Professional Documents

Culture Documents

KSKV Teknologi Pembinaan Sem1 Hingga Sem4

Uploaded by

Muhd Muhd Hasif100%(1)100% found this document useful (1 vote)

2K views215 pagesko

Original Title

7. KSKV Teknologi Pembinaan Sem1 Hingga Sem4

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentko

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

2K views215 pagesKSKV Teknologi Pembinaan Sem1 Hingga Sem4

Uploaded by

Muhd Muhd Hasifko

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 215

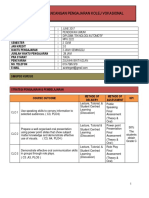

T P CR-HR T P CR-HR T P CR-HR T P CR-HR T P CR-HR T P CR-HR T P CR-HR T P CR-HR

KOD S1 S2 S3 S4 S5 S6 S7 S8 GENERAL MODULES

AMT 101 201 301 401 BAHASA MELAYU I - IV 2.0 1.0 2.0 2.0 1.0 2.0 2.0 1.0 2.0 2.0 1.0 2.0

AMT 102 202 302 402 PENDIDIKAN ISLAM I - IV** 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0

AMT 103 203 303 403 PENDIDIKAN MORAL I - IV** 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0

AMT 104 204 ENGLISH I - II 1.0 1.0 1.0 1.0 1.0 1.0

AMT 605 BAHASA CINA** 1.0 1.0 1.0

AMT 606 BAHASA ARAB** 1.0 1.0 1.0

AMT 107 207 SEJARAH 1.0 0.0 1.0 1.0 0.0 1.0

AMT 108 MATHEMATICS 1.0 2.0 2.0

AMT 209 MATHEMATICS FOR TECHNOLOGIST 1.0 2.0 2.0

AMT 111 SCIENCE 1.0 2.0 2.0

AMT 212 SCIENCE FOR TECHNOLOGIST 1.0 2.0 2.0

SUK 101 201 301 401 501 SUKAN I - V ***

PJK 101 201 301 401 501 PJ & PK ***

KKU 102 202 302 402 502 KOKURIKULUM I - V ***

JUMLAH 7 7 9 7 7 9 3 2 3 3 2 3 0 0 0 2 2 1 0 0 0 0 0 0 25.0 19%

VOCATIONAL MODULES

CVAM 201 FINANCIAL MANAGEMENT & CONSUMERISM 1.0 1.0 1.0

CVAM 302 402 EMPLOYABILITY SKILLLS 1.0 1.0 1.0 1.0 1.0 1.0

CCCT 101 INTRODUCTION TO CONSTRUCTION TECHNOLOGY 1.0 2.0 2.0

CCCT 102 SAFETY PRACTICES IN CONSTRUCTION INDUSTRY 1.0 1.0 1.0

CCCT 103 CONSTRUCTION TOOLS AND EQUIPMENTS 1.0 1.0 1.0

CCCT 104 TECHNICAL AND BUILDING DRAWING 1.0 3.0 2.0

CCCT 105 SHALLOW AND DEEP FOUNDATION 1.0 3.0 2.0

CCCT 106 REINFORCEMENT AND CONCRETE WORKS I 1.0 3.0 2.0

CCCT 207 FRAME STRUCTURES 1.0 3.0 2.0

CCCT 208 BRICKWORKS 1.0 3.0 2.0

CCCT 209 PLASTERING WORKS I 1.0 3.0 2.0

CCCT 210 FINISHING WORKS I 1.0 2.0 2.0

CCCT 211 SANITATION, DRAINAGE AND SEWERAGE MATERIAL 1.0 2.0 1.0

CCCT 312 FENCING WORKS 1.0 4.0 3.0

CCCT 313 BUILDING DRAWING 1.0 4.0 3.0

CCCT 314 FORMWORK AND CONCRETE WORKS II 1.0 4.0 3.0

CCCT 315 MASONRY WORKS 1.0 4.0 3.0

CCCT 316 SCAFFOLDING SYSTEM 1.0 2.0 2.0

CCCT 417 PLASTERING AND WORKS II 1.0 5.0 3.0

CCCT 418 FINISHING WORKS II 1.0 5.0 3.0

CCCT 419 SANITATION,DRAINAGE AND SEWERAGE SYSTEM 1.0 5.0 3.0

CCCT 420 BUILDING MAINTENANCE 1.0 5.0 3.0

CCCT 521 COST AND ESTIMATING WORKS 2.0 5.0 4.0

CCCT 522 SITE PREPARATION 2.0 5.0 4.0

CCCT 523 ROOFING WORKS 2.0 5.0 4.0

CCCT 524 DECORATIVE RETAINING WALLS 2.0 5.0 4.0

CCCT 625 DEMOLISHING AND RENOVATION WORKS 2.0 5.0 4.0

CCCT 626 CONSTRUCTION MANAGEMENT 2.0 5.0 4.0

CCCT 627 CONSTRUCTION COMMUNITY PROJECT 2.0 5.0 4.0

DCCT 728 MANAGE PRE CONSTRUCTION ACTIVITIES 2.0 5.0 4.0

DCCT 729 MANAGE CIVIL ENGINEERING WORKS 2.0 5.0 4.0

DCCT 730 CIVIL AND STRUCTURAL WORKS 2.0 5.0 4.0

DCCT 731 ADD DIPLOMA MODULE 2.0 5.0 4.0

DCCT 832 CIVIL ENGINEERING AND STRUCTURAL SITE MANAGEMENT 2.0 5.0 4.0

DCCT 833 MANAGE SITE PERSONNEL 2.0 5.0 4.0

DCCT 834 ADD DIPLOMA MODULE 2.0 6.0 5.0

DCCT 835 ADD DIPLOMA MODULE 2.0 6.0 5.0

JUMLAH 6 13 10 5 13 9 6 19 15 5 21 13 8 20 16 6 15 12 8 20 16 8 22 18 109.0 81%

JUMLAH BESAR 13 20 19 12 20 18 9 21 18 8 23 16 8 20 16 8 17 13 8 20 16 8 22 18

JUMLAH 134.0 100%

NOTA : ** ELECTIVE COURSES

*** PASS FAIL COURSES

NISBAH JK UMUM : VOKASIONAL JUMLAH JK MODUL UMUM SIJIL 25.0 25%

JUMLAH JK MODUL VOKASIONAL SIJIL 75.0 75%

JUMLAH JAM KREDIT SIJIL 100.0 100%

JUMLAH JK MODUL UMUM DIPLOMA 25.0 19%

JUMLAH JK MODUL VOKASIONAL DIPLOMA 109.0 81%

JUMLAH JAM KREDIT DIPLOMA 134.0 100%

NISBAH TEORI : PRAKTIKAL JUMLAH JAM KONTAK TEORI (SIJIL) 58.0 32%

JUMLAH JAM KONTAK PRAKTIKAL ( SIJIL) 121.0 68%

JUMLAH JAM KONTAK (SIJIL) 179.0 100%

JUMLAH JAM KONTAK TEORI (DIPLOMA) 74.0 31%

JUMLAH JAM KONTAK PRAKTIKAL (DIPLOMA) 163.0 69%

JUMLAH JAM KONTAK (DIPLOMA) 237.0 100%

SEM 4 SEM 5 SEM 6 SEM 7 SEM 8

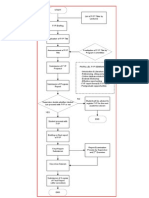

PELAKSANAAN MERENTAS KURIKULUM

STRUKTUR PROGRAM KOLEJ VOKASIONAL KEMENTERIAN PELAJARAN MALAYSIA

PROGRAMME : CONSTRUCTION TECHNOLOGY

CLUSTER : CIVIL ENGINEERING TECHNOLOGY

MODUL CODE MODULE TITLE

SEM 1 SEM 2 SEM 3

Document Standard Curriculum Draf, Vocational College MoE

Latest Edited 24-27 Oktober 2011-kuching

MINISTRY OF EDUCATION, MALAYSIA

MODULE INFORMATION

Confidential

MODULE

CODE

:

:

1 - INTRODUCTION TO CONSTRUCTION TECHNOLOGY

CCCT 101

LEVEL : 1 SEMESTER 1

CREDIT UNIT : 2.0

CONTACT HOUR : 3.0 HOURS / WEEK

COMPETENCY :

MODULE STATUS : VOCATIONAL

PREREQUISITE : N A

Document Standard Curriculum Draf, Vocational College MoE

Latest Edited 24-27 Oktober 2011-kuching

MODULE OUTCOMES

At the end of the module, students should be able to:

1. understand the building trade and systems using blue print, specifications, catalogue and broaches.

2. understand the importance of safety precaution in the construction industry.

