Professional Documents

Culture Documents

s0!00!10 - Foundation Typical Details and Schedules

Uploaded by

huyxpkissCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

s0!00!10 - Foundation Typical Details and Schedules

Uploaded by

huyxpkissCopyright:

Available Formats

ARCH E 36"x48"

1-#4 TOP AND BOTTOM, TYPICAL REFER TO SCHEDULE 2" TYPICAL CONSTRUCTION JOINT EQUAL A NOTES: 1. WHERE CLEAR SPACING BETWEEN ADJACENT SLEEVES IS LESS THAN 3", THE SLEEVE GROUP SHALL BE TREATED AS AN EQUIVALENT RECTANGULAR OPENING WITH LENGTH "L" AND WIDTH "W" AS SHOWN. 2. WHERE CLEAR SPACING BETWEEN ADJACENT SLEEVES IS GREATER THAN OR EQUAL TO 3", SCHEDULED SLAB BAR REINFORCEMENT SHALL BE OFFSET AS REQUIRED TO MISS SLEEVES. 3. REINFORCEMENT SHOWN IS IN ADDITION TO SCHEDULED SLAB REINFORCEMENT. 4. SCHEDULED SLAB MESH REINFORCEMENT MAY BE CUT AS REQUIRED TO MISS PIPE SLEEVES. 5. REFER TO MECHANICAL, ELECTRICAL, AND PLUMBING DRAWINGS FOR LOCATION AND SIZE OF SLEEVES. 6. ISOLATED PIPE SLEEVES THAT ARE SMALLER THAN 5" AND DO NOT INTERRUPT REINFORCEMENT DO NOT REQUIRE THE USE OF THIS DETAIL. 7. THIS DETAIL SHOULD NOT BE USED FOR OPENING GROUPS WITH DIAMETERS LARGER THAN 12". CONSULT STRUCTURAL ENGINEER FOR FRAMING OF SUCH CONDITIONS. 8. PROVIDE HALF OF INTERRUPTED REINFORCEMENT PLUS ONE ADDITIONAL BAR OF SAME SIZE ON EACH SIDE OF EQUIVALENT RECTANGULAR OPENING. PROVIDE A MINIMUM OF 1-#4 TOP AND BOTTOM EACH SIDE OF OPENING. ADDITIONAL REINFORCEMENT, REFER TO SCHEDULE BELOW EQUAL SCHEDULED SLAB REINFORCEMENT CONTINUOUS THROUGH JOINT T/2 T/2 P1 h1 SLAB SURFACE PROFILE

10'-0" (120") P2

SIGN CONVENTION h,z : (+) IS MORE UPHILL ELEVATION h2 z 2= h 2 - h1

REFER TO NOTE 1 1-#4 CONTINUOUS AT PERIMETER WITH 1-#4x4'-0" AT EXTERIOR CORNERS AND 1-#4x4'-0" DIAGONAL AT RE-ENTRANT CORNERS 2'-0" 2'-0"

4' -0 "

TOP REINFORCEMENT, REFER TO SCHEDULE BOTTOM REINFORCEMENT, WHERE SCHEDULED 3/4" CHAMFER, TYPICAL

2'-0"

SLAB-ON-GRADE, REFER TO PLAN FOR THICKNESS AND REINFORCEMENT AND REFER TO SPECIFICATIONS FOR CURING METHOD VAPOR RETARDER DIRECTLY BELOW SLAB

DATUM

MEASURE OF FLOOR LEVELNESS

12"

0

12"

0

1-#4 TOP AND BOTTOM

P1 d2 h2

0

SLAB SURFACE PROFILE P2 d3

0

SIGN CONVENTION q : TROUGH, q>0 CREST, q<0 P3

EXTERIOR CORNERS

RE-ENTRANT CORNERS

HOUSEKEEPING PAD REINFORCEMENT SCHEDULE

h3 q3 = d3 - d2 = h3 - 2h2 + h1 DATUM PAD THICKNESS T = 4" 4" < T <= 6" 6" < T <= 8" TOP REINFORCEMENT WWR 4x4-W2.9xW2.9 OR #3@12" EACH WAY WWR 4x4-W4xW4 OR #4@18" EACH WAY WWR 4x4-W6xW6 OR #4@12" EACH WAY #4@18" EACH WAY #4@12" EACH WAY BOTTOM REINFORCEMENT NONE NONE NONE #4@18" EACH WAY #4@12" EACH WAY 4" SELECT NONPLASTIC SAND COMPACTED TO AT LEAST 75% OF RELATIVE DENSITY OR 95% OF THE STANDARD PROCTOR MAXIMUM DRY DENSITY 4" AGGREGATE BASE COURSE CONFORMING TO SUBSECTIONS 1003.03 (b) OR 1003.03 (c) OF THE LOUISIANA DOTD SPECIFICATIONS COMPACTED, PREPARED SUBGRADE, REFER TO SPECIFICATIONS

0 0

2'-0"

0

PLAN FOR A>=3"

2" TYPICAL L Ld+L/2 2'-0" MINIMUM A

ADDITIONAL REINFORCEMENT SCHEDULE

SLAB THICKNESS T=4" 4"<T<=6" 6"<T<=8" REINFORCEMENT #4x2'-6" @ 18" #4x2'-6" @ 12" #5x3'-0" @ 12" #6x3'-8" @ 12"

h1

0

MEASURE OF FLOOR FLATNESS

NOTES: 1. FL = LEVELNESS F-NUMBER FL= 12.5 _______ WHERE (3 x Sz) + z 2. FL= FLATNESS F-NUMBER FL= 4.57 _______ WHERE (3 x Sq) + q

z = MEAN VALUE OF ALL x FLOOR READINGS Sz = STANDARD DEVIATION OF ALL z FLOOR READINGS q = MEAN VALUE OF ALL q FLOOR READINGS Sq = STANDARD DEVIATION OF ALL q FLOOR READINGS

8" < T <= 12" 12" < T <= 16"

8<T<=12" REFER TO NOTE 8

Ld+W/2 2'-0" MINIMUM

EQUIVALENT RECTANGULAR OPENING

NOTES: 1. CONSTRUCTION JOINTS SHOULD BE LOCATED ON THE MIDDLE THIRD OF THE SLAB SPAN. 2. CONCRETE SURFACE AT CONSTRUCTION JOINT SHALL BE CLEAN AND FREE OF LAITANCE. 3. DO NOT USE FOR POST-TENSIONED SLABS.

