Professional Documents

Culture Documents

Marc Mentat FEM PDF

Uploaded by

Mahmud Kori EffendiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Marc Mentat FEM PDF

Uploaded by

Mahmud Kori EffendiCopyright:

Available Formats

Composite Structures 71 (2005) 140158 www.elsevier.

com/locate/compstruct

Three-dimensional nite element analysis of single-bolt, single-lap composite bolted joints: part Imodel development and validation

M.A. McCarthy *, C.T. McCarthy 1, V.P. Lawlor, W.F. Stanley

Department of Mechanical and Aeronautical Engineering, Composites Research Centre, Materials and Surface Science Institute, University of Limerick, Limerick, Ireland Available online 5 November 2004

Abstract Three-dimensional nite element models have been developed to study the eects of bolthole clearance on the mechanical behaviour of bolted composite (graphite/epoxy) joints. The joint type studied was single-bolt, single-lap, which is a standard test conguration in both a civilian and a military standard for composite joints. In this Part I of a two part paper the model is constructed in the non-linear nite element code MSC.Marc and attempts are made to validate it by comparing results with experiments and other nite element solutions generated in a European project on composite bolted joints. Issues in modelling the contact between the joint parts, which aect the accuracy and eciency of the model are presented. Experimental measurements of surface strains and joint stiness are compared with results from a nite element parameter study involving variations in mesh density, element order, boundary conditions, analysis type and material modelling. The ability of the models to capture three-dimensional eects such as secondary bending and through-thickness variations in stress and strain is evaluated, and the presence of mathematical singularities in such models is highlighted. The validated model is used in Part II to investigate the eects of clearance on joint stiness, stress state and failure initiation. 2004 Elsevier Ltd. All rights reserved.

Keywords: Composite; Bolted Joints; Finite element analysis; Clearance; Validation

1. Introduction Bolted joints are critical elements in designing safe and ecient aerospace structures from carbonbre reinforced polymer materials. Because joints represent potential weak points in the structure, the design of the joint can have a large inuence over the structural integrity and load-carrying capacity of the overall structure. Due to factors such as bolt bending and tilting, bolt pre-load (due to torquing) and secondary bending,

Corresponding author. Tel.: +353 61 202222; fax: +353 61 202944. E-mail address: michael.mccarthy@ul.ie (M.A. McCarthy). 1 Present address: Materials Ireland, Department of Mechanical Engineering, University College Dublin, Dublin 4, Ireland. 0263-8223/$ - see front matter 2004 Elsevier Ltd. All rights reserved. doi:10.1016/j.compstruct.2004.09.024

*

stresses and strains in bolted joints vary three-dimensionally. In addition, in composite joints, the stress-eld near the hole is three-dimensional due to the presence of interlaminar stresses at the free edges, and the bearing mode of failure is particularly dependent on such three-dimensional eects. Methods for analysis of composite joints include analytical methods [15], and nite element methods [625]. Despite the three-dimensional nature of the problem, to date the majority of nite element studies have been two-dimensional [614]. This is mainly due to the significant requirements for model development time and processing power with three-dimensional analysis. With the recent increases in computing power, threedimensional nite element modelling of composite

M.A. McCarthy et al. / Composite Structures 71 (2005) 140158

141

bolted joints has become feasible and such analyses have begun to appear in the open literature [1525]. In these studies, to account for through-thickness variations in stiness, the laminates have been modelled either with one or more orthotropic solid elements per ply [17,20,21] or with layered solid elements representing multiple plies [19]. Some of the earlier studies [15 17,24] did not consider contact between the bolt and the hole, but made simplifying assumptions to simulate the presence of the bolt, such as xing the radial displacement of the nodes around the hole [17,24]. In later studies, explicit modelling of contact between the bolt and hole has been used [1921,23]. In these cases, nonlinear nite element codes were needed to solve for the continuously changing boundary conditions brought about by changes in contact between the bolt and laminate. Some authors modelled the bolt as a rigid cylindrical contact surface [20,21], while others considered it as elastic and modelled it with three-dimensional nite elements [19,23]. As part of a collaborative European Union research project, BOJCASBolted Joints in Composite Aircraft Structures [26], several approaches are being examined for modelling and designing composite bolted joints in the future. One of these approaches is threedimensional nite element analysis, which currently can be regarded as a research rather than a design tool. In the future, processing power can be expected to increase to the point where routine three-dimensional analysis of bolted joints in a design environment will be feasible. However, to support such advancement, much work is needed to show that three-dimensional nite element models can provide distinct advantages over existing design rules [27,28] or two-dimensional analysis programs [29,30]. Furthermore, such threedimensional models need to be validated against experiments, and the best approaches for producing accurate yet ecient models need to be determined. The aim of this rst part of a two-part paper is to examine dierent approaches to three-dimensional modelling of composite bolted joints, in terms of their ability to produce accurate results with a reasonable level of computational eciency. For the investigation, a nite element model of a single-bolt, single-lap composite joint is developed in the non-linear nite element code MSC.Marc. The accuracy of the model is critically examined by comparing results with experiments and other nite element solutions generated in the research project BOJCAS. Attempts are made to improve the model through a series of mesh renements, increases in element order, and modications to boundary conditions, material modelling and analysis type. The singlebolt, single-lap joint was chosen as it provides a suitable test case for three-dimensional modelling since it involves secondary bending and three-dimensional variations in stress and strain. It is also one of the standard

congurations for characterisation of mechanically fastened composite joints in MIL-HDBK-17 [31,32], and in ASTM standard D 5961/D 5961M-96 [33]. MILHDBK-17 states that the single-lap conguration is more representative than the double-lap conguration of most critical aircraft bolted joint applications. In the second part of this paper, the usefulness of three-dimensional analysis is demonstrated by studying the eects of bolthole clearance in such single-lap joints. Since clearance signicantly alters the threedimensional stress state in the laminates it provides an interesting topic for three-dimensional modelling. In addition, no three-dimensional study on variable clearance was found in the open literature and so this work adds to existing two-dimensional investigations [3,9,12,14,34]. The only results on clearance presented in Part I of this paper are those relevant to the validation exercise. Part II concentrates entirely on the eect of clearance on joint stiness, stress state and failure initiation.

2. Problem description An experimental study, which involved over 80 tests to failure and percentages of failure, was carried out on the eects of clearance in single-lap, single-bolt joints. This study was reported on in [35], so only brief details are given here. The specimen geometry is shown in Fig. 1. The joint geometry is based on the ASTM standard D 5961/D 5961 M-96, [33]. The geometric ratios, w/d = 6, e/d = 3, d/t = 1.6, were designed to induce bearing failure. The carbon bre/epoxy material used in the experiments was HTA/6376, manufactured by Hexcel Composites, a high-strength material currently used in the aircraft industry. Two dierent lay-ups were used: one quasi-isotropic with stacking sequence [45/0/ 45/90]5s, the other zero-dominated with stacking sequence [(45/02/45/90)345/02/45/0]s. The latter lay-up is representative of lay-ups suitable for composite aircraft wing skins. The ply thickness was nominally 0.13 mm, yielding a nominal laminate thickness of 5.2 mm when cured. The bolts used were aerospace grade Titanium alloy fasteners with nominal diameter 8 mm. Steel nuts together with steel washers were also used. The clearances chosen for this study are shown in Table 1. For a nominal 8 mm hole diameter, they represent percentage clearances of 0%, 1%, 2% and 3% and are respectively coded C1C4. Clearances C1 and C2 are within current aerospace tolerances, while C3 and C4 are slightly outside. The latter two are thus of interest in examining the possible eects of out-of-tolerance aerospace holes (or fasteners), and also in non-aerospace applications. For further details on the rationale for choosing these clearances, see [35]. The clearances

142

M.A. McCarthy et al. / Composite Structures 71 (2005) 140158

Fig. 1. Specimen geometry.

Table 1 Clearances in present study Clearance code C1 C2 C3 C4 Nominal clearance (lm) 0 80 160 240

3. Finite element model Several models of varying complexity were constructed for this study. Most of these were a renement of a Base Model and are discussed later (Section 4). This section describes the development of the Base Model of the bolted joint. 3.1. Finite element mesh

were obtained experimentally using four reamers of different diameters, specially manufactured for this study to a tight tolerance, by an aerospace supplier. In the experiments modelled here, the bolts were torqued to 0.5 N m, which was regarded as the lowest, repeatable torque that could be applied, hence representing nger-tight conditions. Finger-tight represents the worst-case scenario of a bolt loosened during fatigue loading from an initial fully torqued condition. To remove bolt position as a variable in the current study (especially for the larger clearance specimens), a mounting jig was designed to locate the bolt in the centre of the hole, prior to testing. This jig is described in more detail in [36].

