Professional Documents

Culture Documents

Solid Energy New Zealand Limited.

Uploaded by

bento183Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solid Energy New Zealand Limited.

Uploaded by

bento183Copyright:

Available Formats

Solid Energy New Zealand Limited.

Typical Stockton Coking Coal

Specifications

Typical Guaranteed Typical

MOISTURE (%) GIESELER PLASTOMETER VALUES (degrees C)

Total 7.8 8.0 Initial Softening Temperature 405

Maximum Fluidity Temperature 454

PROXIMATE ANALYSIS (air dried basis) (%) Resolidification Temperature 490

Ash 2 to 5 Plastic Range 85

Inherent moisture 1.5 Maximum Fluidity 500

Volatile Matter 32.0 approx. Log Maximum Fluidity 2.7

Fixed Carbon by diff.

SPECIFIC ENERGY

ULTIMATE ANALYSIS (dry mineral matter free) (%) Gross Air Dried 8,120

Carbon 86.7

Hydrogen 5.6

Nitrogen 1.2

Sulphur 1.8 MACERAL ANALYSIS (%)

Oxygen 4.7 Vitrinite 96

Exinite 1

ASH ANALYSIS Inertinite 1

SiO2 48.90 Mineral Matter 2

Al2O3 32.60

Fe2O3 7.60 Shapiro & Gray Reactives 97

K2O 2.50

TiO2 2.20 Shapiro & Gray Inerts 3

CaO 1.20

P2O5 0.68 REFLECTANCE (%)

Na2O 0.67 Mean Maximum Reflectance 1.15

Mn3O4 0.43

MgO 0.43 Coking Pressure (PSI) 0

SO3 0.01

Other 2.78

PHYSICAL ANALYSES

Size Analysis (%)

6.3-50mm 31

3.35-6.3mm 13

2-3.35mm 11

1-2mm 18

Below 1mm 27

Hardgrove Grindability Index 80 to 95

CHEMICAL ANALYSES

Sulphur (air dried basis) (%)

Total Sulphur 1.5 to 3

Chlorine (%) 0.06

Phosphorus (%) very low

SWELLING, CAKING & PLASTOMETRIC TESTS

Crucible Swelling Number 9 7

Grey King Coke Type G10

AUDIBERTSoftening Temperature 405

Temperature of max contraction 435

Temperature of max dilatation 485

Maximum Contraction (%) 29

Maximum Dilatation (%) 135

Total Dilatation (%) 164

2-Nov-21

You might also like

- MABU - HCC 2022-SpecDocument2 pagesMABU - HCC 2022-SpecDUANJUNXINo ratings yet

- MLV - HCC SpecV1-2022Document1 pageMLV - HCC SpecV1-2022DUANJUNXINo ratings yet

- Metropolitan Hard Coking Coal 2010 Typical SpecificationDocument1 pageMetropolitan Hard Coking Coal 2010 Typical Specificationnaresh adusumilliNo ratings yet

- Mavis Downs Hard CokingDocument1 pageMavis Downs Hard Cokingnaresh adusumilliNo ratings yet

- Indicative Specification For 2013: WotongaDocument1 pageIndicative Specification For 2013: Wotonganaresh adusumilliNo ratings yet

- Appin Coking Coal: Proximate and Other AnalysisDocument1 pageAppin Coking Coal: Proximate and Other Analysisnaresh adusumilliNo ratings yet

- AlcOxid T 38 - CatalogDocument3 pagesAlcOxid T 38 - CatalogArantxa SanchezNo ratings yet

- Typical Specification - Russian PCI Coal - KravaskyDocument1 pageTypical Specification - Russian PCI Coal - Kravaskynaresh adusumilliNo ratings yet

- Characteristics Units Result Test Method: Southern Pars 1 CondensateDocument14 pagesCharacteristics Units Result Test Method: Southern Pars 1 CondensatemohammadhadiNo ratings yet

- 1.0 Design Criteria - Rev 1Document9 pages1.0 Design Criteria - Rev 1Ramesh-NairNo ratings yet

- Crude Summary Report: Crude: OSEBERG 2016 04 Reference: OSEBERG201604Document3 pagesCrude Summary Report: Crude: OSEBERG 2016 04 Reference: OSEBERG201604Jorge Rodriguez HerreraNo ratings yet