3. 4.

PLAN FOR A<3"

FL AND F F SHALL BE STATISTICALLY DETERMINED ACCORDING TO ASTM E 1155 "STANDARD TEST METHOD FOR DETERMINING FLOOR FLATNESS AND LEVELNESS USING THE F-NUMBER SYSTEM." REFER TO CONCRETE SPECIFICATIONS FOR REQUIRED FL AND F F VALUES

NOTES: 1. REFER TO ARCHITECTURAL, STRUCTURAL, OR MEP DRAWINGS FOR HOUSEKEEPING PAD PLAN DIMENSIONS AND THICKNESS (4" MINIMUM THICKNESS). 2. CONTRACTOR SHALL COORDINATE DIMENSIONS AND OTHER SPECIAL REQUIREMENTS WITH EQUIPMENT MANUFACTURERS AND PROVIDE WHERE REQUIRED WHETHER SHOWN ON STRUCTURAL DRAWINGS OR NOT.

ADDITIONAL REINFORCEMENT AROUND PIPE SLEEVES

NO SCALE

03300-FL-SLOPG-02 COPYRIGHT WALTER P. MOORE AND ASSOCIATES, INC. 2010

TYPICAL CONSTRUCTION JOINT IN CONCRETE STRUCTURAL SLAB

NO SCALE

03251-FL-ONSLB-01 COPYRIGHT WALTER P. MOORE AND ASSOCIATES, INC. 2010

TYPICAL SLAB SURFACE TOLERANCE

NO SCALE

03300-FL-SLTOL-01 COPYRIGHT WALTER P. MOORE AND ASSOCIATES, INC. 2011

2

6"

TYPICAL HOUSEKEEPING PAD OVER SLAB-ON-GRADE

NO SCALE

03300-FN-SOG-10 COPYRIGHT WALTER P. MOORE AND ASSOCIATES, INC. 2010

TYPICAL SLAB-ON-GRADE SUBGRADE PREPARATION

NO SCALE

02230-FN-SUPRP-01C COPYRIGHT WALTER P. MOORE AND ASSOCIATES, INC. 2010

REFER TO PLAN TOP OF SLAB SCHED

PER

REFER TO PLAN TOP OF CAP SCHEDULED BEAM TOP AND BOTTOM REINFORCEMENT. DO NOT DISCONTINUE AT CONSTRUCTION JOINT 1" CLEAR CONSTRUCTION JOINT LOCATION FORMED SHEAR KEY (HORIZONTAL) 2" 3" 2" 3" 2'-6 "

EQUAL 1" TAPER

EQUAL

8" UNLESS NOTED OTHERWISE

SLAB REINFORCEMENT, TYPICAL

B/2 + Ld

" -6 2'

TURN GRADE BM DOWN TO TOP OF PILE CAP WHERE TOP OF PILE CAP IS BELOW BOT OF GRADE BM #4 DOWELS @12" CENTERED IN GRADE BM

3"

Project Management Initials: Designer: Designer Checked: Checker Approved: Approver

BEAM

PROVIDE 1-#4 TOP AND 1-#4 BOTTOM CORNER BARS

DEPTH D D/3 D/3 D/3

30 <= A <= 150

A

0"

AT NEW PILE CAP PROVIDE CORNER BARS TOP AND BOTTOM. PROVIDE CORNER BARS FOR EACH LAYER OF BEAM REINFORCING SPECIFIED REFER TO PLAN TOP OF SLAB 6" PER SCHED

0

REFER TO PLAN TOP OF SLAB REFER TO PLAN TOP OF GRADE BEAM SCHEDULED STIRRUPS SCHEDULED REINFORCING

1 1/2" CLEAR

0"

30 <= A <= 150 PROVIDE STANDARD 90 END HOOKS FOR TOP STEEL INSIDE TOP STEEL OF SUPPORT BEAMS

0

SCHEDULED GRADE BEAM DEPTH D

ADDITIONAL DOWELS, USE 2-#5x4'-0" TOP AND BOTTOM UNLESS REQUIRED OTHERWISE BY NOTE 3 OR 4

PROVIDE (1) ADDITIONAL BEAM STIRRUP EACH SIDE OF CONSTRUCTION JOINT AND EACH END OF ADDITIONAL DOWELS (NOT SCHEDULED)

REFER TO PLAN TOP OF CAP

A SLAB REINFORCEMENT, TYPICAL NOTES: 1. GENERAL CONTRACTOR SHALL SUBMIT DESIRED CONSTRUCTION JOINT LAYOUT AS A SHOP DRAWING FOR APPROVAL A MINIMUM OF TWO WEEK PRIOR TO POUR. 2. CONSTRUCTION JOINT LOCATIONS SHALL BE COORDINATED WITH REINFORCING STEEL SUPPLIER AND ERECTOR. 3. ACCEPTABLE JOINT LOCATIONS ARE AS FOLLOWS: a. FOR BEAMS NOT SUPPORTING INTERSECTING BEAMS: PLACE JOINT MIDDLE THIRD OF SPAN. b. FOR BEAMS SUPPORTING INTERSECTING BEAMS, CHECK WITH STRUCTURAL ENGINEER. 4. FOR JOINT LOCATIONS OTHER THAN WITHIN MIDDLE THIRD OF SPAN, CONTRACTOR SHALL COORDINATE REQUIRED ADDITIONAL REINFORCEMENT WITH THE ENGINEER ON THE SHOP DRAWINGS. TURN GRADE BM DOWN TO TOP OF PILE CAP WHERE TOP OF PILE CAP IS BELOW BOT OF GRADE BM NOTES: 1. GRADE BEAMS SHALL BE POURED MONOLITHICALLY AROUND CORNERS. REFER TO TYPICAL GRADE BEAM CONSTRUCTION JOINT DETAIL FOR ACCEPTABLE CONSTRUCTION JOINT LOCATIONS. NOTES: 1. GRADE BEAMS SHALL BE POURED MONOLITHICALLY AT INTERSECTIONS. REFER TO TYPICAL GRADE BEAM CONSTRUCTION JOINT DETAIL FOR ACCEPTABLE CONSTRUCTION JOINT LOCATIONS. #4 DOWELS @12" CENTERED ON GRADE BM DRILL AND EPOXY 8" INTO EXIST PILE CAP WITH HILTI HIT RE 500-SD ADHESIVE AT EXISTING PILE CAP

A/2 + Ld

PROVIDE HALF OF INTERRUPTED REINFORCEMENT PLUS ONE ADDITIONAL BAR OF SAME SIZE ON EACH SIDE OF OPENING

SCHEDULED GRADE BEAM WIDTH W

NOTES: 1. WHERE GRADE BEAMS OF UNEQUAL DEPTH FRAME TO THE SAME SUPPORT, TOP OF SUPPORT SHALL BE AT THE BOTTOM OF THE DEEPEST GRADE BEAM. 2. REFER TO GENERAL NOTES FOR CLEAR COVER AT SIDES, TOP AND BOTTOM OF BEAM.

