Professional Documents

Culture Documents

Buckling of Struts

Uploaded by

Ikhwan Z.Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Buckling of Struts

Uploaded by

Ikhwan Z.Copyright:

Available Formats

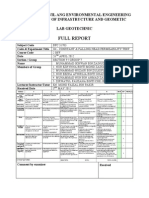

FACULTY OF CIVIL AND ENVIRONMENTAL ENGINEERING DEPARTMENT OF STRUCTURE AND MATERIAL ENGINEERING LAB MATERIAL

REPORT

Subject Code Code & Experiment Title Course Code Date Section / Group Name Members of Group BFC 21201 BUCKLING OF STRUTS 2 BFF/1 03/10/2011 2 MUHAMAD ASYRAF BIN AB MALIK 1.MUHAMMAD IKHWAN BIN ZAINUDDIN 2.AHMAD FARHAN BIN RAKAWI 3.IDAMAZLIZA BINTI ISA 4.AINUN NAZHIRIN BINTI ABD JALIL EN MOHAMAD HAIRI BIN OSMAN 17 OCTOBER 2011

(DF100108) (DF100018) (DF100142) (DF100128) (DF100076)

Lecturer/Instructor/Tutor Received Date

Comment by examiner

Received

STUDENT CODE OF ETHIC (SCE)

DEPARTMENT OF STRUCTURE AND MATERIAL ENGINEERING FACULTY OF CIVIL & ENVIRONMENTAL ENGINEERING UTHM

We, hereby confess that we have prepared this report on our effort. We also admit not to receive or give any help during the preparation of this report and pledge that everything mentioned in the report is true.

___________________________ Student Signature Name : MUHAMAD ASYRAF AB MALIK Name ___________________________ Student Signature : IDAMAZLIZA ISA

Matric No. : DF100108 Date : 17/10/2011

Matric No. : DF100128 Date : 17/10/2011

___________________________ Student Signature Name : AHMAD FARHAN RAKAWI Name

___________________________ Student Signature : AINUN NAZHIRIN ABD JALIL

Matric No. : DF100142 Date : 17/10/2011

Matric No. : DF100076 Date : 17/10/2011

_______________________ Student Signature Name : MUHAMMAD IKHWAN ZAINUDDIN

Matric No. : DF100018 Date : 17/10/2011

1.0

OBJECTIVE 1.1 To examine how shear force varies with an increasing point load. 1.2 To examine how shear force varies at the cut position of the beam for various loading condition.

2.0

LEARNING OUTCOME 2.1 The application the engineering knowledge in practical application. 2.2 To enhance technical competency in structural engineering through laboratory application. 2.3 To communicate effectively in group. 2.4 To identify problem, solving and finding out appropriate solution through laboratory application.

3.0

INTRODUCTION A compressive member can fail in two ways. The first is via rupture due to the direct stress and the second is by an elastic mode of failure called buckling. Short wide compressive member tends to fail by material crushing. When buckling occurs the strut will no longer carry any more load and it will simply continue to buckle i.e its stiffness then becomes zero and it is useless as a structural member.

4.0

THEORY To predict the buckling load Euler buckling formula is used. The crictical value in Euler Formula is the slenderness ratio, which is the ratio of the length of the strut to its radius of gyration (L/K). The Euler formula become inaccurate for struts with L/K ratio of less than 1.125 and this should be taken into account in any design work.

Euler buckling formula for pin struts: Pe=2EI/L2 Where; Pe = Euler buckling load (N) E = Youngs Modulus (Nm-2) I = Second moment of area ( m4 ) L = length of strut ( m )

5.0

APPARATUS

Buckling of Strut Digital Display Force

Buckling of Strut Equipment

Steel Strut

6.0

PROCEDURES

Part 1 1. Fit the bottom chuck to the machine and remove the top chuck (to give two pinned ends). Select the shortest strut, number 1, and measured the cross section using the vernier provided and calculated the second moment of area, I,for the strut. ( bd3/12) 2. Adjust the position of the sliding crosshead to accept the strut using the thumbnut to lock off the slider. Ensure that there is the maximum amount of travel available on the hand wheel threat to compress the strut. Finally tighten the locking screw . 3. Carefully back- off the handwheel so that the strut is resting in the notch but not transmitting any load. Rezero the forcemeter using the front panel control. 4. Carefully start to load the strut. If the strut begin to buckle to the left, flick the strut to the right and vice versa (this reduces any error associated wih the straightness of strut). Turn the hand wheel until there is no further increase in load (the load may peak and then drop as it settles in the notches). 5. Record the final load in Table 1. Repeat with strut numbers 2, 3, 4 and 5 adjusting the crosshead as required to fit the strut.

