Professional Documents

Culture Documents

Vernacular Architecture SHEET X REVISED-Model

Uploaded by

Shalesh Yadav0 ratings0% found this document useful (0 votes)

347 views1 pageSTART THE RETAINING WALL 3 FT BELOW VEGETABLE SOIL AND PREPARE A BASE HALF AS WIDE AS THE FINISHED WALL HEIGHT. FOR EVERY 5 FT OF HEIGHT, GO 1 FT BACK. INCLINE THE FRONT OF THE WALL IN A RATIO 1:5.

Original Description:

Original Title

Vernacular Architecture SHEET X REVISED-Model (1)

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSTART THE RETAINING WALL 3 FT BELOW VEGETABLE SOIL AND PREPARE A BASE HALF AS WIDE AS THE FINISHED WALL HEIGHT. FOR EVERY 5 FT OF HEIGHT, GO 1 FT BACK. INCLINE THE FRONT OF THE WALL IN A RATIO 1:5.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

347 views1 pageVernacular Architecture SHEET X REVISED-Model

Uploaded by

Shalesh YadavSTART THE RETAINING WALL 3 FT BELOW VEGETABLE SOIL AND PREPARE A BASE HALF AS WIDE AS THE FINISHED WALL HEIGHT. FOR EVERY 5 FT OF HEIGHT, GO 1 FT BACK. INCLINE THE FRONT OF THE WALL IN A RATIO 1:5.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

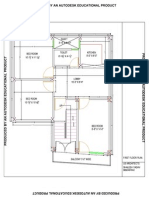

VERNACULAR ARCHITECTURE

STEPS OF FULL BAMBOO CONSTRUCTION

1. START THE RETAINING WALL 3 FT BELOW VEGETABLE SOIL

AND PREPARE A

BASE HALF AS WIDE AS THE FINISHED WALL HEIGHT.

2. MAXIMUMHEIGTH OF A RETAINING WALL SHOULD NOT

EXCEED 8 FT. THE

LOWER THE WALL.

3. INCLINE THE FRONT OF THE WALL IN A RATIO 1:5. THAT IS,

FOR EVERY 5 FT OF

HEIGHT, GO 1 FT BACK.

4. INCLINE THE STONES AT A RIGHT ANGLE TO THE FRONT.

5. PLACE AS MANY THROUGH-STONES` AS POSSIBLE, BUT AT

LEAST EVERY

2 FT ALONG THE HEIGHT AND LENGTH OF THE WALL

6. IF MORTAR IS USED, LEAVE 4X4 DRAINAGE HOLES IN THE

LOWER PART

OF THE WALL, EVERY 2 FT.

7. INSTEAD OF MAKING ONE HIGH WALL, SUBDIVIDE IT INTO

SEVERAL LOWER

WALLS, STEPPING BACK EACH TIME THE SAME DISTANCE AS

THE HEIGTH

OF THE LOWER WALL.

8. KEEP THE BUILDING AWAY FROMTHE RETAINING WALLS.

ON THE LOWER SIDE AT LEAST THE

SAME DISTANCE AS THE HEIGTH OF THE WALL.

ON THE UPPER SIDE AT LEAST 3 FT FROM THE RETAINING

WALL.

9. CURVED RETAINING WALLS ARE STRONGER.

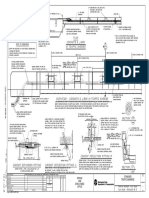

FLASHING

1. TO PROTECT THE WALL AGAINST SPLASHING RAIN, NAIL A

TIMBER BOARD OR A CGI SHEET AGAINST THE

LOWER PART OF THE WALL STRUCTURE (TO BOTH BASE

PLATE AND POSTS)

2. TO AVOID INFILTRATION OF WATER UNDER THE BASE

PLATE IT`S ADVISABLE TO FIX A GALVANIZED METAL

FLASHING WHICH COVERS BOTH THE BASE PLATE AND THE

PLINTH BEAM

NAME :

PRN NO :

YEAR : III YEAR SEM : VI

DATE :

SESSION : J UN 2013 - DEC 2013

BATCH : 01 ( 2010 - 2015 )

CO-ORD : Prof. SUMEET RAI

: Prof. PRIYADARSHINI AGARWAL

BUI LDI NG CONSTRUCTI ON -VI

FOUNDATION:

1.FOUNDATIONS MUST BE AT LEAST 2 FT

DEEP IN SOLID GROUND (EXCEPT ON

ROCK) AND AT LEAST 2 FT WIDE.

