Professional Documents

Culture Documents

Sren 10216

Uploaded by

Marcel BurlacuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sren 10216

Uploaded by

Marcel BurlacuCopyright:

Available Formats

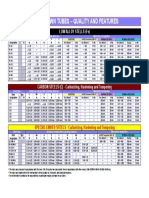

COMPOZIIA CHIMIC I CARACTERISTICILE MECANICE

ALE MATERIALELOR PENTRU FITINGURI-EURONORME

COMPOZITIA CHIMICA

MARCA DE MATERIAL

Simbolizare

Simboliz.

alfanumerica

numerica

C

Si

Mn

P

S

Al

%

%

%

%

%

%

max. max. max. max. max. min.

3

4

5

6

7

8

SR EN 10216-1:2003

CARACTERISTICI MECANICE

Cr

Cu

Mo

Nb

%

%

%

%

max. max. max. max.

9

10

11

12

Ni

Ti

V

Cr+Cu+

Rm

Rp 0.2 A5

%

%

% Mo+Ni% N/mm2 N/mm2 %

max. max. max. max.

min. min.

13

14

15

16

17

18

19

KV 0C KV -10C Rp 0.2cald

J

J

N/mm2

min.

min.

min.

20

21

22

TEVI DE OTEL FARA SUDURA UTILIZATE LA PRESIUNE

TEVI DE OTEL NEALIAT, CU CARACTERISTICI PRECIZATE LA TEMPERATURA AMBIANTA

1

P195TR1

P195TR2

P235TR1

P235TR2

P265TR1

P265TR2

1.0107

1.0108

1.0254

1.0255

1.0258

1.0259

3

0.13

0.13

0.16

0.16

0.20

0.20

4

0.35

0.35

0.35

0.35

0.40

0.40

5

0.70

0.70

1.20

1.20

1.40

1.40

6

0.025

0.025

0.025

0.025

0.025

0.025

SR EN 10216-2:2003

7

8

9

10

11

12

0.020

0.30 0.30 0.08 0.010

0.020 0.020 0.30 0.30 0.08 0.010

0.020

0.30 0.30 0.08 0.010

0.020 0.020 0.30 0.30 0.08 0.010

0.020

0.30 0.30 0.08 0.010

0.020 0.020 0.30 0.30 0.08 0.010

13

0.30

0.30

0.30

0.30

0.30

0.30

14

0.040

0.040

0.040

0.040

0.040

0.040

15

0.02

0.02

0.02

0.02

0.02

0.02

16

0.70

0.70

0.70

0.70

0.70

0.70

17

320-440

320-440

360-500

360-500

410-570

410-570

18

195

195

235

235

265

265

19

27

27

25

25

21

21

20

21

40

28

40

28

40

28

22

TEVI DE OTEL FARA SUDURA UTILIZATE LA PRESIUNE

TEVI DE OTEL NEALIAT SI ALIAT, CU CARACTERISTICI PRECIZATE LA TEMPERATURA RIDICATA

10CrMo5-5

3

0.13

0.16

0.20

0.120.20

1.7338 0.15

13CrMo4-5

1.7335

10CrMo9-10

1.7380

11CrMo9-10

1.7383

P195GH

P235GH

P265GH

16Mo3

1.0348

1.0345

1.0425

1.5415

20CrMoV13-5-5

1.7779

X10CrMoVNb9-1

1.4093

X20CrMoV11-1

1.4922

4

0.35

0.35

0.40

0.35

0.501.00

0.10- 0.35

0.17

0.08- 0.50

0.14

0.08- 0.50

0.15

3

4

0.17- 0.150.23 0.35

0.08- 0.200.12 0.50

0.17- 0.150.23 0.50

5

0.70

1.20

1.40

0.400.90

0.300.60

0.400.70

0.300.70

0.400.80

5

0.300.50

0.300.60

1.00

6

0.025

0.025

0.025

0.025

7

0.020

0.020

0.020

0.020