Part 2 1. To study the effect of end conditions, follow the same basic procedure as in part 1, but this time remove the bottom chuck and clamp the specimen using the cap head screw and plate to make a pinned-fixed end condition. 2. Record your result in Table 2 and calculate the values of 1/ L2 for the struts. 3. Fit the top chuck with the two cap head screws and clamp both ends of the specimen to make a pinned pinned end condition. Calculate the new values of 1/L2. 4. Enter the result into Table 3

7.0

RESULTS

Strut Number 1 2 3 4 5

Length (m) 0.32 0.37 0.42 0.47 0.52

Buckling Load (N) Experiment -92 -56 -24 -13 -16 Table 1

Buckling Load (N) Theory 88.65 66.31 51.46 41.09 33.57

Strut Number 1 2 3 4 5

Length (m) 0.32 0.37 0.42 0.47 0.52

Buckling Load (N) -196 -106 -105 -101 -48 Table2

Buckling Load (N) Theory 177.30 132.62 102.92 82.19 67.14

1/L2 ( m-2) 9.77 7.30 5.67 4.53 3.70

Strut Number 1 2 3 4 5

Length (m) 0.32 0.37 0.42 0.47 0.52

Buckling Load (N) -397 -284 -252 -174 -155 Table 3

Buckling Load (N) Theory 354.60 265.24 205.85 164.38 134.29

1/L2 ( m-2)

9.77 7.30 5.67 4.53 3.70

8.0

DATA ANALYSIS Part 1 To calculate Buckling Load (N) Theory ( pinned-pinned end condition) Pe = 2 EI/L2 = 2 ( 69 x 10 9 ) ( 13.33 x 10 -12 ) 0.322 = 88.65 N I = bd3 12 = ( 0.02 ) ( 2 x 10 -3 ) 12 = 13.33 x 10 -12 m

Part 2 To calculate Buckling Load (N) Theory ( pinned-fixed end condition) Pe = 22 EI/L2 = 22 ( 69 x 109 ) ( 13.33 x 10 -12 ) 0.322 = 177.30 N I = bd3 12 = ( 0.02 ) ( 2 x 10 -3 ) 12 = 13.33 x 10 -12 m Part 3 To calculate Buckling Load (N) Theory ( fixed-fixed end condition) Pe = 42 EI/L2 = 42 ( 69 x 109 ) ( 13.33 x 10 -12 ) 0.322 = 354.60 N I = bd3 12 = ( 0.02 ) ( 2 x 10 -3 ) 12 = 13.33 x 10 -12 m

9.0

DISCUSSION Part 1: 1) Examine the Euler buckling equation and select an appropriate parameter to establish a linear relationship between the buckling load and the length of the strut. Write the relationship below.

Based Eular formula and Table 1, 2 and 3, Pe = Euler buckling load (N), L = length

We can consider that when L is bigger, Pe will be small, relation between buckling load and the length of the strut is inversely proportional in linear condition.

2) Calculate the value and enter them in Table 1 with an appropriate title. Show on Table 1 using formula: ( )

3) Plot a graph to prove the relationship is linear. Compare your experimental value to those calculated from Euler formula by entering a theoretical line onto the graph. Comment on the result. Graph plotted = In the graph paper.

Base on the graft that we plotted, the difference to the end of the pins for the results of gradient experiments is 1.46 and the slope of the theoretical calculation results of 1.28. Difference to the fixed -pin end of the gradient experiment results were 1.33 and gradient theory results of the calculation is 1.29. In addition, the differences for fixedfixed end conditions are for the gradient experiment results are 1.25 and theoretical calculations are the result of the slope is 1.25. This experiment result shows that the slope is greater than the slope of the calculation results. In practice, the buckling of the experiment is higher than theoretical.

4) Explain that the Euler Formula can predict the buckling load or not. Euler Formula can predict the buckling load, because the ratio between the Buckling Load (N) and the 1/L (m) is consistence within the graft, and show accurately that inversely proportional as approve at point 0,0 when the length is 0, then the buckling Load should be 0.

Part 2: 1. Plot separate graphs of buckling load versus 1/ L2 and calculate the gradient of each line. Graph Plotted = In Graph Paper. Gradient in the graph plotted.