FOR 2 STOREY BUILDINGS, FOUNDATIONS

SHOULD BE AT LEAST 2`-6 WIDE.

2. ADD A PLINTH OF 1 FT ON TOP OF THE

FOUNDATION TO KEEP THE BASE

PLATE AWAY FROMTHE GROUND.

3. FINISH THE OUTER PART OF THE TOP

SURFACE OF THE PLINTH WITH A SLOPE

TOWARDS OUTSIDE TO DRAIN WATER

AWAY FROMTHE BASE PLATE.

4. IT`S BETTER TO KEEP THE TOP SURFACE

OF THE FOUNDATION IRREGULAR

TO AVOID WATER GETTING TRAPPED

UNDER THE BASE PLATE.

5. DON`T USE STRAPS OR REBARS PLACED

IN THE PLINTH.

6. IF AVAILABLE, USE GALVANIZED

ANCHOR RODS WITH A THREAD. IF

GALVANIZED RODS ARE UNAVAILABLE, PAINT THE RODS

BEFORE USE WITH ANTI-CORROSION PAINT.

7. PLACE THE ANCHOR RODS WHILE MAKING THE

FOUNDATION AND MAKE SURE THAT THE RODS ARE

EMBEDDED IN 1 OF MORTAR ALL AROUND (CEMENT MORTAR

PROTECTS AGAINST RUST). FILL IN MORTAR BY AND BY

WHILE RAISING THE FOUNDATION AND COMPACT WELL.

8. KEEP THE FIRST ANCHOR RODS 2 FT FROM THE CORNER

AND PLACE THE FOLLOWING LESS THAN 6 FT APART.

FRAMING STRUCTURE :

1. FOR THE MAIN FRAME USE ONLY THE BEST TIMBER

AVAILABLE. THE BASE PLATE SHOULD BE IN ROT RESISTANT

WOOD (E.G. CEDAR) OR BE TREATED

WITH WOOD PRESERVATIVES

2. THE POSTS OF THE MAIN FRAME ARE MADE OF TIMBER

WITH A MINIMAL CROSS SECTION OF 4X 4 PLACED AT 6 FT

SPACING CENTRE TO CENTRE.

3. FOR TWO STOREY BUILDINGS THE POSTS ON THE GROUND

FLOOR SHOULD BE STRONGER AND HAVE A MINIMUMCROSS

SECTION OF 4X5. PLACE

THE LARGER SIDE OF THE POST IN THE

DIRECTION OF THE WALL.

4. FOR THE SECONDARY SUBDIVISION USE TIMBER HALF AS

THICK AS THE POSTS (THAT IS 2X 4 INSTEAD OF (4 X4) AND

PLACE IT AT 2 FT, 3 FT

OR 18 DEPENDING ON THE CHOSEN FINAL SUBDIVISION

PATTERN.

5. WALLS CAN BE SUBDIVIDED IN VARIOUS WAYS. THE

STRENGTH OF THE FINISHED WALL DEPENDS ON THE

QUALITY OF CONNECTIONS AND THE NUMBER OF BRACING

BOARDS.

6. NAIL SIZES:

6 NAILS TO CONNECT THE MAIN FRAME ELEMENTS(4X4)

4 NAILS FOR 2 BOARDS (USE 2 NAILS AT EACH END)

3 NAILS FOR 1 BOARDS.

7. DON`T SAVE MONEY ON NAILS.WHENEVER TWO PIECES OF

TIMBER

MEET, CONNECT THEMWITH NAILS.

FIXING DETAILS :

1. TO FIX THE POSTS ON THE BASE PLATE,

A MORTISE AND TENON JOINT ENSURES

THE STRONGEST CONNECTION .FOR

ADDITIONAL STRENGTH ,THE JOINT MAY

BE SECURED WITH TWO 6NAILS.

