Professional Documents

Culture Documents

Charles Nelson Pouge (US Pat. 1750354)

Uploaded by

GaleriaTechniki.PLCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Charles Nelson Pouge (US Pat. 1750354)

Uploaded by

GaleriaTechniki.PLCopyright:

Available Formats

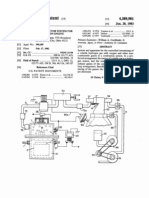

March 11, 1930.

C.N. POGUE

1,750,354

CARBURETOR

Filed Aug. 20. 1927

2 Sheets-Sheet 1

lj_i.

CHARLES.N. POG E.

8Yc:?~- ~.

ATTORNEY.

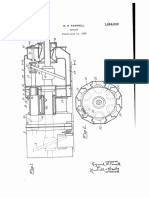

March 11, 1930.

C. N. POGUE

1,750,354

CARBURETOR

Filed Aug. 20. 1927

2 Shoots-Sheet 2

INYENTOR.

CHARLES.N.POGU£.

8Yd-~f',e.

ATTORNEYS.

Patented Mar. 11, 1930

1,750,354

UNITED STATES PATENT' OFFICE

CHARLES NELSON POGUE, Ol!' WINNIPEG, MANITOBA, CANADA, ASSIGNOR TO ALFRED JOSEPH ANDREWS, TRUSTEE, OF WINNIPEG, CANADA

CARBURETOR

Application filed August 20,.1927. Serial No. 214,361.

This invention relates. to improvements in moving the float in the event of the valve sinkcarburetors, and the general objects of the ing, or for other purposes, I provide a recipinvention are to economically produce a dry rocable plunger 16 in the top of the casing properly proportioned combustible mixture held in raised position by a spring 17, which

I from a liquid fuel, and generally to improve extends between the top of the casing and a Iili

and simplify the means for doing same. knurled head 18 on the rod 16, the upward

More particular objects of the invention movement of the rod being limited by a pin are to provide a positive feed of the liquid 19, which engages the underside of the casing. fuel, and the vaporization of the same after A certain proportion of the liquid fuel in

10 atomization, and further to provide for the the chamber B is fed to the bottom of the cas- 60 preliminary heating of the combustible mix- ing A by means of a conduit 19&, which mav ture. at one point have a screen 20 therein, opposite

In its construction, the invention includes the -drain plug 21.

means for maintaining the supply of liquid The liquid fuel which accumulates in the

15 fuel, and atomizing the same, means for pos- bottom of the casing A is adapted to be posi- 61S itively feeding the fuel by both pumping. tively raised therefrom by pumping means, means and a compressed air injector, a vapor- the particular pumping means,which I have izing chamber, means for heating the vapor- illustrated, comprises a reciprocable plunger izing chamber from the exhaust gases of an C, mounted in a cylinder D and actuated by

20 engine, and means for effecting mixture of a cam 22 on a cross shaft 23, which may be 70 gases and vapors in the vaporizing chamber, driven in any convenient way as from the

all constructed and arranged as described in pulley 24.. "

detail in the accompanying specification and The strap 25 surrounds the cam and is con-

drawings. nected to the plunger C by a link 26. A port

21i In the drawings: 27 in the side of the casing D permits the 7G

Figure 1 is a sectional elevation of an em- liquid fuel to float into the same, and on the

bodiment of the invention. downwardmovement of the plunger C, it is

Figure 2 is a section on the line 2-2' of propelled through distributing pipes or noz-

Figure 1. zles . 28, into the portion of the interior of

30 Figure 3 is a section on the line 3-3 of the casing A, above the liquid level at the 80

Figure 1. bottom thereof.

In the drawings, like characters of refer- A plurality of distributing . nozzles 28 are

ence indicate corresponding parts in all the provided, arranged at a slight inclination to figures. the vertical, and communicating through a

35 Referring to the drawings, A indicates the port 29 at the bottom of the cylinder D. 85 casing of suitable shape to provide for the These nozzles 28 are tubular in form and various ports and passages, and to contain provided on the outer side with discharge certain of the working parts., ports 30, having on the outside- inclined de-

B indicates the liquid fuel tank designed to fleeting plates 31, directed upwardly, where-

"'0 contain gasolene, kerosene, crude oil, or other by the discharged liquid fuel will be directed 90 liquid fuel, to be vaporized, and conveniently upwardly into the part of the casing A, formed as an extension at one side of the cas- which constitutes a vaporizing chamber E. ing A. Conveniently the bottom of each of the noz-