3. compare conventional / traditional and modern technology in construction industry.

4. comply with buildings regulations or building codes.

5. organize building team for construction industry.

6. practice and apply building construction technology for various works.

MODULE DESCRIPTION

The module provides an overview of the construction industry. It is designed as an introduction for students who wish to develop their

competence and skills relating to methods of construction technology. Students will be exposed to the process of taking a design

concept from a paper exercise to a finished, full-sized, building that can be occupied. This program provides a foundation in

construction technology. Areas of study include building codes, construction site layout, construction documents, mechanical

systems and construction safety. The goal of the module is to help the student acquire skills that can be used to enter the workplace

as a versatile member of a construction team.

Document Standard Curriculum Draf, Vocational College MoE

Latest Edited 24-27 Oktober 2011-kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 1 - INTRODUCTION TO CONSTRUCTION TECHNOLOGY

COMPETENCY 1 : THE FUNDAMENTAL OF BUILDING TRADE IN CONSTRUCTION INDUSTRY

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

1. IDENTIFY THE

FUNDAMENTAL OF

BUILDING TRADE IN

CONSTRUCTION

INDUSTRY.

1.1 Identify different types of building trade

in construction industry.

1.1.1 Read and gather information on different types of

building trade in construction industry from blue

print, works specifications, catalogue and

brochures with the aids of information technology

(IT).

1.1.2 Utilize basic IT applications to prepare a brief report

on the history of building trade in construction

industry.

1.2 Identify the importance of safety

precaution in construction industry.

1.2.1 Outline safety precautions required in construction

industry in accordance with OSHA requirements

and standards.

1.2.2 Prepare a checklist using standard forms on safety

precautions in the construction industry according

to OSHA requirements and standards.

1.2.3 Prepare a brief report on the importance of safety

precaution in the construction industry according to

OSHA requirements and standards.

1.3 Identify construction technology use in

construction industry.

1.3.1 Select the construction technology use in

construction industry to comply with building by law

and building regulations/codes.

Document Standard Curriculum Draf, Vocational College MoE

Latest Edited 24-27 Oktober 2011-kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 1 - INTRODUCTION TO CONSTRUCTION TECHNOLOGY

COMPETENCY 2 : THE CATEGORY OF BUILDING TRADE IN CONSTRUCTION INDUSTRY

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

2. RECOGNIZE THE

CATEGORY OF

BUILDING TRADE IN

CONSTRUCTION

INDUSTRY.

2.1. Identify conventional or traditional

methods of construction technology in

construction industry.

2.1.1 Define the conventional or traditional methods

construction technology in construction industry.

2.1.2 List down the conventional or traditional methods

construction technology in construction industry

2.2. Identify modern or industrialised

methods of construction technology in

construction industry.

2.2.1 Define modern or industrialised methods of

construction technology in construction industry.

2.2.2 Differentiate between conventional or traditional

methods and modern or industrialised methods of

construction technology in construction industry.

2.3 Identify the stages of progress for

various works within the building trade

in construction industry.

2.3.1 List down stages of progress for one building work

within the building trade

2.3.2 Prepare a brief report for stages of progress for one

building work within the building trade

Document Standard Curriculum Draf, Vocational College MoE

Latest Edited 24-27 Oktober 2011-kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 1- INTRODUCTION TO CONSTRUCTION TECHNOLOGY

COMPETENCY 3 : BUILDING REGULATION AND BY - LAWS

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

3. COMPLY WITH BUILDING

REGULATION AND BY

LAWS.

3.1. Identify building codes in construction

industry.

3.1.1 Define building codes in accordance with the

building standards.

3.1.2 List down common building codes used in housing

developments.

3.2 Identify building regulation and by-law

related to construction industry.

3.2.1 Outline the regulations and by- laws in construction

industry.

3.3. Comply with regulations and building

by-laws.

3.3.1 Apply the buildings regulations and by-laws

appropriately for the construction of a simple single

storey housing to comply with the building

standards.

Document Standard Curriculum Draf, Vocational College MoE

Latest Edited 24-27 Oktober 2011-kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 1 - INTRODUCTION TO CONSTRUCTION TECHNOLOGY

COMPETENCY 4 : BUILDING CONSTRUCTION TEAMS IN CONSTRUCTION INDUSTRY.

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

4. ESTABLISH BUILDING

CONSTRUCTION TEAMS

IN CONSTRUCTION

INDUSTRY.

4.1. Identify the personnel and agencies

involved in the construction industry.

4.1.1 Identify the personnel and agencies involved in the

construction industry in accordance with a

construction team and organization.

4.2. Identify the responsibilities a

professional involved in construction

industry.

4.2.1 List down the responsibilities of a professional

involved in construction industry.

4.3 Organize a construction team for the

construction industry.

4.3.1 Draw a flow chart profile of a construction team in a

construction industry involving the local authorities

and the relevant agencies.

4.3.2 Form a construction team to include the

management and the working personnel in a

construction industry.

Document Standard Curriculum Draf, Vocational College MoE

Latest Edited 24-27 Oktober 2011-kuching

ITEM EMPLOYABILITY SKILL/CORE ABILITIES

01 LOCATE AND PROCESS INFORMATION

01.01 Identify and gather information

01.02 Document information, procedures or processes

01.03 Utilize basic IT applications

02 EXCHANGE/COMMUNICATE INFORMATION

02.01 Interpret and follow manuals, instructions and SOPs

02.02 Follow telephone/ telecommunication procedures

02.03 Communicate clearly

02.04 Prepare brief reports and checklists using standard forms

02.05 Read/interpret flowcharts and pictorial information

03 WORK AND INTERACT WITH PEOPLE

03.01 Apply cultural requirements to the workplace

03.02 Demonstrate integrity and apply ethical practices

03.03 Accept responsibility for own work and work area

03.04 Seek and act constructively upon feedback about performance

03.05 Demonstrate safety skills

03.06 Respond appropriately to people and situations

03.07 Resolve interpersonal conflicts

06 WORK WITHIN AND WITH SYSTEM

06.01 Understand systems

06.02 Comply with and follow chain of command

06.03 Identify and highlight problems

06.04 Adapt competencies to new situations / systems

Draft of Document Standard Curriculum for College Vocational MoE

Latest Edited 24-27 Oktober 2011- Kuching

MINISTRY OF EDUCATION, MALAYSIA

MUDULE INFORMATION

Confidential

MODULE

CODE

:

:

2 - SAFETY PRACTICES IN CONSTRUCTION INDUSTRY

CCCT 102

LEVEL : 1 SEMESTER 1

CREDIT UNIT : 1.0 credit/hr

CONTACT HOUR : 2.0 hr/week

COMPETENCY :

MODULE STATUS : VOCATIONAL

PREREQUISITE : NA

Draft of Document Standard Curriculum for College Vocational MoE

Latest Edited 24-27 Oktober 2011- Kuching

MODULE OUTCOMES:

Upon the success completion of this module, students should be able to:

1 identify, apply and perform OSH practices

2 use safe attires and gears while performing various jobs according to job requirements

3 comply with tools and equipment safety rules

4 adhere to site safety equipment

5 demonstrate the use of fire fighting equipment

6 apply emergency first aid techniques

MODULE DESCRIPTIONS

This module provides construction students an overview of the basic safety practices that will be encountered on a construction site,

how site safety is organized and implemented as well as which areas fall under the umbrella of Construction Industry Development

Board (CIDB) and OSHAs jurisdiction. Students will gain a basic understanding of how regulations and OSHA safeguards operate to

protect both workers and employers, and how they can benefit personally from a better understanding of OSHA standards.

Draft of Document Standard Curriculum for College Vocational MoE

Latest Edited 24-27 Oktober 2011- Kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 2 - SAFETY PRACTICES IN CONSTRUCTION INDUSTRY

COMPETENCY 1 : OSH PRACTICES

CONTENT STANDARD

LEARNING STANDARD

PERFORMANCE CRITERIA

1 IDENTIFY, APPLY

AND PERFORM

OSHA PRACTICES

1.1 Identify the occupational health and

safety policies and rules on construction

sites clearly.

1.1.1 Read and understand the occupational and safety

6.1.1 policies and rules on construction sites.

1.2 Apply the occupational health and safety

policies and procedure on construction

sites correctly.

6.2.1

1.2.1 Practise construction safety when handling tools

1.2.2 and equipment at work place and on site according

to Workshop Procedure

Draft of Document Standard Curriculum for College Vocational MoE

Latest Edited 24-27 Oktober 2011- Kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 2 - SAFETY PRACTICES IN CONSTRUCTION INDUSTRY

COMPETENCY 2 : SAFE ATTIRES AND GEARS FOR VARIOUS JOBS

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

2 USE SAFE ATTIRES AND

GEARS FOR VARIOUS

JOBS ACCORDING TO

JOB REQUIREMENTS.