.2TO SECURE THE JOINT AGAINST

VERTICAL MOVEMENT ,NAIL A STRAP

OR BOARDS ON BOTH SIDES .STRAPS

MUST NOT BE THINNER THAN 1/10

OR 13SWG 2.5(MM )AND SHOULD

GO ALL AROUND THE BASE PLATE.

.3IF NO MORTISE AND TENON JOINT IS

USED ,BLOCKING PADS MUST BE

ADDED ON BOTH SIDES OF THE POST.

.4SECURE THE JOINT WITH TWO 6NAILS

AGAINST LATERAL SLIDING.

.5SECURE THE JOINT AGAINST VERTICAL

MOVEMENT BY ADDING A STRONG

STRAP OR SHORT TIMBER BOARDS

INSIDE AND OUTSIDE.

.6FOR ALL BLOCKING PADS OR BOARDS

USE 4NAILS .TO SECURE STRAPS 3

NAILS SHOULD BE USED.

.7TO JOIN BASE PLATES OR WALL PLATES,

USE A NAILED LAP JOINT .THE LAPS

SHOULD BE AT LEAST 18LONG .FIX

IT WITH THREE 4NAILS ON BOTH THE

UPPER AND LOWER SIDES .TO AVOID

SPLITTING OF THE TIMBER ,TAKE CARE

TO KEEP THE NAILS 4AWAY FROMTHE ENDS.

.8A SCARF (OR KASHMIRI )JOINT MAY ALSO BE

USED .

IT`S ADVISABLE TO SECURE THE JOINT WITH 4

NAILS.

CORNER FIXINGDETAILS:

1. CORNER JOINTS MUST BE MADE WITH GREATEST CARE, AS

THEY ARE PARTICULALRY AT RISK DURING AN EARTHQUAKE.

JOIN THE BASE PLATES WITH A CROSS LAP JOINT. TO ENSURE

STRENGTH LEAVE 1 FT OF TIMBER AFTER THE JOINT.

2. SECURE THE POSTS WITH TWO 6 NAILS DRIVEN

DIAGONALLY THROUGH THE JOINT.

3. ADD BLOCKING PADS ON ALL FOUR SIDES AND FIX EACH OF

THEM ON THE BASE PLATE WITH TWO OR THREE 4 NAILS.

THE OUTER PADS SHOULD BE WEDGE

SHAPED AND BIGGER TO PROTECT THE BASE PLATE ENDS

AGAINST RAIN.

4. FIX THE POST TO THE BASE PLATE TO AVOID UPLIFT

DURING A QUAKE. IF A

STRAP IS USED, IT MUST BE 1/10 THICK (13 SWG, 2.5MM). THE

STRAP

SHOULD BE MADE OF GALVANIZED IRON.

5. DIAGONAL TIMBER BOARDS OF 1 OR 1 THICKNESS CAN

REPLACE THE

STRAP.

6. THE SAME DETAILS APPLY FOR THE CONNECTION BETWEEN

POSTS AND

WALL PLATE. HERE HOWEVER SIMPLE, NON CONICAL PADS

CAN BE USED.

7. NEVER USE NAILED HALF LAP JOINTS IN THE CORNERS.

THEY ARE NOT STRONG ENOUGH, EVEN WITH STRAPS.

PLASTERING

1. FOR INCREASED STRENGTH AND TO SECURE THE STONES

AGAINST FALLING

OUT, A GALVANIZED WIRE MESH CAN BE NAILED TO BOTH

SIDES OF THE

WALL. MAKE SURE THAT ENOUGH NAILS ARE USED FOR

FIXING (EVERY

4-6 INCHES).

2. FOR PLASTERING, MUD OR CEMENT PLASTER MAY BE USED.

3. A GOOD MUD PLASTER MIX IS MADE OF ONE THIRD OF

CLAY, TWO THIRDS OF

SAND AND A FAIR AMOUNT OF PINE NEEDLES OR STRAW.

LOOK ALSO FOR

LOCAL EXPERTISE.