12

TYPICAL OPENING IN CONCRETE SLAB OR WALL

NO SCALE

03300-FL-SLOPG-01 COPYRIGHT WALTER P. MOORE AND ASSOCIATES, INC. 2010

11

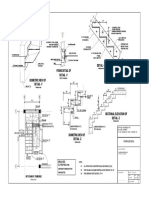

TYPICAL GRADE BEAM CONSTRUCTION JOINT

NO SCALE

03251-FN-GRABM-01 COPYRIGHT WALTER P. MOORE AND ASSOCIATES, INC. 2011

10

TYPICAL GRADE BEAM REINFORCING STEEL SPLICE AT CORNERS (PLAN VIEW)

NO SCALE

03300-FN-GBCOR-01 COPYRIGHT WALTER P. MOORE AND ASSOCIATES, INC. 2011

TYPICAL GRADE BEAM "T" INTERSECTION TOP BAR PLACEMENT DIAGRAM

NO SCALE

03300-FN-GBINT-01 COPYRIGHT WALTER P. MOORE AND ASSOCIATES, INC. 2011

TYPICAL GRADE BEAM TO PILE CAP ATTACHMENT

NO SCALE

TYPICAL INTERIOR GRADE BEAM

NO SCALE

03300-FN-GRABM-01 COPYRIGHT WALTER P. MOORE AND ASSOCIATES, INC. 2011

Last Plotted: 5/8/2013 11:03:11 AM

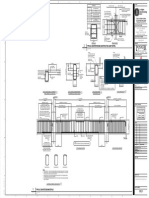

SCHEDULED COLUMN VERTICAL REINFORCEMENT AND TIES

CL COLUMN AND CAP, UNLESS NOTED OTHERWISE 1 ADDITIONAL SET OF TIES AT EACH END OF LAP SPLICE 2'-0" TYPICAL 4" MINIMUM CLEAR REFER TO PLAN TOP OF SLAB VERTICAL SLEEVES COMPACTED SUBGRADE OVER CAP B/3 4" MINIMUM FACE OF COLUMN ADDITIONAL REINFORCEMENT, REFER TO SECTION SCHEDULED BEAM REINFORCEMENT NOTES: 1. GENERAL CONTRACTOR SHALL COORDINATE REQUIRED BEAM SLEEVES WITH MECHANICAL, ELECTRICAL, AND PLUMBING CONTRACTORS. REQUIRED SLEEVES MAY OR MAY NOT BE SHOWN ON THE STRUCTURAL DRAWINGS. GENERAL CONTRACTOR SHALL SUBMIT PLAN SHOWING LAYOUT OF ALL SLEEVES WITH FORMWORK SHOP DRAWING SUBMITTAL. 2. SLEEVES SHALL BE LOCATED WITHIN THE MIDDLE THIRD OF THE SCHEDULED BEAM WIDTH. 3. CONTINUOUS BEAM REINFORCEMENT MAY BE SLIGHTLY DISPLACED (3" MAXIMUM) OR ADJACENT BARS BUNDLED (2 BAR BUNDLES MAXIMUM) TO FACILITATE SLEEVE INSTALLATION. DO NOT CUT, OFFSET, OR BEND REINFORCEMENT. 4. SLEEVES OCCURRING ON OPPOSITE SIDES OF A COLUMN MUST BE IN LINE. 5. THE OUTSIDE DIAMETER OF A SLEEVE MAY NOT EXCEED 15% OF THE SCHEDULED WIDTH OF THE BEAM THROUGH WHICH IT MUST PASS. 6. THE CONTRACTOR SHALL CONTACT THE ENGINEER OF RECORD WHEN A SLEEVE SIZE OR LOCATION DOES NOT MEET THE ABOVE CONDITIONS. 7. SCHEDULED BEAM STIRRUPS NOT SHOWN FOR CLARITY. PENETRATION HEIGHT D/3 D/3 MINIMUM MINIMUM NOTES: 1. GENERAL CONTRACTOR SHALL COORDINATE LOCATION, SIZE, AND ELEVATION AND INCLUDE IN HIS CONTRACT PRICE ALL REQUIRED HORIZONTAL PENETRATIONS THROUGH CONCRETE BEAMS WHETHER SHOWN ON STRUCTURAL DRAWINGS OR NOT. 2. WHERE BEAM PENETRATIONS ARE REQUIRED BUT ARE NOT SPECIFICALLY DETAILED ON THE STRUCTURAL DRAWINGS, CONTRACTOR SHALL SUBMIT DRAWINGS SHOWING DIMENSIONS AND LOCATIONS OF ALL REQUIRED PENETRATIONS FOR REVIEW AND APPROVAL. 3. "D" DENOTES THE DEPTH OF BEAM. 4. CLEAR SPACING BETWEEN PENETRATIONS SHALL BE 24" MINIMUM UNLESS NOTED OTHERWISE BY THE STRUCTURAL ENGINEER. 5. PENETRATIONS SHALL BE LOCATED ACCORDING TO THE FOLLOWING CRITERIA: a. FOR BEAMS NOT SUPPORTING INTERSECTING BEAMS LOCATE PENETRATIONS WITHIN TWO FEET EITHER SIDE OF BEAM MIDSPAN. b. FOR BEAMS SUPPORTING INTERSECTING BEAMS CHECK WITH STRUCTURAL ENGINEER. 6. PENETRATION WIDTH MUST NOT EXCEED PENETRATION HEIGHT, UNLESS NOTED OTHERWISE ON THE STRUCTURAL DRAWINGS. 7. FOR LOCATIONS AND/OR SIZES OF PENETRATIONS NOT CONFORMING TO THE ABOVE CRITERIA AND NOT OTHERWISE DETAILED ON THE STRUCTURAL DRAWINGS, CONTRACTOR SHALL COORDINATE REQUIRED ADDITIONAL REINFORCEMENT WITH THE STRUCTURAL ENGINEER. 8. PROVIDE THE FOLLOWING REINFORCEMENT AT EACH SLEEVE, UNLESS NOTED OTHERWISE ON THE STRUCTURAL DRAWINGS: 1-#5 TOP AND BOTTOM AT BEAMS WITH WIDTHS LESS THAN 9". 2-#5 TOP AND BOTTOM AT BEAMS WITH 2-LEG STIRRUPS. 4-#5 TOP AND BOTTOM AT BEAMS WITH 4-LEG STIRRUPS. "N"-#5 TOP AND BOTTOM AT BEAMS WITH "N"-LEG STIRRUPS. 9. PROVIDE ADDITIONAL STIRRUPS ABOVE AND BELOW PENETRATIONS AT SPACING NOT TO EXCEED ONE THIRD OF THE SCHEDULED STIRRUP SPACING, UNLESS DETAILED OTHERWISE ON THE STRUCTURAL DRAWINGS. 10. SCHEDULED BEAM STIRRUPS NOT SHOWN FOR CLARITY.

