Professional Documents

Culture Documents

Displacement Purge Adsorption

Uploaded by

Nithya RamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Displacement Purge Adsorption

Uploaded by

Nithya RamCopyright:

Available Formats

ulSLACLMLn1 u8CL AuSC81lCn

Adsorbates can be removed from the adsorbent surface by replacing them with a more

preferentially adsorbed species. This displacement fluid, which can be a gas, a vapour or a

liquid, should adsorb about as strongly as the components which are to be desorbed. If the

displacement fluid is adsorbed too strongly then there may be subsequent difficulties in

removing it from the adsorbent.

The mechanism for desorption of the original adsorbate involves 2 aspects:

Partial pressure (or concentration) of original adsorbate in the gas phase surrounding

the adsorbent is reduced

There is competitive adsorption for the displacement fluid. The displacement fluid is

present on the adsorbent and thus will contaminate the product.

One advantage of the displacement fluid method of regeneration is that the net heat generated

or consumed in the adsorbent will be close to zero because the heat of adsorption of the

displacement fluid is likely to be close to that of the original adsorbate. Thus the temperature of

the adsorbent should remain more or less constant throughout the cycle.

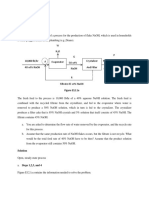

A is the more strongly adsorbed component in the binary feed mixture of (A and B) while D is

the displacement purge gas. The feed mixture of (A and B) is passed through Bed 1 acting as

the adsorber, which is preloaded with D from the previous cycle (when Bed 1 was the

regenerator).

A is adsorbed and the product of a mixture of (B and D) emerges from the top of the column. (B

and D) are easily separated by distillation so that B is collected in a relatively pure state.

The displacement gas D then enters Bed 2 acting as regenerator and from which emerges a

mixture of (A and D). (A and D) can be separated without difficulty in another distillation column.

In effect the original mixture of (A and B), which would have been difficult to separate by PSA or

TSA, is separated by the "intervention" of another strongly adsorbed component D. The ease of

separation of A from D, and B from D, in the additional distillation stages, is crucial in

determining the economies of displacement purge cycle operation.

Examples of commercial processes include the separation of linear paraffins from mixtures

containing branched chain and cyclic isomers in the range of C10 - C18 hydrocarbons.

You might also like

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7From EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7No ratings yet

- Conversion Table (Tabel Konversi)Document1 pageConversion Table (Tabel Konversi)Kevin ArdiansyahNo ratings yet

- Drying of Process MaterialDocument30 pagesDrying of Process MaterialsehagendutNo ratings yet

- Exp 5 Head Loss Due To Friction 2012Document5 pagesExp 5 Head Loss Due To Friction 2012Mohd KhairiNo ratings yet

- Air Pollution Control: Carbon Adsorption For Vocs: Course No: C03-013 Credit: 3 PDHDocument46 pagesAir Pollution Control: Carbon Adsorption For Vocs: Course No: C03-013 Credit: 3 PDHwangbeifuNo ratings yet

- Tugas 1 Termo 2 - Rabu - Putra Maulana - 5213415062Document8 pagesTugas 1 Termo 2 - Rabu - Putra Maulana - 5213415062Putra MaulanaNo ratings yet

- Chapter 10 - EvaporationDocument28 pagesChapter 10 - EvaporationAndrea ZagastizabalNo ratings yet

- Drying 2 PDFDocument75 pagesDrying 2 PDFEli John NovelaNo ratings yet

- Transport ProcessDocument32 pagesTransport Processpidexhitam67% (3)

- Unit-3 Absorption2-DilanDocument29 pagesUnit-3 Absorption2-Dilanchinna erannaNo ratings yet

- 42-Single Effect Evaporator-21-May-2021Material I 21-May-2021 Single Effect EvaporatorDocument8 pages42-Single Effect Evaporator-21-May-2021Material I 21-May-2021 Single Effect EvaporatorAbhishek KarpeNo ratings yet

- Reaktor Trickle BedDocument8 pagesReaktor Trickle BedAgaNo ratings yet

- Thermo Homework 6Document7 pagesThermo Homework 6Danny BoyleNo ratings yet

- Wetted Wall ColumnDocument4 pagesWetted Wall Columnendang dian lestariNo ratings yet