0.025 0.020

0.025 0.020

0.025 0.020

0.025 0.020

6

7

0.025 0.020

0.020

0.025 0.020

8

0.020

0.020

0.020

0.040

max

0.040

max

0.040

max

0.040

max

0.040

max

8

0.040

max

0.040

max

0.040

max

9

0.30

0.30

0.30

0.30

10

0.30

0.30

0.30

0.30

1.001.50

0.701.15

2.002.50

2.002.50

9

3.003.30

8.009.50

10.0012.50

0.30

0.30

0.30

0.30

10

0.30

0.30

0.30

11

0.08

0.08

0.08

0.250.35

0.450.65

0.400.60

0.901.10

0.901.10

11

0.500.60

0.851.05

0.801.20

12

13

14

15

0.010 0.30 0.040 0.02

0.010 0.30 0.040 0.02

0.010 0.30 0.040 0.02

0.30

12

16

17

0.70 320-440

0.70 360-500

0.70 410-570

450-600

18

195

235

265

280

19

27

25

23

22

0.30

410-560

275

22

0.30

440-590

290

22

0.30

480-630

280

22

0.30

540-680

355

20

17

740-880

18

590

19

16

630-830

450

19

690-840

490

17

13

0.30

0.06- 0.40

0.100

0.300.80

14

15

0.450.55

0.180.25

0.250.35

16

20

40

40

40

20C

40

20C

40

20C

40

20C

40

20C

40

20

20C

40

20C

40

20C

40

21

28

28

28

22

400C - 94

450C - 108

450C - 128

500C - 146

500C -143

500C -166

500C -180

500C -239

21

22

500C -370

600C -215

550C -250

SR EN 10216-3:2003

TEVI DE OTEL FARA SUDURA UTILIZATE LA PRESIUNE

TEVI DE OTEL ALIAT, CU GRANULATIE FINA

1

P275NL1

P275NL2

P355N

P355NH

P355NL1

P355NL2

1

P460NL1

P460NL2

1.0488 0.16 0.40 0.501.50

1.1104 0.16 0.50 0.50

1.50

1.0562 0.20 0.50 0.901.70

1.0565 0.20 0.50 0.901.70

1.1106 0.18 0.50 0.901.70

1.0566 0.18 0.60 0.901.70

2

3

4

5

1.8915 0.20 0.60 1.001.70

1.8918 0.20 0.60 1.001.70

0.025 0.020

0.025 0.015

0.025 0.020

0.025 0.020

0.025 0.020

0.025 0.015

6

7

0.025 0.020

0.025 0.015

NF EN 10216-4:2002

8

Al / N

max

0.020

0.020

0.020

0.020

0.020

0.020

0.020

0.020

0.020

0.020

0.020

0.020

8

0.020

0.020

0.020

0.020

10

11

12

13

14

15

16

17

Nb+Ti+

V max

0.30 0.30 0.08 0.050 0.50 0.040 0.05

0.05 390-530

0.30

0.050

18

19

275

24

0.040 0.05

0.05 390-530

275

24

0.30 0.30 0.08 0.050 0.50 0.040 0.10

0.12 490-650

355

22

0.30 0.30 0.08 0.050 0.50 0.040 0.10

0.12 490-650

355

22

0.30 0.30 0.08 0.050 0.50 0.040 0.10

0.12 490-650

355

22

0.30 0.30 0.08 0.050 0.50 0.040 0.10

0.12 490-650

355

22

9

10

11

12

13

14

15

0.30 0.70 0.10 0.050 0.80 0.040 0.20

16

17

0.22 560-730

18

460

19

19

0.30 0.70 0.10 0.050 0.80 0.040 0.20

0.22 560-730

460

19

20

21

22

KV KV +20C

min.

min.

