Professional Documents

Culture Documents

Charles Nelson Pouge (US Pat. 1997497)

Uploaded by

GaleriaTechniki.PLCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Charles Nelson Pouge (US Pat. 1997497)

Uploaded by

GaleriaTechniki.PLCopyright:

Available Formats

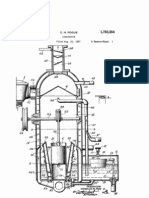

. April 9, ,1935.

C; N. POGUE CARBURETOR

Filed Nov. 3, 1934

1,997,497

2 Sheets-Sheet 1

7TT~J. 79li .~ B4#lJ

", ? /79 ~ 7~

.. .. . ,,_.- )n

! ~ 2G'1l! . ---

;; .2//~ Y U

'/

~

'/f-2O ~""

~ :/

V U

V

~ l/

-0

~

u

~

1

n

~ 29 --

76 1 76R~ 1---, .70 26rjJ -_ ..... ~~92~

~@~

z =72~~ y ~ :7011L?7

..7-' 9 .3.3 ':_~:lM~--- pi( 2?!'

x- ~_C:) -a-1 ~~-C

v-'~,~

r3 (D ~~ '}L -o- 28

- ,

'r-7Q - <3 :'\

0

.mm

777~.2. , Ii 111111111

, ? f'l 7

00 e 0 0 0 e 0 00 0.....

c a a ..5

o 00 c--/

c 0 0 if _ 0

o 0 0 0 0 o 0 0 0

o ,0 0 0 0 0 0:' 0

-0 0 -0 0 0

o •

o 0

o 00

o 0 0

o 0 0

o 0

o 0 0,0

o 0 0 0

o 0

o 0 0'0

00 0 0 o 00 0 c 00 0

d·WCwl:M Cka:r/csMPo,gue:

April 9, 1935.

C. N. POGUE

1,997,497

CARBURETOR Filed Nov. 3, 1934

2 Sheets-Sheet 2

Patented Apr. 9, 1935

1,997,497

UNITED STATES PATENT OFFICE

I,99'JAn CABBUBBTOB

Charles Nelson Pope, Nonrooc1, 1IaDItoba, Canada

AppUcatlon November 3, 19K, SeI'IaI No. 'J51,SH 8 Claims. (CL Z81-1Il

This invention relates to a. device for obtalnlng tained and tile miXture of air and fuel vapors intimate contact between a. liquid in a truly vapor- will exPlode·in the engme cylinders without any ous state and a gas, and particularly to such a. apparent burning of the fuel whlch would result device which may serve as a carburetor for inter- in unduly raf8ing the operating temperature of

G nal combustion engines, and is an improvement the engine. . »

on the form of device shown in my Patent No. More partiCularly, the present invention com-

1,938,497, granted December 5, 1933. prises a. carburetor in which liquid fuel vapors are

In carburetors as commonly used for supplying passed from a ma.in wporiZlng chamber under at a combustible mixture of air and liquid fuel to least a slight pressure into and through a heated

10 internal combustion engines a rela.tively large chamber where they are caused to exPand and in 10 amount of the atomized liquid fuel is not·vapor- . which droplets of liquid fuel a.re either vaporized ized and enters the engine cylinder more or less or separa.ted from the Wpm'S. so that the fuel

in the form of microscopic droplets. When such 1lnally introduced into the engine cylinders is in

a. charge is "fired" in the engine cylinder onlY true vapor phase. The chamber in which the liq-

15 that portion of the liquid fuel which has been con- uid. fuel vapors are heated and caused to expand ]5 verted into the vaporous and consequently the prefel-ably comprises a. series of passages through molecular state, combines with the air to give an which the vapors and the exhaust gases from the explosive mixture. The remaining portion of the engine pass in tortuous paths and in such manner liquid fuel which is drawn into the engine Cylin- that the exbaust gases are brought into heat in-

20 ders and remains in the form of small droplets terchange ·relation with the vapors and give up a. 20 does not explode and thereby impart power to part of their heat to the vapors to cause their the engine, but burns with a fiame and raises heating and expansion.

the temperature of the engine above that at which The invention will be further described in conthe engine operates most emciently, i. e., from nection with the accompa.oying drawings. but this