PER COLUMN SCHEDULE

3"

LAP SPLICE LENGTH

0"

3" MAXIMUM

ADDITIONAL REINFORCEMENT AT EACH PENETRATION, REFER TO NOTE 8

PLAN

BEAM TOP AND BOTTOM REINFORCEMENT

PROVIDE (2) ADDITIONAL STIRRUPS EACH SIDE OF EACH PENETRATION TO MATCH SCHEDULED BEAM STIRRUPS REFER TO NOTE 9 MINIMUM PENETRATION HEIGHT SQUARE OR RECTANGULAR PENETRATION

REFER TO NOTE 9 ROUND PENETRATION

CAP THICKNESS

SCHEDULED

SCHEDULED BEAM WIDTH, B

REFER TO PLAN TOP OF CAP SCHEDULED CAP REINFORCEMENT, REFER TO TYPICAL CAP DETAIL

0"

B/3

VERTICAL SLEEVE

SCHEDULED BEAM DEPTH, D

BEAM DEPTH, D

SCHEDULED BEAM TOP REINFORCEMENT

B/3

D/3

D/3

REFER TO TYPICAL CAP DETAIL COLUMN BELOW SCHEDULED COLUMN DOWELS WITH STANDARD HOOKS SUPPORTED ON CAP BOTTOM REINFORCEMENT CONCRETE PILES, REFER TO OTHER DETAILS FOR LAYOUT ADDITIONAL TIES AROUND DOWELS, TOP AND BOTTOM PROVIDE ONE SET OF ADDITIONAL STIRRUPS ON EACH SIDE OF SLEEVE (NOT SCHEDULED)

MINIMUM

D/3

D/3

PLAN

EDGE OF BEAM OR GIRDER BELOW

SECTION

PROVIDE ADDITIONAL 2-#5 ON EACH SIDE OF BEAM CENTERED ON SLEEVE, EXTEND 2'-0" MINIMUM EACH WAY PAST SLEEVE

D/3

17

B

TYPICAL CONCRETE COLUMN ON PILE CAP

NO SCALE

02350-FN-PCAP-01 COPYRIGHT WALTER P. MOORE AND ASSOCIATES, INC. 2010

SCHEDULED BEAM BOTTOM REINFORCEMENT

2" TYPICAL 1 1/2" CLEAR 2'-0" MINIMUM TYPICAL PENETRATION WIDTH, REFER TO NOTE 6

ADDITIONAL REINFORCEMENT AT EACH PENETRATION, REFER TO NOTE 8

0 0

ELEVATION

2" TYPICAL 1 1/2" CLEAR 2'-0" MINIMUM TYPICAL PENETRATION WIDTH, REFER TO NOTE 6

16

TYPICAL VERTICAL PENETRATION IN CONCRETE BEAM

NO SCALE

03300-FL-BMOPG-02 COPYRIGHT WALTER P. MOORE AND ASSOCIATES, INC. 2010

14

TYPICAL HORIZONTAL PENETRATION IN CONCRETE BEAM

NO SCALE

03300-FL-BMOPG-01 COPYRIGHT WALTER P. MOORE AND ASSOCIATES, INC. 2012

TOP OF PILE SLAB ON GRADE, REFER TO PLAN ds hs hwash hnut OVERRUN SLAB REINFORCING PER PLAN SLAB ON GRADE, REFER TO PLAN La da hnom hc dc 6" ds hs ds hs hs hwash hnut OVERRUN

SLAB REINFORCING PER PLAN

hnom

La

da La hc dc

da hc dc hnom

8"

Filename: C:\localdata\Kelly-Revit\NOA\NEW ORLEANS ARENA - CENTRAL.rvt

SLAB TURNDOWN AROUND PILE

8"

EQ

EQ

8"

SLAB TURNDOWN AROUND EXIST PILE CAP/GRADE BM La > La,min = hnom + hs + hwash + hnut + OVERRUN EXPANSION AND UNDERCUT La > La,min = hnom + hs SCREW La > La,min = hnom + hs + hwash + hnut + OVERRUN ADHESIVE

6"

1'-0"

EQ

EQ

1'-0" PILE

EXIST PILE CAP/GRADE BM EXIST PILE DEFINITIONS:

ANCHOR SIZE FOR ORDER: DRILLED HOLE:

'da' DIAMETER x 'La' ANCHOR LENGTH 'dc' DIAMETER x 'hc' DEEP

2'-2" 2'-10"

da = dc = ds = La,min = La =

DIAMETER OF ANCHOR (IN) DIAMETER OF HOLE IN CONCRETE = DIAMETER OF DRILL BIT (IN) DIAMETER OF HOLE IN STEEL ATTACHMENT (IN) MINIMUM LENGTH OF ANCHOR (IN) ORDERED LENGTH OF ANCHOR (IN)

hnom = NOMINAL EMBEDMENT DEPTH (IN) hc = DEPTH OF HOLE IN CONCRETE (IN) hs = THICKNESS OF STEEL ATTACHMENT (IN) hwash = THICKNESS OF WASHER (IN) hnut = HEIGHT OF HEX NUT (IN) OVERRUN =1/4" UNLESS NOTED OTHERWISE