4. APPLY THE PLASTER IN SEVERAL LAYERS NOT EXCEEDING

EACH. IF YOU

MAKE THE LAYERS TOO THICK, THEY WILL CRACK.

5. FOR PAINT USE WHITE WASH (LIME). DON`T USE SYNTHETIC

PAINT, IT

DOESN`T ADHERE PROPERLY ON MUD

PLASTER.

6. IF CEMENT PLASTER IS USED, ALL STONES IN THE WALL

MUST BE CLEANED

THOROUGHLY TO ENSURE PROPER

ADHERENCE OF THE PLASTER.

7. WHEN USING CEMENT PLASTER COVER THE WALLS FIRST

WITH WALLS WIRE

MESH. THE MESH WILL ENSURE THAT THE PLASTER REMAINS

IN PLACE.

TIMBER HOUSE

TIMBER HOUSE CONSTRUCTION DETAIL

SHOWING J OISTS FRAMEDSTRUCTURE

FOUNDATION TO ROOF STRUCTURE

You might also like

- Area Statement and ConceptDocument12 pagesArea Statement and ConceptPrachi Somani100% (1)

- Funicular Shells Part-1Document2 pagesFunicular Shells Part-1yadavshemant0% (1)

- Structural Systems: Lamella DomesDocument19 pagesStructural Systems: Lamella DomesMohammad KHNo ratings yet

- BUILDING CONSTRUCTION TECHNOLOGY STUDYDocument9 pagesBUILDING CONSTRUCTION TECHNOLOGY STUDYAksh RdNo ratings yet

- Proposed General Hospital Site Analysis in Ghansoli, Navi MumbaiDocument20 pagesProposed General Hospital Site Analysis in Ghansoli, Navi MumbaiPrianca JadhavNo ratings yet

- Govardhan Eco Village PranavDocument3 pagesGovardhan Eco Village Pranavpranav nanavareNo ratings yet

- Presentation 1Document11 pagesPresentation 1Rahul ChandraNo ratings yet

- Moderate Mary Ma ThewDocument4 pagesModerate Mary Ma ThewShyam Kumar0% (2)

- Vernacular Architecture OF GujaratDocument21 pagesVernacular Architecture OF Gujaratshashank joshiNo ratings yet

- Energy-Efficient CMC Building in Warm Humid MumbaiDocument6 pagesEnergy-Efficient CMC Building in Warm Humid MumbaiAr Tharini NatarajanNo ratings yet

- Kamath HouseDocument4 pagesKamath HouseIshita AryaNo ratings yet

- Diffrent Income Group Houses in IndiaDocument1 pageDiffrent Income Group Houses in IndiaAatma SahniNo ratings yet

- Anchaviyo ResortDocument21 pagesAnchaviyo ResortShafaq SulmazNo ratings yet

- Literature Case Study: Indian Farmhouse: Submitted By: Pooja Agrawal Vivek M Jain Rishab Chopda Gaurav NaharDocument19 pagesLiterature Case Study: Indian Farmhouse: Submitted By: Pooja Agrawal Vivek M Jain Rishab Chopda Gaurav NaharPooja AgrawalNo ratings yet

- Ar. Raj Rewal: Working LifeDocument15 pagesAr. Raj Rewal: Working Lifepranita chavan0% (1)

- Belapur CBD Income Tax Colony Housing-HistoryDocument1 pageBelapur CBD Income Tax Colony Housing-HistoryJay DoshiNo ratings yet

- Ad Case StudyDocument12 pagesAd Case StudyMeet Makwana100% (1)

- Belapur - Housing:: A) Project BriefDocument17 pagesBelapur - Housing:: A) Project BriefNaGamani KanDanNo ratings yet

- Vernacular Architecture of GujaratDocument19 pagesVernacular Architecture of Gujaratarshad rahman100% (1)

- Brochure - INSDAG Architecture Award Competition 2023Document10 pagesBrochure - INSDAG Architecture Award Competition 2023ebinhorrison sNo ratings yet

- Architectural Considerations for Composite Climate ZonesDocument14 pagesArchitectural Considerations for Composite Climate Zoneseyob0% (1)

