Professional Documents

Culture Documents

Caustic Scrubber-Indirect Hydration IPA Production

Uploaded by

Rishikesh AwaleCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Caustic Scrubber-Indirect Hydration IPA Production

Uploaded by

Rishikesh AwaleCopyright:

Available Formats

Caustic Scrubber The Role of caustic scrubber in IPA plant manufacturing IPA by indirect hydration method is to neutralize the

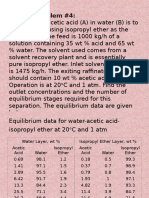

two streams one of which contains diisipropyl ether (30 to 50 wt%) isopropyl alcohol (30 to 40 wt%) and propylene (10 to 20 wt%) and the other one which has vapour mixture of isopropyl alcohol, diisopropyl ether and minor amount of propylene and water using 10wt% NaOH.The operating temperature and pressure in scrubber are 373 K and 14.7psi respectively.The effluent from the scrubber consists of 55% IPA and transferred to crude isopropyl alcohol tank. From this tank, the mixture is send to the ether column C105 via stream 20 which is operated at a temperature of 362 K and a pressure of 14.7 psi. In this column distillation process will take place to separate diisopropyl ether and hexene. The overhead product, diisopropyl ether is withdrawn via stream 21 to the diisopropyl column C109. Then, it is washed to produce washed diisopropyl ether at 95 wt.%.

You might also like

- Synthesis of P2PDocument15 pagesSynthesis of P2PRiki Mandol83% (24)

- Airbus CMLDocument132 pagesAirbus CMLKnashye Nh80% (5)

- Isophorone Production From AcetoneDocument4 pagesIsophorone Production From AcetonesandeepNo ratings yet

- Hydration of PropyleneDocument3 pagesHydration of PropyleneAlfredArulapanAlexanderNo ratings yet

- Project 1 - Isopropanol and Acetone From Propylene PDFDocument8 pagesProject 1 - Isopropanol and Acetone From Propylene PDFAnonymous RJkpep7D0rNo ratings yet

- BZP SynthesisDocument3 pagesBZP SynthesisScientology1No ratings yet

- Advanced Pharmaceutical analysisFrom EverandAdvanced Pharmaceutical analysisRating: 4.5 out of 5 stars4.5/5 (2)

- Chemical Engg Basic IndiabixDocument123 pagesChemical Engg Basic IndiabixRishikesh Awale100% (3)

- TWI Training CSWIP 3.1 Pipe 01 (Complete)Document8 pagesTWI Training CSWIP 3.1 Pipe 01 (Complete)Suli HartoNo ratings yet

- 1 - Elmar 10K English ALL GENERIC PDFDocument74 pages1 - Elmar 10K English ALL GENERIC PDFElectro kill100% (1)

- Project WorkDocument1 pageProject WorkUmaMuniandyNo ratings yet

- TEPZZ 9 9995A - T: European Patent ApplicationDocument10 pagesTEPZZ 9 9995A - T: European Patent ApplicationAyub riyanNo ratings yet

- Isopropyl Alcohol: The Process Flow Diagram IpaDocument40 pagesIsopropyl Alcohol: The Process Flow Diagram IpaGraciaVelitarioNo ratings yet

- Flow Diagram of Isopropyl AlcoholDocument2 pagesFlow Diagram of Isopropyl Alcoholshamsullah100% (1)

- Lecture 18: Isopropanol and Acetone From Propylene: Module 3: PetrochemicalsDocument2 pagesLecture 18: Isopropanol and Acetone From Propylene: Module 3: Petrochemicalsshamsullah hamdardNo ratings yet

- Production of Isopropanol: B.Sc. VI Sem Industrial ChemistryDocument7 pagesProduction of Isopropanol: B.Sc. VI Sem Industrial ChemistryAyub riyanNo ratings yet

- Receipe For MethylamineDocument3 pagesReceipe For MethylamineCharles Sullivan100% (1)