A typical nite element mesh for the Base Model is shown in Fig. 2. Five separate parts were meshed two laminates, two washers and a combined bolt-nut. The meshing of the laminates is similar to that used by Ireman [19] with a relatively high radial mesh density near the hole and under the washer, where high strain gradients exist. However, dierently from [19], the washers were modelled separately. The only disadvantage of modelling the washers separately is the increase in model size due to the increased number of elements and contact bodies. Advantages are that including the washers allows the actual contact conditions in the joint to be modelled more accurately, including movement of the

Fig. 2. Finite element model with boundary conditions.

M.A. McCarthy et al. / Composite Structures 71 (2005) 140158

143

washer under load, and studies on bolt to washer clearance like those carried out by Tong [37] and Herrington and Sabbaghian [38] can be conducted. Both linear 8noded and quadratic 20-noded isoparametric hexahedral elements have been used for comparison. Wedge elements were used to form the core of the bolt. 3.2. Boundary conditions and loading The boundary conditions shown in Fig. 2 were used in most cases, i.e. the gripped part of the specimen was assumed perfectly gripped and was not modelled. Instead, the left end of the top laminate had all three displacement degrees of freedom (DOF) xed so as to simulate the stationary grip of the tensile testing machine. Load was introduced by applying a prescribed displacement in the x-direction to the rightmost end of the bottom laminate to mimic a quasi-static displacementcontrolled loading in the experiments. In some models, these boundary conditions were modied, as described later. To avoid potential rigid body modes, light springs were applied to the components not fully constrained such as the bolt, washers and bottom laminate. To simulate bolt pre-load due to applied torque, orthotropic thermal expansion coecients (allowing thermal expansion/contraction only in the direction of the longitudinal axis of the bolt) were given to one of the washers. This washer was then subjected to a positive temperature dierential prior to mechanical loading which had the eect of stretching the bolt and clamping the laminates, which is essentially what happens experimentally. Using this scheme, the bolt also reduces in diameter during application of pre-load (due to the Poisson eect), which is what happens in practice when torque is applied. For the nger-tight experiments modelled here, a bolt pre-stress of 7.2 MPa was applied. This value was obtained from the axial gauges in specially manufactured instrumented bolts (Fig. 3). A loading device designed to introduce a pure axial load was used to produce a relationship between axial load and strain in the gauges, while a second test measured the relationship between strain and torque. From these two tests, the torque versus axial load relationship was obtained. For further details of these tests refer to [39]. 3.3. Material modelling The unidirectional stiness properties of the composite material (HTA/6376) were obtained from an industrial partner in the BOJCAS project [40] and are

Table 2 Unidirectional stiness properties for HTA/6376 (Friberg [40]) E11 (GPa) 140 E22 (GPa) 10 E33 (GPa) 10 G12 (GPa) 5.2 G13 (GPa) 5.2 G23 (GPa) 3.9 m12 0.3 m13 0.3 m23 0.5 Fig. 3. Instrumented bolts used for calibrating bolt pre-loadnote: gauges also axed on opposing side of bolt (not visible): (a) instrumented bolt, (b) schematic.

shown in Table 2. Two methods of modelling the layups used in the experiments were implemented. In the rst, the laminates were modelled with the layered solid continuum element available in MSC.Marc (Element 149). This element allows a maximum of ve orthotropic layers per element, with each layer containing four integration points in-plane. Thus, stresses in each ply can be recovered and the correct bending-twisting coupling is obtained. In this case, the laminates were modelled with ten elements through the thickness, with each element modelling four plies of the composite material. Models using this method are referred to here as layered models. As will be shown in Part II of this paper, these models are important for application of failure criteria to determine joint strength. In the second method, homogeneous, orthotropic material properties were derived by performing a series of tensile and shear numerical experiments on a block of layered material and the in-plane properties were validated against classical laminate theory. Homogeneous properties obtained for the quasi-isotropic and zerodominated lay-ups in this study are shown in Table 3. Models using this method are referred to as homogeneous models and were developed primarily to reduce complexity to help debug contact. Concerning the other joint components, the titanium bolt and steel washers were modelled with isotropic material properties, with material constants Eb = 110 GPa, mb = 0.29 for the bolt, and Ew = 210 GPa, mw = 0.3 for the washers. 3.4. Contact description Contact was modelled using the direct constraint method in MSC.Marc. The method requires the denition of contact bodies, i.e. bodies that potentially

144 Table 3 Equivalent laminate stiness properties

M.A. McCarthy et al. / Composite Structures 71 (2005) 140158

Exx (GPa) Derived homogeneous properties for quasi-isotropic lay-up Derived homogeneous properties for zero-dominated lay-up

a

Eyy (GPa) 54.25

a

Ezz (GPa) 12.59 12.47

Gxy (GPa) 20.72

a

Gxz (GPa) 4.55 4.74

Gyz (GPa) 4.55 4.35

mxy 0.309 0.355

a

mxz 0.332 0.299

myz 0.332 0.402

54.25

77.23a

40.57a

17.62a

Veried by laminate theory.

may come in contact with each other. Contact bodies can simply be the physical bodies themselves (e.g. the laminates, bolt and washers), but it was found that it is more ecient to select subsets of the physical bodies which are likely to be involved in contact (see Fig. 4) since less checking for contact is required at each solution step. Eciency was improved further by using a contact table available in MSC.Marc. Contact tables dene which contact bodies are likely to contact each other during an analysis step. For example, it was known a

priori that the two washers would never come into contact, so the contact table was set to eliminate checking for this possibility. The contact table used here is shown in Fig. 5. Seven contact bodies are dened in this table. Body Top_washer_c_lap is made up of the elements in the upper washer (see Fig. 4) which can contact the upper laminate. Top_washer_c_bolt consists of the elements in the upper washer which can contact the bolt. The next two contact bodies in the table (Bottom_washer_c_lap and Bottom_washer_c_bolt) perform similar functions for the lower washer. Bodies

Fig. 4. Contact bodies dened by possible contacting elements only: (a) section through single-bolt model highlighting contact bodies, (b) contact bodies isolated.

M.A. McCarthy et al. / Composite Structures 71 (2005) 140158

145

Fig. 5. A contact table dened in MSC.Mentat for the bolted joint model (T indicates touching contact between two bodies).

lap1 and lap2 represent the elements within the upper and lower laminates, respectively, which can contact other bodies. Finally the bolt contact body contains the elements in the bolt which can contact other bodies. A blank entry indicates that no contact search is performed between two bodies, while a T indicates that it will. For example the T in row 5, column 7 indicates that contact will be checked between the contact bodies lap1 and bolt. As self-contact (i.e. a body bending over and contacting itself) was unlikely to occur during the analysis, the leading diagonal had no entries, thus eliminating checking for this possibility. The lower left area of the contact table was deactivated as a result of using a single-sided contact denition (discussed later). With the direct constraint method, detection of contact is done by checking if potential contact nodes are in contact with potential contact segments. In threedimensional deformabledeformable contact, contact segments are the element faces on the surface of the contact bodies. A tolerance is used to decide if a node is in

contactsee Fig. 6(a). If the trial position of the node is within the contact tolerance zone, it is considered to be in contact with the segment and is placed on that segment by means of a multi-point (tying) constraint. If it lies beyond the contact zone (as in Fig. 6(a)), it is considered to have penetrated and the increment is split and a new trial position found. Too small a tolerance leads to a lot of increment splitting (and hence high computational cost), but too large a tolerance leads to premature contact detection. The default tolerance in MSC.Marc is one twentieth of the smallest element edge length. However, because a primary goal of this work was to examine dierences between small clearances, a 10 lm tolerance (which is signicantly smaller than the default value) was used. This value was obtained by some trial and error in a separate numerical study. This contact tolerance was used with a Bias Factor of 0.9. This biased the contact zone into the contacted bodythus the contact zone ranged from (1-Bias) tolerance (i.e. 1 lm) above the body to (1 + Bias) tolerance (i.e. 19 lm) into the body, as shown in Fig. 6(b). Again,

Fig. 6. Contact searching in MSC.Marc: (a) contact tolerance showing penetration (which leads to increment splitting), (b) contact tolerance with bias factor used here.