- Housing in IndiaDocument17 pagesHousing in IndiaLúi CastilloNo ratings yet

- Bs Case StudyDocument20 pagesBs Case Studyinsiya farhullahNo ratings yet

- Grape County, Nashik (Presented by MR Tejas Chavan)Document34 pagesGrape County, Nashik (Presented by MR Tejas Chavan)YeshmssNo ratings yet

- Architect Bijoy Jain PhilosophyDocument1 pageArchitect Bijoy Jain PhilosophyAffan ChapekarNo ratings yet

- Advant Presentation IIDocument26 pagesAdvant Presentation IIdhoo_babyNo ratings yet

- Modern Wedding Hall Garden DesignDocument3 pagesModern Wedding Hall Garden DesignMendoza, Kyle S.No ratings yet

- Case Study of Shiv Nadar School FaridabadDocument32 pagesCase Study of Shiv Nadar School Faridabadtamlarai567No ratings yet

- Koti BanalDocument32 pagesKoti BanalSakshi GopalNo ratings yet

- Thesis Case StudyDocument13 pagesThesis Case StudyYOGITA VAGHMARENo ratings yet

- Dipshikha Meti SchoolDocument13 pagesDipshikha Meti SchoolNasrinNaharTuliNo ratings yet

- Anuj Vikas Apartment, AurovillDocument3 pagesAnuj Vikas Apartment, AurovillAnuj Sharma Spa BhopalNo ratings yet

- Case Study PDFDocument8 pagesCase Study PDFSonu KumawatNo ratings yet

- Sustainable Building-HIVE HOMEDocument18 pagesSustainable Building-HIVE HOMEBhavagithaNo ratings yet

- Ad 5 Case StudyDocument11 pagesAd 5 Case StudyPushkarani NNo ratings yet

- Vernacular Housing of ChampawatDocument12 pagesVernacular Housing of ChampawatAgrim JainNo ratings yet

- Koti Banal Architecture - Earthquake Resisting Stone Masonry SystemDocument6 pagesKoti Banal Architecture - Earthquake Resisting Stone Masonry SystemRushikesh Ingole50% (2)

- IIT Kanpur Campus Case StudyDocument36 pagesIIT Kanpur Campus Case StudyApurva mahadikNo ratings yet

- Sustainability ProjectDocument20 pagesSustainability Projectkumar AbhishekNo ratings yet

- ITC Green Center - Composite-1 PDFDocument4 pagesITC Green Center - Composite-1 PDFHarshitKhannaNo ratings yet

- Amanora Future Towers Net Case Study (INTERNATIONAL)Document40 pagesAmanora Future Towers Net Case Study (INTERNATIONAL)Rekha S100% (1)

- 309105sheikhsaraibuildingcomplexnewdelhi 180326180941 PDFDocument18 pages309105sheikhsaraibuildingcomplexnewdelhi 180326180941 PDFMOHAMMED SADDAM HUSSAIN100% (2)

- Kathputli ColonyDocument14 pagesKathputli ColonynihaNo ratings yet

- Tal Chhapar: By: Kamath Design StudiosDocument11 pagesTal Chhapar: By: Kamath Design StudiosChanchal SoniNo ratings yet

- Study of Vernacular Architecture of A International VillageDocument11 pagesStudy of Vernacular Architecture of A International VillageNaitik JaiswalNo ratings yet

- Affordable Row Housing Project for EWS in RampurDocument41 pagesAffordable Row Housing Project for EWS in RampurJasim QamarNo ratings yet

- CDSA PUNE, MaharashtaDocument4 pagesCDSA PUNE, MaharashtaAishwaryaNo ratings yet

- OrphanageDocument4 pagesOrphanagekratika gargNo ratings yet

- Literature StudyDocument27 pagesLiterature StudyHaktasticDemonNo ratings yet

- Case Study SheetsDocument2 pagesCase Study SheetsSahar ZehraNo ratings yet

- Literature Study ThesisDocument5 pagesLiterature Study ThesisDivya SreeNo ratings yet

- Ladakh Ecological Development Group (Ledeg) Hostel, LehDocument27 pagesLadakh Ecological Development Group (Ledeg) Hostel, LehAstha SinghNo ratings yet

