Professional Documents

Culture Documents

Branch Table

Uploaded by

knsaravanaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Branch Table

Uploaded by

knsaravanaCopyright:

Available Formats

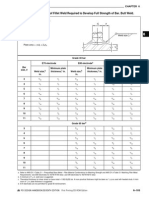

BRANCH TABLE GENERATOR

BY A.V. Acharya

Procedure for using branch generator.

1)There are 2 components for the spreadsheet the calculation part and the brach table generator.

2)The coloured part of the spreadsheet can be changed

Consequently the table for the branch table also changes

3)its preferable to use master copy of excel sheet before each calculation for each spec

4)the branch table generated can be copied to other spreadsheets for use

5) Start with the work sheet " 36" master for data entry " enter data fully , when data has been entered fully the consequent tables also change ,

but it is advisable to check data in the consequent tables of correctness

6) When the data has been entered and it can bee seen that the branch table worksheet changes , indicating that reinforcement is required or not

7)If refinforcement is required then pad has to be provided

Piping

Spec-:

A1A

2"

3"

4"

6"

8"

P

6"

P

4"

P

3"

P

2"

10"

12"

HEADER

14"

16"

18"

20"

22"

24"

26"

28"

30"

32"

34"

36"

R

P

36"

P

34"

P

P

P

P

P

P

P

P

P

P

P

P

32" 30" 28" 26" 24" 22" 20" 18" 16" 14" 12" 10"

BRANCH

R-Reinforcement pad is reqd

P-Pipe to pipe joint

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR.

TO =

Pd =

Sh=

Sb=

Eh=

Eb=

Y=

bradians

VALUES

HDR./BR.

36/34

150.0000

150.0000

Api 5l

Api 5l

DATA ENTRY SYMBOL.

VALUES

VALUES

VALUES

HDR./BR.

HDR./BR.

HDR./BR.

36/32

36/30

36/28

150.0000

150.0000

150.0000

150.0000

150.0000

150.0000

Api 5l

Api 5l

Api 5l

VALUES

HDR./BR.

36/26

150.0000

150.0000

VALUES

HDR./BR.

36/24

150.0000

150.0000

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

20000

20000

1.0000

1.0000

0.4000

1.5708

0.5000

0.5000

0.4375

0.4375

0.1000

12.5000

12.5000

36.0000

36.0000

0.2500

20000

20000

1.00

1.00

0.40

1.57

0.500

0.315

0.4375

0.2756

0.100

12.500

12.5000

36.000

34.000

0.220

20000

20000

1.00

1.00

0.40

1.57

0.500

0.315

0.4375

0.2756

0.100

12.500

12.5000

36.000

32.000

0.221

20000

20000

1.00

1.00

0.40

1.57

0.500

0.315

0.4375

0.2756

0.100

12.500

12.5000

36.000

30.000

0.221

20000

20000

1.00

1.00

0.40

1.57

0.500

0.315

0.4375

0.2756

0.100

12.500

12.5000

36.000

28.000

0.221

20000

20000

1.00

1.00

0.40

1.57

0.500

0.315

0.4375

0.2756

0.100

12.500

12.5000

36.000

26.000

0.221

20000

20000

1.00

1.00

0.40

1.57

0.500

0.375

0.4375

0.3281

0.100

12.500

12.5000

36.000

24.000

0.250

th=

tb=

A1=

A2=

A3=

tc=

0.1346

0.1346

4.7546

7.1676

0.3424

0.2500

0.3535

0.1346

0.1271

4.5290

6.8275

0.0426

0.2205

0.2227

0.1346

0.1196

4.2598

6.4217

0.0492

0.2205

0.2227

0.1346

0.1122

3.9906

6.0158

0.0557

0.2205

0.2227

0.1346

0.1047

3.7214

5.6100

0.0623

0.2205

0.2227

0.1346

0.0972

3.4522

5.2042

0.0689

0.2205

0.2227

0.1346

0.0897

3.1689

4.7771

0.1579

0.2500

0.2651

in2

in2

0.2500

7.7600

0.0992

6.9692

0.0992

6.5700

0.0992

6.1708

0.0992

5.7716

0.0992

5.3723

0.1406

5.0756

Th*=

Tb*=

C=

%=

%=

Dh=

Db=

W=

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

VALUES

HDR./BR.