146

M.A. McCarthy et al. / Composite Structures 71 (2005) 140158

this bias factor was obtained by some trial and error in a separate numerical study. In MSC.Marc, both single-sided and doublesided contact is available. For this type of analysis, single-sided contact was found to be more suitable because double-sided contact led to holes and gaps occurring in some contact interfaces. In single-sided contact, when two contact bodies come into contact, the contact body dened rst is the contacting body and supplies the contacting nodes, while the other body is the contacted body and provides the contacted segments. Thus, the order in which contact bodies are dened is important and this places restrictions on the mesh. For example, the MSC.Marc documentation [41] recommends that the body with the ner mesh should be dened rst, i.e. should be the contacting body. As can be seen in the contact table (Fig. 5), this guideline has been generally followed as the washers (nest meshessee Fig. 2) were dened before the laminates (medium meshes) which themselves were dened before the bolt (coarse mesh). One exception is the contact between the two laminates. Both these contact bodies have identical meshes so the order in which they were dened was arbitrary. A problem with single-sided contact arises when a contacting body overhangs a contacted body as shown for contact between the two laminates in Fig. 7. Laminate 1 is dened rst and therefore is the contacting body (i.e. supplies contacting nodes), while Laminate 2

is the contacted body (i.e. supplies contacted segments). When the joint is deformed, the overhanging contacting node on Laminate 1 in Fig. 7(a) does not interface with a contacted segment and so meets no restraint. This allows penetration as shown. Reversing the order of definition of the two contact bodies would only shift the problem to the other side of the joint. This problem cannot be fully eliminated but can be reduced to a negligible level by radial renement of the mesh, as shown in Fig. 7(b). The nal issue with contact was the use of so-called analytical contact rather than discrete contact. The tying constraint applied when a node contacts a segment, uses information regarding the segments outward

Fig. 7. Issues with single-sided contact: (a) penetration due to overhanging contacting body, (b) reduced by rened radial mesh in this area.

Fig. 8. Radial strain distribution, err, with dierent contact algorithms: (a) discrete contact, (b) analytical contact.

M.A. McCarthy et al. / Composite Structures 71 (2005) 140158

147

normal. In discrete contact, the nite element piecewise linear representation of the surface is used for calculating this normal, leading to unique normals emanating from each element face. A problem then occurs when a contacting node slides from one face to another because it tends to get stuck due to these discontinuous normals. This has an adverse eect on the quality of the solution. For example, Fig. 8(a) shows the radial strain distribution, err, in the bottom laminate from a model with homogeneous orthotropic material properties (dened in Section 3.3). As can be seen, the result is seriously awed since peaks in radial strain occur not just at the 0 position in the hole (i.e. the bearing plane), but also at other locations; the err distribution is also not symmetric which it should be with these material properties. When analytical contact is implemented, MSC.Marc ts a smooth Coons surface through the nodes of the contacted body. This analytical surface is then used to generate a continuous normal over the surface of the body, thus removing the problem with contacting nodes getting stuck. This procedure also results in a more accurate representation of the physical geometry, especially curved geometries. Fig. 8(b) shows the radial strain distribution in the bottom laminate when using the analytical contact algorithm. Comparing to the discrete contact algorithm (Fig. 8(a)), it can be seen that the strain distribution is symmetric and much smoother, and a peak only occurs once at the expected location (i.e. the bearing plane or 0 location).

4. Model validation In this section, results from the three-dimensional nite element model developed in the previous section are compared with results from experiments and also results from other nite element solutions generated in the BOJCAS project. The relevant experimental results are rst presented, and then results from the Base Model are given. Following that a parameter study to improve model behaviour is discussed, and nally a comparison is made between the improved model and nite element results from other project partners. 4.1. Experimental results Two dierent metrics are used to compare the experiments and simulations: 1. Strains at selected points on the joint surface 2. Joint stiness The experimental measurements for these two quantities are now presented. 4.1.1. Surface strains Four joints were strain gauged and loaded to a level that did not cause detectable damage to the laminates (5 kN). The four congurations were quasi-isotropic lay-up with C1 and C4 clearances (i.e. neat-t and 240 lm), and zero-dominated lay-up, also with C1 and C4

Fig. 9. Strain gauge locations.

148

M.A. McCarthy et al. / Composite Structures 71 (2005) 140158

clearances. Only the quasi-isotopic results are presented here. Fig. 9 shows the positions of the strain gauges, which had a 3 mm gauge length; note that all gauges were aligned with the loading direction except gauge 7, which was aligned in the transverse direction. Note also that gauge 2 was on the inner face of the laminate (i.e. on the shear plane of the joint) while the other gauges were on the outward-facing surface. Each test was repeated 34 times (dissembling the joint between each test), and results were repeatable within approximately 15 microstrain. Fig. 10 shows the experimental results for the quasi-isotropic, C1 clearance joint and the following observations can be made from this gure: Gauges 1 and 2 indicate a signicant amount of bending at this location. For gauge 1, the tensile strain due to the applied load is virtually balanced by the compressive strain due to bending, giving a near-zero output. The axial strain in the laminate, obtained by averaging the strains in gauges 1 and 2, is 379.3 microstrain at an applied load of 5 kN, or a gross-section stress of 20.0 MPa. Thus, the measured axial strain indicates a material modulus of 52.8 GPa, which compares well with the theoretical value (see Exx for the quasi-isotropic lay-up in Table 3). This provided some condence that the gauges were reading correctly. The bending strain at the same location, obtained by dierencing the strains in gauges 1 and 2, and dividing by two, is 380.9 microstrain. The outer surface of the overlap region (gauges 3, 4, 5, 6 and 8) is in compression despite the fact that a tensile load is being applied to the joint. This is due to bending of the joint (termed secondary bending). Gauge 4 (which is in line with the edge of the washer) displays the highest compressive strains of all the longitudinally-oriented gauges.

Gauges 5 and 8 dier slightly at higher loads indicating some possible twisting of the joint about its longitudinal axis, but the amount of the dierence is within the scatter band of the test repeats. The transverse gauge 7 shows signicant compressive strains. If the surface of the laminate possessed singlecurvature only (at across the width) this strain would be expected to be tensile due to Poissons eect (since the longitudinal strain on the surface is compressive). The fact that it is compressive indicates that a saddling eect is occurring (i.e. the surface has double curvature). Concerning the eects of clearance, the experimental strains at 5 kN are listed for both the C1 and C4 quasiisotropic joints in Table 4. As can be seen, since dierences of less than 30 microstrain are within the scatter band, the most signicant dierence due to clearance was in gauge 6 and, to a lesser extent, gauge 7. 4.1.2. Joint stiness The experimental loaddeection curves were found to be essentially linear between applied loads of 2 7 kN, so the stiness of the joint was measured over this range. The joint load was obtained directly from the load cell of the testing machine. However, an accurate measurement of joint displacement for this single-lap conguration proved dicult. A number of procedures were carried out to try and estimate the displacement of the free length of the joint, and hence the true stiness of the joint, as listed below: 1. From a series of tests on unnotched laminates with known stinesses determined from laminate theory, a machine stiness, lumping all the compliance eects of the cross-head components, was determined. This stiness was then used to apply a

5 G1 G2 G3 G4 G5 G6 G7 G8

Load (kN)

0 -800 -600 -400 -200 0 200 400 600 800

Microstrain

Fig. 10. Experimental strain gauge readings from quasi-isotropic, C1 (neat-t) clearance joint.

M.A. McCarthy et al. / Composite Structures 71 (2005) 140158 Table 4 Experimental and numerical strains at 5 kN applied load (quasi-isotropic lay-ups) Gauge number Experimental results C1 clearance (microstrain) 1 2 3 4 5 6 7 8 1.8 760 349 488 400 218 367 353 C4 clearance (microstrain) 11.6 757 346 482 381 313 438 385 Finite element results Base Model C1 clearance (microstrain) 231 548 209 374 302 191 430 302 Improved Model C1 clearance (microstrain) 149 633 244 438 346 182 414 346

149

Improved Model C4 clearance (microstrain) 132 606 219 427 362 339 427 362

correction to the stiness of joint specimens calculated from the cross-head displacement, using a simple springs in series analysis. 2. Extensometers were attached to the joint in the overlap region as shown in Fig. 11(a) and used to measure the stiness of this region. Hand calculations were then carried out to estimate the stiness of the ends of the joint (outside the overlap region). Finally, these quantities were combined using a springs in series approach and an estimate of the joint stiness was obtained. 3. Small steel blocks were attached to the side of the specimen as shown in Fig. 11(b). Linear variable displacement transducers (LVDTs) were then used to measure the displacement of these blocks and from this the joint stiness was determined. The method was also used on at, unnotched laminates of known stiness to test its accuracy. After quite a lengthy study involving several repeats of experiments on a number of dierent specimens (for further details, see [39]), it was found that procedure 3 above gave the most consistent results so this was taken as the most appropriate measurement technique. The joint stiness was determined to be 28 kN/mm. 4.2. Results from the base model This section presents strain and stiness results from the Base Model developed in Section 3. For this calibration study small changes were made to the mesh in Fig. 2 to ensure nodes existed at the centre of each gauge location. Fig. 12 shows the axial strain distribution on the outer surface of the laminate. The Base Model had homogeneous material properties, which allowed the use of a half-model. From this gure, it can be seen that, as in the experiments, the surface of the overlap region is in compression, with the maximum compressive values being in line with the edge of the washer. Table 4 lists the numerical strain values from this model (obtained from the node at the centre of each gauge) at 5 kN

Fig. 11. Methods used to determine the joint stiness: (a) extensometers attached across over-lap region, (b) LVDT measuring displacement of attached block.