2.1 Identify the suitable clothing while

performing various works.

2.1.1 Choose types of clothing according to job

specification.

2.1.2 Wear proper cloth while working in workshop

according to job requirement.

2.2 Check the condition of safety attires

regularly.

2.2.1 Select appropriate safety attires to prevent

accident according to job specification.

2.2.2 Recognize any defect while choosing safety

equipments.

2.2.3 Organize safety attires while performing

various works in the correct way according to

OSHA requirement.

2.2.4 Check the condition of safety attires

according to OSHA procedures.

2.3 Use safe attires and gears properly. 2.3.1 Use safety attires while operating a machine

according to job requirement.

Draft of Document Standard Curriculum for College Vocational MoE

Latest Edited 24-27 Oktober 2011- Kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 2 SAFETY PRACTICES IN CONSTRUCTION INDUSTRY

COMPETENCY 3 : TOOLS AND EQUIPMENT SAFETY RULES

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

3 COMPLY WITH TOOLS

AND EQUIPMENT

SAFETY RULES

3.1 Ensure all equipment are in good

condition.

3.1.1 Identify tools and equipment to be used are

in good condition for any job.

3.1.2 Operate the machinery in safe condition by

complying to safety regulations of

machinery.

3.2 Obey all safety instructions at working

place.

3.2.1 Follow safety regulations according to

requirement.

3.2.2 Label all safety signs at the appropriate

points in the workshop.

Draft of Document Standard Curriculum for College Vocational MoE

Latest Edited 24-27 Oktober 2011- Kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 2 - SAFETY PRACTICES IN CONSTRUCTION INDUSTRY

COMPETENCY 4 : SAFETY EQUIPMENT

CONTENT STANDARD

LEARNING STANDARD

PERFORMANCE CRITERIA

4. ADHERE TO SITE

SAFETY

EQUIPMENT

4.1 Check work site safety.

4.1.1 Select various instruction symbols and signs

about at the work according to OSHA

requirement.

4.2 Ensure all equipment arranged

accordingly.

4.2.1 Ensure all equipments used on site are

arranged according to specifications.

4.3 Obey all safety instructions on site.

4.3.1 Follow optimum safety precautions while

operating the equipment on site.

Draft of Document Standard Curriculum for College Vocational MoE

Latest Edited 24-27 Oktober 2011- Kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 2 - SAFETY PRACTICES IN CONSTRUCTION INDUSTRY

COMPETENCY 5 : THE USE OF FIRE FIGHTING EQUIPMENT

CONTENT STANDARD

LEARNING STANDARD

PERFORMANCE CRITERIA

5. DEMONSTRATE THE

USE OF FIRE FIGHTING

EQUIPMENT

5.1 Identify causes of fire.

5.1.1 List causes of fires in workplace in accordance

with workshop safety manual.

5.2 Select the appropriate fire extinguisher.

5.2.1 Identify location of fire extinguisher in worksite

in accordance with workshop safety manual.

5.2.2 Identify the types appropriate fire extinguisher.

5.3 Check the fire extinguisher regularly.

5.3.1 Check the condition of fire extinguisher regularly

according to requirement specifications.

5.4 Operate fire extinguisher.

5.4.1 Use fire extinguisher according to worksite

practice.

Draft of Document Standard Curriculum for College Vocational MoE

Latest Edited 24-27 Oktober 2011- Kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 2 - SAFETY PRACTICES IN CONSTRUCTION INDUSTRY

COMPETENCY 6 : EMERGENCY FIRST AID TECHNIQUES

CONTENT STANDARD

LEARNING STANDARD

PERFORMANCE CRITERIA

6 APPLY EMERGENCY

FIRST AID

TECHNIQUES

6.1 Identify common injuries.

6.1.1 List down common injuries in workshop and

construction site according to workshop safety

procedure.

6.2 Select the right medicine and

Treatment.

6.2.1 Choose the right medicine and treatment according

to workshop safety procedure.

6.2.2 Apply medicine and treatment for emergency

treatment according to safety procedure.

6.2.3 Perform various method of dressing and bandaging

by using the right medicine and treatment as

specifications.

6.2.4 Perform life saving treatment using artificial

respiration according to specifications.

6.2.5 Demonstrate Cardiopulmonary Resuscitation (CPR)

using proper method according to OSHA procedure.

6.2.6 Apply CPR by proper method that comply with the

safety procedure.

Draft of Document Standard Curriculum for College Vocational MoE

Latest Edited 24-27 Oktober 2011- Kuching

6.3 Identify emergency and evacuation

procedures at construction sites.

6.3.1 Practice the emergency and evacuation

procedures at construction site according to

emergency procedures.

6.3.2 Follow the emergency and evacuation procedures

at construction sites according to emergency

treatment procedures.

6.4 Call ambulance for serious cases

Immediately.

6.4.1 Make an emergency call according to emergency

procedure.

Draft of Document Standard Curriculum for College Vocational MoE

Latest Edited 24-27 Oktober 2011- Kuching

ITEM CORE ABILITIES

01 LOCATE AND PROCESS INFORMATION

01.01 Identify and gather information

01.02 Document information, procedures or processes

01.03 Utilize basic IT applications

02 EXCHANGE/COMMUNICATE INFORMATION

02.04 Prepare brief reports and checklists using standard forms

02.05 Read/interpret flowcharts and pictorial information

03 WORK AND INTERACT WITH PEOPLE

03.01 Apply cultural requirements to the workplace

03.02 Demonstrate integrity and apply ethical practices

03.03 Accept responsibility for own work and work area

03.04 Seek and act constructively upon feedback about performance

03.05 Demonstrate safety skills

03.06 Respond appropriately to people and situations

03.07 Resolve interpersonal conflicts

06 WORK WITHIN AND WITH SYSTEM

06.01 Understand systems

06.02 Comply with and follow chain of command

06.03 Identify and highlight problems

06.04 Adapt competencies to new situations / systems

Document Standard Curriculum Draft, Vocational College, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

MINISTRY OF EDUCATION, MALAYSIA

MODULE INFORMATION

Confidential

MODULE

CODE

:

:

3 - CONSTRUCTION TOOLS AND EQUIPMENT

CCCT 103

LEVEL : 1 SEMESTER 1

CREDIT UNIT : 1.0 credit/hr

CONTACT HOUR : 2.0 hr/week

COMPETENCY :

MODULE STATUS : VOCATIONAL

PREREQUISITE : NA

Document Standard Curriculum Draft, Vocational College, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

MODULE OUTCOMES:

At the end of the module, students should be able to:-

1. Follow and practise basic security procedures.

2. Avoid workplace hazards.

3. Identify and use hand tools and machine according to various types of jobs

4. Identify, use and maintain power tools

5. Identify, use and maintain equipment /plants

6. Practise construction safety when handling tools and equipment or plants at on site

MODULE DESCRIPTION

This module Identifies the usage and maintenance of hand machine tools , power tools, power tools and the equipment based on the

required specifications. It is also to ensure that the construction safety are practiced as to avoid the work place hazards and the

tasks are carried out as scheduled.

Document Standard Curriculum Draft, Vocational College, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 3 - CONSTRUCTION TOOLS AND EQUIPMENTS

COMPETENCY 1 : HAND AND MACHINE TOOLS USAGE AND MAINTENANCE IDENTIFICATION

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

1. IDENTIFY, USE AND

MAINTAIN HAND

AND MACHINE TOOLS

1.1 Identify the tasks to be done

Clearly.

1.1.1 Recognize the nature of task to be carried out.

1.2 Select the appropriate hand tools

for tasks.

1.2.1 Select appropriate hand tools to suit the given task .

1.2.2 Use hand tools and machine tools to complete the task

according to requirement.

1.3 Determine the location of the

proposed tasks correctly.

1.3.1 Select the location of proposed work according to the task.

1.4 Identify appropriate machine tools

to be used .

1.4.1 Select machine tools to be used to suit the task

1.4.2 Operate machine tools according to the Manufacturer's

Instructions and Specification

1.5 Make proper maintenance and

store hand tools and machine

tools.

1.5.1 Locate equipment at their proper place as scheduled

1.5.2 Clean and grease the hand tools and machine tools in

accordance with the manufacturer's instructions and

specification.

1.5.3 Maintain all parts/ components in good condition according

to Manual Manufacturing Procedure.

1.5.4 Store tools in their proper place according to layout plan.

Document Standard Curriculum Draft, Vocational College, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 3 - CONSTRUCTION TOOLS AND EQUIPMENTS

COMPETENCY 2 : POWER TOOLS IDENTIFICATION USAGE AND MAINTENANCE

CONTENT STANDARD

LEARNING STANDARD

PERFORMANCE CRITERIA

2 IDENTIFY, USE AND

MAINTAIN POWER

TOOLS

2.1 Identify appropriate types of

power tools.

