Professional Documents

Culture Documents

Step 1: Gauging and Cutting Wher Required Between Lt-P0010, Lt-P0011, and Lt-P0009

Uploaded by

zodhhashoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Step 1: Gauging and Cutting Wher Required Between Lt-P0010, Lt-P0011, and Lt-P0009

Uploaded by

zodhhashoCopyright:

Available Formats

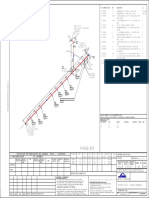

DRAWING NO :

PE95-LT-PV-0002

Rev. :

Effective date: 16/05/2013

Step 1: GAUGING AND CUTTING WHER REQUIRED BETWEEN LT-p0010, LT-p0011, and LT-p0009

Gauging/cut

NOTE: Above mentioned step applicable for both sites

DRAWING NO :

PE95-LT-PV-0002

Rev. :

Effective date: 16/05/2013

STEP 2:

CLAMP OR LOCKDOWN AS CLOSE AS POSSIBLE TO PLATES LT-p0012/LT-p0013

Shim plate

Shim plate

DRAWING NO :

PE95-LT-PV-0002

Rev. :

Effective date: 16/05/2013

Step 3

Use jack or ram for straightening

Brace

Stopper

90

-Align plates LT-p0012/LT-p0013 90 to base plate LT-k0005 and weld in brace before release hydraulic RAM. - Same technique for all plates.

DRAWING NO :

PE95-LT-PV-0002

Rev. :

Effective date: 16/05/2013

Step 4

1st Form Support before

removing the shim plate.

Check levelness for bottom part upon straightening the side plate

Note: 1) Dimension tolerance for bottom plate should be less than 5mm if more than 5mm fairing to be done.

DRAWING NO :

PE95-LT-PV-0002

Rev. :

Effective date: 16/05/2013

STEP 5

HEATING POINT

HEATING POINT

NOTE: 1) Please refer to the procedure FFCM-PDR-PE95-01 for fairing methods. 2) Supports should NOT be removed after the fairing works, Item will be sending for PWHT.

You might also like

- Step 1: Gauging and Cutting Wher Required Beetwen Lt-P0010, Lt-P0011, and Lt-P0009Document5 pagesStep 1: Gauging and Cutting Wher Required Beetwen Lt-P0010, Lt-P0011, and Lt-P0009zodhhashoNo ratings yet

- CAMERON France S.A.S: Front SheetDocument27 pagesCAMERON France S.A.S: Front SheetkrishnsgkNo ratings yet

- Evaporator Data Sheet - SKO0501049 Rev0Document10 pagesEvaporator Data Sheet - SKO0501049 Rev0chublackNo ratings yet

- RLV SB Process SheetDocument155 pagesRLV SB Process SheetSudhakar PalletiNo ratings yet

- Reference Drawing/ Document:: 1. Jumpering of IO Signals at DCS End Shall Be Done by BHELDocument5 pagesReference Drawing/ Document:: 1. Jumpering of IO Signals at DCS End Shall Be Done by BHELarunNo ratings yet

- SD 14 eDocument12 pagesSD 14 eseaqu3stNo ratings yet

- 10418AE0026-30 - Rev - 0 Rev CCDocument43 pages10418AE0026-30 - Rev - 0 Rev CCcecilNo ratings yet

- Roots BlowerDocument4 pagesRoots Blowerprashant mishraNo ratings yet

- HD Valvulas de ControlDocument5 pagesHD Valvulas de ControlIsmaelCruzNo ratings yet

- Service NewsDocument19 pagesService NewsMuhammad HardiusNo ratings yet

- Control ValveDocument254 pagesControl ValveAJAY1381No ratings yet

- Freightliner Fld120Document19 pagesFreightliner Fld120LO Consigo Antofagasta75% (4)

- 8SC/SCJ Hardware Kit - K212103996SDocument3 pages8SC/SCJ Hardware Kit - K212103996SWilson BuenoNo ratings yet

- Xr696 Power AmpDocument11 pagesXr696 Power AmpMauricio ManchegoNo ratings yet

- CDL138 Test Report QA & QCDocument11 pagesCDL138 Test Report QA & QCNZNo ratings yet

- Sello Mecánico PDFDocument3 pagesSello Mecánico PDFatenciajNo ratings yet

- SB 14 BC 03 PDFDocument19 pagesSB 14 BC 03 PDFmates isNo ratings yet

- Cat D8R Folding Stair ManualDocument26 pagesCat D8R Folding Stair Manualkasahun tesifayeNo ratings yet

- 3092834-Varco Bulletin On TDSDocument9 pages3092834-Varco Bulletin On TDSSushil GuptaNo ratings yet

- SBLM2500 Ind 162Document6 pagesSBLM2500 Ind 162Daniil SerovNo ratings yet

- 160.75-RP1 (210) - Yk (G)Document92 pages160.75-RP1 (210) - Yk (G)JayashtonNo ratings yet

- Back-up Warning System Parts ListDocument6 pagesBack-up Warning System Parts ListomarandradeNo ratings yet