150

M.A. McCarthy et al. / Composite Structures 71 (2005) 140158

Fig. 12. Distribution of axial strain exx in upper layer of elements.

applied load. Examining the values in Table 4 for the Base Model, the following is evident: From gauges 1 and 2, the axial strain is 389.3 microstrain, which compares well with the experiment (379.3). However, the bending strain from gauges 1 and 2 is 158.5 microstrain, which is considerably less than the experimental value (380.9). Gauges 3, 4, and 5 show compressive strains, as in the experiment, and the trend in going from gauge 3 to 4 to 5 is the same as the experiment (maximum compressive strain at gauge 4). However, the size of these strains is underestimated by 100140 microstrain. Gauge 6 (behind the hole) shows good agreement with the experiment. Gauge 7 shows a slight overestimation of the transverse compressive strain. Gauge 8 is the same as gauge 5 because of the use of a half model with homogeneous properties. Overall, behaviour involving tension and compression (i.e. axial strain in the laminate, compressive strain behind the hole) appeared to give quite good agreement, but the model was stier in bending than the experiment. In addition, the axial joint stiness was 34.6 kN/ mm, which is 23.6% higher than the experimentally measured stiness. Note that the stiness from the layered model (see Section 3.3) was virtually identical to that from the homogeneous model. Fig. 13 shows that the saddling eect noticed in the experimental results also occurred in the model; the gure shows the deformation of the upper laminate at a magnication factor of 10. This eect is characteristic of bending in wide beams [42]. Interestingly, the transverse bending changes from concave about half way between the hole and the clamped end to convex near the end of the laminate. The concave transverse bending (observed experimentally with the strain gauges) is a re-

Fig. 13. Saddle eect observed in the nite element model.

sult of high, localised contact forces from the washer acting in the thickness direction, while the convex transverse bending is due to the wide beam eect. This phenomenon could be referred to as tertiary bending. 4.3. Parameter study to improve model behaviour To try and improve the base model a parameter study, which involved varying the element order, mesh density, boundary conditions, material modelling and analysis type, was carried out. The rst parameter examined was number of degrees of freedom. Three variations were examined: 1. increasing the element order to second order (20noded brick elements); 2. rening the non-overlap region (see Fig. 14(a)); 3. rening both the non-overlap and overlap regions (Fig. 14(b)).

M.A. McCarthy et al. / Composite Structures 71 (2005) 140158

151

Fig. 14. Mesh renements: (a) Renement 1: non-overlap region only; (b) Renement 2: overlap region and non-overlap region.

As might be expected, these modications improved the bending behaviour. The strains in the second-order model and the Renement 2 model were almost the same, and showed improvements in almost all gauges over the base model. The Renement 1 model showed improvements in gauges 13 only. However, Table 5 shows that improved accuracy comes at increased computational cost, which is not linearly related to number of degrees of freedom. In fact, of most signicance to run-time are the changes brought about in the contact conditions (increased number of elements in contact or second-order elements in contact), so Renement 1 is cheap, but the others are not. A much less expensive way of improving bending behaviour was found to be to use the assumed strain formulation in MSC.Marc. The assumed strain formulation is similar to that used in the incompatible modes elements in ABAQUS and it improves the bending performance of 8-noded brick elements. Standard 8-noded brick elements do not represent bending correctly, since their sides remain straight and cannot therefore represent the curvature that exists when a block of material is loaded in pure bending. As a result,

Table 5 CPU times on 1 GHz Pentium 4 with 1 GB RAM Model Base model, Fig. 2 Renement 1, Fig. 14(a) Renement 2, Fig. 14(b) Second-order elements, mesh as in Fig. 2 DOF 19,536 25,146 51,336 58,062 CPU time (h) 1.02 1.15 5.56 14.78

right angles in the element are not preserved, and spurious shear strains are introduced. This makes the element too sti in bending because applied bending moments are resisted by the expected exural stress plus spurious shear stresses. To improve this behaviour, the displacement eld is augmented by so-called incompatible modes, which add additional internal degrees of freedom, and allow a state of constant curvature to be described. This allows bending to be represented correctly, without using second-order elements. It was found that using assumed strain in addition to Renement 1 gave virtually identical results to the second-order model, with only a small increase in run time over the Base Model (1.4 h CPU time). Some of the other variables in the parameter study were use of reduced integration elements; use of geometrically non-linear analysis; use of separate tensile and compressive elastic moduli: Data from the industrial partners in the BOJCAS project [43] indicated that the tensile modulus for the unidirectional material was 140 GPa, while the compressive modulus was 130 GPa. A user-dened subroutine was written to implement this in MSC.Marc. The decision as to whether the element was in tension or compression was based on the sign of the volumetric strain tensor; modelling the clamped area of the joint as shown in Fig. 15. By xing only the surface of the clamped region, some ow of the interior material in the

152

M.A. McCarthy et al. / Composite Structures 71 (2005) 140158

Fig. 15. Modied gripping boundary conditions.

clamped region is allowed, which is closer to the true situation than assuming all the clamped material is completely xed. Using reduced integration elements slightly improved gauges 1, 2 and 7 but dis-improved gauges 3, 4 and 5. Using geometric non-linear analysis had little eect since the joint was relatively thick and short, so out-of-plane displacements tended to be small. The most improvement was provided by the use of separate tensile/compressive properties and modelling the clamped area. The procedures above that independently improved the behaviour of the model were combined in a so-called Improved Model. This model thus included a rened non-overlap region, use of assumed strain, separate tensile/compressive properties and modelling of the clamped area of the joint. The strain results are listed in Table 4. Comparing with the experimental values, signicant improvements over the Base Model are seen in almost all gauges. In addition, the joint stiness decreased to 31.5 kN/mm, which is only 12.6% higher than the experimental value. Fig. 16 shows the strains in the Improved Model as the applied load increases from 0 to 5 kN, which compares well with the experimental values in Fig. 10. Shown also in Table 4 is the improved

model with a C4 clearance. Similarly to the experiments, the main eect of clearance in the models was on gauge 6 (i.e. the gauge behind the hole). 4.4. Comparison with other FE solutions The above validation exercise was presented to the BOJCAS [26] consortium and the neat-t (C1) clearance joint subsequently became a benchmark for comparison of three-dimensional modelling eorts in the project. Andersson [44] of the Aeronautical Research Institute of Sweden (FFA) used an in-house h-p nite element code entitled STRIPE to model the benchmark joint. Extensive computational resources were available for running STRIPE and so the joint models had very rened meshes with up to fourth-order elements (giving up to 1.2 million degrees of freedom), thus providing accurate reference solutions. Ekh [45] from the Royal Institute of TechnologyStockholm modelled the benchmark joint using the commercially available nite element code ABAQUS. The number of degrees of freedom used was similar to that used here, but the in-plane meshing scheme was dierent. An initial comparison between these alternative models and the Base Model developed here in terms of joint

5 G1 G2 G3 G4 G5 G6 G7

Load (kN)

0 -800 -600 -400 -200 0 200 400 600 800

Microstrain

Fig. 16. Numerical strain gauge readings from quasi-isotropic, C1 (neat-t) clearance joint (improved model).