25 1600 to 1800 F. further disclosure and description is to be taken 25

In my aforesaid patent there is shown and de- merely as an exempliOcaUon of the invention, scribed a form of carburetor in which the liquid and the same is not limited thereby. except as is fuel is substantiaJIy completely va.porized prior to pointed out iii the appended claims..

its introduction into the engine cylinders, and in In the drawings, Fig. 1 is a..vertical cross-sec-

30 which means are provided for maintaining a re- tiona.l view through a. carburetor embodying my 30 verse supply of "dry" vapors available for lntro- invention. Fig. 2 is a horizontal sectional view duction into the engine cylinder. Such a car- through the ma.in vaporizing or atomizing chamburetor has been found superior to the standard bee, the same being taken on line Z-Z of Fig. 1. type of carburetor referred to above a.nd to give Fig. 3 is a. sldeelevation of the carburetor, FIg. 4

35 better engine performance with far less eonsump- is a detail sectional view of one of the a.tomlzing 35

tion of fuel. nOflZles a.nd its associated parts. Fig. 5 is a. detail

It is an object of the present invention to pro- cross-sectional view showing the means for convide a carburetor in which the liquid fuel is broken trolling the passage of gases from the vaporup and prepared in advance of and independent expanding chamber into the intskema.nifold of

40 of the suction of the engine and in which a reserve the engine. Fig •• 6 is a perspective view of one of 40 supply of dry vapors will be maintained under the valves shown in FIg. 5. Fig. '1 is a cross-seepressure ready for introduction into the engine tiona! view showing means for adjusting the cylinder at all times. It is also an object of the. valves shown in Fig. 5 and Pig. 8 is a cross-secinvention to provide a carburetor in which the t100al view on line 1-1 of FIg. '1.

45 dry vapors are heated. to a sumcient extent prior Referring now to the drawings, the numeral I 45

to being mixed With the main supply of air which indicates a. ma.in va.porizing and a.tomizing chamcarries them into the engine cylinder to cause ber for the liquid fuel loca.ted at the bottom of them to expand so that they will be relatively and communicating with a. vapor heating and lighter and will become more intimately mixed exPanding chamber Z.

150 with the air prior to their explosion in the engine The vaporizing chamber is provided with a 50

. cylinders. perforated false bottom I and is normally filled

I have found that when the reserve supply of with liquid fuel to the level s: Atmospheric air dry vapors is heated and expanded prior to being from a conduit. enters the SP&ce below the false admixed with the atmospheric air a greater pro- bottom I and passes upwardly through perfora-

16 portion of the potential energy of the fuel is ob- tiona I in said bottom and . then bubbles up 55

2

through the liquid fuel vaporizing a portion of it.

Liquid fuel for maintaining the level x in the chamber , passes from the usual fuel tank (not shown) through a pipe 6, and is forced by a

6 pump 1 through a pipe 8 into and through a pair of nozzles 9 having their outlets located in the chamber " just above the level of the liquid fuel therein. The pump 1 may be of any approved form but is preferably of the diaphragm. type, as

10 such fuel pumps are now standard equipment on most automobiles.

The nozzles 9 are externally threaded at their lower ends to facilitate their assembly in the chamber , and to permit them to be removed 15 readily, should cleaning be necessary.

The upper ends of the nozzles 9 are surrounded by venturi tubes 10 having a baIDe " located at their upper ends opposite the outlets of the nozzles. The liquid fuel being forced from the

20 ends of the nozzles 9 into the restricted portions of the . Venturi tubes causes a rapid circulation of the air and vapors in the chamber through the tubes 10 and brings the air and vapors into intimate contact with the liquid fuel, with the

25 result that.a portion thereof is vaporized. Unvaporized portaons of the liquid fuel strike . the baftles II and are thereby further broken up and deflected downwardly into the upwardly flowing current of air and vapors.

30 The pump 1 is regulated to supply a greater amount of liquid fuel to the nozzles 9 than will be vaporized. The excess over that vaporized will drop into the chamber , and cause the liquid to be maintained at the indicated level. When

35 the liquid fuel rises above that level,a float valve 12 will be lifted and the excess will flow through an overflow pipe 13 into a pipe 14 leading back to the pipe 6 on the intake side of the pump 1. Such an arrangement permits a large amount of

40 liquid fuel to be circulated by.the pump 1 without more fuel being withdrawn from the fuel tank than is actualiy vaporized and consumed in the engine. As the float valve 12 will set upon the end of the outlet pipe '3 as soon as the Ilqutd level

45 drops below the Indicated level, there is no danger of vapors passing into the pipe 14 and hence into the pump 1 to interfere with its normal operation.