2. Fill the table below showing the comparison between experimental and theoretical ratio by end condition Pinned-Pinned Experimental Gradient Experimental Ratio Theoretical Ratio 1.28/1.28=1 1.29/1.28 = 1.008 1.25/1.28 = 0.98 1.46/1.46 = 1 1.33/1.46 = 0.911 1.25/1.46 = 0.86 1.46 Pinned-Fixed 1.33 Fixed-Fixed 1.25

Notes: 1. *Use the experimental gradient fom Part 1 2. Experimental ratio = Exp. Gradient / gradient of pinned-pinned. 3. Theoretical ratio can be obtained from Euler Formula for pinnedfixed and fixed-fixed.

3. Comment on the experimental and theoretical ratio. From the table, experimental ratio is not consistence with the usage of end of connection, we basically we know that the fixed end is much stronger than the pins end as per theoretical ratio value. This shows the more force should be imposed on the members of the joint fixed-fixed end compared to the pin-pin connection. When one of the end is changed from pin end to fix end, the ratio is two times larger than the pinned-pinned, it the same case happed when both of the end changed to Fixed-fixed end. The experimental ratio is not consistence with theoretical ratio because there was several errors when conduct the experiment, such as the screw is not tightens carefully, the sliding crosshead are not tighten to the experiment apparatus.

4.

What conclusion can you made from the experiments. Based from the experiment of Buckling of Strut, we can conclude that Fixed end is much stronger than the Pinned end and more force should be imposed on the member of the joint fixed-fixed end connection, but in other criteria the usage in fixed end connection usually apply for concrete beam or column connection, The Pinned end is used for Steel connection because, usually fixed end connection is for permanent connection, steel always use bolt and nut rather than weld fabricating connection.

10.0

CONCLUSION Based from the experiment of Buckling of Strut, we can conclude that Fixed end were

much stronger than the Pinned end and more force should be imposed on the member of the joint fixed-fixed end connection, but in other criteria the usage in fixed end connection usually apply for concrete beam or column connection. The Pinned end is used for Steel connection because,it is usually fixed end connection is for permanent connection..

You might also like

- Lab Report Experiment TrussesDocument14 pagesLab Report Experiment TrussesNEWTAN100% (3)

- Road Accident and Safety & Traffic Management and ControlDocument9 pagesRoad Accident and Safety & Traffic Management and ControlIkhwan Z.No ratings yet

- Lab Report On Waren GirderDocument12 pagesLab Report On Waren GirderSamuel Ogeda Otieno100% (2)

- S3-Deflection in Beam and CantileverDocument97 pagesS3-Deflection in Beam and CantileverBruh100% (1)

- Full Report Flow in Open ChannelDocument13 pagesFull Report Flow in Open ChannelMuhammad Aimi100% (2)

- Buckling of Struts: Effects of Length and End ConditionsDocument12 pagesBuckling of Struts: Effects of Length and End ConditionsJoshua ReynoldsNo ratings yet

- CBR TestDocument8 pagesCBR TestSyafiq Latif100% (2)

- Constant & Falling Head Permeability TestDocument14 pagesConstant & Falling Head Permeability TestIkhwan Z.89% (72)

- 01 132kV FEEDER HALDIA DUPLEXDocument55 pages01 132kV FEEDER HALDIA DUPLEXhbj1990No ratings yet

- Plastic Analysis Lab ReportDocument11 pagesPlastic Analysis Lab ReportAsyiqindinia100% (1)

- Lab 1aDocument6 pagesLab 1aAre NepNo ratings yet

- Bending Beam LabDocument17 pagesBending Beam Labdoremon50% (2)

- Electrical DrivesDocument102 pagesElectrical DrivesDeepanshu Saxena100% (1)

- Flow in Open Channel Lab Report AnalysisDocument24 pagesFlow in Open Channel Lab Report AnalysisIkhwan Z.60% (10)

- Faculty of Civil and Environmental Engineering Department of Structure and Material Engineering Lab MaterialDocument19 pagesFaculty of Civil and Environmental Engineering Department of Structure and Material Engineering Lab MaterialIkhwan Z.83% (6)

- Low Viscosity Drilling Fluid, LSRVDocument8 pagesLow Viscosity Drilling Fluid, LSRVMohitTagotraNo ratings yet

- Engineering Geology Site VisitDocument31 pagesEngineering Geology Site VisitIkhwan Z.79% (14)