- Unit Ops (Supplementary Problem)Document2 pagesUnit Ops (Supplementary Problem)Aduchelab AdamsonuniversityNo ratings yet

- Checal 1Document2 pagesChecal 1VaanNo ratings yet

- United States Patent 0 ": Patented Dec. 15, 1959Document2 pagesUnited States Patent 0 ": Patented Dec. 15, 1959Aaron CurrieNo ratings yet

- 1 2 3 Properties 4 Different Product From Ipa 5 Different Processes 6 Ipa by Indirect Hydration 7 Process Flow Diagram 8 Uses 9 Safety 10 Toxicology 11 ReferencesDocument12 pages1 2 3 Properties 4 Different Product From Ipa 5 Different Processes 6 Ipa by Indirect Hydration 7 Process Flow Diagram 8 Uses 9 Safety 10 Toxicology 11 ReferencesArpit PatelNo ratings yet

- Problem Set#1Document3 pagesProblem Set#1YanYan CarpioNo ratings yet

- Evaporation QuizDocument1 pageEvaporation QuizBenedick Jayson MartiNo ratings yet

- Process-1 - Direct-Esterification - Process DescDocument7 pagesProcess-1 - Direct-Esterification - Process DescaibbycatalanNo ratings yet

- Isopropyl AlcoholDocument3 pagesIsopropyl AlcoholSavita GuptaNo ratings yet

- NaCN Process DescriptionDocument9 pagesNaCN Process DescriptionFrank MtetwaNo ratings yet

- Arease: Nov. 8, 1966 W. Wogt Et Al 3,284,495 Process For The Continuous Manufacture, Purification andDocument3 pagesArease: Nov. 8, 1966 W. Wogt Et Al 3,284,495 Process For The Continuous Manufacture, Purification andRachmad HermawanNo ratings yet

- Bioprocess Engg Lab Assignment: Olivia Newton 119BT0433Document5 pagesBioprocess Engg Lab Assignment: Olivia Newton 119BT0433olivia6669No ratings yet

- Preparation and Assay of Acetyl PhosphateDocument4 pagesPreparation and Assay of Acetyl PhosphatecataawwwNo ratings yet

- Flowsheeting Sheet (1) 21/2/2015: Ag-CatalystDocument5 pagesFlowsheeting Sheet (1) 21/2/2015: Ag-CatalystAhmed Hamdy Khattab100% (1)

- Thioglycolic Acid ProductionDocument2 pagesThioglycolic Acid Productionfake77No ratings yet

- Vinyl AcetateDocument5 pagesVinyl AcetateroxetteNo ratings yet

- 13-Ethyl Alcohol or Ethanol Production From Molasses by FermentationDocument2 pages13-Ethyl Alcohol or Ethanol Production From Molasses by FermentationCaro Villa MoraNo ratings yet

- Make CocaineDocument19 pagesMake CocaineRahul WaskelNo ratings yet

- AAS Methods 2520of 2520 ProductionDocument4 pagesAAS Methods 2520of 2520 Productionapi-3714811No ratings yet

- Sample Problem 4Document8 pagesSample Problem 4Emmanuel PlazaNo ratings yet

- US3816523Document5 pagesUS3816523Argo Rizky Kusuma 2007110716No ratings yet

- Propofol Russian SU443019A1 Translated From Hydroxybenzoic AcidDocument3 pagesPropofol Russian SU443019A1 Translated From Hydroxybenzoic AcidBen de LangeNo ratings yet

- AlkylationDocument9 pagesAlkylationabhishek sharma100% (1)

- Alkylation PDFDocument7 pagesAlkylation PDFVasthadu Vasu Khanan DLNo ratings yet

- Alkylation PDFDocument7 pagesAlkylation PDFAnagha kvNo ratings yet

- Problem Statement Methanol, Also Known As MethylDocument3 pagesProblem Statement Methanol, Also Known As MethyldeviancemNo ratings yet

- Industrial Alcohol ProductionDocument4 pagesIndustrial Alcohol ProductionSheraz AliNo ratings yet