The upper end of the vaporizing and atomizing

50 chamber I is open and vapors formed by the atmospheric air bubbling through the liquid fuel in the bottom of the chamber and those formed as the result of the atomization at the nozzles 9 will pass into the heating and expanding cham-

55 ber 2. As is clearly shown in Fig. 1, the chamber 2 comprises a series of tortuous passages '5 and 16 leading from the bottom to the top. The vapors pass through the passages 15 and the hot exhaust gases of the engine pass through the pas-

60 sages 16, a suitable entrance 11 and exit 18 being provided for that purpose.

The vapors' passing· upwardly in a zigzag path through the passages.5 will be brought into heat interchange relation with the hot walls of

65 the passages 16 for the exhaust gases. The tot!\.l length of the passages 15 and 16 is such that a relatively large reserve supply of the liquid fuel is always maintained in the chamber 2, and by

70 maintaining the vapors in heat interchange relation with the hot exhaust gases for a substantial period, the vapors will absorb sufficient heat from those gases to cause the vapors to expand, with the result that when they are withdrawn

';5 from the top of the chamber 2, they will be in

1,997,497

the true vapor phase and, due to their expansion, relatively light._-.

Any minute droplets of liquid fuel entrained

by the vapors in the chamber I will precipitate out in the lower passages 15 and flow back into 5 the chamber " or else be vaporized by heat which the vapors absorb from the hot exhaust gases in their passage through the chamber 2.

The upper end of the vapor passage 15 communlcates with openings 19 adjacent the upper 10 end of a down-draft air tube 20 leading to the intake manifold of the engine. Valves 21 are interposed in the openings , 9, so that the passaseor the vapors therethrough into the air tube may be controlled. The valves 21 preferably are 15 of the rotary plug type and are controlled as hereinafter described.

Suitable means are provided for causing the vapors to be maintained in the chamber 2 under

a pressure greater than atmospheric so that when 20 the valves. 21 are opened, the vapors will be forced into the air tube 20 independently of the suction of the engine. Such means may comprise an air pump (not shown) for forcing the atmospheric air through the pipe 4 into the 25 chamber I, beneath the false bottom 3, but I prefer merely to provide the pipe 4 with a funnel-shaped inlet end 22 and located just back of the usual fan 23 of the engine. That will cause the air to pass through the pipe 4 with sufficient 30 force to maintain the desired pressure in the chamber 2, and the air being drawn through the radiator by the fan will be preheated prior to its introduction into the chamber , and hence will vaporize greater amounts of the liquid fuel. If 35 desired, the pipe • may be surrounded by an electric or other heater, or exhaust gases from the engine may be passed around it to further preheat the air passing therethrough prior to its introduction into the liquid fuel in the bottom 40 of the chamber I, The air tube 20 is provided with a butterfly throttle valve 24 and a choke valve 24a, as is customary with carburetors, used for internal combustion engines. The upper end of the air tube 20 extends above the cham- 45 ber 2 a distance sufficient to receive an air filter and/or silencer, if desired.

A low speed or idling jet 25 has its upper end communicating with the passage through the air tube 20 adjacent the throttling valve 24 and its 50 lower end extending into the liquid fuel in the bottom of the chamber I for supplying fuel to the engine when the valves are in a position such as to close the passages '9. However, the passage through the idling jet 25 is so small that {jiJ under normal operations the suction thereon. is not sufficient to lift liquid fuel from the bottom

of the chamber I.

To prevent the engine from backfiring into the vapor chamber 2, the ends of the passages , 9 (iO are covered with a fine mesh screen 26 which, operating on the principle of a miner's lamp, will prevent the vapors in the chamber 2 from exploding in case of a backfire, but will not interfere substantially with the passage of the vapors (;;) from the chamber 2 into the air tube 20 when the valves 21 are in open position. The air tube

20 preferably is in the form of a venturi with the greatest restriction being at that point where j'O the openings 19 are located, so that when the valves 2' are opened there will be a pulling force

on the vapors because of the increased velocity

of the air at the restricted portion of the air tube

20 opposite the openings 19, as weUas an ex- 75

pelling force on them due to the pressure in the chamber 2.