36/36

150.0000

150.0000

Reinf not reqd

Reinf not reqd Reinf not reqd Reinf not reqd Reinf not reqd Reinf not reqd

181454434.xls.ms_office

Reinf not reqd

3 OF 131

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR.

TO =

Pd =

Sh=

Sb=

Eh=

Eb=

Y=

bradians

VALUES

HDR./BR.

36/20

150.0000

150.0000

VALUES

HDR./BR.

36/18

150.0000

150.0000

VALUES

HDR./BR.

36/16

150.0000

150.0000

VALUES

HDR./BR.

36/14

150.0000

150.0000

VALUES

HDR./BR.

36/12

150.0000

150.0000

VALUES

HDR./BR.

36/10

150.0000

150.0000

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

20000

20000

1.00

1.00

0.40

1.57

0.500

0.375

0.4375

0.3281

0.100

12.500

12.5000

36.000

22.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.500

0.375

0.4375

0.3281

0.100

12.500

12.5000

36.000

20.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.500

0.375

0.4375

0.3281

0.100

12.500

12.5000

36.000

18.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.500

0.375

0.4375

0.3281

0.100

12.500

12.5000

36.000

16.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.500

0.375

0.4375

0.3281

0.100

12.500

12.5000

36.000

14.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.500

0.375

0.4375

0.3281

0.100

12.500

12.5000

36.000

12.750

0.250

20000

20000

1.00

1.00

0.40

1.57

0.500

0.365

0.4375

0.3193

0.100

12.500

12.5000

36.000

10.750

0.250

th=

tb=

A1=

A2=

A3=

tc=

0.1346

0.0823

2.8997

4.3713

0.1664

0.2500

0.2651

0.1346

0.0748

2.6305

3.9655

0.1749

0.2500

0.2651

0.1346

0.0673

2.3613

3.5597

0.1834

0.2500

0.2651

0.1346

0.0598

2.0921

3.1539

0.1920

0.2500

0.2651

0.1346

0.0523

1.8229

2.7481

0.2005

0.2500

0.2651

0.1346

0.0477

1.6547

2.4944

0.2058

0.2500

0.2651

0.1346

0.0402

1.3879

2.0922

0.1965

0.2500

0.2580

in2

in2

0.1406

4.6783

0.1406

4.2810

0.1406

3.8838

0.1406

3.4865

0.1406

3.0892

0.1406

2.8409

0.1332

2.4219

Reinf not reqd

Reinf not reqd

Th*=

Tb*=

C=

%=

%=

Dh=

Db=

W=

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

VALUES

HDR./BR.

36/22

150.0000

150.0000

181454434.xls.ms_office

Reinf not reqd

Reinf not reqd

Reinf not reqd

Reinf not reqd

Reinf not reqd

4 OF 131

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR. VALUES

HDR./BR.

36/8

TO =

150.0000

Pd =

150.0000

Api 5l

Api 5l

VALUES

HDR./BR.

36/4

150.0000

150.0000

VALUES

HDR./BR.

36/3

150.0000

150.0000

VALUES

HDR./BR.

36/2

150.0000

150.0000

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Sh=

20000

Sb=

20000

Eh=

1.00

Eb=

1.00

Y=

0.40

bradians 1.57

0.500

0.322

Th*=

0.4375

Tb*=

0.2818

C=

0.100

%=

12.500

%=

12.5000

Dh=

36.000

Db=

8.625

W=

0.225

20000

20000

1.00

1.00

0.40

1.57

0.500

0.280

0.4375

0.2449

0.100

12.500

12.5000

36.000

6.625

0.196

20000

20000

1.00

1.00

0.40

1.57

0.500

0.337

0.4375

0.2949

0.100

12.500

12.5000

36.000

4.500

0.236

20000

20000

1.00

1.00

0.40

1.57

0.500

0.300

0.4375

0.2625

0.100

12.500

12.5000

36.000

3.500

0.210

20000

20000

1.00

1.00

0.40

1.57

0.500

0.343

0.4375

0.3000

0.100

12.500

12.5000

36.000

2.375

0.240

th=

tb=

A1=

A2=

A3=

tc=

0.1346

0.0322

1.1120

1.6763

0.1359

0.2254

0.2277

0.1346

0.0248

0.8527

1.2854

0.0871

0.1959

0.1979

0.1346

0.0168

0.5532

0.8340

0.1735

0.2359

0.2383

0.1346

0.0131

0.4273

0.6442

0.1214

0.2100

0.2121

0.1346

0.0089

0.2658

0.4007

0.1912

0.2400

0.2424

in2

in2

0.1037

1.9159

0.0784

1.4509

0.1136

1.1210

0.0900

0.8556

0.1176

0.7095

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

VALUES

HDR./BR.