The required fuel may be supplied through zles 28 is provided with a screen 32 opposite

45 a conduit 10 to an inlet port 11, controlled a drainage plug 33, and a check valve 32&, 95 by a needle valve 12 on a rod 13, pivoted to the check valve preventing any. condensate the pin 14, on the tank B, the opposite ex- returning to the cylinder D.

tremity of which is connected to a float 15, by The liquid fuel discharged from the nozwhich a determined level of liquid is main- zles 28 is designed to be atomized and to fa-

50 tained in the tank B. For convenience in cilitate this, provision is made for the dis-

2

charge of suitable quantities of air adjacent to the point where the fuel is discharged from the nozzles 28. The means I show for this purpose, comprise air discharge nozzles 34,

IS of tubular form designed to discharge adjacent to the upper ends of the nozzles 28, the lower extremities of the nozzles 34 communicating with an air manifold 35, which communicates with an air supply either under at-

10 mospheric or any desired pressure. In the case of the atmospheric pressure, the air will be drawn in by the suction of the engine.

Means are also provided to provide a further supply of fuel and air in the upper part

15 of the vaporizing chamber E. These means include an injector device F, having an interior air nozzle 36, connected to a supply of compressed air, and an outer fuel conduit 37, thelower extremity of which extends beneath

20 the surface of the liquid fuel in the tank B.

The upper extremity of the conduit 37 is connected to a discharge nozzle 38 ,gischarging near the top and at the centre of the

vaporizing chamber E. .

25 To further provide for mixing of the fuel and the air in the upper part of the vaporizing chamber, a mixing screen G is provided conveniently of conical form, and supported on the interior side walls of the chamber E.

30 An outlet port 39 is provided in the top of the vaporizing chamber E communicating with a connecting conduit 40, from which connections to the cylinder of the engine, in which the combustible fuel is to be used, may

35 be made. This conduit is preferably provided with a back-firing screen 41, and a vapor control valve 42.

If it is desired to introduce water vapor into the combustible mixture, it may be done 40 through a pipe 43 connecting the side of the conduit 40.

For many instances, it will be desirable to pre-heat the combustible mixture while in the vaporizing chamber E. For this purpose,

(5 I surround the casing E with a heating chamber H, through which the supply of hot gases conveniently obtained from the exhaust of the engine is desired to pass. These hot gases being introduced through a port 44 at one

50 side and out a conduit 45 at the opposite side, which matter may be conveniently led to the muffler when the device is used on. an automobile.

To provide for proper circulation of the 55 heating gases, a spiral baffle 46 may be arranged within the chamber H.

It will also be found convenient to regulate the quantity of hot gases supplied by a thermostat I, of any convenient form and 60 connected to the conduit 47, which supplies the gases to the port 40.

In many instances, it is desired to provide for additional quantities of air in the upper part of the vaporizing chamber E. For this (IS purpcee I pto~ide an auxiliary air conduit

1,71S0,3l14

48, opening into the chamber E near the top thereof, and controlled by a butterfly

valve 49. '

As a further means to prevent backfiring,

I may provide a -valve 50 in the conduit 40, 70 adapted to be spring held in closed position, but designed to be opened by the suction of the engine.

In the operation of the device, the pump Cis positively operated by a turning of the 75 shaft 23. This continuously discharges fuel from the nozzle 28, which is atomized by the air passing through the nozzles 34, the engine producing a suction upon the chamber

E in the usual way. The chamber E being so of relatively large size, temporarily maintains the combustible mixture in suspension

in order to enable the vapors of the same to

be complete .

.As the gases or air rises to the top of the 85 chamber, it meets further quantities of gas and air introduced through the conduit 38, and coming against the mixing screen C, is thoroughly admixed before passing out of the chamber. The heating gases passing 90 through the chamber A, will also serve to complete the vaporization and form the prop-

er proportion of dry combustible mixture.

As many changes could be made in the above construction, and many apparently 95 widely different embodiments of my invention, within the scope of the claims, construct-

ed without departing from the spirit or scope thereof, it is intended that all matter contained in the accompanying specification and 100 drawings shall be interpreted as illustrative

and not in a limiting sense.