- Line Class FHC1 - R3Document6 pagesLine Class FHC1 - R3Tommy ArjanggiNo ratings yet

- EIC B 1018 0 HPV Double Vane Pump RTR Tyytry RD T Rdtyrt DHGFHJGF Jtyhutr Hrdfty RGD Htrghyrdftyrgd Rtyudr Rtyudr Ur Rty Esetyrdy Yetyrtyyr Etyr5sdey Et Esytyrtdgyhrtd Styr RTSSTDGHR RytuhtrsDocument17 pagesEIC B 1018 0 HPV Double Vane Pump RTR Tyytry RD T Rdtyrt DHGFHJGF Jtyhutr Hrdfty RGD Htrghyrdftyrgd Rtyudr Rtyudr Ur Rty Esetyrdy Yetyrtyyr Etyr5sdey Et Esytyrtdgyhrtd Styr RTSSTDGHR RytuhtrsPravinPMKoolNo ratings yet

- SEVPL BrochureDocument20 pagesSEVPL BrochureNaveen AnandNo ratings yet

- HiNo DutRo Fuel Injection Pump DiagramDocument8 pagesHiNo DutRo Fuel Injection Pump Diagramjoe88% (16)

- B737-200 Flight ControlDocument4 pagesB737-200 Flight ControlLa Team masqueNo ratings yet

- RG125F - 92-94 Vues EclateesDocument125 pagesRG125F - 92-94 Vues EclateesJacquetNo ratings yet

- Esquire Builders Hoist Opt & Maint ManualDocument15 pagesEsquire Builders Hoist Opt & Maint Manualmailme_viju100% (1)

- MARUTI ENGINEERING Hydraulic Goods Loading PlatformDocument8 pagesMARUTI ENGINEERING Hydraulic Goods Loading PlatformKush ThumarNo ratings yet

- CAJA T12000 1102FT12345Document41 pagesCAJA T12000 1102FT12345bvaleriochucoNo ratings yet

- S05 Hydraulic CircuitDocument38 pagesS05 Hydraulic CircuitAdri MelendezNo ratings yet

- 033 244752 El 06 0Document27 pages033 244752 El 06 0dinari8180No ratings yet

- Sb-15-010 11my-15my Egr Valve HeaterDocument10 pagesSb-15-010 11my-15my Egr Valve HeaterPhil B.No ratings yet

- CANRIG1250触摸屏MAINTENANCE MESSAGE与PLC变量间的对应关系Document3 pagesCANRIG1250触摸屏MAINTENANCE MESSAGE与PLC变量间的对应关系xlzyydf2015No ratings yet

- Bomba de Lubricação Automatca de MarteloDocument53 pagesBomba de Lubricação Automatca de MarteloDaniel F BarrosNo ratings yet

- Electrical Documentation - Table of Contents - StructureDocument52 pagesElectrical Documentation - Table of Contents - StructurethanhNo ratings yet

- Supplier P/Ninternational P/N Pressure Type Thread Terminal Application Band Single TerminalDocument1 pageSupplier P/Ninternational P/N Pressure Type Thread Terminal Application Band Single TerminalJIMJEO0% (1)

- SC/V Pneumatic Piston Actuator Data Sheet: G E N E R A LDocument1 pageSC/V Pneumatic Piston Actuator Data Sheet: G E N E R A LHumayun NawazNo ratings yet

- IsometricsDocument4 pagesIsometricsMuhammedHafisNo ratings yet

- 6" 6" 6" 6" WRDP WRDP WRDP WRDP - 2MP 2MP 2MP 2MP - NS Safety Valve NS Safety Valve NS Safety Valve NS Safety ValveDocument20 pages6" 6" 6" 6" WRDP WRDP WRDP WRDP - 2MP 2MP 2MP 2MP - NS Safety Valve NS Safety Valve NS Safety Valve NS Safety ValvePilar HernandezNo ratings yet

- Rotorseal Tech Specs PDFDocument19 pagesRotorseal Tech Specs PDFMykola TitovNo ratings yet

- As BuiltDocument12 pagesAs BuiltAnurag PandeyNo ratings yet

- How To Start Combined Cycle Power PlantDocument37 pagesHow To Start Combined Cycle Power PlantBv Rao100% (1)

- Gate Valve DSDocument5 pagesGate Valve DSkhaireddin100% (1)

- 033 244752 El 05 0Document26 pages033 244752 El 05 0dinari8180No ratings yet

- Planilha Equipamentos para Fechamento - OutubroDocument4 pagesPlanilha Equipamentos para Fechamento - OutubroGustavo MouraNo ratings yet

- Service and Parts Manual Rexel Shredder P170 & 190s Range 230V Issue 18Document34 pagesService and Parts Manual Rexel Shredder P170 & 190s Range 230V Issue 18Raltec Ltd100% (1)

- Manual Specifications - 2657668154 - 025Document92 pagesManual Specifications - 2657668154 - 025mm100% (1)