2.1.1 Select various types of power tools on construction

site according to the tasks.

2.2 Select the appropriate

Accessories.

2.2.1 Select the appropriate accessories according to

tasks requirement.

2.3 Assemble part of accessories

Correctly.

2.3.1 Fit together the parts of power tools according to

Manufacturer's Instructions .

2.4 Adjust the cutting parts correctly

2.4.1 Rearrange the cutting parts of power tools in accordance with

manufacturer's Instructions.

2.5 Connect tools to power supply.

2.5.1 Ensure that the power supply is correctly connected to the

Tools.

2.6 Operate power tools effectively

according to Manual .

2.6.1 Operate power tools correctly according to the Manual

Instruction

2.7 Disassemble parts of accessories.

2.7.1 Disassemble parts of accessories according to the

Manual Instructions

Document Standard Curriculum Draft, Vocational College, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

2.8 Make proper maintenance and

store power tools.

2.8.1 Locate equipment at their proper place as in a schedule.

2.8.2 Clean and grease the power tools according to manual

manufacturing instructions.

.

2.8.3 Maintain all parts/ components in good condition according to

Manual Manufacturing Procedure.

2.8.4 Store tools in their proper place according to the layout plan.

Document Standard Curriculum Draft, Vocational College, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 3 - CONSTRUCTION TOOLS AND EQUIPMENTS

COMPETENCY 3 : EQUIPMENT/PLANTS IDENTIFICATION, USAGE AND MAINTENANCE

CONTENT STANDARD

LEARNING STANDARD

PERFORMANCE CRITERIA

3 IDENTIFY ,USE AND

MAINTAIN

EQUIPMENT/PLANTS

3.1 Identify appropriate types of

equipment / plants.

3.1.1 Select equipment according to tasks requirement

3.2 Select the appropriate

Accessories.

3.2.1 Select the appropriate accessories according to

power tools job requirement

3.3 Assemble part of accessories

Correctly.

3.3.1 Fit together the parts of accessories of equipment correctly.

3.4 Perform maintenance according

to manual.

3.4.1 Perform maintenance in accordance with the manufacturer's

Instructions and Manual.

3.5 Operate equipment according to

Manual .

3.5.1 Operate equipment according to Manual Operating

Procedures.

3.6 Ensure the equipment

functions correctly.

3.6.1 Check to ensure that equipment are functioning

well according manufacturer's directions and manual

3.7 Make proper maintenance and

store equipment.

3.7.1 Locate equipment to the proper place as in a schedule

3.7.2 Clean and grease the power tools according to Manual

Manufacturing Instructions.

3.7.3 Maintain all parts/ components in good condition according to

Manual Manufacturing Procedures

3.7.4 Store tools in their proper place according to layout plan.

Document Standard Curriculum Draft, Vocational College, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 3 - CONSTRUCTION TOOLS AND EQUIPMENTS

COMPETENCY 4 : CONSTRUCTION SAFETY IN HANDLING TOOLS AND EQUIPMENT/PLANT

CONTENT STANDARD

LEARNING STANDARD

PERFORMANCE CRITERIA

4. IDENTIFY

CONSTRUCTION

SAFETY IN

HANDLING TOOLS

AND EQUIPMENT

/PLANTS AT

CONSTRUCTION SITE

4.1 Identify the safety practice when

using special tool at construction

site.

4.1.1 List safety practice when using special tool at construction

site according to Safety Procedure

4.1.2 Write a report of safety practice when using special tools at

construction site.

4.2 Prepare a report writing for safety

environment at construction site.

4.2.1 Identify the safety environment at construction site.

4.2.2 Write a report of safety environment at construction

site.

Document Standard Curriculum Draft, Vocational College, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

ITEM CORE ABILITIES

01 LOCATE AND PROCESS INFORMATION

01.01 Identify and gather information

01.02 Document information, procedures or processes

01.03 Utilize basic IT applications

02 EXCHANGE/COMMUNICATE INFORMATION

02.04 Prepare brief reports and checklists using standard forms

02.05 Read/interpret flowcharts and pictorial information

03 WORK AND INTERACT WITH PEOPLE

03.01 Apply cultural requirements to the workplace

03.02 Demonstrate integrity and apply ethical practices

03.03 Accept responsibility for own work and work area

03.04 Seek and act constructively upon feedback about performance

03.05 Demonstrate safety skills

03.06 Respond appropriately to people and situations

03.07 Resolve interpersonal conflicts

06 WORK WITHIN AND WITH SYSTEM

06.01 Understand systems

06.02 Comply with and follow chain of command

06.03 Identify and highlight problems

06.04 Adapt competencies to new situations / systems

Document Standard Curriculum Draft, Vocational College, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

MINISTRY OF EDUCATION, MALAYSIA

MODULE INFORMATION

Confidential

MODULE

CODE

:

:

4 - TECHNICAL AND BUILDING DRAWING

CCCT 104

LEVEL : 1 SEMESTER 1

CREDIT UNIT : 2.0 credit/hrs

CONTACT HOUR : 4.0 hr/week

COMPETENCY :

MODULE STATUS : VOCATIONAL

PREREQUISITE : NA

Document Standard Curriculum Draft, Vocational College, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

MODULE OUTCOMES:

At the end of the module, students should be able to:-

1. draw basic technical drawing by using the appropriate drawing instruments.

2. identify types of drawings in building construction according to building drawing standard.

3. draw various symbols in technical drawings and building plan according to building drawing standard.

4. draw building plan for single storey building.

5. interpret building plans for single storey building.

MODULE DESCRIPTION

This module is designed for students to master basic technical drawing by using appropriate drawing instruments which is according

to the building drawing standard. It is also designed to enable them to draw and interpret the single storey building plan

Document Standard Curriculum Draft, Vocational College, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 4 - TECHNICAL AND BUILDING DRAWING

COMPETENCY 1 : BASIC TECHNICAL DRAWING USING THE DRAWING INSTRUMENTS

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

1 DRAW BASIC

TECHNICAL

DRAWING BY USING

THE APPROPRIATE

DRAWING

INSTRUMENTS

1.1 Set a drawing paper on drawing

board correctly according to

drawing specification.

1.1.1 1.1.1 Identify types and size of drawing paper for technical

1.1.2 drawing according to specification

1.1.3 1.1.2 Setting the drawing paper on the drawing board by using

1.3.1 the clips

1.2 Select appropriate drawing

Instruments.

1.2.1 1.2.1 Identify appropriate drawing instruments according to

1.2.2 specification.

1.2.3 1.2.2 Draw the types of lines in drawing by using the drawing

1.2.4 instrument set

1.2.5 1.2.3 Apply the various techniques of letter writing by using

letter block and free hand

1.3 Perform basic technical drawing

as required correctly

1.3.1 Draw basic technical drawing by using an instrument set

as shown in the drawing sheet.

Document Standard Curriculum Draft, Vocational College, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 4 - TECHNICAL AND BUILDING DRAWING

COMPETENCY 2 : TYPES OF DRAWINGS IN BUILDING CONSTRUCTION

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

2 IDENTIFY TYPES OF

DRAWINGS IN

BUILDING

CONSTRUCTION

ACCORDING TO

BUILDING DRAWING

STANDARD

2.1 Select various types of drawing in

building construction

1.1.4 2.1.1 Identify the various types of drawing in

building construction according to job

specification

1.3.2

2.2 Verify drawings used in building

construction

1.2.6 2.2.1 List the drawings used in building according

1.2.7 to job specification.

.

Document Standard Curriculum Draft, Vocational College, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 4 - TECHNICAL AND BUILDING DRAWING

COMPETENCY 3 : VARIOUS SYMBOLS IN TECHNICAL DRAWINGS AND BUILDING PLAN

CONTENT STANDARD LEARNING STANDARD

PERFORMANCE CRITERIA

3 DRAW VARIOUS

SYMBOLS IN

TECHNICAL

DRAWINGS AND

BUILDING PLAN

ACCORDING TO

STANDARD

SYMBOLS AND

DRAWING SCALE

3.1 Imply standard symbols used in

related drawing.