- Engineering Geology Site VisitDocument31 pagesEngineering Geology Site VisitIkhwan Z.79% (14)

- Deflection of A Simply Supported BeamDocument6 pagesDeflection of A Simply Supported BeamZhao Xian Lai20% (5)

- Determination of Field Density of Soils by Sand Replacement & Core Cutter MethodDocument9 pagesDetermination of Field Density of Soils by Sand Replacement & Core Cutter MethodIkhwan Z.100% (15)

- CALCULATING COMPRESSIBILITY FACTOR z FOR GASESDocument3 pagesCALCULATING COMPRESSIBILITY FACTOR z FOR GASESSrihari KodimelaNo ratings yet

- Traffic Study & Traffic Flow TheoryDocument8 pagesTraffic Study & Traffic Flow TheoryIkhwan Z.100% (2)

- Bending Moment in A BeamDocument19 pagesBending Moment in A BeamIkhwan Z.87% (102)

- Light Structure Lab Report AnalysisDocument18 pagesLight Structure Lab Report AnalysisAshraf Azhan100% (4)

- Determination of Specific Gravity by Pcynometer TestDocument13 pagesDetermination of Specific Gravity by Pcynometer TestIkhwan Z.94% (49)

- Shear Force Variation Beam Point Load LabDocument16 pagesShear Force Variation Beam Point Load LabAlif Bukhari Imran Naim57% (7)

- Road Safety Awareness for StudentsDocument10 pagesRoad Safety Awareness for Studentsalip100% (1)

- Lab ReportDocument20 pagesLab ReportJoshua Reynolds67% (3)

- Span Deflection (Double Integration Method)Document14 pagesSpan Deflection (Double Integration Method)Ikhwan Z.88% (8)

- 004-The Stability of A Floating BodyDocument10 pages004-The Stability of A Floating BodyHafizah Fadil100% (1)

- Plastic Anlysis Full ReportDocument15 pagesPlastic Anlysis Full ReportMoganraj100% (3)

- Lab 5-Force in A Statically Determinate Cantilever Truss UTHMDocument15 pagesLab 5-Force in A Statically Determinate Cantilever Truss UTHMMoly Muliyani75% (8)

- Deflection of A Simply Supported BeamDocument15 pagesDeflection of A Simply Supported Beamshuqing heongNo ratings yet

- Mechanic of Material Lab ReportDocument28 pagesMechanic of Material Lab ReportMuhd Farhan Bin Ibrahim50% (2)

- Strut Buckling Lab AnalysisDocument19 pagesStrut Buckling Lab AnalysisEsyad E-chad50% (2)

- Shear Centre of C-Channel SectionDocument12 pagesShear Centre of C-Channel SectionAshrafur Rahman100% (1)

- How Shear Force Varies with Increasing Point LoadsDocument12 pagesHow Shear Force Varies with Increasing Point LoadsAzri Arif Zainal Arif100% (1)

- ForcEs in a StatIcally IndetermInate cantIlEver trussDocument19 pagesForcEs in a StatIcally IndetermInate cantIlEver trussAwang Ridhuan64% (14)

- Pin-Jointed Truss LabreportDocument4 pagesPin-Jointed Truss LabreportFatin Afiqah40% (5)

- Relationship Between Strut Length and Buckling LoadDocument9 pagesRelationship Between Strut Length and Buckling LoadAlif Bukhari Imran NaimNo ratings yet

- Kjelstrup. Non-Equilibrium Thermodynamics For Engineers - 2010 PDFDocument273 pagesKjelstrup. Non-Equilibrium Thermodynamics For Engineers - 2010 PDFSantiago GiraldoNo ratings yet

- Shear Force Full ReportDocument14 pagesShear Force Full ReportMoganraj93% (72)

- Shear Force Influence LineDocument32 pagesShear Force Influence LineIkhwan Z.80% (5)

- Shear Force Influence LineDocument32 pagesShear Force Influence LineIkhwan Z.80% (5)

- Equilibrium of A BeamDocument5 pagesEquilibrium of A Beamawe_em50% (4)

- Shear Force Influence LinesDocument15 pagesShear Force Influence Linesajai_maravilla75% (4)

- Shear Force in A BeamDocument16 pagesShear Force in A BeamIkhwan Z.100% (7)

- Shear Force in A BeamDocument16 pagesShear Force in A BeamIkhwan Z.100% (7)