- Unit-3 Absorption2Document43 pagesUnit-3 Absorption2chinna erannaNo ratings yet

- Resumen CH04 FelderDocument45 pagesResumen CH04 Feldercuberbill1980No ratings yet

- Physical Properties TableDocument32 pagesPhysical Properties Tablemidooooo198767% (3)

- Filtrasi-2 No VideosDocument24 pagesFiltrasi-2 No Videostyopra01No ratings yet

- Air BindingDocument8 pagesAir BindingRishabh SethiNo ratings yet

- Azeotropic Mass BalanceDocument25 pagesAzeotropic Mass BalancesowjanyaavkNo ratings yet

- ChE 195 Problem Set No. 2Document1 pageChE 195 Problem Set No. 2Jahz ChannelNo ratings yet

- A Presentaion On DryingDocument40 pagesA Presentaion On DryingMd. Abu Bakar Siddique TayefNo ratings yet

- Mass Transfer Lecture 3-1Document20 pagesMass Transfer Lecture 3-1EDWIN SIMBARASHE MASUNUNGURENo ratings yet

- 4.3. Consider The Flowsheet For The Manufacture of Vinyl Chloride in Figure 4.8Document2 pages4.3. Consider The Flowsheet For The Manufacture of Vinyl Chloride in Figure 4.8Anonymous QwUTQlAO100% (1)

- Transport Phenomena 1Document20 pagesTransport Phenomena 1Kaify PeshmergaNo ratings yet

- Drying Operation: Meika Syahbana RusliDocument69 pagesDrying Operation: Meika Syahbana RusliFrida GinaNo ratings yet

- LO2: Heat ConvectionDocument36 pagesLO2: Heat ConvectionBilal AhmedNo ratings yet

- Gas AbsorptionDocument42 pagesGas AbsorptionRishab Srivatsa100% (1)

- Lampiran A Sudah FinalDocument20 pagesLampiran A Sudah FinalBayu Handika PrasetyoNo ratings yet

- H2O2 TechnologyDocument3 pagesH2O2 TechnologyalijadoonNo ratings yet

- Reactor Report PDFDocument39 pagesReactor Report PDFStheh Ka NkosiNo ratings yet

- Ayırma İşlemleri SorularDocument9 pagesAyırma İşlemleri SorularElif Yaren Öztürk0% (1)

- Chemical Reaction Engineering Chapter 6Document133 pagesChemical Reaction Engineering Chapter 6sc9112008100% (1)

- Wetted-Wall Column: Separation ProcessDocument3 pagesWetted-Wall Column: Separation ProcessHuzaifa AftabNo ratings yet

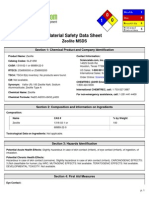

- Msds Asam TaninDocument6 pagesMsds Asam TaninArfin FardiansyahNo ratings yet

- Climbing Film GanganDocument20 pagesClimbing Film GanganAdeniran Joshua50% (2)

- Stripping Notes PDFDocument28 pagesStripping Notes PDFnimi khalidNo ratings yet

- Presentation Lumped Parameter Model, Conservation of Mass, Reaction (Group 6) FixDocument16 pagesPresentation Lumped Parameter Model, Conservation of Mass, Reaction (Group 6) FixPrayogo KuntoroNo ratings yet

- ASTM D 130-10 - Corrosiveness To Copper From Petroleum Products by Copper Strip TestDocument9 pagesASTM D 130-10 - Corrosiveness To Copper From Petroleum Products by Copper Strip TestAnak Ayam100% (1)

- Operasi Teknik Kimia Iii Rizka Amalia, S.T., M.TDocument60 pagesOperasi Teknik Kimia Iii Rizka Amalia, S.T., M.TEnricoNo ratings yet

- Packed Bed ColumnDocument14 pagesPacked Bed ColumnUmar DrazNo ratings yet

- HimmelblauDocument17 pagesHimmelblauadilla nitaaNo ratings yet

- Ruzicka CP Estimation MethodDocument11 pagesRuzicka CP Estimation MethodAndreea Cristina PetcuNo ratings yet

- CLO-2 Packed and Fluidized BedsDocument44 pagesCLO-2 Packed and Fluidized BedskhalifaNo ratings yet