M.A. McCarthy et al. / Composite Structures 71 (2005) 140158

153

stiness, revealed a close agreement between the three models, with the rened model of Andersson [44] showing slightly lower stiness than the Base Model. Considering three dierent contact schemes are used in these codes, this result was encouraging. The modications in material properties and boundary conditions made to the Improved Model, described above were not made to the models of [44,45], so no further comparisons regarding stiness were made. To provide a closer comparison between the models, three further criteria are used here: 1. out-of-plane displacements, 2. surface strains, 3. stresses in the laminates at the hole.

the layered model developed here are shown in Fig. 17b and c, respectively; refer to Fig. 17a for the coordinate system used. The values shown are at a joint displacement of 0.5 mm. As can be seen, both models are in excellent agreement and predict considerable secondary bending in the laminate and some negative (using the right-hand rule) twisting about the x-axis of the joint. The twisting is a result of non-uniform contact forces from the bolt (due to bolt rotation) acting through the thickness of the laminate, which result in dierent contact pressure on the 45 plies than the 45 plies (since they are at dierent positions through the thickness). Although the degree of twisting is small, this phenomenon could be of relevance in bolted/bonded joints or joints in applications that require sealing. 4.4.2. Surface strains The strains in gauges 17 (see Fig. 9 for gauge locations) are shown in Fig. 18 for the Improved Model developed here and the fourth-order model developed by Andersson [44]. Both models used the homogeneous quasi-isotropic material properties in Section 3.3. Data was only available at one load level from Andersson [44] and so is represented as a single point on the graphs. As can be seen, agreement between the Improved Model and the fourth-order model is excellent. This suggests that the Improved Model is approaching a converged state (with respect to surface strains). It also appears

4.4.1. Out-of-plane displacements The experimental strain results from gauges 5 and 8 (see Fig. 10) indicated that the joint may have been twisting about its longitudinal axis (the x-axis in Fig. 2). Ekh [45], using layered solid elements in ABAQUS, plotted out-of-plane displacements along lines on either side of the laminate, and half-way through the thickness (see Fig. 17a). From this he also observed that the benchmark joint tended to twist about the x-axis since the out-of-plane displacements on the two sides of the joint were dierent. The results from Ekhs model and

Fig. 17. Out-of-plane displacements at the sides of the joint: (a) coordinate system used, (b) model developed by Ekh [45] (at 0.5 mm joint displacement), (c) model developed here with layered solid elements (at 0.5 mm joint displacement).

154

M.A. McCarthy et al. / Composite Structures 71 (2005) 140158

Fig. 18. Comparison of surface strains between the Improved Model developed here and the fourth-order model developed by Andersson [44].

that the relatively poor agreement between the experiments and the simulations in terms of bending behaviour will not be improved by further mesh renements. 4.4.3. Stresses at the hole To examine the stresses at the hole, the mesh of the laminates shown in Fig. 2 was modied by rening radially in the washer zone. Two levels of renement were used, referred to here as Renement 3 and Renement 4, with 12 elements and 24 elements in the washer zone, respectively, as shown in Fig. 19(a) and (b). It

should be noted that Renement 4 took considerable time to run and is thus at the limit of current modelling capabilities with the high-end single processor PCs used here. In the next two sections, stresses are presented for both the homogeneous and layered material properties and comparisons are made with the fourth-order solutions given by Andersson [44]. The models used for generating the layered stress results were full (not half) models. The graphs are plotted at a joint displacement of 0.5 mm since results were only available from Andersson [44] at this displacement.

M.A. McCarthy et al. / Composite Structures 71 (2005) 140158

155

[44], displacements near locations where edge contact occurs are of the type u $ rk ; Rek < 1 1

where r is the distance to the edge and k is the singular exponent which depends on the position along the edge. Hence, stresses and strains are innite at these locations for arbitrarily small loads, and the quality of the nite element solution is very poor in such regions unless very rened meshes are employed. If rened meshes are not feasible, great care is needed when using stresses close to the singular region for computing failure criteria or stress concentration factors. The stress singularities are examined further in Part II of this paper.

Fig. 19. Mesh renements in washer region: (a) Renement 3: 12 elements in washer region; (b) Renement 4: 24 elements in washer region.

4.4.3.1. Homogeneous models. The radial stress at the hole along a line in the bearing plane going from the shear plane to the free face of the joint is shown in Fig. 20 for a number of homogeneous models with different levels of mesh renement and element orders. It should be noted that origin of this line (i.e. the point on the shear plane) represents a singularity in the model since at this point, due to tipping of the bolt in the hole, line contact exists between the bolt and the edge of the hole. As can be seen in Fig. 20, all models (including the fourth-order model) are in good agreement up to approximately 0.5 mm or four ply thicknesses from this point. As the shear plane is approached (i.e. as we move to the base of the vertical axis in the graph), the stress increases with increasing radial mesh density, with no evidence of convergence. As pointed out by Andersson

4.4.3.2. Layered models. A plot of the radial stresses in each ply at the hole along the same line as in the previous section is shown in Fig. 21. The stresses were obtained from the current layered model by averaging the radial stress values from the two integration points nearest the bearing plane. As can be seen, agreement between the current model and the fourth-order model with layered properties from [44] is excellent for the 0, +45 and 45 plies and not so good for the 90 plies. However, since the 90 plies are under very low stress due to their low transverse stiness, the result was considered acceptable. The 0 plies are under the highest stress in the bearing plane which is due to their high stiness in the loading direction. The +45 and 45 plies are under considerably less stress, but interestingly, the stresses in the +45 plies are slightly higher than the 45 plies. This could be due to the joint twisting which may cause the bolt to tilt slightly toward the +45 direction, but is more likely due to the +45 plies being located closer to the shear plane; the contact pressure is highest at the shear plane and drops o through the thickness of the joint [19]. It is interesting to note that the average of the layered stresses in Fig. 21 is

Fig. 20. Radial stress distribution at the hole along a line in the bearing plane going from the shear plane to the free face of the joint (see picture at left). Stresses calculated at a joint displacement of 0.5 mm using the homogeneous model.

156

M.A. McCarthy et al. / Composite Structures 71 (2005) 140158

Fig. 21. Radial stress distribution at the hole along a line in the bearing plane going from the shear plane to the free face of the joint (see picture at left). Stresses calculated at a joint displacement of 0.5 mm using layered model.

approximately equal to the homogeneous result in Fig. 20.

5. Concluding remarks In this rst of a two-part paper, a nite element model of a single-lap, single-bolt composite joint has been developed, and validated against experimental results and results from other nite element analysis solutions. The model has been developed for a study of the eects of bolthole clearance which will be presented in detail in Part II of the paper. A number of factors were found to aect the accuracy and eciency of the solution. The joint was modelled using MSC.Marc. Eciency was improved by dening contact bodies as sub-parts of the joint components, and using a contact table to dene which contact bodies could come into contact. For joints with very small clearances, the contact tolerance had to be carefully chosen, and single-sided contact needed to be used. Use of single-sided contact placed restrictions on the meshing of the dierent joint parts, and the order in which contact bodies were dened. The mesh also had to be adjusted to minimise passing through of overhanging nodes. Finally, it was found to be vital to choose the analytical contact option, which ts a smooth surface through the contact body. A number of joints were strain gauged and the following eects were found in both the experiments and simulations. Signicant amounts of bending of the laminates occurred (termed secondary bending), so that the external surface of the joint was in compression, despite the tensile loading applied to the joint. Double-curvature of the surface was detected, indicating the joint was saddling like a wide beam in bending. The joint was also found to twist slightly about its longitudinal axis. The surface strain distribution was found to be unaected by bolthole clearance, except for close to the loaded side of the hole.

The axial stiness of the joint was measured using a number of dierent methods. Obtaining an accurate measure of the joint displacement proved to be dicult for this single-lap conguration. Comparisons between the strains from an initial Base Model and the experiments revealed good agreement for axial strain in the laminate and compressive strain behind the hole, but an overestimation of the bending stiness by the model. The axial joint stiness was also too high in the model. A parameter study was carried out in an eort to improve the correlation with experiment, without incurring an excessive penalty in computational cost. The factors that most improved the model were a rened non-overlap region, use of the assumed strain formulation with rst-order elements, implementing a routine to allow separate tensile and compressive properties, and modelling the clamped area of the joint. These factors were incorporated into an Improved Model, and signicant improvement in correlation with experimental strain values and axial joint stiness was obtained. The computational cost of these improvements was relatively small. The most detrimental eect on computational cost occurred when the number of elements in contact was increased, or when second-order elements were in contact. A comparison was made with two other nite element models from partners in the BOJCAS project [26], using dierent nite element codes. Axial joint stiness was similar for all three models, and the degree of secondary bending and twisting about the longitudinal axis of the joint found here was in close agreement with the model in [44]. Surface strains from the Improved Model tied up very closely with a model with over 106 degrees of freedom in [44]. Thus further mesh renement would not lead to improved correlation with the experiment in terms of bending properties. Possible ways to improve the correlation may be to modify the boundary conditions to better represent the actual gripping conditions

M.A. McCarthy et al. / Composite Structures 71 (2005) 140158

157

or to model the resin-rich layers in the composite, which might allow some relative movement between plies. Implementation of a non-linear shear constitutive relationship might also improve the behaviour of the oaxis plies. Concerning stresses at the hole, it is important to recognise the presence of singularities in the model. These singularities actually exist in several places, i.e. at the washerbolt, washerlaminate, and boltlaminate interfaces, and interfaces between plies (at hole surfaces). Great care is needed when using stresses close to the singular regions for computing failure criteria or stress concentration factors. The stresses at the hole were compared with the very rened model in [44] using both homogeneous and layered properties. The values in the present models were found to agree closely with the values in [44] at distances approximately 4 ply thicknesses away from the shear plane where a singularity occurs. With radial mesh renements, the stresses at the shear plane approached those in [44], although it should be recognised that the stresses are in fact innite at this location. Radial stresses were found to be much higher in the plies oriented in the loading direction than in other plies, as expected. Overall, it has been found that three-dimensional nite element models of composite bolted joints capable of being run in reasonable timeframes on standard PC hardware, can produce results in close agreement with experiment and much more rened models, in all respects except stresses close to singular locations. Three-dimensional eects such as bolt tilting, secondary bending and through-thickness variations in stress and strain are well represented by such models. However, the process is far from routine and requires careful consideration of many issues. Acknowledgements BOJCASBolted Joints in Composite Aircraft Structures is a RTD project partially funded by the European Union under the European Commission GROWTH programme, Key Action: New Perspectives in Aeronautics, Contract No. G4RD-CT99-00036. The authors would like to thank the following: the EU for funding the project; and the BOJCAS partners for many helpful discussions. References

[1] Madenci E, Ileri L. Analytical determination of contact stresses in mechanically fastened composite laminates with nite boundaries. Int J Solids Struct 1993;30(18):246984. [2] Xiong Y. An analytical method for failure prediction of multifastener composite joints. Int J Solids Struct 1996;33(29): 4395409.