As shown in FIg. 3, theopera.ting mechanism for the valves 21 is -lk) connected to the operat-

IS ing mechanism for the throttle valve 24 that they are opened and closed simultaneously with the opening and closing of the throttle valve, so that the amount of vapor supplied to the engine will at all times be in proportion to the de-

10 mands placed upon the engine. To that end, each valve 21. has an extension or operating stem 21 protruding through one of the side walls of the vapor-heating and expanding chamber 2. Packing glands 28 of the ordinary construction

] 5 surround the stems 21 where they pass through the chamber wall to prevent leakage of vapors at those points,

Operating arms 29 are rigidly secured to the outer ends of the stems 21 and extend towards

20 each other. The arms are pivotally and adjustably connected to a pair of links 30 which at their lower ends are pivotally connected to an operating link 31, which in tum is pivotally connected to an arm 32 rigidly. secured on an outer extension 33

25 of the stem of the throttle valve 24. The extension 33 also has rigidly secured thereto an arm 34. to which is connected an operating link 35 leading from the means for accelerating the engine.

The means for adjustably connecting the upper

30 ends of the links 30 to the valve stems n. of the valves 21, so that the amount of vapors delivered from the chamber 2 may be regulated to cause the most efficient operation of the particular engine to which the carburetor is attached, com-

35 prises angular slides 36 to which· the upper ends of the links 30 are fastened, and which are slidably, but non-rotatably mounted in guideways 31 in the arms 29. The slides 36 have threaded bores through which screws 38 pass. The screws 38 are

40 rotatably mounted in the arms 29, but are held against longitudinal movement so that when they are rotated the slides 36 will be caused to. move along the guideways 31 and change the relative position of the links 3D to the valve stems 21, so

45 that a greater or less movement, and consequently a greater or less opening of the ports 19 will take place when the throttle valve 24 is operated.

For safety, and for most emcient operation of the engine. the vapors in the chamber 2 should not

50 be heated or expanded beyond a predetermined amount, and in order to control the extent to which the vapors are heated, and consequently the extent to which they are expanded, a valve 39 is located in the exhaust passage 16 adjacent the

Iii; inlet 11. The valve 39 is preferably thermostatically controlled, as, for example. by an expanding rod thermostat' 40 which extends through the chamber 2. However. any other means may be provided, for reducing the amount of hot exhaust

60 gases entering the passages 16 when the temperature of the vapors in the chamber reaches or exceeds the optimum.

The carburetor has been described in detail in connection with a down-draft type of carburetor,

(;5 but it is to be understood that its usefulness is not restricted to that particular type of carburetor, and that the manner in which the mixture of atmospheric air and vapors is introduced into the engine cylinders is immaterial as far as the

70 advantages of the carburetor are concerned.

The term "dry vapor" is used herein to define the physical condition of the liquid fuel vapor after removal of liquid droplets, or the mist which is frequently entrained in what· is ordinarily

75 termed a vapor.

1,997,497

3

From. the. foregoing description it will be seen thatthepresentinventlonprovides a carburetor

In. which the breaking up of the liquid fuel. for subsequent use is Independent of the suction created by the engine, and that after the liquid fuel Ii is broken up it is maintained under pressure in a heated space for a length of time sufficient to permit all entrained liquid particles to be separated

or vaporized and to permit the dry vapors to expand prior to their introduction into, and admix- 10 ture with the main volume of atmospheric air passing into the engine cylinders.

I claim: , .

1. A carburetor for internal combustion engines comprising a vaporizing chamber, means for va- 15 porizing liqUid fuel therein, a vapor-heating and expanding chamber communicating with the vaporizing chamber. a passage for. atmospheric air extending entirely through said heating and vaporizing chamber and adapted to communicate 20 with the intake manifold of the engine, and means for conducting vapors from the heating and expanding chamber into said air passage.