36/6

150.0000

150.0000

Reinf not reqd

181454434.xls.ms_office

Reinf not reqd

Reinf not reqd

Reinf not reqd Reinf not reqd

5 OF 131

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR.

TO =

Pd =

Sh=

Sb=

Eh=

Eb=

Y=

bradians

Api 5l

DATA ENTRY SYMBOL.

VALUES

VALUES

VALUES

VALUES

HDR./BR.

HDR./BR.

HDR./BR.

HDR./BR.

34/32

34/30

34/28

34/26

150.0000 ## 150.0000 ## 150.0000 ## 150.0000

150.0000 ## 150.0000 ## 150.0000 ## 150.0000

Api 5l

Api 5l

Api 5l

Api 5l

VALUES

HDR./BR.

34/24

150.0000

150.0000

VALUES

HDR./BR.

34/22

150.0000

150.0000

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

20000

20000

1.0000

1.0000

0.4000

1.5708

0.3150

0.3150

0.2756

0.2756

0.1000

12.5000

12.5000

34.0000

34.0000

0.1929

20000

20000

1.00

1.00

0.40

1.57

0.315

0.315

0.2756

0.2756

0.100

12.500

12.5000

34.000

32.000

0.221

20000

20000

1.00

1.00

0.40

1.57

0.315

0.315

0.2756

0.2756

0.100

12.500

12.5000

34.000

30.000

0.221

20000

20000

1.00

1.00

0.40

1.57

0.315

0.315

0.2756

0.2756

0.100

12.500

12.5000

34.000

28.000

0.221

20000

20000

1.00

1.00

0.40

1.57

0.315

0.315

0.2756

0.2756

0.100

12.500

12.5000

34.000

26.000

0.221

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

34.000

24.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

34.000

22.000

0.250

th=

tb=

A1=

A2=

A3=

tc=

0.1271

0.1271

4.2774

1.6310

0.0426

0.2205

0.2227

0.1271

0.1271

4.2774

1.6310

0.0426

0.2205

0.2227

0.1271

0.1196

4.0231

1.5341

0.0492

0.2205

0.2227

0.1271

0.1122

3.7689

1.4371

0.0557

0.2205

0.2227

0.1271

0.1047

3.5147

1.3402

0.0623

0.2205

0.2227

0.1271

0.0972

3.2471

1.2382

0.1149

0.2500

0.2651

0.1271

0.0897

2.9928

1.1412

0.1215

0.2500

0.2651

in2

in2

0.0992

1.7728

0.0992

1.7728

0.0992

1.6825

0.0992

1.5921

0.0992

1.5017

0.1406

1.4937

0.1406

1.4033

Reinf reqd

Reinf reqd

Reinf reqd

Reinf reqd

Th*=

Tb*=

C=

%=

%=

Dh=

Db=

W=

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

VALUES

HDR./BR.

34/34

150.0000

150.0000

Reinf reqd

181454434.xls.ms_office

Reinf reqd

Reinf reqd

6 OF 134

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR.

TO =

Pd =

Sh=

Sb=

Eh=

Eb=

Y=

bradians

VALUES

HDR./BR.

34/18

150.0000

150.0000

VALUES

HDR./BR.

34/16

150.0000

150.0000

VALUES

HDR./BR.

34/14

150.0000

150.0000

VALUES

HDR./BR.

34/12.75

150.0000

150.0000

VALUES

HDR./BR.

34/10.75

150.0000

150.0000

VALUES

HDR./BR.