- Aranya Housing Case StudyDocument25 pagesAranya Housing Case StudyMEGHNA GANGULYNo ratings yet

- Video 3.7: Kalpana Housing Complex, AurovilleDocument2 pagesVideo 3.7: Kalpana Housing Complex, AurovilleAissatou Inna YayaNo ratings yet

- Traditional House in Solan (Himachal Pradesh, India) (The East Side Elevation)Document20 pagesTraditional House in Solan (Himachal Pradesh, India) (The East Side Elevation)IshuNo ratings yet

- Asian Games HousingDocument22 pagesAsian Games HousingShivam RavalNo ratings yet

- Design Brief-Project2 Cultural Center: M E A S I Academy of ArchitectureDocument2 pagesDesign Brief-Project2 Cultural Center: M E A S I Academy of ArchitectureLakshmiKantNo ratings yet

- Synopsis: For Architectural Thesis Project OnDocument14 pagesSynopsis: For Architectural Thesis Project OnManasvi AgarwalNo ratings yet

- Construction Dhaji DeewariDocument4 pagesConstruction Dhaji DeewariNajaf aliNo ratings yet

- Bhatar Construction: Re VI Si OnDocument16 pagesBhatar Construction: Re VI Si OnkhurshidqNo ratings yet

- IncaDocument16 pagesIncaMihaela IlieNo ratings yet

- Name: Shalesh Yadav PNR NO. UV2200097 Course: B.Arch (Second Sem) Aayojan School of Architecture (Ycmou) SignDocument6 pagesName: Shalesh Yadav PNR NO. UV2200097 Course: B.Arch (Second Sem) Aayojan School of Architecture (Ycmou) SignShalesh YadavNo ratings yet

- Fundamentals and A Brief History of Computer SystemsDocument48 pagesFundamentals and A Brief History of Computer SystemsShalesh YadavNo ratings yet

- Autodesk Educational Product DocumentDocument1 pageAutodesk Educational Product DocumentShalesh YadavNo ratings yet

- History: Rajaraja Chola I Tamil Tamil Chola Axial Symmetrical Geometry Faceted Columns CapitalsDocument6 pagesHistory: Rajaraja Chola I Tamil Tamil Chola Axial Symmetrical Geometry Faceted Columns CapitalsShalesh YadavNo ratings yet

- Fundamentals of Computers: I. Computer Architecture (Ca)Document4 pagesFundamentals of Computers: I. Computer Architecture (Ca)sumanctsNo ratings yet

- Jawahar Kala KendraDocument1 pageJawahar Kala KendraShalesh YadavNo ratings yet

- MAIT AutocadDocument93 pagesMAIT AutocadMadhav LohchabNo ratings yet

- Sid (P) Subi DDocument1 pageSid (P) Subi DShalesh YadavNo ratings yet

- MAIT AutocadDocument93 pagesMAIT AutocadMadhav LohchabNo ratings yet

- MAIT AutocadDocument93 pagesMAIT AutocadMadhav LohchabNo ratings yet

- Site For School (1) Recover Recover Recover (1) Recover Recover-ModelDocument1 pageSite For School (1) Recover Recover Recover (1) Recover Recover-ModelShalesh YadavNo ratings yet

- Full TextDocument8 pagesFull TextShalesh YadavNo ratings yet

- Floor FinishesDocument58 pagesFloor FinishesSpace AnagramNo ratings yet

- Raft Slab Bottom Short Bars DetailsDocument1 pageRaft Slab Bottom Short Bars DetailsDINESH M.NNo ratings yet

- CE8009-Indsutrial Structures - by WWW - Learnengineering.inDocument14 pagesCE8009-Indsutrial Structures - by WWW - Learnengineering.inSanthi KaruppiahNo ratings yet

- Design of doubly reinforced beam LRFDDocument6 pagesDesign of doubly reinforced beam LRFDUsman AfzalNo ratings yet

- 1st Proposal BeamDocument513 pages1st Proposal BeamCh OuNo ratings yet

- Residential Apartment Building Estimation & Rate AnalysisDocument32 pagesResidential Apartment Building Estimation & Rate AnalysisEng-Ahmed BaasaayNo ratings yet