3.1.1 Identify the symbols in technical drawings and building

plan according to drawing requirement

3.1.2 Draw the types of symbols in technical drawing and

building plan using drawing instrument set

3.2 Apply standard drawing scale

used in drawing

3.2.1 Identify drawing scale used in technical drawings and

building plan according to drawing requirement

3.2.2 Use the drawing scale in technical drawing according to

drawing requirement

3.2.3 Use the architectural scale in drawing plan

according to drawing requirement

Document Standard Curriculum Draft, Vocational College, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 4 - TECHNICAL AND BUILDING DRAWING

COMPETENCY 4 : BUILDING PLAN FOR SINGLE STOREY BUILDING

CONTENT STANDARD

LEARNING STANDARD

PERFORMANCE CRITERIA

4 DRAW BUILDING

PLAN FOR

SINGLE STOREY

BUILDING

4.1 Interpret building plan for single storey

building according to drawing given

4.1.1 Read and understand the drawing given

4.1.2 Identify related drawing

4.2 Draw floor plan and scale correctly

4.2.1. Set the drawing paper on the board using

the paper clip correctly

4.2.2 Identify the orthography drawing building plan

according to drawing given

4.2.3 Draw floor plan and scale according to drawing

given

4.3 Draw front elevation, side

elevation and rear elevation correctly

4.3.1. Draw front elevation, side and rear elevation

and scale according to drawing given

4.4 Draw roof plan correctly

4.4.1 Draw roof plan and scale according to drawing

Given

4.5 Draw section view correctly

4.5.1 Draw section view and scale according to

drawing given

Document Standard Curriculum Draft, Vocational College, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 4 - TECHNICAL AND BUILDING DRAWING

COMPETENCY 5 : INTERPRETATION OF BUILDING PLANS FOR SINGLE STOREY BUILDING

CONTENT STANDARD LEARNING STANDARD

PERFORMANCE CRITERIA

5 INTERPRET SINGLE

STOREY BUILDING PLAN

5.1 Read and understand the

building drawing clearly

5.1.1 Identify the types, shapes and sizes of material

drawing according to drawing plan

5.1.2 Identify the types of finishing and their applications

according to drawing plan

5.2 Identify related drawing

5.2.1 Identify related drawing according to single storey

building plan

Document Standard Curriculum Draft, Vocational College, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

ITEM CORE ABILITIES

01 LOCATE AND PROCESS INFORMATION

01.01 Identify and gather information

01.02 Document information, procedures or processes

01.03 Utilize basic IT applications

02 EXCHANGE/COMMUNICATE INFORMATION

02.04 Prepare brief reports and checklists using standard forms

02.05 Read/interpret flowcharts and pictorial information

03 WORK AND INTERACT WITH PEOPLE

03.01 Apply cultural requirements to the workplace

03.02 Demonstrate integrity and apply ethical practices

03.03 Accept responsibility for own work and work area

03.04 Seek and act constructively upon feedback about performance

03.05 Demonstrate safety skills

03.06 Respond appropriately to people and situations

03.07 Resolve interpersonal conflicts

06 WORK WITHIN AND WITH SYSTEM

06.01 Understand systems

06.02 Comply with and follow chain of command

06.03 Identify and highlight problems

06.04 Adapt competencies to new situations / systems

Document Standard Curriculum Draf, Vocational Collage, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

MINISTRY OF EDUCATION, MALAYSIA

MODULE INFORMATION

Confidential

MODULE

CODE

:

:

5 - SHALLOW AND DEEP FOUNDATION

CCCT 105

LEVEL : 1 SEMESTER 1

CREDIT UNIT : 2.0 credit/hrs

CONTACT HOUR : 4.0 hr/week

COMPETENCY :

MODULE STATUS : VOCATIONAL

PREREQUISITE : NA

Document Standard Curriculum Draf, Vocational Collage, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

MODULE OUTCOMES:

At the end of the module, students should be able to:-

1. avoid workplace hazards.

2. maintain cleanliness of work area and equipment.

3. follow basic security procedure.

4. setting out and excavate trenches for shallow trench.

5. provide pest control services.

6. construct timbering and shoring.

7. pour and screed lean concrete on the trenches bed.

8. perform piling works.

9. perform pile cap works.

MODULE DESCRIPTION

This module is designed as an introduction to students about shallow trenches set up and excavation, pest control services, timbering

and shoring construction, the pouring and screeding of lean concrete on trenches bed, piling work and pile cap work. Students will be

exposed to the instructions and procedures of the work that suit the current industrial needs. They will learn how to use all the

necessary plans, tools and equipment so that the work can be proceeded according to the work specifications. They will also be

introduced to the roles of supervisory. Workplace safety guidance material is also included in this module that contributes to the state of

knowledge about hazards and risks and the ways of removing or reducing the hazard and risk.

Document Standard Curriculum Draf, Vocational Collage, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 5 - SHALLOW AND DEEP FOUNDATION

COMPETENCY 1 : SHALLOW TRENCHES

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

1. SETTING OUT AND

EXCAVATING

TRENCHES FOR

SHALLOW TRENCH

1.1 Set out measurements for

excavation

1.2 Identify and select tools for

manual excavation

1.3 Perform manual excavations

1.4 Arrange the machinery for

excavation work

1.5 Maintain the tools after an

excavation work

1.6 Keep the record for daily

excavation work progress

1.1.1 Set out the measurements for shallow trench excavation.

1.2.1 Choose appropriate manual digging tools for shallow trenches

1.3.1 Perform excavation for shallow trenches manually

1.4.1 Identify the type of machines for digging deep trenches

1.5.1 Cleans and maintain the tools after work for maintenance

purposes.

1.6.1 Read the daily work progress on the excavation work

performed

Document Standard Curriculum Draf, Vocational Collage, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 5 - SHALLOW AND DEEP FOUNDATION

COMPETENCY 2 : PEST CONTROL SERVICES

CONTENT STANDARD LEARNING STANDARD

PERFORMANCE CRITERIA

2. PROVIDING PEST

CONTROL SERVICES

2.1 Determine the areas that require pest

control treatment.

2.2 Keep records of areas being serviced

2.3 Perform site supervision

2.1.1 Identify the areas that need pest control treatment.

2.1.2 Mark the areas that need pest control treatment.

2.2.1 Record details of pest control services for the

serviced area.

2.3.1 Perform site supervision of the serviced area.

Document Standard Curriculum Draf, Vocational Collage, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 5 - SHALLOW AND DEEP FOUNDATION

COMPETENCY 3 : TIMBERING AND SHORING

CONTENT STANDARD LEARNING STANDARD

LEARNING STANDARD

3. CONSTRUCT TIMBERING

AND SHORING

3.1 Determine the size of timber to shore up

the bank of the shallow trenches.

3.2 Supply and deliver timber to the work site

3.3 Prepare, measure and cut timbering

and shoring materials correctly

3.4 Place the timbering and shoring materials

accordingly

3.5 Clear debris and generate good work

areas

3.1.1 Determine the type of wood used for shallow

trenches based on the detail blueprint.

3.1.2 Determine the size of the wood used for the work

concerned as specified in the detail blueprint..

3.2.1 Determine adequate materials needed for

timbering and shoring construction as stated in the

work specification.

3.2.2 Transpot the selected timber to the worksite.

3.3.1 Prepare the measurement and cutting of the

timbering and shoring materials based on the

blueprint.

3.4.1 Install wooden struts in the shallow trench in

accordance to the detail blueprint.

3.5.1 Clear debris at the site after the completion of the

required work.

Document Standard Curriculum Draf, Vocational Collage, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 5 - SHALLOW AND DEEP FOUNDATION

COMPETENCY 4 : LEAN CONCRETE ON THE TRENCH BEDS

CONTENT STANDARD LEARNING STANDARD

LEARNING STANDARD

4 POUR AND SCREED

LEAN CONCRETE ON

THE TRENCH BEDS

4.1 Prepare work surface for pouring of the

concrete.

4.2 Prepare the area for mixing of lean

concrete.

4.3 Prepare the equipment and tools for

the mixing of the lean concrete

manually.

4.4 Mixing the lean concrete at the mixing

place.

4.5 Pour and level the lean concrete to the

required trench beds (on site mixing or

ready-mixed concrete)

4.6 Maintain and generate a good work

area

4.1.1 Prepare work surface for pouring of concrete at the location

specified.

4.2.1 Prepare the area for mixing of the lean concrete at the

location specified.

4.3.1 List and prepare equipment and tools for mixing of the lean

concrete manually.

4.4.1 State the materials and mix ratio for the lean concrete.

4.4.2 Mix the lean concrete at the mixing place.

4.4.3 Practise safety precautions while handling hand tools.

4.5.1 Pour and screed lean concrete on the trench beds by using

appropriate tools so that a good and clean surface of screed

lean can be obtained.

4.6.1 Clean the waste at the site after the completion of the work

carried out.