34/8.625

150.0000

150.0000

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

34.000

20.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

34.000

18.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

34.000

16.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

34.000

14.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

34.000

12.750

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.365

0.2756

0.3193

0.100

12.500

12.5000

34.000

10.750

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.322

0.2756

0.2818

0.100

12.500

12.5000

34.000

8.625

0.225

th=

tb=

A1=

A2=

A3=

tc=

0.1271

0.0823

2.7386

1.0443

0.1281

0.2500

0.2651

0.1271

0.0748

2.4844

0.9473

0.1346

0.2500

0.2651

0.1271

0.0673

2.2301

0.8504

0.1412

0.2500

0.2651

0.1271

0.0598

1.9759

0.7534

0.1478

0.2500

0.2651

0.1271

0.0523

1.7217

0.6565

0.1543

0.2500

0.2651

0.1271

0.0477

1.5650

0.5968

0.1507

0.2500

0.2580

0.1271

0.0402

1.3203

0.5034

0.1243

0.2254

0.2277

in2

in2

0.1406

1.3130

0.1406

1.2226

0.1406

1.1322

0.1406

1.0418

0.1406

0.9514

0.1332

0.8807

0.1037

0.7315

Reinf reqd

Reinf reqd

Reinf reqd

Reinf reqd

Reinf reqd

Th*=

Tb*=

C=

%=

%=

Dh=

Db=

W=

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

VALUES

HDR./BR.

34/20

150.0000

150.0000

Reinf reqd

Reinf reqd

181454434.xls.ms_office

7 OF 134

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR. VALUES

HDR./BR.

34/6.625

TO =

150.0000

Pd =

150.0000

Api 5l

Api 5l

VALUES

HDR./BR.

34/3.5

150.0000

150.0000

VALUES

HDR./BR.

34/2.375

150.0000

150.0000

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Sh=

20000

Sb=

20000

Eh=

1.00

Eb=

1.00

Y=

0.40

bradians 1.57

0.315

0.280

Th*=

0.2756

Tb*=

0.2449

C=

0.100

%=

12.500

%=

12.5000

Dh=

34.000

Db=

6.625

W=

0.196

20000

20000

1.00

1.00

0.40

1.57

0.315

0.337

0.2756

0.2949

0.100

12.500

12.5000

34.000

4.500

0.236

20000

20000

1.00

1.00

0.40

1.57

0.315

0.300

0.2756

0.2625

0.100

12.500

12.5000

34.000

3.500

0.210

20000

20000

1.00

1.00

0.40

1.57

0.315

0.343

0.2756

0.3000

0.100

12.500

12.5000

34.000

2.375

0.240

th=

tb=

A1=

A2=

A3=

tc=

0.1271

0.0322

1.0596

0.4040

0.0817

0.1959

0.1979

0.1271

0.0248

0.7926

0.3022

0.1493

0.2359

0.2383

0.1271

0.0168

0.5307

0.2024

0.1184

0.2100

0.2121

0.1271

0.0131

0.3941

0.1503

0.1641

0.2400

0.2424

in2

in2

0.0784

0.5640

0.1136

0.5651

0.0900

0.4107

0.1176

0.4320

Reinf reqd

Reinf reqd

Reinf reqd

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

VALUES

HDR./BR.

34/4.5

150.0000

150.0000

181454434.xls.ms_office

Reinf not reqd

8 OF 134

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR.

TO =

Pd =

Sh=

Sb=

Eh=

Eb=

Y=

bradians

Th*=

Tb*=

C=

%=

%=

Dh=

Db=

W=

th=

tb=

A1=

A2=

A3=

tc=

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

in2

in2

181454434.xls.ms_office

9 OF 134

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR.

TO =

Pd =

Sh=

Sb=

Eh=

Eb=

Y=

bradians

Th*=

Tb*=

C=

%=

%=

Dh=

Db=

W=

th=

tb=

A1=

A2=

A3=

tc=

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

in2

in2

181454434.xls.ms_office

10 OF 134

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR.

TO =

Pd =

Sh=

Sb=

Eh=

Eb=

Y=

bradians

Th*=

Tb*=

C=

%=

%=

Dh=

Db=

W=

th=

tb=

A1=

A2=

A3=

tc=

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

in2

in2

181454434.xls.ms_office

11 OF 134

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR.

TO =

Pd =

Sh=

Sb=

Eh=

Eb=

Y=

bradians

Th*=

Tb*=

C=

%=

%=

Dh=

Db=

W=

th=

tb=

A1=

A2=

A3=

tc=

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

in2

in2

181454434.xls.ms_office

12 OF 134

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR.

TO =

Pd =

Sh=

Sb=

Eh=

Eb=

Y=

bradians

VALUES

HDR./BR.

32/30

150.0000

150.0000

Api 5l

Api 5l

DATA ENTRY SYMBOL.

VALUES

VALUES

VALUES

HDR./BR.

HDR./BR.