23

Printed on 30% Post-Consumer Recycled Content Paper

TYPICAL PILE AT SLAB ON GRADE

NO SCALE

22

5

TYPICAL EXISTING COMPOSITE PILE WITH CAP AT NEW SLAB ON GRADE

NO SCALE

CONTRACTOR AND INSTALLER NOTES: 1. ONLY POST-INSTALLED ANCHOR PRODUCTS SPECIFIED IN THE CONTRACT DOCUMENTS SHALL BE USED WHERE SPECIFIED IN THE CONTRACT DOCUMENTS. THE CONTRACTOR SHALL PROVIDE SIGNED AND SEALED CALCULATIONS TO THE ENGINEER OF RECORD (EOR) FOR ANCHOR PRODUCTS SUBSTITUTED FOR THOSE INDICATED IN THE CONTRACT DOCUMENTS. THE CONTRACTOR SHALL OBTAIN APPROVAL FROM THE EOR PRIOR TO USING POST-INSTALLED ANCHORS FOR MISSING OR MISPLACED CAST-IN ANCHORS AND REINFORCEMENT. 2. ANCHOR LENGTHS SPECIFIED IN THE CONTRACT DOCUMENTS INDICATE THE NOMINAL EMBEDMENT DEPTH . REFER TO THE ANCHOR TYPE FOR THE DEFINITION OF NOMINAL EMBEDMENT DEPTH 'hnom'. IT IS THE RESPONSIBILITY OF THE CONTRACTOR TO DETERMINE THE CORRECT ANCHOR LENGTH 'La' FOR ORDER BASED ON THE SPECIFIED NOMINAL EMBEDMENT DEPTH, ATTACHMENT THICKNESS AND OTHER ANCHOR CHARACTERISTICS NOTED. 3. MINIMUM ANCHOR LENGTH 'La,min' IS DETERMINED AS SHOWN FOR EACH ANCHOR. ORDER AND INSTALL AN ANCHOR LENGTH EQUAL TO OR GREATER THAN THIS VALUE. INSTALLED ANCHOR LENGTHS SHALL NOT HAVE NOMINAL EMBEDMENT DEPTHS THAT EXCEED THEIR CORRESPONDING MINIMUM CONCRETE THICKNESS LIMITS. REFER TO ANCHOR'S ICC-ES EVALUATION SERVICE REPORT (ESR). 4. REFER TO THE ANCHOR'S ICC-ES EVALUATION SERVICE REPORT (ESR) FOR DRILL BIT TYPE AND DIAMETER, AND DEPTH OF HOLE TO BE DRILLED IN THE CONCRETE. 5. FOLLOW THE MANUFACTURER'S PRINTED INSTALLATION INSTRUCTIONS (MPII).

6.

7. 8. 9.

PRIOR TO STEEL FABRICATION OR DRILLING OF EXISTING CONCRETE LOCATE EXISTING REINFORCING STEEL AND PRESTRESSING STRANDS (IF APPLICABLE) USING GROUND PENETRATING RADAR (GPR) OR EQUIVALENT NON-DESTRUCTIVE METHODS. COORDINATE HOLE LOCATIONS TO AVOID EXISTING REINFORCING STEEL. IF RESULTING ANCHOR OR REBAR PATTERN DIFFERS FROM THAT SHOWN ON THE CONTRACT DOCUMENTS, FORWARD EACH NEW PATTERN TO THE ENGINEER FOR REVIEW AND APPROVAL. AFTER APPROVAL, FABRICATE CONNECTIONS, ANGLES OR PLATES AFTER ANCHORS HAVE BEEN INSTALLED TO MATCH AS-BUILT ANCHOR PATTERN. CORING OF CONCRETE TO INSTALL ANCHORS OR REBAR IS NOT ALLOWED. HAMMER DRILLING IS THE ONLY APPROVED METHOD FOR INSTALLING ANCHORS OR REBAR INTO HARDENED CONCRETE. HOLES THAT HAVE BEEN DRILLED INTO EXISTING CONCRETE BUT ABANDONED SHALL BE FILLED WITH EPOXY PER SPECIFICATION 03 30 00. HOLES SHALL BE PREPARED PER MANUFACTURERS INSTRUCTIONS PRIOR TO EPOXY INJECTION. SEE SPECIFICATIONS 033000 AND 014529 FOR ADDITIONAL INFORMATION REGARDING POST-INSTALLED ANCHOR AND REBAR INSTALLATION AND REQUIRED INSPECTIONS.

21

4

TYPICAL POST-INSTALLED ANCHOR AND REBAR INFORMATION

NO SCALE

05500-CN-PIANC-01 COPYRIGHT WALTER P. MOORE AND ASSOCIATES, INC. 2011

2

2"

0

3

A

6

" -6 2'

PROJECT

NEW ORLEANS ARENA ENHANCEMENTS 2012 ARENA RENOVATION & EXPANSION LSED # NOA-ENH-2012-AFC35.4M

New Orleans Arena 1501 Girod Street New Orleans, LA 70113

CLIENT

LOUISIANA STADIUM AND EXPOSITION DISTRICT

1500 Girod Street New Orleans, LA 70112

ARCHITECTS

AECOM LOUISIANA, A PROFESSIONAL CORPORATION

2380 McGee Suite 200 Kansas City, Missouri 64108 816.561.4443 tel 816.561.2863 fax www.aecom.com

ESKEW+DUMEZ+RIPPLE

365 Canal Street Suite 3150 New Orleans, LA 70130 504.561.8686 tel 504.522.2253 fax www.eskewdumezripple.com

MANNING ARCHITECTS

650 Poydras Street Suite 1250 New Orleans, LA 70130 504.412.2000 tel 504.412.2001 fax www.manningarchitects.com

CONSULTANTS

CIVIL AECOM

232 Third Street, Suite 201 Baton Rogue, LA 70801 225.663.4309 tel www.aecom.com

CENTERLINE BEAM AND FOOTING TO COINCIDE UNLESS NOTED OTHERWISE POUR SLAB DOWN ONTO TOP OF GRADE BEAM

LANDSCAPE AECOM

1360 Peachtree Street NE Suite 500 Atlanta, GA 30309 404.965.9627 tel www.aecom.com

COST ESTIMATING DAVIS LANGDON An AECOM Company

710 Second Avenue Suite 100 Seattle, WA 98104 206.343.8119 tel 206.343.8541 fax www.davislangdon.com

CODE CONSULTANT FP&C Consultants, Inc.