What I claim as my invention is :

1. A carburetor comprising a casing, the upper part of which is adapted to form a 105 vaporizing chamber, the lower part of which

is adapted to contain liquid fuel, a fuel tank connected to the bottom of the casing, a float valve arranged in the same, controlling the level of liquid, a· conduit between the tank 110 and the casing, a recifrocating pump in the casing, a plurality 0 nozzles for the same having spaced openings and designed to discharge the fuel upwardly, a plurality of air nozzles opening adjacent to the aforesaid 115 nozzles, an injector adapted to be connected

to a supply of compressed air, and to the fuel

in the aforesaid tank, a discharge nozzle for

the injector in the upper part of the vaporizing chamber, a screen in the upper part of 120 the vaporizing chamber, a heating chamber surrounding the casing, and means for pass-

ing hot gases through the heating chamber.

2. The device as claimed in claim 1, in which an auxiliary air supply conduit is con- 125 nected to the upper part of the vaporizing chamber.

3. In a carburetor and in combination a cas-

ing formed with a vaporizing chamber in the upper part thereof and designed to contain a 130

3

supply of liquid fuel in the bottom thereof, pumping means provided to elevate the liquid fuel, a plurality of nozzles connected to the pumping means designed to discharge the

5 fuel in an upward .direct~on, a plurality of arr nozzles discharging ad] acent to the afore-

, said nozzles, means in the upper part of the

~ casing for causing admixture between the fuel and the air, the fuel nozzles being tubular in _ 10 form and provided with a plurality of discharge ports having deflecting plates on the exterior thereof.

4. The combination of the device as claimed in claim 30f compressed air means for feed- 15 ing further quantities of fuel to the upper part of the va]?orizing chamber.

5. The combination of the device as claimed in claim 3, of an injector adapted to supply further quantities of fuel and air to the upper 20 part of the vaporizing chamber.

In witness whereof I have hereunto set my

, hand. -

CHARLES NELSON POGUE.

30

35

411

45

50

You might also like

- SU Carbs TuningDocument13 pagesSU Carbs TuningXDBDNo ratings yet

- Jan. 4, L 1966 T. W. Spack 3,227,148Document6 pagesJan. 4, L 1966 T. W. Spack 3,227,148MainAvelNo ratings yet

- Free Energy Stanley Meyer - Hydrogen Gaz Injector For Internal Combustion Engine - 4389981Document14 pagesFree Energy Stanley Meyer - Hydrogen Gaz Injector For Internal Combustion Engine - 4389981Markerter60100% (2)

- Mechanical Training PreheatDocument15 pagesMechanical Training Preheattricky777100% (1)

- Charles Nelson Pogue - US Patent - 1759354Document18 pagesCharles Nelson Pogue - US Patent - 1759354PM100% (1)

- Nicola Tesla (US Pat. 685955)Document7 pagesNicola Tesla (US Pat. 685955)GaleriaTechniki.PLNo ratings yet

- Pierburg 2E3Document13 pagesPierburg 2E3Michiel Dequidt67% (3)

- Aircraft Technical and GeneralDocument8 pagesAircraft Technical and GeneralNagapranav Nagapranavm.j100% (1)

- Nicola Tesla (US Pat. 1655114)Document8 pagesNicola Tesla (US Pat. 1655114)GaleriaTechniki.PL100% (1)

- A Practical Guide To Free Energy' Devices: US Patent 642,434 12th November 1932 Inventor: Charles N. PogueDocument8 pagesA Practical Guide To Free Energy' Devices: US Patent 642,434 12th November 1932 Inventor: Charles N. PogueXavi Granados ContrerasNo ratings yet

- H. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962Document4 pagesH. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962Josh FullerNo ratings yet

- Jan. 7, 1936. C. N. Pogue 2,026,798: Filed Sept. 27, 1935 2. Sheets-Sheet LDocument6 pagesJan. 7, 1936. C. N. Pogue 2,026,798: Filed Sept. 27, 1935 2. Sheets-Sheet LJesus ValleNo ratings yet

- Us2960824 PDFDocument5 pagesUs2960824 PDFgrigNo ratings yet

- US3094165 Wheeler Manfac-PatentDocument7 pagesUS3094165 Wheeler Manfac-Patentsoubhadra nagNo ratings yet

- Byyeqwla: 2 I / I I VDocument5 pagesByyeqwla: 2 I / I I VaegosmithNo ratings yet

- United States Patent (191: McguganDocument6 pagesUnited States Patent (191: McguganJamesStenhouseNo ratings yet

- CarburettorsDocument3 pagesCarburettorsAlejandro GonzalezNo ratings yet

- Sept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LDocument4 pagesSept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LRakeshNo ratings yet