40

70

KV-40C

40

100

KV-50C

40

55

KV-20C

40

55

400C - 167

KV-20C

40

70

KV-40C

40

100

KV-50C

20

21

22

40

70

KV-40C

40

90

KV-40C

TEVI DE OTEL FARA SUDURA UTILIZATE LA PRESIUNE

TEVI DE OTEL NEALIAT SI ALIAT, CU CARACTERISTICI SPECIFICATE LA TEMPERATURA SCAZUTA

1

P265NL

26CrMo4-2

12Ni14

X12Ni5

X10Ni9

2

3

4

5

1.0453 0.20 0.40 0.601.40

1.7219 0.22- 0.35 0.500.29

0.80

1.5637 0.15 0.15- 0.300.35 0.80

1.5680 0.15 0.35 0.300.80

1.5682 0.13 0.15- 0.300.35 0.80

6

7

8

9

10

11

12

13

14

15

0.025 0.020 0.020 0.30 0.30 0.08 0.100 0.30 0.040 0.02

0.025 0.020

0.025 0.010

0.9- 0.30 0.151.20

0.30

0.30

0.020 0.010

0.30

0.020 0.010

0.30

3.253.75

4.505.30

8.509.50

16

17

410-570

18

265

19

24

560-740

440

18

0.05

440-620

345

22

0.05

510-710

390

21

0.05

690-840

510

20

20

40

KV-40C

40

KV-60C

40

KV-100C

40

KV-120C

40

KV-196C

21

50

60

65

70

70

22

DIN EN 10216-5:2004

TEVI DE OTEL FARA SUDURA UTILIZATE LA PRESIUNE

TEVI DE OTEL INOXIDABIL

OTELURI AUSTENITICE REZISTENTE LA COROZIUNE

3

4

5

6

7 N max 9

10

11

12

13

14

15

16

X2CrNi19-11

1.4306 0.03 1.00 2.00 0.040 0.015 0.110 18.0010.020.00

12.00

X5CrNi18-10

1.4301 0.07 1.00 2.00 0.040 0.015 0.110 17.008.019.50

10.50

X6CrNiTi18-10

1.4541 0.08 1.00 2.00 0.040 0.015

17.009.0- 5xC kalt

19.00

12.00 0.700

X6CrNiTi18-10 warm 1.4541

X6CrNiNb18-10

1.4550 0.08 1.00 2.00 0.040 0.015

17.0010xC - 9.019.00

1.000 12.00

X2CrNiMo17-12-2 1.4404 0.03 1.00 2.00 0.040 0.015 0.110 16.502.0010.018.50

2.50

13.00

X5CrNiMo17-12-2 1.4401 0.07 1.00 2.00 0.040 0.015 0.110 16.502.0010.018.50

2.50

13.00

X6CrNiMoTi17-12-2 1.4571 0.08 1.00 2.00 0.040 0.015

16.502.0010.5- 5xC kalt

18.50

2.50

13.50 0.700

X6CrNiMoTi17-12-2 1.4571

warm

X6CrNiMoNb17-12-2 1.4580 0.08 1.00 2.00 0.040 0.015

16.502.00- 10xC - 10.518.50

2.50 1.000 13.50

X2CrNiMo18-14-3 1.4435 0.03 1.00 2.00 0.040 0.015 0.110 17.002.5012.519.00

3.00

15.00

1

17

460-680

18

180

19

40

KV+20C KV-196C

100

60

500-700

195

40

100

60

500-730

200

35

100

60

460-680

510-740

180

205

35

35

100

100

60

60

490-690

190

40

100

60

510-710

205

40

100

60

500-730

210

35

100

490-690

190

35

100

510-740

215

35

100

490-690

190

40

100

60

60

22

You might also like

- EG-Instalatii de ParatrasnetDocument33 pagesEG-Instalatii de Paratrasnetcarmen_maria99No ratings yet

- Norme Deviz - CG - PardoseliDocument34 pagesNorme Deviz - CG - Pardoselicarmen_maria99100% (1)

- Indicator de NormeDocument279 pagesIndicator de Norme&R1No ratings yet

- 6.PTT ZarnestiDocument13 pages6.PTT ZarnestiDanuta NicolaiNo ratings yet

- Norme Deviz - CM GeamuriDocument34 pagesNorme Deviz - CM Geamuricarmen_maria99100% (1)