3770 Broadway Kansas City, MO 64111 816.931.3777 tel 816.931.3378 fax www.fpc-consultants.com

BRANDING/GRAPHICS INFINITE SCALE DESIGN GROUP

16 Exchange Place Salt Lake City, UT 84111 801.363.1881 tel 801.363.1841 fax www.infinitescale.com

FOOD SERVICE CONSULTANT S20 CONSULTANTS, INC.

452 W. James Way Cary, IL 60013 224.717.1999 tel 847.516.5855 fax www.S20Consultants.net

ENGINEERING MAZZETTI NASH LIPSEY BURCH

650 Poydras Street Suite 2242 New Orleans, LA 70130 615.329.4460 tel 615.329.3660 fax www.mazzetti.com

STRUCTURAL WALTER P MOORE

920 Main Street, Tenth Floor Kansas City, MO 64105 816.701.2100 tel 816.701.2200 fax www.walterpmoore.com

SPORTS TECHNOLOGIES WRIGHTSON JOHNSON HADDON & WILLIAMS

4801 Spring Valley Road Suite 113 Dallas, TX 75244 972.934.3700 tel 972.934.3720 fax www.wjhw.com

REGISTRATION

CONFORMED SET

PACKAGE ISSUED DATE: 2013.05.08

ISSUE / REVISION

1 2013.02.13 NO. DATE

ADDENDUM #7 DESCRIPTION

KEY PLAN

PROJECT NORTH

PROJECT NUMBER

60263613

SHEET TITLE

FOUNDATION TYPICAL DETAILS AND SCHEDULES

SHEET NUMBER

S0.00.10

You might also like

- Hi Tracy: Total Due Here's Your Bill For JanuaryDocument6 pagesHi Tracy: Total Due Here's Your Bill For JanuaryalexNo ratings yet

- Method Statement For Steel Structure & Erection PDFDocument16 pagesMethod Statement For Steel Structure & Erection PDFDomie Neil Bucag Salas83% (24)

- Pile NotesDocument16 pagesPile NotesSatya kaliprasad vangara100% (1)

- s5-1-2 - Typical Steel Beam DetailsDocument1 pages5-1-2 - Typical Steel Beam DetailsMihai CojocaruNo ratings yet

- Roof Truss Span TableDocument1 pageRoof Truss Span TableWilliam100% (1)

- Individual Drawings Architectural PDFDocument56 pagesIndividual Drawings Architectural PDFVanessa ChuaNo ratings yet

- E-2 Sidewalk Ramp With Handrails Section - 201407301802192344Document1 pageE-2 Sidewalk Ramp With Handrails Section - 201407301802192344Dhina karan75% (4)

- s0!00!20 - Steel Framing Typical DetailsDocument1 pages0!00!20 - Steel Framing Typical DetailshuyxpkissNo ratings yet

- Structural Engineering CAD Drawing Steel Timber PDFDocument6 pagesStructural Engineering CAD Drawing Steel Timber PDFSushil DhunganaNo ratings yet

- Multi-Storied Steel Building Design and ConstructionDocument24 pagesMulti-Storied Steel Building Design and ConstructionPrashant100% (1)

- Labone Office Complex Structural Design Report Rev 01 PDFDocument99 pagesLabone Office Complex Structural Design Report Rev 01 PDFBoris Escubio100% (1)

- General Notes: Roof Slab PlanDocument1 pageGeneral Notes: Roof Slab PlansolebNo ratings yet

- LRFD For MicropilesDocument108 pagesLRFD For MicropilesJonathan Bennett PE DGE100% (2)

- Structural DrawingsDocument10 pagesStructural DrawingsEdin MazalovicNo ratings yet

- Metal Building Software, Inc.: Element in AnalysisDocument11 pagesMetal Building Software, Inc.: Element in Analysisgenkatrov100% (1)

- Structural NotesDocument4 pagesStructural NotesGerald GeCu Cuñado50% (2)

- RevitKeynotes Imperial 2004Document90 pagesRevitKeynotes Imperial 2004huyxpkiss100% (1)

- Challan Form OEC App Fee 500 PDFDocument1 pageChallan Form OEC App Fee 500 PDFsaleem_hazim100% (1)

- s5-3-1 - Typical Composite and Steel Deck DetailsDocument1 pages5-3-1 - Typical Composite and Steel Deck Detailscewaleed2590No ratings yet

- Typical Deck EdgeDocument1 pageTypical Deck EdgeShane AndersonNo ratings yet

- s5-0-2 - Typical Braced Frame Connection DetailsDocument1 pages5-0-2 - Typical Braced Frame Connection DetailsCancio Florez100% (1)

- Typical Structural Abbreviations Typical Symbols Legend Typical Plan NotesDocument33 pagesTypical Structural Abbreviations Typical Symbols Legend Typical Plan NotesINNOBUNo7No ratings yet

- Structural - AOBDocument21 pagesStructural - AOBMr. Mark B.No ratings yet

- Concrete Slender Wall DesignDocument9 pagesConcrete Slender Wall Designamokhta100% (1)

- Typical Detail PDFDocument20 pagesTypical Detail PDFkhaingkhaing528100% (1)

- 01.structural FLATDocument36 pages01.structural FLATin678No ratings yet

- DetailingDocument1 pageDetailingGodino ChristianNo ratings yet

- 15-320 Struct DWG Full SetDocument20 pages15-320 Struct DWG Full SetAnonymous 9MDGo2jNo ratings yet

- Standard Structural Designs For Low Rise Residential BuildingsDocument125 pagesStandard Structural Designs For Low Rise Residential BuildingsUmange RanasingheNo ratings yet

- Design Basis For Roof TrussDocument22 pagesDesign Basis For Roof TrussUmer AziqNo ratings yet

- s0!00!06 - Structural Demolition General NotesDocument1 pages0!00!06 - Structural Demolition General NoteshuyxpkissNo ratings yet

- Repair and RehabilitationDocument22 pagesRepair and RehabilitationConstro FacilitatorNo ratings yet

- Roof DetailsDocument237 pagesRoof DetailsDominic McAndrewNo ratings yet

- Steel Portal Frames: Comparisionof BendingmomentsDocument1 pageSteel Portal Frames: Comparisionof BendingmomentsMuskan KhanNo ratings yet