HDR./BR.

32/28

32/26

32/24

150.0000

150.0000

150.0000

150.0000

150.0000

150.0000

Api 5l

Api 5l

Api 5l

VALUES

HDR./BR.

32/22

150.0000

150.0000

VALUES

HDR./BR.

32/20

150.0000

150.0000

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

20000

20000

1.0000

1.0000

0.4000

1.5708

0.3150

0.3150

0.2756

0.2756

0.1000

12.5000

12.5000

32.0000

32.0000

0.1929

20000

20000

1.00

1.00

0.40

1.57

0.315

0.315

0.2756

0.2756

0.100

12.500

12.5000

32.000

30.000

0.221

20000

20000

1.00

1.00

0.40

1.57

0.315

0.315

0.2756

0.2756

0.100

12.500

12.5000

32.000

28.000

0.221

20000

20000

1.00

1.00

0.40

1.57

0.315

0.315

0.2756

0.2756

0.100

12.500

12.5000

32.000

26.000

0.221

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

32.000

24.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

32.000

22.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

32.000

20.000

0.250

th=

tb=

A1=

A2=

A3=

tc=

0.1196

0.1196

3.7865

1.7718

0.0492

0.2205

0.2227

0.1196

0.1122

3.5472

1.6599

0.0557

0.2205

0.2227

0.1196

0.1047

3.3079

1.5479

0.0623

0.2205

0.2227

0.1196

0.0972

3.0686

1.4359

0.0689

0.2205

0.2227

0.1196

0.0897

2.8168

1.3181

0.1215

0.2500

0.2651

0.1196

0.0823

2.5775

1.2061

0.1281

0.2500

0.2651

0.1196

0.0748

2.3382

1.0941

0.1347

0.2500

0.2651

in2

in2

0.0992

1.9202

0.0992

1.8148

0.0992

1.7094

0.0992

1.6040

0.1406

1.5802

0.1406

1.4748

0.1406

1.3694

Reinf reqd

Reinf reqd

Reinf reqd

Reinf reqd

Th*=

Tb*=

C=

%=

%=

Dh=

Db=

W=

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

VALUES

HDR./BR.

32/32

150.0000

150.0000

Reinf reqd

181454434.xls.ms_office

Reinf reqd

Reinf reqd

13 OF 134

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR.

TO =

Pd =

Sh=

Sb=

Eh=

Eb=

Y=

bradians

VALUES

HDR./BR.

32/16

150.0000

150.0000

VALUES

HDR./BR.

32/14

150.0000

150.0000

VALUES

HDR./BR.

32/12.75

150.0000

150.0000

VALUES

HDR./BR.

32/10.75

150.0000

150.0000

VALUES

HDR./BR.

32/8.625

150.0000

150.0000

VALUES

HDR./BR.

32/6.625

150.0000

150.0000

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

32.000

18.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

32.000

16.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

32.000

14.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

32.000

12.750

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.365

0.2756

0.3193

0.100

12.500

12.5000

32.000

10.750

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.322

0.2756

0.2818

0.100

12.500

12.5000

32.000

8.625

0.225

20000

20000

1.00

1.00

0.40

1.57

0.315

0.280

0.2756

0.2449

0.100

12.500

12.5000

32.000

6.625

0.196

th=

tb=

A1=

A2=

A3=

tc=

0.1196

0.0673

2.0990

0.9822

0.1412

0.2500

0.2651

0.1196

0.0598

1.8597

0.8702

0.1478

0.2500

0.2651

0.1196

0.0523

1.6204

0.7582

0.1544

0.2500

0.2651

0.1196

0.0477

1.4708

0.6883

0.1585

0.2500

0.2651

0.1196

0.0402

1.2337

0.5773

0.1573

0.2500

0.2580

0.1196

0.0322

0.9884

0.4625

0.1313

0.2254

0.2277

0.1196

0.0248

0.7579

0.3547

0.0871

0.1959

0.1979

in2

in2

0.1406

1.2640

0.1406

1.1586

0.1406

1.0532

0.1406

0.9873

0.1332

0.8678

0.1037

0.6975

0.0784

0.5201

Reinf reqd

Reinf reqd

Reinf reqd

Reinf reqd

Reinf reqd

Th*=

Tb*=

C=

%=

%=

Dh=

Db=

W=

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

VALUES

HDR./BR.