- Norme Deviz V - Lucrari Instalatii de VentilatieDocument885 pagesNorme Deviz V - Lucrari Instalatii de VentilatieGavan Liviu50% (2)

- Norme de Deviz RPCDocument30 pagesNorme de Deviz RPCVaida Cosmin-IonutNo ratings yet

- Norme de Deviz - ACDocument1,165 pagesNorme de Deviz - ACVasile Ciprian DavidNo ratings yet

- RPC - Norme de DevizDocument30 pagesRPC - Norme de DevizOdagescu StefanNo ratings yet

- Indicator Norme Deviz C Lucrari de ConstructiiDocument1,278 pagesIndicator Norme Deviz C Lucrari de ConstructiiTecu CristiNo ratings yet

- Plan Armare Grinda de Coronament Directia LongitudinalaDocument1 pagePlan Armare Grinda de Coronament Directia LongitudinalaFlorian RapanuNo ratings yet

- RPS NormeDocument649 pagesRPS NormeAlexandrescuDanNo ratings yet

- Greutati Teava RotundaDocument3 pagesGreutati Teava RotundaCiprian100% (1)

- DZ-Prepararea Semifabricatelor Si Confectii de SantierDocument46 pagesDZ-Prepararea Semifabricatelor Si Confectii de Santiercarmen_maria99No ratings yet

- Tabel BetoaneDocument2 pagesTabel Betoaneaares13No ratings yet

- Norme Deviz Instalatii Incalzire Gaze Indicator IDocument310 pagesNorme Deviz Instalatii Incalzire Gaze Indicator ICălin Tăuţan100% (1)

- Norme de DevizDocument2,636 pagesNorme de DevizRakasz Andrei100% (2)

- DH - Lucrari de Reparatii Si Intretinere DrumuriDocument9 pagesDH - Lucrari de Reparatii Si Intretinere Drumuricarmen_maria99No ratings yet

- IzDocument32 pagesIzAndrei Alexandru TulbureanuNo ratings yet

- Suruburi 14399 - Momente de StrangereDocument1 pageSuruburi 14399 - Momente de StrangereAnonymous 6aGAvbNNo ratings yet

- Norme Deviz G - Lucrari de Instalatii de GazeDocument618 pagesNorme Deviz G - Lucrari de Instalatii de Gazecatalin_alexaNo ratings yet

- Norme Deviz MDT - Lucrari de Montare, Demon Tare, Transport UtilajeDocument90 pagesNorme Deviz MDT - Lucrari de Montare, Demon Tare, Transport UtilajeAndrei CosmescuNo ratings yet

- Norme Deviz L1 - Lucrari de Cai FerateDocument291 pagesNorme Deviz L1 - Lucrari de Cai FerateAndreea GovorNo ratings yet

- Norme Deviz - CN - Zugraveli, VopsitoriiDocument28 pagesNorme Deviz - CN - Zugraveli, Vopsitoriicarmen_maria99100% (1)

- Indicator Norme Deviz Automatizari atDocument58 pagesIndicator Norme Deviz Automatizari atNicusor MiertescuNo ratings yet

- Fisa Foraj F1 KM 440+860-ModelDocument1 pageFisa Foraj F1 KM 440+860-ModelFlavNo ratings yet

- DE - Incadrari Pavaje, Imbracaminti, TrotuareDocument16 pagesDE - Incadrari Pavaje, Imbracaminti, Trotuarecarmen_maria99No ratings yet

- Norme Deviz M1 - Montaj Utilaj GeneralDocument1,230 pagesNorme Deviz M1 - Montaj Utilaj GeneralRadu Stratila0% (1)

- Extras LemnDocument1 pageExtras LemnSantiago_Maresca77No ratings yet

- Profile Metalice HEA-Caracteristici GeometriceDocument1 pageProfile Metalice HEA-Caracteristici GeometriceCristi PopNo ratings yet

