagesAttachment To Division Memorandum No. - , S, 2020Jasmin Move-RamirezNo ratings yet

- Manufacturing Egg Trays from Waste PaperDocument17 pagesManufacturing Egg Trays from Waste Paperravibarora86% (7)

- Learning One-to-One - Book ReviewDocument3 pagesLearning One-to-One - Book Reviewwhistleblower100% (1)

- Design Rules CMOS Transistor LayoutDocument7 pagesDesign Rules CMOS Transistor LayoututpalwxyzNo ratings yet

- Module 8 SAHITA ConcreteDocument11 pagesModule 8 SAHITA ConcreteHarrybfnNo ratings yet

- Milenium BypassDocument1 pageMilenium BypassdinotecNo ratings yet

- How The Draganflyer Flies: So How Does It Work?Document5 pagesHow The Draganflyer Flies: So How Does It Work?sav33No ratings yet

- BSC Prospectus 2019-20Document37 pagesBSC Prospectus 2019-20Gaurav VamjaNo ratings yet