Document Standard Curriculum Draf, Vocational Collage, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 5 - SHALLOW AND DEEP FOUNDATION

COMPETENCY 5 : PILING WORK

CONTENT STANDARD

LEARNING STANDARD PERFORMANCE CRITERIA

5 PERFORM PILING WORK

5.1 Mark of the piling points

5.2 Set up the piling rings frame

5.3 Stake the piling materials on

project site

5.4 Perform piling work with the

supervision of supervisor

5.5 Cut the piles according to the

specification

5.1.1 Interpret the blueprint given to locate the piling points

5.1.2 Perform the marking of piling points according to the

blueprint given

5.2.1 Set up the piling rings frame while ensuring safety

measures

5.3.1 Stake the piling materials on the project site while

ensuring safety measures

5.3.2 Understand and communicate with the supervisor and

machine operator using sign language

5.4.1 Perform the piling work with the supervision of the

supervisor while ensuring safety measures

5.5.1 Check and mark the required level of the piles for

cutting purposes

5.5.2 Perform the cutting of piles using appropriate

machinery

Document Standard Curriculum Draf, Vocational Collage, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 5 - SHALLOW AND DEEP FOUNDATION

COMPETENCY 6 : PILE CAP WORKS

CONTENT STANDARD

LEARNING STANDARD PERFORMANCE CRITERIA

6. PERFORM PILE CAP WORK

6.1 Excavate earth for pile cap work

according to the required area and

depth.

6.2 Cut the pile to the cut off level.

6.3 Prepare the work area for the

placing of formwork.

6.4 Place the lean concrete to the

required level.

6.5 Place reinforcement bar for the pile

Cap.

6.1.1 Demonstrate the excavation of earth surface for pile

cap work to the required area and depth.

6.2.1 Cut the pile to the cut off level by using proper power

tools.

6.3.1 Prepare the work area to carry out cleaning work to

install formwork.

6.4.1 Place and shape the formwork by referring to the

blueprint given.

6.4.2 Place the lean concrete by using proper procedures

and techniques.

6.5.1 Prepare the reinforcement bar for the pile cap

according to the size needed.

6.5.2 Place reinforcement bar correctly.

6.5.3 Use and place spacer blocks under the reinforcement

bar appropriately.

Document Standard Curriculum Draf, Vocational Collage, MoE

Latest Edited 24-27 Oktober 2011 - Kuching

ITEM CORE ABILITIES

01.02 Document information, procedures or processes

01.03 Utilize basic IT applications

02 EXCHANGE/COMMUNICATE INFORMATION

02.01 Interpret and follow manuals, instructions and SOPs

02.02 Follow telephone/ telecommunication procedures

02.03 Communicate clearly

02.04 Prepare brief reports and checklists using standard forms

02.05 Read/interpret flowcharts and pictorial information

03 WORK AND INTERACT WITH PEOPLE

03.01 Apply cultural requirements to the workplace

03.02 Demonstrate integrity and apply ethical practices

03.03 Accept responsibility for own work and work area

03.04 Seek and act constructively upon feedback about performance

03.05 Demonstrate safety skills

03.06 Respond appropriately to people and situations

03.07 Resolve interpersonal conflicts

06 WORK WITHIN AND WITH SYSTEM

06.01 Understand systems

06.02 Comply with and follow chain of command

06.03 Identify and highlight problems

06.04 Adapt competencies to new situations / systems

Document Standard Curriculum: Draft, Vocational College, MoE

1

Last Edited, Riverside Majestic Hotel 24-27 October 2011

MINISTRY OF EDUCATION, MALAYSIA

MODULE INFORMATION

Confidential

MODULE

CODE

:

:

6 - REINFORCEMENT AND CONCRETE WORKS I

CCCT 106

LEVEL : 1 SEMESTER 1

CREDIT UNIT : 2.0 credit/hr

CONTACT HOUR : 3.0 hours/week

COMPETENCY :

MODULE STATUS : VOCATIONAL

PREREQUISITE :

Document Standard Curriculum: Draft, Vocational College, MoE

2

Last Edited, Riverside Majestic Hotel 24-27 October 2011

MODULE OUTCOMES:

At the end of the module, the students should be able to :

1. avoid workplace hazards.

2. maintain cleanliness of work area and equipment.

3. identify types of materials and prepare for required reinforcement.

4. cut the required reinforcement using proper tools and equipment.

5. bend the bar reinforcement according to the given specification.

6. fabricate and place reinforcement in position for up to two storey building by lifting.

7. install outlet traps accordingly.

8. make spacer blocks by referring to the specification using appropriate materials and tools.

9. install necessary spacers in a required position.

10. identify two types of aggregate in concrete mixture.

11. mix concrete according to procedure and proper ratios.

12. place and compact concrete by applying proper procedures and techniques.

13. perform curing concrete by applying proper procedure and technique.

14. use suitable coverage materials in curing process.

15. practice safety procedure in workplace tools and equipment.

Document Standard Curriculum: Draft, Vocational College, MoE

3

Last Edited, Riverside Majestic Hotel 24-27 October 2011

MODULE DESCRIPTION

This module is designed to explain ways to select the correct types of steel reinforcement and technique to bend the steel

reinforcement according to the work specification. It provides clear contents input on how to fabricate and place steel reinforcement

with suitable method for up to two-storey building.

The module also provides thorough explanation on how to produce spacer block, explain its function and identify the correct position

to place it.

This further explains the proper procedural process of choosing material types, deciding proportion ratio, placing, compacting and

curing in a concrete mixture works. It finally provides descriptions to install outlet traps accordingly.

Document Standard Curriculum: Draft, Vocational College, MoE

4

Last Edited, Riverside Majestic Hotel 24-27 October 2011

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 6 - REINFORCEMENT AND CONCRETE WORKS I

COMPETENCY 1 : TYPES IDENTIFICATION OF MATERIAL AND REQUIRED REINFORCEMENT

PREPARATION

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

1 IDENTIFY TYPES OF

MATERIALS AND

PREPARE FOR

REQUIRED

REINFORCEMENT

1.1 Select the steel reinforcement bar.

1.2 Clean the steel reinforcement bar.

1.3 Cut the steel reinforcement bar properly.

1.4 Stack the steel reinforcement bar in array of

sizes correctly.

1.1.1 Identify steel reinforcement bar according to

sizes and grades shown in the blue print.

1.1.2 Choose the identified bars according to work

safety procedure.

1.2.1 Select the right size of steel reinforcement

bar according to the blue print.

1.2.2 Remove rust and undesired elements using

proper cleaning equipment properly.

1.3.1 Prepare and test the cutting equipment

according to the operating procedure

carefully.

1.3.2 Cut the steel reinforcement bars to the

required length according SOP.

1.3.3 Label the steel reinforcement bar according

to sizes, grades and lengths.

1.4.1 Arrange the steel reinforcement bar

according to the label properly.

Document Standard Curriculum: Draft, Vocational College, MoE

5

Last Edited, Riverside Majestic Hotel 24-27 October 2011

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 6 - REINFORCEMENT AND CONCRETE WORKS I

COMPETENCY 2 : FABRICATION AND PLACE REINFORCEMENT IN POSITION FOR UP

TWO STOREY BUILDING

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

2 FABRICATE AND PLACE

REINFORCEMENT IN

POSITION FOR UP TO TWO

STOREY BUILDINGS

2.1 Select steel reinforcement for bar bending

works correctly..

2.2 Fabricate reinforcement steel bar.

2.3 Stack complete fabricated reinforcement

steel bar.

2.4 Place the reinforcement steel bar.

2.5 Joint and tighten the reinforcement steel

bar

.

2.1.1 Pick steel reinforcement bar for bending

works of all types and sizes according to the

drawing.

2.2.1 Fabricate reinforcement steel bar according to

the requirement.

2.3.1 Select of complete fabricated reinforcement

steel bar at proposed working site.

2.4.1 Lift and place the reinforcement steel bar into

the required formwork as specified by using

crane or manually carefully.

2.5 .1 Prepare the proper equipment to join the

reinforcement bar.

2.5.2 Join and tie the reinforcement steel bar

according to the drawing

Document Standard Curriculum: Draft, Vocational College, MoE

6

Last Edited, Riverside Majestic Hotel 24-27 October 2011

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 6 - REINFORCEMENT AND CONCRETE WORKS I

COMPETENCY 3 : OUTLET TRAPS INSTALLATION

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

3 INSTALL

NECESSARY

OUTLET TRAPS

ACCORDINGLY

3.1 Identify and select outlet trap materials

3.2 Fix outlet trap materials to work site.

3.3 Identify location and fix outlet traps.

3.4 Clear debris from the work site.

3.1.1 Prepare and select materials for installing outlet

trap according to the drawing work.

3.2.1 Carry and fix the materials to work site by using

suitable methods according to the drawing work.