- Norme de DevizDocument1 pageNorme de DevizMunteanu Catalin0% (1)

- Norme Deviz - CL MontareDocument32 pagesNorme Deviz - CL Montarecarmen_maria99100% (1)

- Stefan SCENARIU de Siguranta La Foc. ExempluDocument23 pagesStefan SCENARIU de Siguranta La Foc. ExempluBarabas Sandra100% (1)

- Preturi ValromDocument127 pagesPreturi ValromIlie Cristian100% (4)

- Metal Trade Impex - Europrofile, Profile UNP, InP, IPE, UNPE, UPE, HEA, HEB, HEM, Produse MetalurgiceDocument5 pagesMetal Trade Impex - Europrofile, Profile UNP, InP, IPE, UNPE, UPE, HEA, HEB, HEM, Produse MetalurgiceTudoran MarianNo ratings yet

- SR EN 14161 Sisteme de Transport Prin Conducte PDFDocument99 pagesSR EN 14161 Sisteme de Transport Prin Conducte PDFMihai Persinaru100% (1)

- Conectori Metal BetonDocument2 pagesConectori Metal BetonCorbean AlexandruNo ratings yet

- Norme Deviz M3 - Lucrari de Montaj Utilaje Industria Chimica, Petroliera, HartieDocument159 pagesNorme Deviz M3 - Lucrari de Montaj Utilaje Industria Chimica, Petroliera, HartieRadu StratilaNo ratings yet

- Gard 14Document1 pageGard 14Emil EremiaNo ratings yet

- 10 - Liste Estimative Cantitati Cladire SpitalDocument12 pages10 - Liste Estimative Cantitati Cladire SpitalMircea Valentin GlodianuNo ratings yet

- Scara de Pisica PDFDocument1 pageScara de Pisica PDFadriana_mihaela2000100% (1)

- Indicator Rpa-Reparatii Apa Si CanaluizareDocument551 pagesIndicator Rpa-Reparatii Apa Si CanaluizareRelu123100% (1)

- Norme Deviz VDocument674 pagesNorme Deviz VAndrei PopNo ratings yet

- Sarpanta Mansarda 01Document2 pagesSarpanta Mansarda 01Abrudan EugenNo ratings yet

- Calculul Planseelor Tip Dala Mixta Otel BetonDocument28 pagesCalculul Planseelor Tip Dala Mixta Otel Betoncretz2100% (2)

- Armare Zid de SprijinDocument1 pageArmare Zid de Sprijincr15tiNo ratings yet

- Indicator Norme Deviz AUT - Lucrari de AutomatizariDocument26 pagesIndicator Norme Deviz AUT - Lucrari de Automatizaricristinefx100% (1)

- Calcule Proiect IVCDocument67 pagesCalcule Proiect IVCAlexNo ratings yet

- Norme L-M-SDocument40 pagesNorme L-M-SDan LazarNo ratings yet

- Bush Material PDFDocument2 pagesBush Material PDFVijay AnandNo ratings yet

- Magvant CatalogueDocument54 pagesMagvant CataloguemalsttarNo ratings yet

- 45SCD6 - 45SiCrMo6Document2 pages45SCD6 - 45SiCrMo6iso9002No ratings yet

- GDocument481 pagesGamaNo ratings yet

- Mini Projet Mimoun BPELDocument9 pagesMini Projet Mimoun BPELjihad1568No ratings yet

- Otel de CementareDocument2 pagesOtel de CementareSara HeartNo ratings yet

- Material ListDocument1 pageMaterial ListRamasamy PNo ratings yet

- SHS 80X80X3 & SHS 120X120X3Document2 pagesSHS 80X80X3 & SHS 120X120X3Özgün BıçakNo ratings yet

- Note de CalculDocument7 pagesNote de CalculRahim CerbereNo ratings yet

- Brochure InoxDocument2 pagesBrochure InoxSmail MiloudiNo ratings yet