[3] Hyer MW, Klang EC, Cooper DE. The eects of pin elasticity, clearance, and friction on the stresses in a pin-loaded orthotropic plate. J Composite Mater 1987;21(3):190206. [4] Kradinov V, Barut A, Madenci E, Ambur DR. Bolted double-lap composite joints under mechanical and thermal loading. Int J Solids Struct 2001;38:780137. [5] Fan WX, Qiu CT. Load distribution of multi-fastener laminated composite joints. Int J Solids Struct 1993;30(21):301323. [6] Chutima S, Blackie AP. Eect of pitch distance, row spacing, end distance and bolt diameter on multi-fastened composite joints. Composites Part A 1996;27(2):10510. [7] Rowlands RE, Rahman MU, Wilkinson TL, Chiang YI. Single and multiple bolted joints in orthotropic materials. Composites 1982;13(3):2739. [8] Pradhan B, Kumar R. Stresses around partial contact pin-loaded holes in FRP composite plates. J Reinf Plastics Composites 1984;3(1):6984. [9] Naik RA, Crews Jr JH. Stress analysis method for a clearance-t bolt under bearing loads. AIAA J 1986;24(8):134853. [10] Ramamurthy TS. New studies on the eect of bearing loads in lugs with clearance t pins. Composite Struct 1989;11:13550. [11] Kim SJ, Kim JH. Finite element analysis of laminated composite plates with multi-pin joints considering friction. Comput Struct 1995;55(3):50714. [12] Ko HY, Kwak BM. Contact analysis of mechanically fastened joints in composite laminates by linear complementarity problem formulation. Composite Struct 1998;40(34):187200. [13] Lanza Di Scalea F, Cappello F, Cloud GL. On the elastic behaviour of a cross-ply composite pin-joint with clearance ts. J Thermoplastic Composite Mater 1999;12:1322. [14] Pierron F, Cerisier F, Grediac M. A numerical and experimental study of woven composite pin-joints. J Composite Mater 2000;34(12):102854. [15] Matthews FL, Wong CM, Chryssatis S. Stress distribution around a single bolt in bre reinforced plastic composites. London: Butterworth; 1982. p. 31622. [16] Marshall IH, Arnold WS, Wood J, Mousley RF. Observations on bolted connections in composite structures. Composite Struct 1989;13:13351. [17] Benchekchou B, White RG. Stresses around fasteners in composite structures in exure and eects on fatigue damage initiation. Part 1: cheese-head bolts. Composite Struct 1995;33(2):95108. [18] Oh HH, Kim YG, Lee DG. Optimum bolted joints for hybrid composite materials. Composite Struct 1997;38:32941. [19] Ireman T. Three-dimensional stress analysis of bolted composite single-lap joints. Composite Struct 1998;43:195216. [20] Camanho PP, Matthews FL. A progressive damage model for mechanically fastened joints in composite laminates. J Composite Mater 1999;33(24):224880. [21] Camanho PP, Matthews FL. Delamination onset prediction in mechanically fastened joints in composite laminates. J Composite Mater 1999;33(10):90627. [22] Chen WH, Lee SS, Yeh JT. Three-dimensional contact stress analysis of a composite laminate with bolted joint. Composite Struct 1995;30:28797. [23] McCarthy MA, McCarthy CT. Finite element analysis of the eects of clearance on single shear, composite bolted joints. J Plastics, Rubbers Composites 2003;32(2):6570. [24] Lessard BL, Shokrieh MM, Esbensen JH. Analysis of stress singularities in laminated composite pinned/bolted joints. In: 38th International SAMPE Symposium 1993. p. 5360. [25] Persson E, Madenci E, Eriksson I. Delamination initiation of laminates with pin-loaded holes. Theor Appl Fracture Mech 1998;30:87101. [26] McCarthy MA. BOJCAS: bolted joints in composite aircraft structures. Air Space Eur 2001;3/4(3):13942.

158

M.A. McCarthy et al. / Composite Structures 71 (2005) 140158 [35] McCarthy MA, Lawlor VP, Stanley WF, McCarthy CT. Bolt hole clearance eects and strength criteria in single-bolt, singlelap, composite bolted joints. Composites Sci Technol 2002;62:141531. [36] Lawlor VP, Stanley WF, McCarthy MA. DFC-6 Conference Proceedings, 2001. p. 37786. [37] Tong L. Bearing failure of composite bolted joints with nonuniform bolt to washer clearance. Composites Part A 2000;31:60915. [38] Herringtion PD, Sabbaghian M. Eect of radial clearance between bolt and washer on the bearing strength of composite bolted joints. J Composite Mater 1992;26(12):182643. [39] Lawlor VP. PhD Thesis. Ireland: University of Limerick; 2004. [40] Friberg M. Personal communication. SAAB; 2000. [41] MSC.Marc Users Manual, vol. A: theory and user information. MSC.Software Corporation; 2000. [42] Swanson SR. Anticlastic eects and the transition from narrow to wide behaviour in orthotropic beams. Composite Struct 2001;53:44955. [43] Hachenberg, Personal communication. Airbus Deutschland; 2001. [44] Andersson B. A splitting method for fast solution of 3D contact problems in bolted joints (interim report). Deliverable Number D4.3-5, BOJCAS, EU Contract # G4RD-CT-1999-00036, Programme: GROWTH, New Perspectives in Aeronautics; 2001. [45] Ekh J. Three-dimensional stress analysis (interim report). Deliverable Number D4.1-1, BOJCAS, EU Contract # G4RDCT-1999-00036, Programme: GROWTH, New Perspectives in Aeronautics; 2001.

[27] Hart-Smith LJ. Bolted joints in graphiteepoxy composites. NASA Contractor Report, 1976 [NASA CR-1444899]. [28] Nelson WD, Bunin BL, Hart-Smith LJ. Critical joints in large composite aircraft structures. Army Materials and Mechanics Research Centre Manuscript Report, 1983 [AMRC MS 83-2]. [29] Garbo SP, Ogonowski JM. Eect of variances and manufacturing tolerances on the design strength and life of mechanically fastened composite joints: vol. 3bolted joint stress eld model (BJSFM) computer program users manual. AF Wright Aeronautical Laboratories Technical Report, 1981 [AFWAL-TR-81-3041]. [30] Rankumar RI, Tossavainen EW. Bolted joints in composite structures: design, analysis and vericationsingle fastener joints. AF Flight Dynamics Laboratory, WrightPatterson AFB, 1984 [AFWAL-TR-84-3074]. [31] DODSSP, Polymer matrix composites, MIL-HDBK-17, DODSSP, Naval Publications and Forms Center, Standardization Documents Order Desk, Building 4D, 700 Robbins Ave., Philadelphia, PA [19111-5094]. [32] Shyprykevich P. Characterization of bolted joint behaviour: MILHDBK-17 accomplishments at standardization. J Composites Technol Res 1995;17(3):26070. [33] ASTM standard D 5961/D 5961M-96, Standard Test Method for Bearing Response of Polymer Matrix Composite Laminates, 1996. [34] DiNicola AJ, Fantle SL. Bearing strength behaviour of clearancet fastener holes in toughened graphite/epoxy laminates. In: Camponeshi Jr ET, editor. Composite materials: testing and design. ASTM STP 1206, vol. 11. Philadelphia: American Society for Testing and Materials; 1993. p. 22037.