- Wwkzii: Jan. 10, 1933. R. H. FarwellDocument3 pagesWwkzii: Jan. 10, 1933. R. H. Farwellmonem2014100% (1)

- Bob Neal Overunity Compression Unit - US2030759Document5 pagesBob Neal Overunity Compression Unit - US2030759John CarterNo ratings yet

- CarburettorsDocument4 pagesCarburettorsAlejandro GonzalezNo ratings yet

- US1926463Document3 pagesUS1926463Kamal Vijay Ram R SNo ratings yet

- In The DrawingsDocument8 pagesIn The DrawingsLalit KumarNo ratings yet

- GT LL: NN W///, WM)Document5 pagesGT LL: NN W///, WM)lfilippiniNo ratings yet

- CarburettorsDocument4 pagesCarburettorsAlejandro GonzalezNo ratings yet

- Us 2109297Document6 pagesUs 2109297lfilippiniNo ratings yet

- US4143639 Friction Heat Space Heater, Eugene FrenetteDocument6 pagesUS4143639 Friction Heat Space Heater, Eugene FrenetteBastien Gall de SilléNo ratings yet

- Carburador de Hidrógeno PatE8Document7 pagesCarburador de Hidrógeno PatE8Maximo CozzettiNo ratings yet

- Q ' Eden EEC,: July 30, 1946. G. R. AndersonDocument3 pagesQ ' Eden EEC,: July 30, 1946. G. R. AndersonKrozeNo ratings yet

- No. 686,313. Patented Nov. 12, 1901. A. S. MANN..: Feed Water HeaterDocument5 pagesNo. 686,313. Patented Nov. 12, 1901. A. S. MANN..: Feed Water HeaterpavandattaNo ratings yet

- Electrolytic Carburetor by Charles H. Garrett (Patent)Document11 pagesElectrolytic Carburetor by Charles H. Garrett (Patent)max386No ratings yet

- US1306865Document4 pagesUS1306865Kamal Vijay Ram R SNo ratings yet

- Us3771455 PDFDocument3 pagesUs3771455 PDFdgfsduuwioNo ratings yet

- (1975, Sept. 9) US3903963 Heat ExchangerDocument4 pages(1975, Sept. 9) US3903963 Heat ExchangeraegosmithNo ratings yet

- CarburettorsDocument3 pagesCarburettorsAlejandro GonzalezNo ratings yet

- March23, 1954 J. L, Dunnlgan Y 2,672,853: Sealed Cooling System For Internal-Combustion EnginésDocument3 pagesMarch23, 1954 J. L, Dunnlgan Y 2,672,853: Sealed Cooling System For Internal-Combustion Enginésmonem2014No ratings yet

- Filed Dec. 23, 1959: Aug. 15, 1961 L. A. Botkin 2,996,222Document4 pagesFiled Dec. 23, 1959: Aug. 15, 1961 L. A. Botkin 2,996,222sqmiNo ratings yet

- US1153992 - Collumn StillDocument4 pagesUS1153992 - Collumn StilletyseNo ratings yet

- US5231917 - Wobble PistonDocument5 pagesUS5231917 - Wobble PistondevheadbotNo ratings yet

- Another Corn Dog Machine PatentDocument14 pagesAnother Corn Dog Machine PatentMinnesota Public RadioNo ratings yet

- Filed March 20, 1943Document8 pagesFiled March 20, 1943Andrés RamírezNo ratings yet

- LLL Billion" .Vizíaßllllla: July 14, 1959 F.V F. EhrlchDocument6 pagesLLL Billion" .Vizíaßllllla: July 14, 1959 F.V F. EhrlchDouglas SanchezNo ratings yet

- Reciprocating EngineDocument4 pagesReciprocating EnginePaulFerryNo ratings yet

- US2210720 Rocket PatentDocument3 pagesUS2210720 Rocket PatentGedi MinsterNo ratings yet

- Van - Usen: Geothermal, Exchange SystemDocument6 pagesVan - Usen: Geothermal, Exchange SystemLuis OlivaNo ratings yet

- Aug. 26, 1969 R. M. Lockwood ETAL 3,462,955: Filed June 29, 1967Document4 pagesAug. 26, 1969 R. M. Lockwood ETAL 3,462,955: Filed June 29, 1967billy dillpickerNo ratings yet

- Once Through Boiler Recirculation PumpDocument6 pagesOnce Through Boiler Recirculation Pumpபிரசன்னகுமார் ஆனந்தன்No ratings yet