- Specification Hydrate FinalDocument6 pagesSpecification Hydrate FinalSanjayNo ratings yet

- Product Specifications Hydrate2018Document6 pagesProduct Specifications Hydrate2018Jayakumar ANo ratings yet

- GeneralData Forozan NewDocument1 pageGeneralData Forozan NewRos Neftegaz TransitNo ratings yet

- GeneralData Lavan NewDocument1 pageGeneralData Lavan NewRos Neftegaz TransitNo ratings yet

- Statoil Eagle Ford Gen Grade 2017 07Document5 pagesStatoil Eagle Ford Gen Grade 2017 07AhmedAlhosaniNo ratings yet

- Russian Origin-Hard Coking Coal: Analysis Basis Typical ValueDocument1 pageRussian Origin-Hard Coking Coal: Analysis Basis Typical Valuenaresh adusumilli100% (1)

- 1.0 Design Criteria - Rev 1Document9 pages1.0 Design Criteria - Rev 1Ramesh-NairNo ratings yet

- Black Hill Coking CoalDocument1 pageBlack Hill Coking Coalnaresh adusumilliNo ratings yet

- Workshop 3BDocument7 pagesWorkshop 3BSantiago MartinezNo ratings yet

- Equipment:: (Feed 120000 Bbl/yr About 14000 M /yr)Document8 pagesEquipment:: (Feed 120000 Bbl/yr About 14000 M /yr)Mohamed Sayed AbdoNo ratings yet

- Petroleum SystemDocument49 pagesPetroleum SystemHisham K. MustafaNo ratings yet

- Technical Data Sheet Rigid 4000Document2 pagesTechnical Data Sheet Rigid 4000dikimanNo ratings yet

- GTC 01062Document22 pagesGTC 01062Prakash ChavanNo ratings yet

- Snowhite 80Document1 pageSnowhite 80Mateus PachecoNo ratings yet

- Ail Bis Infrapro PPC 2021 09 38 35DDocument1 pageAil Bis Infrapro PPC 2021 09 38 35DAmit RathNo ratings yet

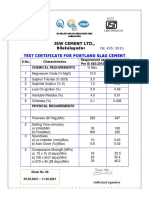

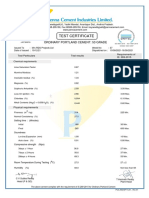

- Calcom Cement India Limited: For Dalmia Ordinary Portland Cement 43 (OPC43)Document1 pageCalcom Cement India Limited: For Dalmia Ordinary Portland Cement 43 (OPC43)MarshallNo ratings yet

- Tough 1500 TDS ENDocument2 pagesTough 1500 TDS ENMert SunNo ratings yet

- TC OPC 53Gr Week 20Document1 pageTC OPC 53Gr Week 20divithNo ratings yet

- Week No 40,43 GR, 3 Day'sDocument1 pageWeek No 40,43 GR, 3 Day'sshinde rushiNo ratings yet

- (Tech-Lotte) GAA - TDSDocument1 page(Tech-Lotte) GAA - TDSIMRAN KHANNo ratings yet

- SOK Clinker OPCDocument2 pagesSOK Clinker OPCAmr A. NaderNo ratings yet

- GeneralData IranianLight NewDocument1 pageGeneralData IranianLight NewRos Neftegaz Transit100% (1)

- Coal Spec Wahana 6300 GarDocument1 pageCoal Spec Wahana 6300 GarAmatơ Hà ThànhNo ratings yet

- Castes Resin by FormlabDocument2 pagesCastes Resin by FormlabAhmed IbrahimNo ratings yet

- 06 Week PSC TEST CERTIFICATEDocument1 page06 Week PSC TEST CERTIFICATEKamal NathNo ratings yet

- Wadi Cement Work Ordinary Portland Cement 53 Grade: Chemical CharacteristicsDocument1 pageWadi Cement Work Ordinary Portland Cement 53 Grade: Chemical CharacteristicsAshish SontakkeNo ratings yet

- Jordan Petroleum Refinery Co. Ltd. Gasoline 90 Specification QS-PL 103 Laboratories & Quality Control DepartmentDocument2 pagesJordan Petroleum Refinery Co. Ltd. Gasoline 90 Specification QS-PL 103 Laboratories & Quality Control DepartmentMohammed NuseirNo ratings yet