- Composite Slab DesignDocument8 pagesComposite Slab DesignOladunni AfolabiNo ratings yet

- 4 Double Tee Design PDFDocument19 pages4 Double Tee Design PDFnfaayedNo ratings yet

- Structural Drawings-Brooklyn NYDocument20 pagesStructural Drawings-Brooklyn NYRobert SiqecaNo ratings yet

- Floor Deck CatalogDocument184 pagesFloor Deck CatalogJelean NavalNo ratings yet

- Structural Design Report - AuditoriumDocument22 pagesStructural Design Report - AuditoriumThe Safe Matrix IndiaNo ratings yet

- Reinforcement DetailingDocument47 pagesReinforcement DetailingSun Rise100% (1)

- Ready-Built Steel Structures BrochureDocument26 pagesReady-Built Steel Structures BrochureFauziah AminatunNo ratings yet

- Beam Schedule: 250 3Rd FloorDocument1 pageBeam Schedule: 250 3Rd FloorNhel AlbrechtNo ratings yet

- Technical specifications for reinforced concrete structural designDocument11 pagesTechnical specifications for reinforced concrete structural designMD Shakil AhmedNo ratings yet

- Crack Width Check (CoP Concrete 2013) CPRDocument4 pagesCrack Width Check (CoP Concrete 2013) CPRAndrew WtchengNo ratings yet

- Use of Bolted Steel Plates For Strengthening of Reinforced Concrete Beams and ColumnsDocument34 pagesUse of Bolted Steel Plates For Strengthening of Reinforced Concrete Beams and Columnszakaria200811060No ratings yet

- Detailing of Concrete Masonry-Solid-Units-140mmDocument40 pagesDetailing of Concrete Masonry-Solid-Units-140mmbrian1mugadzaNo ratings yet

- Steel Floor Decking 05 31 13Document6 pagesSteel Floor Decking 05 31 13Taher AmmarNo ratings yet

- Portal Frame Structures1745,1735Document25 pagesPortal Frame Structures1745,1735Priya Chauhan100% (1)

- Detail - X Detail - Y Isometric View of Fixing Detail Of: Key Plan of StaircaseDocument1 pageDetail - X Detail - Y Isometric View of Fixing Detail Of: Key Plan of StaircaseMuhammadWazimAkramNo ratings yet

- Status-B Approved With Comments:-: 1-The Proposed System Is Subject To Architectural and Shop Drawings ApprovalsDocument60 pagesStatus-B Approved With Comments:-: 1-The Proposed System Is Subject To Architectural and Shop Drawings ApprovalsChandra MohanNo ratings yet

- Hollow Core DesignDocument15 pagesHollow Core DesignMelinda Gordon100% (1)

- CH 12 Connections For Lattice StructuresDocument42 pagesCH 12 Connections For Lattice Structuresamanpreet_ahuja0% (1)

- Structural DrawingsDocument28 pagesStructural DrawingsJason Cuison100% (1)

- 7568-2144 Typical Manhole DetailsDocument1 page7568-2144 Typical Manhole DetailsKhabbab Hussain K-hNo ratings yet

- Ribbed and Waffle SlabsDocument5 pagesRibbed and Waffle SlabsRenzon Sison100% (1)

- Reinforced Concrete Flat Slab Design GuideDocument93 pagesReinforced Concrete Flat Slab Design GuideTan100% (1)

- Metal Buildings: ChangersDocument24 pagesMetal Buildings: ChangersBwabt sathishNo ratings yet

- AISI Wall Stud 2004Document34 pagesAISI Wall Stud 2004MoGHNo ratings yet

- Masonry Chapter 21 - IBC PDFDocument84 pagesMasonry Chapter 21 - IBC PDFShanmuga SundaramNo ratings yet

- Irregular DiaphragmsDocument8 pagesIrregular DiaphragmsJose L Mexia100% (1)

- Generalcons Tructionnot ES: General NotesDocument10 pagesGeneralcons Tructionnot ES: General NotesJejomar MotolNo ratings yet

- DetailDocument1 pageDetailGodino ChristianNo ratings yet

- Typical Concrete Beam Construction Joint Detail: Los Angeles Community College DistrictDocument1 pageTypical Concrete Beam Construction Joint Detail: Los Angeles Community College DistrictMary Emalaine SerranoNo ratings yet

- Tekla - Bridge-Std - Noi Dung Dao TaoDocument3 pagesTekla - Bridge-Std - Noi Dung Dao TaohuyxpkissNo ratings yet

- The Project Benefits of Building InformationDocument6 pagesThe Project Benefits of Building InformationhuyxpkissNo ratings yet

- BS 8666 - 2005 Rebar - Shape - Code PDFDocument1 pageBS 8666 - 2005 Rebar - Shape - Code PDFhuyxpkiss100% (1)

- High Rise BuildingsDocument50 pagesHigh Rise BuildingsMustafa Kutanis88% (17)

- Ts-Cip-Footing-Sample DWGDocument1 pageTs-Cip-Footing-Sample DWGhuyxpkissNo ratings yet

- As 13wi 2Document3 pagesAs 13wi 2huyxpkissNo ratings yet

- Bim PDFDocument10 pagesBim PDFŽanesa LjevoNo ratings yet

- BIM For Cost ManagersDocument23 pagesBIM For Cost ManagersKarthiktrichyNo ratings yet

- RevitKeynotes Metric CustomDocument66 pagesRevitKeynotes Metric CustomFelipe VictorNo ratings yet

- AstmDocument2 pagesAstmanumnedNo ratings yet

- Guidelines and Rules For Detailing Ofreinforcement in Concrete StructuresDocument403 pagesGuidelines and Rules For Detailing Ofreinforcement in Concrete Structuresamino222No ratings yet

- Tekla User Assistance - Understanding Part Orientation - 2015-03-11Document9 pagesTekla User Assistance - Understanding Part Orientation - 2015-03-11LeviMtnNo ratings yet

- Slab ProfilesDocument1 pageSlab ProfileshuyxpkissNo ratings yet

- Tekla Structures 2016 Open API Release NotesDocument8 pagesTekla Structures 2016 Open API Release NoteshuyxpkissNo ratings yet