- United States Patent: KiernanDocument12 pagesUnited States Patent: KiernanharisupayNo ratings yet

- G. M. Holley: Filed Nov. 24, 1924Document5 pagesG. M. Holley: Filed Nov. 24, 1924Daniel KnightNo ratings yet

- DRLA Parts and Set UpDocument8 pagesDRLA Parts and Set UpRobert DennisNo ratings yet

- Umted States Patent (191 (111 4,138,969: Tho-Plan Et A1. (45) Feb. 13, 1979Document12 pagesUmted States Patent (191 (111 4,138,969: Tho-Plan Et A1. (45) Feb. 13, 1979_Asylum_No ratings yet

- Us2181099 PDFDocument4 pagesUs2181099 PDFAt ChecoNo ratings yet

- John /AL/QQ: Filed May 19, 71922 4 Sheets-Sheet 1Document9 pagesJohn /AL/QQ: Filed May 19, 71922 4 Sheets-Sheet 1sukanta60No ratings yet

- June 7, 1955 A, D. Kinser Et Al 2,710,071: Fi'iled Nov. 17. 1951Document3 pagesJune 7, 1955 A, D. Kinser Et Al 2,710,071: Fi'iled Nov. 17. 1951محمود محمدNo ratings yet

- Berthier Us1366863Document9 pagesBerthier Us1366863cll1968No ratings yet

- July 5, 1949. ' R. - Hasche - 2,475,282: Filed Jan. 21, 1946 ' 2 Sheets-Sheet 1Document5 pagesJuly 5, 1949. ' R. - Hasche - 2,475,282: Filed Jan. 21, 1946 ' 2 Sheets-Sheet 1Yanpiero BalladoresNo ratings yet

- Apparatus For ElectrolysisDocument3 pagesApparatus For Electrolysissanela1615No ratings yet

- Us 3460614Document7 pagesUs 3460614scibduser001No ratings yet

- Is A Perspective View From The Inner Side of An Inlet End Plate and Inlet Manifold of The EngineDocument13 pagesIs A Perspective View From The Inner Side of An Inlet End Plate and Inlet Manifold of The EngineAbdul SamiNo ratings yet

- Description: (OCR Text May Contain Errors)Document3 pagesDescription: (OCR Text May Contain Errors)SachinNo ratings yet

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- US Pat. 3881777Document6 pagesUS Pat. 3881777GaleriaTechniki.PLNo ratings yet

- Canada Patent - 135.174Document12 pagesCanada Patent - 135.174GustavBlitzNo ratings yet

- US Pat. 3693731Document10 pagesUS Pat. 3693731GaleriaTechniki.PLNo ratings yet

- Thomas Galen Hieronymous (US Pat. 2482773)Document6 pagesThomas Galen Hieronymous (US Pat. 2482773)GaleriaTechniki.PL100% (1)

- Franklin B. Mead Jr. (US Pat. 5590031)Document15 pagesFranklin B. Mead Jr. (US Pat. 5590031)GaleriaTechniki.PLNo ratings yet

- Canada Patent - 24.033Document12 pagesCanada Patent - 24.033GustavBlitzNo ratings yet

- Canada Patent - 29.537Document24 pagesCanada Patent - 29.537GustavBlitzNo ratings yet

- Canada Patent - 142.352Document18 pagesCanada Patent - 142.352GustavBlitzNo ratings yet

- Canada Patent - 30.142Document10 pagesCanada Patent - 30.142GustavBlitzNo ratings yet

- United Kingdom Patent - 8575Document6 pagesUnited Kingdom Patent - 8575GustavBlitzNo ratings yet

- Nicola Tesla (US Pat. 787412)Document6 pagesNicola Tesla (US Pat. 787412)GaleriaTechniki.PLNo ratings yet

- United Kingdom Patent - 2812Document7 pagesUnited Kingdom Patent - 2812GustavBlitzNo ratings yet

- United Kingdom Patent - 6502Document5 pagesUnited Kingdom Patent - 6502GustavBlitzNo ratings yet

- United Kingdom Patent - 6481Document9 pagesUnited Kingdom Patent - 6481GustavBlitzNo ratings yet

- United Kingdom Patent - 2801Document5 pagesUnited Kingdom Patent - 2801GustavBlitzNo ratings yet

- United Kingdom Patent - 2975Document9 pagesUnited Kingdom Patent - 2975GustavBlitzNo ratings yet

- United States Patent - 685.957Document5 pagesUnited States Patent - 685.957GustavBlitzNo ratings yet