- Mares Blend Assay (June 2018) PDFDocument4 pagesMares Blend Assay (June 2018) PDFMonica Rocio Salamanca CuitivaNo ratings yet

- Raw Materials Burnability Testing Reports, Port Daniel Cement Plant ProjectDocument48 pagesRaw Materials Burnability Testing Reports, Port Daniel Cement Plant ProjectNihar Ranjan TripathyNo ratings yet

- Crude Summary Report: Reference: Cupiagua17 Tipo II Crude: Cupiagua Tipo IIDocument2 pagesCrude Summary Report: Reference: Cupiagua17 Tipo II Crude: Cupiagua Tipo IIDiana Alejandra GodoyNo ratings yet

- 5+MTC+Ultrafine Week+No.+27Document1 page5+MTC+Ultrafine Week+No.+27Mathi Vinoth PillaiNo ratings yet

- Test Certificate: Ordinary Portland Cement: 53 GradeDocument1 pageTest Certificate: Ordinary Portland Cement: 53 GradeRDS KMRNo ratings yet

- Test Certificate: Star Cement LimitedDocument1 pageTest Certificate: Star Cement Limiteddibyendu650% (1)

- Umm Lulu - UMMLULU201810Document6 pagesUmm Lulu - UMMLULU201810asad raza100% (2)

- Agbami 2012 03Document5 pagesAgbami 2012 03eke23No ratings yet

- TC-NVL - Infracem - Opc WK-16-2023-28DDocument1 pageTC-NVL - Infracem - Opc WK-16-2023-28DSirajul IslamNo ratings yet

- Test Certificate: Ordinary Portland Cement: 53 GradeDocument1 pageTest Certificate: Ordinary Portland Cement: 53 GradeLOHITH NNo ratings yet

- Naphthenic Acid Corrosion Risk Assessment and MitigationDocument24 pagesNaphthenic Acid Corrosion Risk Assessment and MitigationSampat100% (3)

- GeneralData Siri NewDocument1 pageGeneralData Siri NewRos Neftegaz TransitNo ratings yet

- Apiay Blend 2019Document2 pagesApiay Blend 2019Natalia Valentina Agudelo UrreaNo ratings yet

- Rigid 10k DatasheetDocument2 pagesRigid 10k DatasheetAna Maria RodrigoNo ratings yet

- Engineering Failure Analysis: Changjun Zou, Pinwen Zhao, Meng Wang, Delei Liu, Hongda Wang, Zhang WenDocument6 pagesEngineering Failure Analysis: Changjun Zou, Pinwen Zhao, Meng Wang, Delei Liu, Hongda Wang, Zhang WenVishal AryaNo ratings yet

- Vibfast Tartrazine - TDSDocument1 pageVibfast Tartrazine - TDSMahmoud LotfyNo ratings yet

- Crudo 1 Abgami NigeriaDocument2 pagesCrudo 1 Abgami NigeriaFlorencia GonzalezNo ratings yet

- Zeolites, Synthesis, Characterizations and Applications: Sandip ChakrabartiDocument32 pagesZeolites, Synthesis, Characterizations and Applications: Sandip ChakrabartiSmyle KatariaNo ratings yet

- Uv Absorber 360Document3 pagesUv Absorber 360N.S CompanyNo ratings yet

- CoA HYDROXYLAMINE HYDROCHLORIDE Loba ChemieDocument1 pageCoA HYDROXYLAMINE HYDROCHLORIDE Loba ChemieimamaptNo ratings yet

- Inductively Coupled Plasma-Mass Spectrometry: Practices and TechniquesFrom EverandInductively Coupled Plasma-Mass Spectrometry: Practices and TechniquesNo ratings yet

- Marine / Petroleum C175 Engine: Global Service TrainingDocument8 pagesMarine / Petroleum C175 Engine: Global Service TrainingJose FavaNo ratings yet

- Rxs25ebvma, Rxs35ebvmaDocument79 pagesRxs25ebvma, Rxs35ebvmaShing SkNo ratings yet

- Peso Print 1Document34 pagesPeso Print 1Eugine Bryan Son CadizNo ratings yet

- Service Manual: JCB Service Rocester, Staffordshire, St14 5Ls. EnglandDocument242 pagesService Manual: JCB Service Rocester, Staffordshire, St14 5Ls. EnglandWillian Ticlia RuizNo ratings yet

- Nat. Gas ReformingDocument6 pagesNat. Gas Reformingabdullah farhanNo ratings yet