2. A carburetor for internal combustion engines comprising means for vaporizing liquid fuel, a 25 vapor-heating and expanding chamber into which the vaporized liquid fuel passes. means for creating a pressure in said heating and expanding chamber greater than atmospheric during normal operation of the carburetor, and means for con- 30 ducting heated and expanded gases from the heating and expanding chamber to the intake manifold of the engine upon a suction being created

in said manifold. .

3. A carburetor for internal combustion engines 35 comprising means for vaporizing liquid fuel, a vapor-heating and expanding chamber into which the vaporized liquid fuel passes, a passage for atmospheric air adapted to be connected with the intake manifold of the engine, a connecting pas- 40 sage between the heating and expanding chamber and said atmospheric air passage, a valve controlling the passage of vapors through said connecting passage, and means for creating a pressure in said heating and vaporizing chamber greater than 45 atmospheric, so that when said valve is opened the pressure under which the vapors are maintained in the heating and expanding chamber will cause at least a part of them to be expelled from said chamber and into the atmospheric air pas- 50 sage.

4. A carburetor. for internal combustion engines comprising a vaporizing chamber. means for vaporizing liquid fuel therein, a vapor-heating and expanding chamber communicating with the 5" vaporizing chamber and adapted to receive vapors therefrom; said heating and vaporizing chamber having tortuous passages therethrough for said vapors and for a heating fluid which is maintained

in heat interchange relation with said vapor pas- 60 sages, a passage for atmospheric air adapted to

be connected with the intake manifold of the engine and extending through said heating and vaporizing chamber, a pair of connectrnapassages extending through the walls or. said atmos- 65 pheric air passage through which vapors from the vapor passage in the heating and expanding chamber may pass into said air passage. a valve

in each of said connecting passages, a valve in said atmospheric air passage controlling the fiow 70 of air and vapors to the engine, and means for operating the valves in said connecting passages

in unison with said air and vapor control valve.

5. A carburetor for internal combustion engines comprising a. vaporizing chamber, a liquid 75

4

1,997,497

fuel nozzle in said vaporizing chamber, a pump conducting heated and expanded vapors from the for forcing liquid fuel through said nozzle, an heating and expanding chamber into the intake overflow passage for liquid fuel located above the manifold of the engine.

bottom of said vaporizing chamber; whereby the 7. A carburetor for internal combustion en-

5 liquid fuel which is projected from said nozzles gines comprising a vaporizing chamber, a liquid 5 and remains unvaporized forms a body in the fuel atomizing nozzle in said chamber, a pump for bottom of the vaporizing chamber, means for in- forcing liquid fuel through said nozzle, a Venturi troducing atmospheric air into said body of liquid tube surrounding said nozzle and having a baIDe fuel whereby the air bubbles upwardly through opposite the outlet of said nozzle for further

10 said body and vaporizes a portion thereof, means breaking up liquid fuel projected from said nozzle, 10 for conducting liquid fuel from said overflow to a heating and expanding chamber communicating the intake of said pump, so that said pump may with the vaporizing chamber and receiving liquid

be regulated to circulate an amount of liquid fuel fuel vapors therefrom, and means for conducting

in excess of that vaporized by the nozzles, a vapor heated and expanded vapors from the heating

15 heating and expanding chamber communicating and expanding chamber into the intake manifold Iii with the vaporizing chamber and receiving va- of the engine.

pors therefrom, and means for conducting heated 8. A carburetor for internal combustion enand expanded vapors from the heating and ex- gines comprising a vaporizing chamber, means panding chamber into the intake manifold Of the -ror vaporizing liquid fuel therein, a vapor heating

20 engine. and expanding chamber communicating with the eo

6. A carburetor for internal combustion en- vaporizing chamber and adapted to receive vapors gines comprising a vaporizing chamber, means therefrom, said heating and vaporizing chamber for maintaining a body of liquid fuel in the bot- comprising a relatively long zig-zag passage for tom of said chamber, a heating and expanding the vapors, a relatively long chamber for a heat-

25 chamber communicating with the vaporizing ing fluid interleaved with the zig-zag passages ~:; chamber, means for introducing atmospheric air for the vapors and in heat interchange relation into the body of liquid in the vaporizing chamber with said vapor passage, and means for conductunder a pressure greater than atmospheric, where- ing heated and expanded vapors from the heating

by said air will bubble upwardly through the and expanding chamber into the intake manifold