- SERVICE TOOL CATALOG Carrier TransicoldDocument98 pagesSERVICE TOOL CATALOG Carrier Transicoldgamagg100% (3)

- Ivar Aasen Field Development Proj Ect - PDQ: 230V Ac Ups Sub-Db 85El0105A - Circuit/Wiring DiagramDocument27 pagesIvar Aasen Field Development Proj Ect - PDQ: 230V Ac Ups Sub-Db 85El0105A - Circuit/Wiring DiagramayemyothantNo ratings yet

- Carrier Parts CatalogueDocument161 pagesCarrier Parts CatalogueHyury VeríssimoNo ratings yet

- 98-05110 r1 FP Rogator 854 InstallDocument18 pages98-05110 r1 FP Rogator 854 InstallJulio CRNo ratings yet

- Landing gear oil streaks and shock strut seal replacementDocument2 pagesLanding gear oil streaks and shock strut seal replacementSoorajNo ratings yet

- VHP, VGF, AT/275GL+Document2 pagesVHP, VGF, AT/275GL+waqar ahmadNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- R R Radius of Pipe T Pipe Wall Thick H Height: Given MS Plate As DrawingsDocument10 pagesR R Radius of Pipe T Pipe Wall Thick H Height: Given MS Plate As DrawingszodhhashoNo ratings yet

- 175 PMP Sample Questions PDFDocument109 pages175 PMP Sample Questions PDFKamlakar MohiteNo ratings yet

- Strategy Facility PlanningDocument22 pagesStrategy Facility PlanningIbrahim Orhanli50% (2)

- Paint Guide Galvanized SteelDocument12 pagesPaint Guide Galvanized SteelzodhhashoNo ratings yet

- Piping - HDPE Product Catalogue - PipestarDocument12 pagesPiping - HDPE Product Catalogue - PipestarRotax_KidNo ratings yet

- Atlas Technical Handbook Rev July 2010Document49 pagesAtlas Technical Handbook Rev July 2010Sharad SrivastavaNo ratings yet

- Design of Lifting and Tailing LugsNetsc001Document30 pagesDesign of Lifting and Tailing LugsNetsc001Tshilidzi Irene Netselo100% (1)

- 2standards Development in Facilities Management For WebDocument4 pages2standards Development in Facilities Management For WebzodhhashoNo ratings yet

- Facility / Maintenance Management at A Glance - by Rupesh SinghDocument14 pagesFacility / Maintenance Management at A Glance - by Rupesh SinghzodhhashoNo ratings yet

- Metal Coating Processes GuideDocument9 pagesMetal Coating Processes GuideIrfan IslamyNo ratings yet

- CSWIP 3 1 Welding Inspection NotesDocument102 pagesCSWIP 3 1 Welding Inspection NotesPavan KallempudiNo ratings yet

- How To Prevent Control Welding DistortionDocument2 pagesHow To Prevent Control Welding DistortionNilesh DalviNo ratings yet

- Metal Forming ProcessesDocument40 pagesMetal Forming ProcessesRyat AtmadjaNo ratings yet

- Piping - HDPE Product Catalogue - PipestarDocument12 pagesPiping - HDPE Product Catalogue - PipestarRotax_KidNo ratings yet

- Piping - HDPE Product Catalogue - PipestarDocument12 pagesPiping - HDPE Product Catalogue - PipestarRotax_KidNo ratings yet

- PWHT Case StudiesDocument5 pagesPWHT Case Studiestbmari100% (1)

- Basic Principles of Ultrasonic TestingDocument42 pagesBasic Principles of Ultrasonic TestingyoungfpNo ratings yet

- Chapter 9 - Welding DefectsDocument18 pagesChapter 9 - Welding Defectsbibin2010100% (1)

- How To Prevent Control Welding DistortionDocument2 pagesHow To Prevent Control Welding DistortionNilesh DalviNo ratings yet

- Wig 1000 P DS 0002.0.appDocument8 pagesWig 1000 P DS 0002.0.appzodhhashoNo ratings yet

- WHY PWHTDocument2 pagesWHY PWHTzodhhashoNo ratings yet

- Fabrication Method SheetDocument15 pagesFabrication Method SheetzodhhashoNo ratings yet

- (Material Type) (Material Grade) (Pressure Class Limit) (System Type) Piping ClassDocument2 pages(Material Type) (Material Grade) (Pressure Class Limit) (System Type) Piping ClasszodhhashoNo ratings yet

- Engineering Drawing ManualDocument120 pagesEngineering Drawing ManualzodhhashoNo ratings yet

- Sample NTD Inspection ReportDocument127 pagesSample NTD Inspection ReportGeorge NicolaidesNo ratings yet

- As 1576.2 Scaffolding Couplers & AccessoriesDocument36 pagesAs 1576.2 Scaffolding Couplers & Accessoriespvdang100% (2)

- Asme Subsection c7Document6 pagesAsme Subsection c7zodhhashoNo ratings yet

- Sample NTD Inspection ReportDocument127 pagesSample NTD Inspection ReportGeorge NicolaidesNo ratings yet