3.3.1 Recognize the location and fix outlet trap materials

to proposed outlet correctly.

3.4.1 Practice clean and clear debris from the work site

using suitable equipment properly.

Document Standard Curriculum: Draft, Vocational College, MoE

7

Last Edited, Riverside Majestic Hotel 24-27 October 2011

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 6 - REINFORCEMENT AND CONCRETE WORKS I

COMPETENCY 4 : SPACER BLOCKS MAKING

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

4 MAKE SPACER BLOCKS

4.1 Prepare spacer block mould correctly.

4.2 Prepare cement mortar

4.3 Pour and screed cement mortar into

mould.

4.1.1 Prepare an equipment and material to

construct mould for spacer block construction

by using plywood/timber .

4.1.2 Setting the thicknesses of the mould according

to the drawing requirement.

4.2.1 Prepare mortar material according the to

design requirement ( cement and fine

aggregate ).

4.2.2 Prepare mix cement mortar to cast spacer

block according to the concrete ratio, such as

1 : 2 or 1 : 3.

4.3.1 Prepare mix cement mortar manually or by

using concrete mixture machine.

4.3.2 Pour and screed cement mortar into mould for

casting work according to the thickness.

Document Standard Curriculum: Draft, Vocational College, MoE

8

Last Edited, Riverside Majestic Hotel 24-27 October 2011

4.4 Cut into sizes

4.5 Insert steel wire into casted mortar

properly..

4.6 Remove the caster spacer blocks .

4.7 Distribute spacer block.

4..4.1 Cut the mortar properly into sizes to form

spacer block by using suitable equipment

before it harden properly.

4.4.2 Cut the spacer block to square shape .

4.5.1 Cut the steel wire by using cutter to certain

suitable length

4.5.2 Install properly the wire into casted mortar

according to the proper technique.

4.6.1. Dismantle the caster spacer blocks after

mortar hardened by using a suitable tool.

4.6.2 Detach the spacer block and keep it in suitable

place.

4.7.1 Distribute the spacer block to require position

during placing the steel reinforcement bar

works.

Document Standard Curriculum: Draft, Vocational College, MoE

9

Last Edited, Riverside Majestic Hotel 24-27 October 2011

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 6 - REINFORCEMENT AND CONCRETE WORKS I

COMPETENCY 5 : SPACERS INSTALLATION

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

5 INSTALL SPACERS

ACCORDINGLY

5.1 Identify and select proper type of spacer

.

5.2 Install the spacer to required

reinforcement.

5.3 Tighten the fixing of spacer block.

5.1.1 Find proper type of spacer to be fixed on

reinforcement bar works.

5.1.2 Place the spacer block to the required

reinforcement at the necessary position

properly.

5.3.1 Ensure the rigidity of the fixing by using

proper equipment.

Document Standard Curriculum: Draft, Vocational College, MoE

10

Last Edited, Riverside Majestic Hotel 24-27 October 2011

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 6 - REINFORCEMENT AND CONCRETE WORKS I

COMPETENCY 6 : MATERIALS IDENTIFCATION FOR CONCRETE MIXTURES

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

6 IDENTIFY MATERIALS FOR

CONCRETE

MIXTURES

6.1 Identify and select sand and coarse

correctly.

6.2 Identify and select type of cements.

6.3 Identify type of water.

6.4 Identify and prepare proper storage area/

container for placing materials.

6.1.1 Select fine aggregate (sand) and coarse

aggregate ( gravel) according to the correct

criteria.

6.1.2 Remove the undesired element before

mixing it.

6.2.1 Determine type of cements for concrete

mixture

6.2.2 Observe the condition of the material to find

good quality according to the requirement.

6.3.1 Use clean water according to the work

specification.

6.4.1 Ensure the area to store the materials is an

undisturbed area.

Document Standard Curriculum: Draft, Vocational College, MoE

11

Last Edited, Riverside Majestic Hotel 24-27 October 2011

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 6- REINFORCEMENT AND CONCRETE WORKS I

COMPETENCY 7 : MIX CONCRETE PROPORTION

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

7 MIX CONCRETE

ACCORDING TO

PROPORTIONS

7.1 Identify and prepare materials and tools

7.2 Prepare mixing place

7.3 Mix materials according to required

concrete ratios

7.4 Mix concrete according to the proportions

7.1.1 Prepare all equipments and obtain safety

precaution and attire before starting the

operation.

7.1.2 Use selected materials and prepare tools at

the work site

7.2 1 Choose the suitable area for mixing

preparation.

7.3.1 Quote the concrete ratio according to the

requirement.

7.3.2 Select the method of mixing either manual or

using a concrete mixture machine.

7.3.3 Practice dry concrete mixing according to the

ratio needed.

7.3.4 Add water based on cement water ratio

according the concrete ratio needed.

7.4.1 Mix concrete according to proportions by

following procedure

7.4.2 Mix concrete by using tools and equipment

to produce good quality of concrete mixture

according to the required specification.

Document Standard Curriculum: Draft, Vocational College, MoE

12

Last Edited, Riverside Majestic Hotel 24-27 October 2011

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 8 - REINFORCEMENT AND CONCRETE WORKS I

COMPETENCY 8 : CONCRETE PLACING AND COMPASTING

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

8 PLACE AND COMPACT

CONCRETE

8.1 Clean and clear any debris from formwork

and work place.

8.2 Wet the surface of formwork/work place.

8.3 Identify transportations to carry out

concrete.

8.4 Identify and prepare concreting machine

and tools for compacting work.

8.1.1 Practice clean and clear formwork and work

place from any debris.

8.1.2 Apply oil on the inner surface of formwork.

8.2.1 Apply water to the surface formwork before

placing the concrete.

8.3.1 Carry out the concrete to the place required.

8.4.1 Perform concrete compacting by using proper

machine and tools.

8.4.2 Perform right method of concrete compacting

depending on to the structure and condition.

Document Standard Curriculum: Draft, Vocational College, MoE

13

Last Edited, Riverside Majestic Hotel 24-27 October 2011

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 6 - REINFORCEMENT AND CONCRETE WORKS I

COMPETENCY 9 : CURING CONCRETE PERFORMANCE

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

9 PERFORM CURING

CONCRETE

9.1 Identify and prepare materials

9.2 Carry and place materials for curing

process.

9. 1.1 Select and prepare materials and method for

curing work according the requirement.

9.2.1 Carry and place selected curing materials to

work site.

9.2.2 Perform curing work by using water, chemicals

and other suitable materials.

9.2.3 Apply coverage materials to cure surfaces.

9.2.4 Keep covering materials wet properly at

certain interval time to cure from dehydration.

Document Standard Curriculum: Draft, Vocational College, MoE

14

Last Edited, Riverside Majestic Hotel 24-27 October 2011

ITEM CORE ABILITIES

01 LOCATE AND PROCESS INFORMATION

01.01 Identify and gather information

01.02 Document information, procedures or processes

01.03 Utilize basic IT applications

02 EXCHANGE/COMMUNICATE INFORMATION

02.01 Interpret and follow manuals, instructions and SOPs

02.02 Follow telephone/ telecommunication procedures

02.03 Communicate clearly

02.04 Prepare brief reports and checklists using standard forms

02.05 Read/interpret flowcharts and pictorial information

03 WORK AND INTERACT WITH PEOPLE

03.01 Apply cultural requirements to the workplace

03.02 Demonstrate integrity and apply ethical practices

03.03 Accept responsibility for own work and work area

03.04 Seek and act constructively upon feedback about performance

03.05 Demonstrate safety skills

03.06 Respond appropriately to people and situations

03.07 Resolve interpersonal conflicts

06 WORK WITHIN AND WITH SYSTEM

06.01 Understand systems

06.02 Comply with and follow chain of command

06.03 Identify and highlight problems

06.04 Adapt competencies to new situations / systems

Document Standard Curriculum Draf, Vocational Collage, MoE

Last Edited Riverside MajescticHotel Kuching 24 -27 October 2011

1

MINISTRY OF EDUCATION, MALAYSIA

MODULE INFORMATION

Confidential

MODULE

CODE

:

:

7- FRAME STRUCTURES

CCCT 207

LEVEL : 1 SEMESTER 2

CREDIT UNIT : 2.0

CONTACT HOUR : 3.0 HOURS / WEEK

COMPETENCY :

MODULE STATUS : VOCATIONAL

PREREQUISITE : -

Document Standard Curriculum Draf, Vocational Collage, MoE

Last Edited Riverside MajescticHotel Kuching 24 -27 October 2011

2

MODULE OUTCOMES:

At the end of the course, the students should be able to:-

1. select and safely use workplace tools and equipment.

2. avoid workplace hazards.

3. select frames and fix fasteners on frames by following procedure.