30 liquid fuel, vaporize a portion thereof and build of the engine. sn

up a pressure greater than atmospheric in the

heating and expanding chamber, and means for CHARLES NELSON POGUE.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Teaching On Evolution in European SchoolsDocument32 pagesTeaching On Evolution in European SchoolsGaleriaTechniki.PL100% (1)

- Franklin B. Mead Jr. (US Pat. 5590031)Document15 pagesFranklin B. Mead Jr. (US Pat. 5590031)GaleriaTechniki.PLNo ratings yet

- US Pat. 3881777Document6 pagesUS Pat. 3881777GaleriaTechniki.PLNo ratings yet

- Thomas Galen Hieronymous (US Pat. 2482773)Document6 pagesThomas Galen Hieronymous (US Pat. 2482773)GaleriaTechniki.PL100% (1)

- Charles Nelson Pouge (US Pat. 1750354)Document5 pagesCharles Nelson Pouge (US Pat. 1750354)GaleriaTechniki.PLNo ratings yet

- US Pat. 3693731Document10 pagesUS Pat. 3693731GaleriaTechniki.PLNo ratings yet

- Charles Nelson Pouge (US Pat. 2026798)Document6 pagesCharles Nelson Pouge (US Pat. 2026798)GaleriaTechniki.PL100% (1)

- Canada Patent - 142.352Document18 pagesCanada Patent - 142.352GustavBlitzNo ratings yet

- Nicola Tesla (B 19420)Document5 pagesNicola Tesla (B 19420)GaleriaTechniki.PLNo ratings yet

- Nicola Tesla (C 33317)Document16 pagesNicola Tesla (C 33317)GaleriaTechniki.PLNo ratings yet

- Hedy Kesler Markley (US Pat. 2292387)Document7 pagesHedy Kesler Markley (US Pat. 2292387)GaleriaTechniki.PLNo ratings yet

- Nicola Tesla (B 19426)Document5 pagesNicola Tesla (B 19426)GaleriaTechniki.PLNo ratings yet

- Canada Patent - 30.142Document10 pagesCanada Patent - 30.142GustavBlitzNo ratings yet

- Canada Patent - 135.174Document12 pagesCanada Patent - 135.174GustavBlitzNo ratings yet

- Canada Patent - 29.537Document24 pagesCanada Patent - 29.537GustavBlitzNo ratings yet

- Nicola Tesla (B 11293)Document10 pagesNicola Tesla (B 11293)GaleriaTechniki.PLNo ratings yet

- Canada Patent - 24.033Document12 pagesCanada Patent - 24.033GustavBlitzNo ratings yet

- Nicola Tesla (B 16709)Document6 pagesNicola Tesla (B 16709)GaleriaTechniki.PLNo ratings yet

- United Kingdom Patent - 6481Document9 pagesUnited Kingdom Patent - 6481GustavBlitzNo ratings yet

- Nicola Tesla (B 14579)Document9 pagesNicola Tesla (B 14579)GaleriaTechniki.PLNo ratings yet

- Nicola Tesla (B 14550)Document7 pagesNicola Tesla (B 14550)GaleriaTechniki.PLNo ratings yet

- United Kingdom Patent - 2812Document7 pagesUnited Kingdom Patent - 2812GustavBlitzNo ratings yet

- Nicola Tesla (B 6527)Document5 pagesNicola Tesla (B 6527)GaleriaTechniki.PLNo ratings yet

- Nicola Tesla (B 13563)Document5 pagesNicola Tesla (B 13563)GaleriaTechniki.PLNo ratings yet

- United Kingdom Patent - 8575Document6 pagesUnited Kingdom Patent - 8575GustavBlitzNo ratings yet

- Nicola Tesla (B 8200)Document8 pagesNicola Tesla (B 8200)GaleriaTechniki.PLNo ratings yet

- United Kingdom Patent - 6502Document5 pagesUnited Kingdom Patent - 6502GustavBlitzNo ratings yet

- United Kingdom Patent - 2801Document5 pagesUnited Kingdom Patent - 2801GustavBlitzNo ratings yet

- United Kingdom Patent - 2975Document9 pagesUnited Kingdom Patent - 2975GustavBlitzNo ratings yet