- CPE533 Gas Absorption Full Lab ReportDocument28 pagesCPE533 Gas Absorption Full Lab ReportKhairul Fathy Ibnu AsrarNo ratings yet

- SKC4333Dist Zura2010Document69 pagesSKC4333Dist Zura2010Amirul AfiqNo ratings yet

- Two-Phase Flow Gas-Liquid Gas-Solid Liquid-Liquid Liquid-SolidDocument9 pagesTwo-Phase Flow Gas-Liquid Gas-Solid Liquid-Liquid Liquid-SolidKarina MandasariNo ratings yet

- Zeolit PDFDocument5 pagesZeolit PDFYuniAnggraeniNo ratings yet

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationFrom EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNo ratings yet

- Supercritical Fluid ExtractionDocument5 pagesSupercritical Fluid ExtractionUsman WaheedNo ratings yet

- Pressure Swing AdsorptionDocument10 pagesPressure Swing Adsorptionradhika.rdtNo ratings yet

- Absorption Lecture Note - DR Akinsiku PDFDocument7 pagesAbsorption Lecture Note - DR Akinsiku PDFGlory UsoroNo ratings yet

- Chapter 12 AdsorptionDocument52 pagesChapter 12 Adsorptionainmnrh100% (1)

- Absorption EnglishDocument1 pageAbsorption English菖蒲素敵No ratings yet

- Linde PSAsDocument8 pagesLinde PSAsSiji AntonyNo ratings yet

- MASS TRANSFER - 11.weekDocument27 pagesMASS TRANSFER - 11.weekesra göçenNo ratings yet

- Gas RPDocument46 pagesGas RPdhruvNo ratings yet

- Cap. 6. Seader Adsorcion y StrippingDocument32 pagesCap. 6. Seader Adsorcion y StrippingJuan PortillaNo ratings yet

- India's ASEAN Approach - Acting East - The DiplomatDocument3 pagesIndia's ASEAN Approach - Acting East - The DiplomatNithya RamNo ratings yet

- Effect UationDocument38 pagesEffect UationNithya RamNo ratings yet

- Basic Features of Indian and Western Political Thought - A Comparative AnalysisDocument27 pagesBasic Features of Indian and Western Political Thought - A Comparative AnalysisNithya Ram60% (5)

- IASbaba's Prelims Capsule-1Document29 pagesIASbaba's Prelims Capsule-1Nithya RamNo ratings yet

- India's Rare Earths Industry 0Document7 pagesIndia's Rare Earths Industry 0Nithya RamNo ratings yet

- Har Khet Ko PaniDocument6 pagesHar Khet Ko PaniNithya RamNo ratings yet

- District Wise DetailsDocument7 pagesDistrict Wise DetailsNithya RamNo ratings yet

- ElectrophoresisDocument2 pagesElectrophoresisNithya RamNo ratings yet

- Displacement Purge AdsorptionDocument2 pagesDisplacement Purge AdsorptionNithya RamNo ratings yet

- Hybrid MembranesDocument1 pageHybrid MembranesNithya RamNo ratings yet

- Iso 14000 ConceptsDocument12 pagesIso 14000 ConceptstanglarNo ratings yet

- CS461-06 RiskAnalysisDocument33 pagesCS461-06 RiskAnalysisAdrian Bagayan100% (1)

- P 11 Intro 2 EmsDocument22 pagesP 11 Intro 2 EmsNithya RamNo ratings yet

- Unit 5 1. LyophilizationDocument2 pagesUnit 5 1. LyophilizationNithya RamNo ratings yet

- Principles of PervaporationDocument10 pagesPrinciples of PervaporationNithya RamNo ratings yet

- Pressure Swing AdsorptionDocument2 pagesPressure Swing AdsorptionNithya Ram0% (1)

- ElectrophoresisDocument2 pagesElectrophoresisNithya RamNo ratings yet

- Bio SeparationsDocument1 pageBio SeparationsNithya RamNo ratings yet

- Affinity ChromatographyDocument3 pagesAffinity ChromatographyNithya Ram100% (1)

- CBSE Class 12 Syllabus For Accountancy 2014-2015Document5 pagesCBSE Class 12 Syllabus For Accountancy 2014-2015cbsesamplepaperNo ratings yet

- Cross Flow FilterationDocument4 pagesCross Flow FilterationNithya Ram100% (1)