32/18

150.0000

150.0000

Reinf reqd

Reinf reqd

181454434.xls.ms_office

14 OF 134

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR. VALUES

HDR./BR.

32/4.5

TO =

150.0000

Pd =

150.0000

Api 5l

Api 5l

VALUES

HDR./BR.

32/2.375

150.0000

150.0000

Api 5l

Api 5l

Api 5l

Api 5l

Sh=

20000

Sb=

20000

Eh=

1.00

Eb=

1.00

Y=

0.40

bradians 1.57

0.315

0.337

Th*=

0.2756

Tb*=

0.2949

C=

0.100

%=

12.500

%=

12.5000

Dh=

32.000

Db=

4.500

W=

0.236

20000

20000

1.00

1.00

0.40

1.57

0.315

0.300

0.2756

0.2625

0.100

12.500

12.5000

32.000

3.500

0.210

20000

20000

1.00

1.00

0.40

1.57

0.315

0.343

0.2756

0.3000

0.100

12.500

12.5000

32.000

2.375

0.240

th=

tb=

A1=

A2=

A3=

tc=

0.1196

0.0168

0.4918

0.2301

0.1564

0.2359

0.2383

0.1196

0.0131

0.3799

0.1777

0.1214

0.2100

0.2121

0.1196

0.0089

0.2363

0.1106

0.1679

0.2400

0.2424

in2

in2

0.1136

0.5000

0.0900

0.3891

0.1176

0.3960

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

VALUES

HDR./BR.

32/3.5

150.0000

150.0000

Reinf not reqd

Reinf not reqd

Reinf not reqd

181454434.xls.ms_office

15 OF 134

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR.

TO =

Pd =

Sh=

Sb=

Eh=

Eb=

Y=

bradians

Th*=

Tb*=

C=

%=

%=

Dh=

Db=

W=

th=

tb=

A1=

A2=

A3=

tc=

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

in2

in2

181454434.xls.ms_office

16 OF 134

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR.

TO =

Pd =

Sh=

Sb=

Eh=

Eb=

Y=

bradians

Th*=

Tb*=

C=

%=

%=

Dh=

Db=

W=

th=

tb=

A1=

A2=

A3=

tc=

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

in2

in2

181454434.xls.ms_office

17 OF 134

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR.

TO =

Pd =

Sh=

Sb=

Eh=

Eb=

Y=

bradians

Th*=

Tb*=

C=

%=

%=

Dh=

Db=

W=

th=

tb=

A1=

A2=

A3=

tc=

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

in2

in2

181454434.xls.ms_office

18 OF 134

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR.

TO =

Pd =

Sh=

Sb=

Eh=

Eb=

Y=

bradians

Th*=

Tb*=

C=

%=

%=

Dh=

Db=

W=

th=

tb=

A1=

A2=

A3=

tc=

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

in2

in2

181454434.xls.ms_office

19 OF 134

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR.

TO =

Pd =

Sh=

Sb=

Eh=

Eb=

Y=

bradians

Api 5l

DATA ENTRY SYMBOL.

VALUES

VALUES

VALUES

HDR./BR.

HDR./BR.

HDR./BR.

30/28

30/26

30/24

150.0000

150.0000

150.0000

150.0000

150.0000

150.0000

Api 5l

Api 5l

Api 5l

VALUES

HDR./BR.

30/22

150.0000

150.0000

VALUES

HDR./BR.

30/20

150.0000

150.0000

VALUES

HDR./BR.