You might also like

- Docslide - Us Mar 102Document460 pagesDocslide - Us Mar 102Linda Hayes100% (1)

- NFEM Ch01 PDFDocument15 pagesNFEM Ch01 PDFmadhuNo ratings yet

- Characterization of Polymeric Foams PDFDocument35 pagesCharacterization of Polymeric Foams PDFDenisse JiménezNo ratings yet

- A Finite Element Formulation For Nonlinear Incompressible Elastic and Inelastic AnalysisDocument53 pagesA Finite Element Formulation For Nonlinear Incompressible Elastic and Inelastic Analysisguanicad712827No ratings yet

- Abstract - Fatigue Behavior in Strain Cycling in The Low and Intermediate Cycle RangeDocument55 pagesAbstract - Fatigue Behavior in Strain Cycling in The Low and Intermediate Cycle RangeZarra FaktNo ratings yet

- Finite Element Modeling To Verify Residual Stress in Orthogonal Machining PDFDocument124 pagesFinite Element Modeling To Verify Residual Stress in Orthogonal Machining PDF陳國父No ratings yet

- APDL Code For Thermal Analysis of PCBDocument3 pagesAPDL Code For Thermal Analysis of PCBASIM RIAZNo ratings yet

- 2023 Abaqus For Engineers Fe Safe Research Gate PreviewDocument105 pages2023 Abaqus For Engineers Fe Safe Research Gate PreviewSaid EL FakkoussiNo ratings yet

- Adaptive Refinement in Vibrational Analysis and Isogemetric AnalysisDocument22 pagesAdaptive Refinement in Vibrational Analysis and Isogemetric AnalysisAbhishek KumarNo ratings yet

- Thermal Analysis of Pin Fin With Different Shape Forms Using ANSYS PDFDocument8 pagesThermal Analysis of Pin Fin With Different Shape Forms Using ANSYS PDFMuhammad AbbasNo ratings yet

- Tutorial19 Thermal Stress SwitchDocument11 pagesTutorial19 Thermal Stress SwitchRoberto AbreuNo ratings yet

- Tutorial 16 - CEL - BottleDocument14 pagesTutorial 16 - CEL - BottleRezaNo ratings yet

- Dynamic Analysis by Component Mode PDFDocument8 pagesDynamic Analysis by Component Mode PDFRodrigo GarayNo ratings yet

- 3D FEA Simulations in MachiningDocument95 pages3D FEA Simulations in MachiningAyman TamimNo ratings yet

- Fracture Specimen Stree AnalysisDocument15 pagesFracture Specimen Stree AnalysisGaurav PundirNo ratings yet

- Finite Element Modelling and Analysis of Hot Turning OperationDocument55 pagesFinite Element Modelling and Analysis of Hot Turning OperationSangar LingamNo ratings yet

- MTech Semester I Exam Questions on Elasticity and PlasticityDocument2 pagesMTech Semester I Exam Questions on Elasticity and PlasticityNaren GujjarNo ratings yet

- Femap UputstvoDocument66 pagesFemap Uputstvodakiza019-1No ratings yet

- A Review of T-Stress and Its Effects in Fracture MechanicsDocument24 pagesA Review of T-Stress and Its Effects in Fracture MechanicsMarilene Lobato100% (1)

- Buckling, Postbuckling, and Collapse Analysis With Abaqus: About This CourseDocument11 pagesBuckling, Postbuckling, and Collapse Analysis With Abaqus: About This CourseEvgeny ShavelzonNo ratings yet

- Step by Step Procedure To Export A Deformed Geometry in AnsysDocument11 pagesStep by Step Procedure To Export A Deformed Geometry in AnsysvilukNo ratings yet

- Bolt Pattern OptimizationDocument20 pagesBolt Pattern OptimizationNitin Chandra0% (1)

- Inertia Relief: Workshop 17Document18 pagesInertia Relief: Workshop 17dionbesselinkNo ratings yet

- Aerodynamic Analysis of Motion of Two Vehicles and Their Influence On Drag Coefficient.Document3 pagesAerodynamic Analysis of Motion of Two Vehicles and Their Influence On Drag Coefficient.Innovative Research PublicationsNo ratings yet

- MABE 012412 WebDocument4 pagesMABE 012412 WebAltairKoreaNo ratings yet

- E 08Document16 pagesE 08João PauloNo ratings yet

- Experimental Analysis of Composite Bolted Joints Using Digital Image CorrelationDocument13 pagesExperimental Analysis of Composite Bolted Joints Using Digital Image CorrelationHako KhechaiNo ratings yet

- SolidWorks Simulation - Avoiding SingularitiesDocument6 pagesSolidWorks Simulation - Avoiding SingularitiesAnonymous P8Bt46mk5INo ratings yet

- Imp-Thoupal 2009-Mechanics of Mechanically Fastened Joints in Polymer-Matrix Composite Structures - A Review PDFDocument29 pagesImp-Thoupal 2009-Mechanics of Mechanically Fastened Joints in Polymer-Matrix Composite Structures - A Review PDFJamalDilferozNo ratings yet

- Modal Assurance Criterion - Álvaro RiveroDocument48 pagesModal Assurance Criterion - Álvaro Riverorif8750% (2)

- MYSTRAN Demo Problem ManualDocument39 pagesMYSTRAN Demo Problem Manualja_mufc_scribd100% (1)

- ANSYS simulation of beam bendingDocument23 pagesANSYS simulation of beam bendingpatrickNX9420No ratings yet

- Application of The Single Hardening Model in The Finite Element Program ABAQUSDocument50 pagesApplication of The Single Hardening Model in The Finite Element Program ABAQUSBogdan BungardiNo ratings yet

- PaigeDocument15 pagesPaigeklomps_jrNo ratings yet

- Notes On Power Spectral Density (PSD) Estimation Using MatlabDocument10 pagesNotes On Power Spectral Density (PSD) Estimation Using MatlabPhilip Wang100% (1)

- Code Aster Capabilities PDFDocument36 pagesCode Aster Capabilities PDFsb1966No ratings yet

- Design Procedures For Profiled Metal Sheeting and DeckingDocument11 pagesDesign Procedures For Profiled Metal Sheeting and DeckingPrapa KaranNo ratings yet

- 8206 PDFDocument74 pages8206 PDFbahabahabahaNo ratings yet

- Abaqus QuestionsDocument12 pagesAbaqus Questionsmadhu77No ratings yet

- Hyperelastic Material Model Selection ApproachDocument7 pagesHyperelastic Material Model Selection ApproachHemant MishraNo ratings yet

- Study of Process - Improving Efficiency of Closed Die Hot Forging ProcessDocument69 pagesStudy of Process - Improving Efficiency of Closed Die Hot Forging ProcessMrLanternNo ratings yet

- Finite Element Method Analysis of Rectangular Plate With Circular Hole Using AnsysDocument12 pagesFinite Element Method Analysis of Rectangular Plate With Circular Hole Using AnsysNarayana Swamy GNo ratings yet

- Evaluation of The Non-Linear Fracture Parameters J and C With ANSYSDocument11 pagesEvaluation of The Non-Linear Fracture Parameters J and C With ANSYSPeti KovácsNo ratings yet

- Thermal Analysis of Friction Stir Welded Joint For 304l Stainless Steel Material Using Ansys Mechanical APDLDocument6 pagesThermal Analysis of Friction Stir Welded Joint For 304l Stainless Steel Material Using Ansys Mechanical APDLMichael SerraNo ratings yet

- Tutorial 17 - CEL - BoatDocument13 pagesTutorial 17 - CEL - BoatBin VoNo ratings yet

- Final Thesis Crispin Noorman - Final VersionDocument172 pagesFinal Thesis Crispin Noorman - Final VersionShanna ChuNo ratings yet

- Formulation of Stiffness Constant and Effective Mass For A Folded Beam PDFDocument14 pagesFormulation of Stiffness Constant and Effective Mass For A Folded Beam PDFSabino HectorCamposNo ratings yet

- CH 08Document49 pagesCH 08LeonardoMadeira11No ratings yet

- Topology Optimization To Torque Arm in Landing Gear System Based On ANSYS WorkbenchDocument5 pagesTopology Optimization To Torque Arm in Landing Gear System Based On ANSYS WorkbenchAnnaNo ratings yet

- Format of Input File For AbaqusDocument3 pagesFormat of Input File For AbaquspravinNo ratings yet

- UMAT Theory - Nader Abedrabbo, PH.DDocument2 pagesUMAT Theory - Nader Abedrabbo, PH.DSebastiao SilvaNo ratings yet

- MSC Fastener Modeling For Joining Composite Parts 06-SpiritAero - BoshersDocument22 pagesMSC Fastener Modeling For Joining Composite Parts 06-SpiritAero - BoshersSergey Fedorinov100% (1)