- AHU Conversion Kit Application GuideDocument69 pagesAHU Conversion Kit Application GuideBartosz MarciniakNo ratings yet

- Intesci Lab ManualDocument42 pagesIntesci Lab ManualXannyNo ratings yet

- Clean Fleets LCC Tool - enDocument5 pagesClean Fleets LCC Tool - endanutzuNo ratings yet

- Vdocument - in - Certificates Cemp Abnt NBR Iec Atex Other Certifications Iso 90012015Document2 pagesVdocument - in - Certificates Cemp Abnt NBR Iec Atex Other Certifications Iso 90012015ABHISHEK DOLLENo ratings yet

- 2021 Carbon Dioxide Pipelines For CCUSDocument26 pages2021 Carbon Dioxide Pipelines For CCUSropi.saraNo ratings yet

- SS-05 Heat Island EffectDocument3 pagesSS-05 Heat Island Effecthaifa.alpinNo ratings yet

- v60 d6 Plug in Hybrid Awd Automatic 2014 1637347347Document1 pagev60 d6 Plug in Hybrid Awd Automatic 2014 1637347347Adrian VartolomeiNo ratings yet

- Phys HSSC 1 Model PaperDocument7 pagesPhys HSSC 1 Model PaperheheheheNo ratings yet

- Solar Energy Trainer: Salient FeaturesDocument2 pagesSolar Energy Trainer: Salient FeaturesadtronNo ratings yet

- Certificate of Participation: Madelita Z. LucidoDocument47 pagesCertificate of Participation: Madelita Z. LucidoShanikMendozaNo ratings yet

- Pni SH200Document56 pagesPni SH200TonyNo ratings yet

- VPL Scheda Tecnica Raychem NVDocument4 pagesVPL Scheda Tecnica Raychem NVCataloghi TecniciNo ratings yet

- BEAMA Guide Low Voltage Switch and Fusegear DevicesDocument25 pagesBEAMA Guide Low Voltage Switch and Fusegear DevicesAbel OliveiraNo ratings yet

- IPSA DzaficDocument248 pagesIPSA DzaficUdomsak ThanatkhaNo ratings yet

- Unit 1.2, Comparison of Fire Tube Water TubeDocument2 pagesUnit 1.2, Comparison of Fire Tube Water Tubeashu raoNo ratings yet

- RS425 TerexDocument2 pagesRS425 TerexMAQUINARIA 2022No ratings yet

- Electric Vehicle FiresDocument3 pagesElectric Vehicle FiresmenakaNo ratings yet

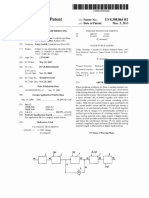

- (1b) ) The-Canonical-Circuit-ModelDocument15 pages(1b) ) The-Canonical-Circuit-ModelClare DianneNo ratings yet

- Dagang Zhang: COTEC Offshore Engineering Solutions China Offshore Oil Engineering Company March 28, 2011Document24 pagesDagang Zhang: COTEC Offshore Engineering Solutions China Offshore Oil Engineering Company March 28, 2011moechamad_aditiaNo ratings yet

- Donaldson Dust Collector Manual Iom Ad3092901 Downflo Oval Dfo 1-1 To 3-3Document36 pagesDonaldson Dust Collector Manual Iom Ad3092901 Downflo Oval Dfo 1-1 To 3-3Aiman JamaluddinNo ratings yet

- Aswich Electrical: EDS6EL DC Isolator IP66 Enclosure (1500V 50A)Document3 pagesAswich Electrical: EDS6EL DC Isolator IP66 Enclosure (1500V 50A)AswichElectricalNo ratings yet

- Scooptram EST1030: Electric Underground Loader With 10-Tonne CapacityDocument8 pagesScooptram EST1030: Electric Underground Loader With 10-Tonne CapacityBenNo ratings yet

- Industrial Training Report SuyashDocument24 pagesIndustrial Training Report Suyash1322 - Prasad KumbharNo ratings yet

- TA400 T4 MM 11151 April 2015 15504853Document518 pagesTA400 T4 MM 11151 April 2015 15504853David McDonellNo ratings yet

- Estimating Calculator) .XLSX UnprotectedDocument38 pagesEstimating Calculator) .XLSX UnprotectedEjay Craig De LeonNo ratings yet