30/18

150.0000

150.0000

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

20000

20000

1.0000

1.0000

0.4000

1.5708

0.3150

0.3150

0.2756

0.2756

0.1000

12.5000

12.5000

30.0000

30.0000

0.2205

20000

20000

1.00

1.00

0.40

1.57

0.315

0.315

0.2756

0.2756

0.100

12.500

12.5000

30.000

28.000

0.221

20000

20000

1.00

1.00

0.40

1.57

0.315

0.315

0.2756

0.2756

0.100

12.500

12.5000

30.000

26.000

0.221

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

30.000

24.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

30.000

22.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

30.000

20.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

30.000

18.000

0.250

th=

tb=

A1=

A2=

A3=

tc=

0.1122

0.1122

3.3255

1.8816

0.0557

0.2205

0.2227

0.1122

0.1047

3.1012

1.7546

0.0623

0.2205

0.2227

0.1122

0.0972

2.8769

1.6277

0.0689

0.2205

0.2227

0.1122

0.0897

2.6407

1.4941

0.1215

0.2500

0.2651

0.1122

0.0823

2.4164

1.3672

0.1281

0.2500

0.2651

0.1122

0.0748

2.1921

1.2403

0.1347

0.2500

0.2651

0.1122

0.0673

1.9678

1.1134

0.1412

0.2500

0.2651

in2

in2

0.0992

2.0365

0.0992

1.9161

0.0992

1.7958

0.1406

1.7563

0.1406

1.6359

0.1406

1.5156

0.1406

1.3952

Reinf reqd

Reinf reqd

Reinf reqd

Reinf reqd

Th*=

Tb*=

C=

%=

%=

Dh=

Db=

W=

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

VALUES

HDR./BR.

30/30

150.0000

150.0000

Reinf reqd

181454434.xls.ms_office

Reinf reqd

Reinf reqd

20 OF 134

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR.

TO =

Pd =

Sh=

Sb=

Eh=

Eb=

Y=

bradians

VALUES

HDR./BR.

30/14

150.0000

150.0000

VALUES

HDR./BR.

30/12.75

150.0000

150.0000

VALUES

HDR./BR.

30/10.75

150.0000

150.0000

VALUES

HDR./BR.

30/8.625

150.0000

150.0000

VALUES

HDR./BR.

30/6.625

150.0000

150.0000

VALUES

HDR./BR.

30/4.5

150.0000

150.0000

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

30.000

16.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

30.000

14.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

30.000

12.750

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.365

0.2756

0.3193

0.100

12.500

12.5000

30.000

10.750

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.322

0.2756

0.2818

0.100

12.500

12.5000

30.000

8.625

0.225

20000

20000

1.00

1.00

0.40

1.57

0.315

0.280

0.2756

0.2449

0.100

12.500

12.5000

30.000

6.625

0.196

20000

20000

1.00

1.00

0.40

1.57

0.315

0.337

0.2756

0.2949

0.100

12.500

12.5000

30.000

4.500

0.236

th=

tb=

A1=

A2=

A3=

tc=

0.1122

0.0598

1.7434

0.9864

0.1478

0.2500

0.2651

0.1122

0.0523

1.5191

0.8595

0.1544

0.2500

0.2651

0.1122

0.0477

1.3789

0.7802

0.1585

0.2500

0.2651

0.1122

0.0402

1.1566

0.6544

0.1573

0.2500

0.2580

0.1122

0.0322

0.9266

0.5243

0.1313

0.2254

0.2277

0.1122

0.0248

0.7106

0.4020

0.0871

0.1959

0.1979

0.1122

0.0168

0.4610

0.2608

0.1564

0.2359

0.2383

in2

in2

0.1406

1.2748

0.1406

1.1545

0.1406

1.0793

0.1332

0.9449

0.1037

0.7593

0.0784

0.5675

0.1136

0.5308

Reinf reqd

Reinf reqd

Reinf reqd

Reinf reqd

Th*=

Tb*=

C=

%=

%=

Dh=

Db=

W=

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

VALUES

HDR./BR.

30/16

150.0000

150.0000

Reinf reqd

Reinf reqd

181454434.xls.ms_office

Reinf not reqd

21 OF 134

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR. VALUES

HDR./BR.

30/3.5

TO =

150.0000

Pd =

150.0000

Api 5l

Api 5l

Api 5l

Api 5l

Sh=

20000

Sb=

20000

Eh=

1.00

Eb=

1.00

Y=

0.40

bradians 1.57

0.315

0.300

Th*=

0.2756

Tb*=

0.2625

C=

0.100

%=

12.500

%=

12.5000

Dh=

30.000

Db=

3.500

W=

0.210

20000

20000

1.00

1.00

0.40

1.57

0.315

0.343

0.2756

0.3000

0.100

12.500

12.5000

30.000

2.375

0.240

th=

tb=

A1=

A2=

A3=

tc=

0.1122

0.0131

0.3561

0.2015

0.1214

0.2100

0.2121

0.1122

0.0089

0.2215

0.1253

0.1679

0.2400

0.2424

in2

in2

0.0900

0.4129

0.1176

0.4108

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

VALUES

HDR./BR.

30/2.375

150.0000

150.0000

Reinf not reqd

Reinf not reqd

181454434.xls.ms_office

22 OF 134

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR.