- Basic Hydrology & Infiltration TestDocument32 pagesBasic Hydrology & Infiltration TestIkhwan Z.98% (66)

- Report Levelling UthmDocument10 pagesReport Levelling Uthmأمير صفوان100% (9)

- Buckling Lab ReportDocument16 pagesBuckling Lab ReportYu Wan100% (5)

- Determining Bitumen Softening PointDocument6 pagesDetermining Bitumen Softening PointFarah Kharuddin100% (4)

- Pelton & Francis TurbinesDocument37 pagesPelton & Francis TurbinesIkhwan Z.100% (11)

- Mechanical Properties of Tension MemberDocument77 pagesMechanical Properties of Tension MemberSky Fire100% (1)

- Road Pavement Condition AnalysisDocument19 pagesRoad Pavement Condition AnalysisShahrel Bin Salleh100% (1)

- Bending Moment in A Beam Lab Report - Green MechanicDocument9 pagesBending Moment in A Beam Lab Report - Green Mechanicmohdiqbal93No ratings yet

- IKI 30 V11 EngDocument2 pagesIKI 30 V11 EngAydın PERÇEMNo ratings yet

- Lab Report 1 - Two and Three Hinged ArchesDocument19 pagesLab Report 1 - Two and Three Hinged ArchesNurshahadah Shahrunnizam100% (3)

- Slake Durability TestDocument7 pagesSlake Durability TestIkhwan Z.100% (2)

- Open Channel Flow Report LabDocument16 pagesOpen Channel Flow Report LabShauQi Lutfi60% (5)

- Buckling of Strut ReportDocument9 pagesBuckling of Strut ReportYamada Takeshi80% (5)

- Force in A Statically Determinate Cantilever TrussDocument12 pagesForce in A Statically Determinate Cantilever TrussIkhwan Z.86% (7)

- Force in A Statically Determinate Cantilever TrussDocument12 pagesForce in A Statically Determinate Cantilever TrussIkhwan Z.86% (7)

- Shear Forces and Bending Moments: Understanding Structural AnalysisDocument2 pagesShear Forces and Bending Moments: Understanding Structural AnalysisKang Lee76% (25)

- Multilane Highway Capacity AnalysisDocument9 pagesMultilane Highway Capacity AnalysisIkhwan Z.100% (1)

- Series & Parallel Pump TestDocument22 pagesSeries & Parallel Pump TestIkhwan Z.100% (23)

- Structure Lab Critical Load On StrutsDocument13 pagesStructure Lab Critical Load On StrutsNurin Adlina67% (3)

- StrutsDocument7 pagesStrutsBatrisyialya RusliNo ratings yet

- Group Members Information: CalculationDocument13 pagesGroup Members Information: CalculationAh Chia50% (2)

- Buckling of Struts Lab Report AnalysisDocument29 pagesBuckling of Struts Lab Report AnalysisAzfar Azpo100% (1)

- Lab Report Instability of StrutDocument13 pagesLab Report Instability of StrutepolNo ratings yet

- Buckling ReportDocument16 pagesBuckling ReportAin Sherin100% (3)

- Lab Report Indeterminate BeamDocument9 pagesLab Report Indeterminate BeamFatin Samsudin60% (5)

- Strut BucklingDocument9 pagesStrut BucklingWai Sheng75% (4)

- Structure Lab-Three Hinge Arc (Example Lab Report)Document13 pagesStructure Lab-Three Hinge Arc (Example Lab Report)NabilZaed0% (2)

- Experiment 2 - Shear Force in BeamsDocument8 pagesExperiment 2 - Shear Force in BeamsSubuk T. Rathod100% (1)

- Lab Experiment 1: Buckling of ColumnsDocument14 pagesLab Experiment 1: Buckling of Columnsabhishek kumarNo ratings yet

- Buckling of StrutsDocument15 pagesBuckling of Strutsalextty100% (1)

- Space Frame ReportDocument14 pagesSpace Frame ReportAsmawiayob100% (1)

- Spot Speed StudyDocument8 pagesSpot Speed StudyMuhammad AimiNo ratings yet

- Lab Report - 2Document3 pagesLab Report - 2Gowtham Ragunathan100% (1)

- Elab 4 Buckling of StrutsDocument11 pagesElab 4 Buckling of StrutsKhairul NazmanNo ratings yet

- Structural Engineering Laboratory: ImportantDocument4 pagesStructural Engineering Laboratory: ImportantScott RandleNo ratings yet