- CE2206 - CPI - Lecture No.05 - Manu. of INDUSTRIAL ALCOHOLDocument17 pagesCE2206 - CPI - Lecture No.05 - Manu. of INDUSTRIAL ALCOHOLRohan GohilNo ratings yet

- Checal ReviewerDocument8 pagesChecal ReviewerChristian Dela CruzNo ratings yet

- TK-315 CPI2 - 1 - NonReacting SystemsDocument33 pagesTK-315 CPI2 - 1 - NonReacting SystemsBayu Purnama Ridjadi75% (4)

- Project Statement S2 2015 (V2)Document10 pagesProject Statement S2 2015 (V2)Devandra Eko RadityoNo ratings yet

- United States Patent (191: Lietard Et A1. (45) Jan. 3, 1978Document7 pagesUnited States Patent (191: Lietard Et A1. (45) Jan. 3, 1978syafiq izzuddin bin sapriNo ratings yet

- Ethyl AcrylateDocument4 pagesEthyl AcrylateFirdaus ImamNo ratings yet

- IPADocument12 pagesIPAEr Bali Pandhare50% (2)

- Mass Balance AssignmentDocument2 pagesMass Balance AssignmentSiti Hajar Mohd PodziNo ratings yet

- United States Patent O?ice: 15H: LLQ?ZDocument3 pagesUnited States Patent O?ice: 15H: LLQ?ZadamNo ratings yet

- Us 3767726Document4 pagesUs 3767726Sujan BasyalNo ratings yet

- Industrial Alcohol: Manufacture ProcessDocument7 pagesIndustrial Alcohol: Manufacture ProcessAbbasNo ratings yet

- Acetone ProductionDocument2 pagesAcetone ProductionpehweihaoNo ratings yet

- FermentationDocument5 pagesFermentationNaveen PalaNo ratings yet

- Topical and Prospective Processes of Acetoxylation: Grzegorz Lewandowski, Marcin Bartkowiak, Eugeniusz MilchertDocument6 pagesTopical and Prospective Processes of Acetoxylation: Grzegorz Lewandowski, Marcin Bartkowiak, Eugeniusz MilchertAnonymous b9fcR5No ratings yet

- Lecture 18 - Isopropanol and Acetone From PropyleneDocument6 pagesLecture 18 - Isopropanol and Acetone From PropyleneRichardN55No ratings yet

- Synthesis of Adrafinil & ModafinilDocument2 pagesSynthesis of Adrafinil & ModafinildjavahkNo ratings yet

- Procesos InglesDocument4 pagesProcesos InglesMarcoDulongJaraNo ratings yet

- Caprolactam Process DescriptionDocument8 pagesCaprolactam Process DescriptionJohannah Jane Abuel100% (2)

- Checal 2 Module ProblemsDocument3 pagesChecal 2 Module Problems5zywgtdkw5No ratings yet

- The Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresFrom EverandThe Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresRating: 5 out of 5 stars5/5 (1)

- The Chemistry of Dairy Products - A Chemical Analysis of Milk, Cream and ButterFrom EverandThe Chemistry of Dairy Products - A Chemical Analysis of Milk, Cream and ButterNo ratings yet

- Shrewd Debate TacticsDocument25 pagesShrewd Debate TacticsRishikesh AwaleNo ratings yet

- Chemical ProcessesDocument150 pagesChemical ProcessesRishikesh AwaleNo ratings yet

- Exact Calculation Procedures For Multicomponent DistillationDocument21 pagesExact Calculation Procedures For Multicomponent DistillationRishikesh AwaleNo ratings yet

- Chemical Process Safety NotesDocument59 pagesChemical Process Safety NotesRishikesh AwaleNo ratings yet

- Ammonia Process InformationDocument4 pagesAmmonia Process InformationRishikesh AwaleNo ratings yet

- Lubricant and GreasesDocument12 pagesLubricant and GreasesRishikesh Awale100% (1)