- Rolling Contact Fatigue Resistance of Hard Coatings On Bearing SteelsDocument24 pagesRolling Contact Fatigue Resistance of Hard Coatings On Bearing Steelsmans2014No ratings yet

- Multidisciplinary Optimisation of A Business Jet Main Exit Door Hinge For Production by Additive ManufacturingDocument16 pagesMultidisciplinary Optimisation of A Business Jet Main Exit Door Hinge For Production by Additive ManufacturingAltairEnlightenNo ratings yet

- Shape and Cross Section Optimisation of A Truss StructureDocument15 pagesShape and Cross Section Optimisation of A Truss StructureAakash Mohan100% (1)

- Nonlinear Ordinary Differential Equations in Transport ProcessesFrom EverandNonlinear Ordinary Differential Equations in Transport ProcessesNo ratings yet

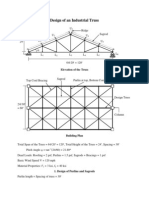

- Industrial Truss Design and AnalysisDocument15 pagesIndustrial Truss Design and AnalysisGurnam Singh Sodhi100% (3)

- Microsoft PowerPoint - B4 - DrydenOpenSeesDays - 9 - 9 - 08 (Compatibility Mode) PDFDocument12 pagesMicrosoft PowerPoint - B4 - DrydenOpenSeesDays - 9 - 9 - 08 (Compatibility Mode) PDFMahmud Kori EffendiNo ratings yet

- 04 ChapterDocument52 pages04 ChapterYirga BezabehNo ratings yet

- Lecture Notes in Structural Engineering Analysis DesignDocument142 pagesLecture Notes in Structural Engineering Analysis DesignPankaj_Taneja_9684100% (1)

- Axially Loaded Concrete-Filled Steel TubesDocument14 pagesAxially Loaded Concrete-Filled Steel TubesMahmud Kori EffendiNo ratings yet

- Microsoft PowerPoint - B4 - DrydenOpenSeesDays - 9 - 9 - 08 (Compatibility Mode) PDFDocument12 pagesMicrosoft PowerPoint - B4 - DrydenOpenSeesDays - 9 - 9 - 08 (Compatibility Mode) PDFMahmud Kori EffendiNo ratings yet

- NEHRP Seismic Design Technical Brief NoDocument40 pagesNEHRP Seismic Design Technical Brief NoMahmud Kori EffendiNo ratings yet

- Flexural Behavior of Reinforced and Pre Stressed Concrete Beams Using Finite Element AnalysisDocument87 pagesFlexural Behavior of Reinforced and Pre Stressed Concrete Beams Using Finite Element AnalysisJinsoo HongNo ratings yet

- FRP-Wrapped Concrete Columns under Axial and Cyclic LoadsDocument11 pagesFRP-Wrapped Concrete Columns under Axial and Cyclic LoadsMahmud Kori EffendiNo ratings yet

- Katalog Gunung Garuda NewDocument36 pagesKatalog Gunung Garuda Newabduh81No ratings yet

- FinalDocument85 pagesFinalDragos ButcaNo ratings yet

- Problem 6.8: A. To FindDocument16 pagesProblem 6.8: A. To FindMahmud Kori EffendiNo ratings yet

- Equivalent Stress ConcreteDocument18 pagesEquivalent Stress ConcreteMahmud Kori EffendiNo ratings yet

- Energy Absorbtion Impact LoadDocument7 pagesEnergy Absorbtion Impact LoadMahmud Kori EffendiNo ratings yet

- Problem 6.8: A. To FindDocument16 pagesProblem 6.8: A. To FindMahmud Kori EffendiNo ratings yet

- Test 2Document3 pagesTest 2Mahmud Kori EffendiNo ratings yet

- Problem 6.8: A. To FindDocument16 pagesProblem 6.8: A. To FindMahmud Kori EffendiNo ratings yet

- Designer Tutorial - 1D Heat TransferDocument7 pagesDesigner Tutorial - 1D Heat TransferPrashanth Nadanahalli ShivegowdaNo ratings yet

- Advanced Topics in ABAQUS SimulationDocument29 pagesAdvanced Topics in ABAQUS SimulationKashif AhmedNo ratings yet

- MSC - Marc and MSC - Marc Mentat: Release GuideDocument112 pagesMSC - Marc and MSC - Marc Mentat: Release GuideMahmud Kori EffendiNo ratings yet

- Certificate of Conformity: No. CLSAN 080567 0058 Rev. 00Document2 pagesCertificate of Conformity: No. CLSAN 080567 0058 Rev. 00annamalaiNo ratings yet

- Masterseal 380 TDSDocument2 pagesMasterseal 380 TDSArasu DonNo ratings yet

- Austenite Formation in Plain Carbon SteelDocument14 pagesAustenite Formation in Plain Carbon SteelAndress SsalomonnNo ratings yet

- Improving Garbage Collection in Brgy. GatbucaDocument9 pagesImproving Garbage Collection in Brgy. GatbucaKaren AsaharNo ratings yet

- Fibre Rope - Terminology and Good PracticesDocument19 pagesFibre Rope - Terminology and Good PracticesLe Quyen NguyenNo ratings yet

- BOQ - Civil, Structural and ArchitecturalDocument46 pagesBOQ - Civil, Structural and ArchitecturalVincent SaysonNo ratings yet

- Instrumental 3.2Document4 pagesInstrumental 3.2deon kumukwayaNo ratings yet

- Li-Ion pd2019 Mot SolutionsDocument2 pagesLi-Ion pd2019 Mot SolutionsManuel BermudezNo ratings yet

- Baking Schedule Ex 3Document2 pagesBaking Schedule Ex 3icepascuNo ratings yet

- Railways: Mechanical Stabilisation of Track Ballast and Sub-BallastDocument12 pagesRailways: Mechanical Stabilisation of Track Ballast and Sub-BallastJohn Archie Dela CruzNo ratings yet

- Masterseal 909: Re-Injectable Hose For Construction and Cold Joints in ConcreteDocument2 pagesMasterseal 909: Re-Injectable Hose For Construction and Cold Joints in Concretevelmurug_balaNo ratings yet

- RM Pattern UK 208printDocument36 pagesRM Pattern UK 208printMarcelo Alberto AiresNo ratings yet

- Awareness of Domestic Solid Waste ManagementDocument6 pagesAwareness of Domestic Solid Waste ManagementJenemarNo ratings yet

- Datasheet For Carbon Steel A333 Grade 6Document10 pagesDatasheet For Carbon Steel A333 Grade 6Aneesh JoseNo ratings yet

- Technical Data Sheet Magnetic Flowmeter Material Selection Guide Data PDFDocument28 pagesTechnical Data Sheet Magnetic Flowmeter Material Selection Guide Data PDFThiagarajNo ratings yet

- Deha Halfen Kkt-EDocument52 pagesDeha Halfen Kkt-ENandeesha RameshNo ratings yet

- Conductors and InsulatorsDocument7 pagesConductors and InsulatorsAzsrul AzrulNo ratings yet

- Die Casting DieDocument156 pagesDie Casting DieHeetNo ratings yet

- Eldorado Stone Finishing DetailsDocument16 pagesEldorado Stone Finishing DetailsGeorges HageNo ratings yet

- Wheels EspecificationsDocument26 pagesWheels Especificationsdavid rosarioNo ratings yet

- Clothing WasteDocument20 pagesClothing WasteVjan Christia RazonNo ratings yet

- Synthesis of Fuel From Waste PlasticDocument63 pagesSynthesis of Fuel From Waste Plasticamirah1999No ratings yet

- Fracture Toughness Testing - TwiDocument5 pagesFracture Toughness Testing - TwiSergio MunhosNo ratings yet

- Fundamentals of Thermodynamics Solutions ch05Document190 pagesFundamentals of Thermodynamics Solutions ch05Cierré No'Middlename Jones100% (10)

- Portable Hardness Testing - Principles and ApplicationsDocument8 pagesPortable Hardness Testing - Principles and ApplicationsvrapciudorianNo ratings yet

- Plastic Roads: A Sustainable Solution to Plastic WasteDocument8 pagesPlastic Roads: A Sustainable Solution to Plastic WasteShahid Bhat0% (1)

- Activities Carried Out in Quality Control LaboratoryDocument61 pagesActivities Carried Out in Quality Control LaboratorySunil SingireddyNo ratings yet

- Optimal DC Cable Selection in PV DesignsDocument8 pagesOptimal DC Cable Selection in PV DesignsHelena AraujoNo ratings yet

- Welding CrackingDocument8 pagesWelding CrackingjensdcvNo ratings yet

- Technical Specification for Submarine CableDocument11 pagesTechnical Specification for Submarine Cablenadi777No ratings yet