- Tekla User Assistance - Area Selection in Model Is Missing - 2016-03-22Document2 pagesTekla User Assistance - Area Selection in Model Is Missing - 2016-03-22huyxpkissNo ratings yet

- How to Create Pipe Development Drawings in Tekla StructuresDocument4 pagesHow to Create Pipe Development Drawings in Tekla StructuresanneacesNo ratings yet

- Tekla User Assistance - How To Unwrap Pipes Through The Mean-Dimeter - 2016-03-28Document3 pagesTekla User Assistance - How To Unwrap Pipes Through The Mean-Dimeter - 2016-03-28huyxpkissNo ratings yet

- Tekla User Assistance - Adding Images in A Template - 2014-08-26Document3 pagesTekla User Assistance - Adding Images in A Template - 2014-08-26huyxpkissNo ratings yet

- RF5 - RAFTER+PART - Rev PDFDocument1 pageRF5 - RAFTER+PART - Rev PDFhuyxpkissNo ratings yet

- Tutorials 3DDocument162 pagesTutorials 3DhuyxpkissNo ratings yet

- CaseStudy 3-Bruecken-Projekt US English PrintDocument2 pagesCaseStudy 3-Bruecken-Projekt US English PrinthuyxpkissNo ratings yet

- Tutorials FoundationDocument178 pagesTutorials FoundationhuyxpkissNo ratings yet

- Brochure DK 2015 New 1936Document12 pagesBrochure DK 2015 New 1936huyxpkissNo ratings yet

- CADWorx PID ProfessionalDocument2 pagesCADWorx PID ProfessionalhuyxpkissNo ratings yet

- Beton Arme - Guide de CalculDocument135 pagesBeton Arme - Guide de CalculHung NGUYEN100% (4)

- Product Sheet: Delivering The Best Possible DesignDocument2 pagesProduct Sheet: Delivering The Best Possible Designevonik123456No ratings yet

- MPDS4 Piping 3D Design Add On enDocument2 pagesMPDS4 Piping 3D Design Add On ensjk_akolNo ratings yet

- Cad Wor X Plant ProfessionalDocument2 pagesCad Wor X Plant ProfessionalThanadkitBunkaewNo ratings yet

- Short EssayDocument3 pagesShort EssayBlue PuppyNo ratings yet

- 02-Procedures & DocumentationDocument29 pages02-Procedures & DocumentationIYAMUREMYE EMMANUELNo ratings yet

- Managerial Accounting 12th Edition Warren Test Bank DownloadDocument98 pagesManagerial Accounting 12th Edition Warren Test Bank DownloadRose Speers100% (21)

- Lecture 9-EVENT BUDGETDocument19 pagesLecture 9-EVENT BUDGETAlbina AbilkairNo ratings yet

- Lesson 3 Lymphatic System and Body DefensesDocument10 pagesLesson 3 Lymphatic System and Body DefensesJulio De GuzmanNo ratings yet

- ESS 4104 AssignmentDocument9 pagesESS 4104 AssignmentSamlall RabindranauthNo ratings yet

- CHP - 3 DatabaseDocument5 pagesCHP - 3 DatabaseNway Nway Wint AungNo ratings yet

- Boston Consulting Group Portfolio Analysis MatrixDocument16 pagesBoston Consulting Group Portfolio Analysis MatrixNimish SharmaNo ratings yet

- OutletsDocument226 pagesOutletsPraveen Kumar Saini100% (1)

- Siege by Roxane Orgill Chapter SamplerDocument28 pagesSiege by Roxane Orgill Chapter SamplerCandlewick PressNo ratings yet

- Specification For Diesel Engines: AugustDocument19 pagesSpecification For Diesel Engines: AugustSerge RINAUDONo ratings yet

- SKILLS TRANSFER PLAN FOR MAINTENANCE OF NAVAL EQUIPMENTDocument2 pagesSKILLS TRANSFER PLAN FOR MAINTENANCE OF NAVAL EQUIPMENTZaid NordienNo ratings yet

- GRADE 8 English Lesson on Indian LiteratureDocument3 pagesGRADE 8 English Lesson on Indian LiteratureErold TarvinaNo ratings yet

- Plusnet Cancellation FormDocument2 pagesPlusnet Cancellation FormJoJo GunnellNo ratings yet

- The Revival Strategies of Vespa Scooter in IndiaDocument4 pagesThe Revival Strategies of Vespa Scooter in IndiaJagatheeswari SelviNo ratings yet

- Lesson 1 Intro - LatinDocument11 pagesLesson 1 Intro - LatinJohnny NguyenNo ratings yet

- TarotDocument21 pagesTarotKrystal Jacquot100% (2)

- 15-8377 - 3521 Calandria Communications L. Rivera PDFDocument20 pages15-8377 - 3521 Calandria Communications L. Rivera PDFRecordTrac - City of OaklandNo ratings yet

- Thompson Industrial Products Inc Is A DiversifiedDocument4 pagesThompson Industrial Products Inc Is A DiversifiedKailash KumarNo ratings yet

- The Rescue FindingsDocument8 pagesThe Rescue FindingsBini Tugma Bini Tugma100% (1)

- Corporate Process Management (CPM) & Control-EsDocument458 pagesCorporate Process Management (CPM) & Control-EsKent LysellNo ratings yet

- Subject Object Schede PDFDocument28 pagesSubject Object Schede PDFanushhhkaNo ratings yet

- GST Project ReportDocument29 pagesGST Project ReportHENA KHANNo ratings yet

- Course Title: Cost Accounting Course Code:441 BBA Program Lecture-3Document20 pagesCourse Title: Cost Accounting Course Code:441 BBA Program Lecture-3Tanvir Ahmed ChowdhuryNo ratings yet

- Motivate! 2 End-Of-Term Test Standard: Units 1-3Document6 pagesMotivate! 2 End-Of-Term Test Standard: Units 1-3Oum Vibol SatyaNo ratings yet

- IAS 8 Tutorial Question (SS)Document2 pagesIAS 8 Tutorial Question (SS)Given RefilweNo ratings yet

- History of Filipino Mural (Filipino Americans: A Glorious History, A Golden Legacy)Document9 pagesHistory of Filipino Mural (Filipino Americans: A Glorious History, A Golden Legacy)Eliseo Art Arambulo SilvaNo ratings yet

- C++ Project On Library Management by KCDocument53 pagesC++ Project On Library Management by KCkeval71% (114)