- AArambh Machine Paper Dish CatalogueDocument6 pagesAArambh Machine Paper Dish CatalogueAtul PatekarNo ratings yet

- 12108040-Zinc Extraction in Contrast With ISP Process PDFDocument20 pages12108040-Zinc Extraction in Contrast With ISP Process PDFSachin MourNo ratings yet

- TDS Gypsum PlasterDocument3 pagesTDS Gypsum PlasterHDS Inc.No ratings yet

- Boiler Compound Paint - B Interior: DescriptionDocument1 pageBoiler Compound Paint - B Interior: DescriptionnanoNo ratings yet

- 02-Chemical Kinetic - Telegram - @JEE - BOOKSDocument11 pages02-Chemical Kinetic - Telegram - @JEE - BOOKSRdNo ratings yet

- UMA Advanced Technology Primer Sealer Bonder (White) : Technical Data XIM-03Document2 pagesUMA Advanced Technology Primer Sealer Bonder (White) : Technical Data XIM-03Jonathan ArboledaNo ratings yet

- Paints - Civil EngineeringDocument4 pagesPaints - Civil EngineeringVando IntechNo ratings yet

- Corus Clad PipeDocument7 pagesCorus Clad PipeDBasak_1974No ratings yet

- Stress RelievingDocument3 pagesStress RelievingAbhishek NagNo ratings yet

- Mat 1140 For SuppliersDocument3 pagesMat 1140 For SupplierskarthimeenaNo ratings yet

- Conservation Vent (Pressure & Vacuum)Document8 pagesConservation Vent (Pressure & Vacuum)Bureau VeritasNo ratings yet

- Rustop 68, 173, 173 DW, 175, 179, 184Document2 pagesRustop 68, 173, 173 DW, 175, 179, 184sumitNo ratings yet

- Company Profile Ias (22-23)Document15 pagesCompany Profile Ias (22-23)Radziel EngineeringNo ratings yet

- PSL1 PSL2 PDFDocument1 pagePSL1 PSL2 PDFArmandoZacariasAcostaNo ratings yet

- Gas Transmission and Distribution Piping Systems ASME B31.12 Hydrogen Piping and PipelinesDocument5 pagesGas Transmission and Distribution Piping Systems ASME B31.12 Hydrogen Piping and PipelinesnasrNo ratings yet

- Table Loctite Vs Loxeal 0215Document4 pagesTable Loctite Vs Loxeal 0215ankesh_ghoghariNo ratings yet

- Formation and Characteristics of Zinc Phosphate CoDocument9 pagesFormation and Characteristics of Zinc Phosphate ComirosekNo ratings yet

- Matus CatalogueDocument101 pagesMatus CatalogueDenis dembskeyNo ratings yet

- Essential Variables For All ProcessesDocument4 pagesEssential Variables For All ProcessesRahulNo ratings yet

- Everbuild® Black Jack® 908 D.P.M.: Product Data SheetDocument4 pagesEverbuild® Black Jack® 908 D.P.M.: Product Data SheetJaysonn KayNo ratings yet

- Datasheet EN 10029 PDFDocument1 pageDatasheet EN 10029 PDFKalpesh JainNo ratings yet

- Pumps Calculation 2Document2 pagesPumps Calculation 2Alchemy EngNo ratings yet

- Fosroc Acid Etch : Concrete Remover, Cleaning and Etching AgentDocument2 pagesFosroc Acid Etch : Concrete Remover, Cleaning and Etching AgentVincent JavateNo ratings yet

- NIVEL Por Presión DiferencialDocument4 pagesNIVEL Por Presión DiferencialArmando MartinezNo ratings yet

- Layout: 4.1 Steel's GenesisDocument2 pagesLayout: 4.1 Steel's GenesisDroffy GuyNo ratings yet

- Milling Machine ReportDocument7 pagesMilling Machine ReportAlex HdezNo ratings yet

- Durablanket SDocument2 pagesDurablanket SMazhar choudharyNo ratings yet