4. use appropriate tools and equipment so that the fastening of fastener is done properly.

5. prepare and fix frames by following procedure.

6. apply proper technique of fixing frames and other relevant support for frames fixing so that the frames are fixed accordingly to

specification.

7. use appropriate tools and equipment to fix lintel accordingly to specification

8. erect lintel over frames by following procedures and technique.

9. maintain cleanliness of work area and equipment.

MODULE DESCRIPTION

This module is designed for students to be able to fix the frame in a correct position. As part of it, they are able to understand the materials and

methods in selecting frames, plus fixing fasteners on frames using proper technique in constructing the frame on the wall. In following the right

technique and procedures, students will also be able to erect lintel over frames. In addition, the module allows awareness among the students

to select and use the workplace tools and equipment safely and at the same time maintain cleanliness of work area and equipment and avoid

workplace hazards.

Document Standard Curriculum Draf, Vocational Collage, MoE

Last Edited Riverside MajescticHotel Kuching 24 -27 October 2011

3

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 7 - FRAME STRUCTURES

COMPETENCY 1 : FRAMES SELECTION AND FASTENERS FIXING ON FRAME

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

1 SELECT FRAMES AND

FIX FASTENERS ON

FRAMES

1.1 Identify,select and prepare frames.

1.2 Apply undercoats to frames.

1.3 Fix fastener to frames.

1.1.1 Identify, select and prepare frames correctly

according to the blueprint.

1.2.1 Apply undercoats to the frames properly as to comply

with the work specification and requirement.

1.3.1 Identify and select fix fastener as specified in the

work requirement correctly.

1.3.2 Fix the fasteners on frames correctly following the

work specification and requirement correctly.

Document Standard Curriculum Draf, Vocational Collage, MoE

Last Edited Riverside MajescticHotel Kuching 24 -27 October 2011

4

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 7 - FRAME STRUCTURES

COMPETENCY 2 : PREPARATION AND FRAMES FIXING

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

2 PREPARE AND FIX

FRAMES

2.1 Identify the working site.

2. 2 Select and transport frames to work

site

2.3 Fix frame on the required proposed

structure

2.4 Measure the height and level of frames

2.5 Support and align the frame properly

2.1.1 Identify the location according to the drawing

correctly.

2.2.1 Select and transport frames to the work site

safely.

2.3.1 Fix frame to the required proposed structure

according to the job procedure sequence

properly.

2.4.1 Ensure the height and level of frames

correctly.

2.5.1 Install brace to support the frame and

adjust their alignment properly as required by

the work specification.

Document Standard Curriculum Draf, Vocational Collage, MoE

Last Edited Riverside MajescticHotel Kuching 24 -27 October 2011

5

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 7 - FRAME STRUCTURES

COMPETENCY 3 : LINTEL OVER FRAMES PLACEMENT

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

3 PLACE LINTEL OVER

FRAMES

3.1 Identify the working site.

3.2 Prepare and transport pre-cast

lintels.

3.3 Prepare Platform and scaffolding to

place lintels on frame

3.4 Fix lintel over the frames

3.1.1 Select correct location.

3.2.1 Select and prepare pre-cast lintels according

to work requirement properly.

3.2.2 Take pre-cast lintel to work site carefully.

3.3.1 Prepare necessary platform and

scaffolding properly.

3.4.1 Place and fix lintel over frames correctly.

Document Standard Curriculum Draf, Vocational Collage, MoE

Last Edited Riverside MajescticHotel Kuching 24 -27 October 2011

6

ITEM CORE ABILITIES

01 LOCATE AND PROCESS INFORMATION

01.01 Identify and gather information

01.02 Document information, procedures or processes

01.03 Utilize basic IT applications

02 EXCHANGE/COMMUNICATE INFORMATION

02.01 Interpret and follow manuals, instructions and SOPs

02.02 Follow telephone/ telecommunication procedures

02.03 Communicate clearly

02.04 Prepare brief reports and checklists using standard forms

02.05 Read/interpret flowcharts and pictorial information

03 WORK AND INTERACT WITH PEOPLE

03.01 Apply cultural requirements to the workplace

03.02 Demonstrate integrity and apply ethical practices

03.03 Accept responsibility for own work and work area

03.04 Seek and act constructively upon feedback about performance

03.05 Demonstrate safety skills

03.06 Respond appropriately to people and situations

03.07 Resolve interpersonal conflicts

06 WORK WITHIN AND WITH SYSTEM

06.01 Understand systems

06.02 Comply with and follow chain of command

06.03 Identify and highlight problems

06.04 Adapt competencies to new situations / systems

Document Standard Curriculum Draf, Vocational Collage, MoE

Last Edited Riverside MajescticHotel Kuching 24 -27 October 2011

7

Document Standard Curriculum Draft, Vocational, MoE

1

Latest Edited 24-27 Oktober 2011-Kuching

MINISTRY OF EDUCATION, MALAYSIA

MODULE INFORMATION

Confidential

MODULE

CODE

:

:

8 - BRICKWORKS

CCCT 208

LEVEL : 1 SEMESTER 2

CREDIT UNIT : 2.0 credit/hr

CONTACT HOUR : 3.0 hours/week

COMPETENCY :

MODULE STATUS : VOCATIONAL

PREREQUISITE : -

Document Standard Curriculum Draft, Vocational, MoE

2

Latest Edited 24-27 Oktober 2011-Kuching

MODULE OUTCOMES:

At the end of the course, the students should be able to:-

1. identify and select materials by observation and testing using proper techniques and methods so that it comply with the

specification required

2. prepare mortar according to proportions by mixing it using hand and machine so that quality of mortar can be obtained

3. construct stretcher, English and Flemish bond wall in various forms with pointing and jointing by laying bricks using proper

method so that it achieve the required strength and quality finishing works

4. construct door and window opening on brick wall by proper procedures using appropriate tools and equipment so that door

and window frame can be installed

5. construct rough arches over openings by proper method using appropriate tools and equipment so that the overhead load can

be carried by the arches effectively and have beautiful finish

6. construct axe arches over openings by proper method using appropriate tools and equipment so that the overhead load can

be carried by the arches effectively and have beautiful finish

7. construct isolated piers by proper method using appropriate tools and equipment so that load of the superstructure can be

distributed down ward effectively

8. construct attached pier by proper method using appropriate tools and equipment so that load of the superstructure can be

distributed down ward effectively and support the wall laterally

9. construct brick pavior by proper procedures using appropriate materials, tools and equipment so that its provide firm and even

surface

10. construct hollow block walls by proper method using appropriate materials tools and equipment so that the wall can be

completed faster and economical

11. construct block and slab pavior by proper method using appropriate materials, tools and equipment so that its provide firm

and even surface

Document Standard Curriculum Draft, Vocational, MoE

3

Latest Edited 24-27 Oktober 2011-Kuching

12. erect coping and capping on brickwork by referring to plan using proper materials, tools and equipment so that it provide a

protective covering to the wall and piers

13. lay damp proof course in brickwork in proper method using appropriate materials, tools and equipment so that it prevents

water from seeping into the building effectively

MODULE DESCRIPTION

This module is designed to give knowledge how to construct the building structures as brick walls in various form , arches , isolated

and attached piers, construct brick pavior , hollow block walls and slab pavior.

It also to explain what is the correct method how to construct and to select the suitable material.

Document Standard Curriculum Draft, Vocational, MoE

4

Latest Edited 24-27 Oktober 2011-Kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 8 - BRICKWORKS

COMPETENCY 1 : IDENTIFICATION AND SELECTION OF MATERIALS

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

1 IDENTIFY AND SELECT

MATERIALS

1.1 Select proper material

1.2 Identify the quality of materials

1.1.1 Perform to select proper materials according to the

specification using proper techniques

1.2.1 Observating and testing the quality of materials

according to

the specification

1.2 Perform testing of materials

1.2.1 Perform the testing of materials according to the

specification using proper techniques and methods

correctly

1.3 Perform grading of materials

1.3.1 Perform and make a grading testing of materials with

the specification required

1.4 Store material

1.4.1 Handle and store the materials according to the

specification required

1.5 Handle material

1.5.1 Handle and managed the materials carefully and

correctly

Document Standard Curriculum Draft, Vocational, MoE

5

Latest Edited 24-27 Oktober 2011-Kuching

CONTENT AND LEARNING STANDARDS

PROGRAMME : CONSTRUCTION TECHNOLOGY

MODULE : 8 - BRICKWORKS

COMPETENCY 2 : PREPARATION OF MORTAR

CONTENT STANDARD LEARNING STANDARD PERFORMANCE CRITERIA

2 PREPARE MORTAR

ACCORDING TO

PROPORTIONS