- FD 1Document38 pagesFD 1DrSuman ManandharNo ratings yet

- Akshay PDFDocument26 pagesAkshay PDFA1DA17CV014Bharatkumar MuddebihalNo ratings yet

- Aldo Van Eyck's Amsterdam Municipal OrphanageDocument6 pagesAldo Van Eyck's Amsterdam Municipal OrphanageSujay Punnoose Thomas100% (3)

- !! A 3D Model For Collapse Analysis of Soft-Story Light-Frame Wood BuildingsDocument8 pages!! A 3D Model For Collapse Analysis of Soft-Story Light-Frame Wood BuildingsAnonymous hprsT3WlPNo ratings yet

- Design and Analysis of Bridge Girders Using Different Codes IJERTV8IS070188Document8 pagesDesign and Analysis of Bridge Girders Using Different Codes IJERTV8IS070188Pritesh RAINo ratings yet

- Multiflex: The Flexible Girder Formwork For SlabsDocument52 pagesMultiflex: The Flexible Girder Formwork For SlabsJack Jeff50% (2)

- RidgeVentsinHighSeismicRegions PDFDocument1 pageRidgeVentsinHighSeismicRegions PDFgrahambrasicNo ratings yet

- ECM 206 CHAPTER 2 Fresh ConcreteDocument4 pagesECM 206 CHAPTER 2 Fresh ConcreteAZUAN BIN AHMAD FAUZINo ratings yet

- AECT210-Lecture 41 PDFDocument14 pagesAECT210-Lecture 41 PDFM Pradeep KumarNo ratings yet

- CHANCE Helical Foundations For Telecom StructuresDocument12 pagesCHANCE Helical Foundations For Telecom StructuresMN Titas Titas100% (1)

- Strengthening of Reinforced Concrete Beams by Using Fiber-Reinforced Polymer Composites - A ReviewDocument12 pagesStrengthening of Reinforced Concrete Beams by Using Fiber-Reinforced Polymer Composites - A ReviewJenkin CacapitNo ratings yet

- Precast concrete pipe rack structureDocument13 pagesPrecast concrete pipe rack structuredinu69inNo ratings yet

- Das Consultants: Design of 1000KL Capacity OHTDocument19 pagesDas Consultants: Design of 1000KL Capacity OHTPrashant GargNo ratings yet

- NUS Steel Structures Course OverviewDocument23 pagesNUS Steel Structures Course Overviewzzz_monsterNo ratings yet

- (James M. Ramirez JR.) : FeaturesDocument7 pages(James M. Ramirez JR.) : FeaturesJames Ramirez Jr.No ratings yet

- Dss Question Bank 2022Document7 pagesDss Question Bank 2022vcb57xbtd5No ratings yet

- Work Instruction of Workability Test of Concrete (Slump)Document1 pageWork Instruction of Workability Test of Concrete (Slump)Biplab dattaNo ratings yet

- Ms. ID FRESH FOOD (INDIA) PVT LTD, EPR-CONTENTDocument15 pagesMs. ID FRESH FOOD (INDIA) PVT LTD, EPR-CONTENTDass DassNo ratings yet

- HES Heavy Engineered Restraint StrapDocument2 pagesHES Heavy Engineered Restraint StrapMarko NakicNo ratings yet

- Structural Analysis of Beams and SlabsDocument61 pagesStructural Analysis of Beams and SlabsnurNo ratings yet

- Straight Flight Staircase S: AnalyticalDocument9 pagesStraight Flight Staircase S: AnalyticalShaurya ChauhanNo ratings yet

- Composition and Testing of ConcreteDocument3 pagesComposition and Testing of ConcreteGerald CatiponNo ratings yet

- Shear Wall Dengan Menggunakan Microsoft Excel Dan AutocadDocument10 pagesShear Wall Dengan Menggunakan Microsoft Excel Dan AutocadForming CA GondangNo ratings yet

- Junction Box Installation in Traffic BarrierDocument1 pageJunction Box Installation in Traffic BarrierAdnan NajemNo ratings yet