TO =

Pd =

Sh=

Sb=

Eh=

Eb=

Y=

bradians

Th*=

Tb*=

C=

%=

%=

Dh=

Db=

W=

th=

tb=

A1=

A2=

A3=

tc=

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

in2

in2

181454434.xls.ms_office

23 OF 134

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR.

TO =

Pd =

Sh=

Sb=

Eh=

Eb=

Y=

bradians

Th*=

Tb*=

C=

%=

%=

Dh=

Db=

W=

th=

tb=

A1=

A2=

A3=

tc=

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

in2

in2

181454434.xls.ms_office

24 OF 134

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR.

TO =

Pd =

Sh=

Sb=

Eh=

Eb=

Y=

bradians

Th*=

Tb*=

C=

%=

%=

Dh=

Db=

W=

th=

tb=

A1=

A2=

A3=

tc=

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

in2

in2

181454434.xls.ms_office

25 OF 134

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR.

TO =

Pd =

Sh=

Sb=

Eh=

Eb=

Y=

bradians

Th*=

Tb*=

C=

%=

%=

Dh=

Db=

W=

th=

tb=

A1=

A2=

A3=

tc=

minimum leg dimension of fillet weld

A4(Area in branch welds)

available area A2+A3+A4=

in2

in2

181454434.xls.ms_office

26 OF 134

REINFORCEMENT PAD ANALYSIS

REQUIREMENT OF REINFORCEMENT FOR PIPE BRANCH OF METALS

Spec-:

A1A

SR. DESCRIPTION

NO.

1

2

3

DESIGN TEMPERATURE (DEG.F.)

DESIGN PRESSURE (PSIG.)

MATERIAL OF CONSTRUCTION FOR HEADER

4

5

6

7

8

9

MATERIAL OF CONSTRUCTION FOR BRANCH

ALLOWABLE STRESS VALUE OF HEADER.(PSI)

ALLOWABLE STRESS VALUE OF BRANCH.(PSI)

JOINT EFFICIENCY FOR HEADER

JOINT EFFICIENCY FOR BRANCH

COEFFICIENT

Branch angle (beta)b

NOMINAL THICKNESS OF HEADER PIPE.(INCH.)

NOMINAL THICKNESS OF BRANCH PIPE.(INCH.)

ACTUAL OR MEASURED THICKNESS HEADER

ACTUAL OR MEASURED THICKNESS BRANCH

CORROSION ALLOWANCE.(INCH.)

MILL TOLERANCE (HEADER).

MILL TOLERANCE (BRANCH).

OUTSIDE DIAMETER OF PIPE HEADER.(INCH.)

OUTSIDE DIAMETER OF BRANCH PIPE.(INCH.)

SIZE OF WELD LEG.(INCH.)

ANALYSIS

MINIMUM PIPE HEADER PRESSURE THICKNESS

MINIMUM PIPE BRANCH PRESSURE THICKNESS

A1 (Required reinforcement area)in2

A2 (Area from excess thickness in pipe wall)=

A3(Area from excess thickness in branch wall)=

10

11

12

13

14

15

16

17

18

19

ABBR.

TO =

Pd =

Sh=

Sb=

Eh=

Eb=

Y=

bradians

Api 5l

Api 5l

Api 5l

VALUES

HDR./BR.

28/22

150.0000

150.0000

VALUES

HDR./BR.

28/20

150.0000

150.0000

VALUES

HDR./BR.

28/18

150.0000

150.0000

VALUES

HDR./BR.

28/16

150.0000

150.0000

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

Api 5l

20000

20000

1.0000

1.0000

0.4000

1.5708

0.3150

0.3150

0.2756

0.2756

0.1000

12.5000

12.5000

28.0000

28.0000

0.2205

20000

20000

1.00

1.00

0.40

1.57

0.315

0.315

0.2756

0.2756

0.100

12.500

12.5000

28.000

26.000

0.221

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

28.000

24.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

28.000

22.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

28.000

20.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

28.000

18.000

0.250

20000

20000

1.00

1.00

0.40

1.57

0.315

0.375

0.2756

0.3281

0.100

12.500

12.5000

28.000

16.000

0.250

th=

tb=

A1=

A2=

A3=

tc=

0.1047

0.1047

2.8944

1.9614

0.0623

0.2205

0.2227

0.1047

0.0972

2.6851

1.8195