- Buckling of StrutsDocument9 pagesBuckling of StrutsMARVINNo ratings yet

- Considered Me A Dork. Nevertheless, I Am Hoping That by Moving To The Hartamas InternationalDocument4 pagesConsidered Me A Dork. Nevertheless, I Am Hoping That by Moving To The Hartamas InternationalIkhwan Z.No ratings yet

- Spot Speed StudyDocument7 pagesSpot Speed StudyJohnson KenNo ratings yet

- Flakiness & Elongation TestDocument7 pagesFlakiness & Elongation TestIkhwan Z.No ratings yet

- Proctor&CompactionDocument4 pagesProctor&CompactionIkhwan Z.No ratings yet

- Softening Point TestDocument5 pagesSoftening Point TestJohnson Ken100% (1)

- Penetration TestDocument8 pagesPenetration Testmeelauk86No ratings yet

- Aggregate Impact ValueDocument4 pagesAggregate Impact ValueIkhwan Z.100% (1)

- Open Ended - Cantilever TrussDocument13 pagesOpen Ended - Cantilever TrussIkhwan Z.100% (1)

- Hydraulics JumpDocument10 pagesHydraulics JumpIkhwan Z.100% (2)

- UNIT-III Signal TXN THR Linear SystemsDocument80 pagesUNIT-III Signal TXN THR Linear SystemsVignan VarmaNo ratings yet

- Optical Characterization TechniqueDocument14 pagesOptical Characterization TechniqueAnis MallaNo ratings yet

- MRAFF ProcessDocument9 pagesMRAFF ProcessAnupam AlokNo ratings yet

- Shock & Vibration Response Spectra Rev DDocument460 pagesShock & Vibration Response Spectra Rev DTom IrvineNo ratings yet

- Ray OpticsDocument10 pagesRay OpticsKesav PillaiNo ratings yet

- W14 Ch5 5 The Substitution RuleDocument21 pagesW14 Ch5 5 The Substitution Rulemohammad alkasassbehNo ratings yet

- Topic 4 - VibrationDocument10 pagesTopic 4 - VibrationXver MLNo ratings yet

- PN 31274Document16 pagesPN 31274Ivan DNo ratings yet

- 3CHEB PS4 Group12-4Document11 pages3CHEB PS4 Group12-4Vicente JonathanNo ratings yet

- CT1 Part 9 Image QualityDocument29 pagesCT1 Part 9 Image Qualityrazan abdalrhmanNo ratings yet

- Speed Control of DC MotorDocument6 pagesSpeed Control of DC MotorTejas MayekarNo ratings yet

- MT7601BE DS-EN - Rev0.90Document7 pagesMT7601BE DS-EN - Rev0.90Vishal dtuNo ratings yet

- Acta Materialia: Full Length ArticleDocument16 pagesActa Materialia: Full Length ArticleDeepak SharmaNo ratings yet

- Year 8. End of Semester Exam Final VersionDocument20 pagesYear 8. End of Semester Exam Final VersionAlejandro EspiNo ratings yet

- 1996 Sag Up CVRD BrazilDocument9 pages1996 Sag Up CVRD BrazilDirceu NascimentoNo ratings yet

- NEA Short & Long Questions on Power Systems TopicsDocument1 pageNEA Short & Long Questions on Power Systems TopicsPhool Mohammad RayeenNo ratings yet

- The Gamma DistributionDocument4 pagesThe Gamma DistributionrashmiNo ratings yet

- James Stewart Chapter 13 - Book Eight EditionDocument3 pagesJames Stewart Chapter 13 - Book Eight Editionabdulrehman gNo ratings yet

- Frederick Terry's Lab Report Fluid Dynamics - AsdDocument19 pagesFrederick Terry's Lab Report Fluid Dynamics - AsdFreddie TerryNo ratings yet

- 3RT1024-1B Siemens Manual DatasheetDocument7 pages3RT1024-1B Siemens Manual Datasheetdisanty94No ratings yet

- Wa0001.Document8 pagesWa0001.Poorni RenuNo ratings yet

- How To Read A Centrifugal Compressor CurveDocument6 pagesHow To Read A Centrifugal Compressor CurveMohamedNo ratings yet

- Physics II Problems PDFDocument1 pagePhysics II Problems PDFBOSS BOSSNo ratings yet

- N13-Stability at Docking-NarrationDocument9 pagesN13-Stability at Docking-NarrationMahami M ProsperNo ratings yet