Professional Documents

Culture Documents

671 - BP Well Control Tool Kit 2002

Uploaded by

Uok RitchieOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

671 - BP Well Control Tool Kit 2002

Uploaded by

Uok RitchieCopyright:

Available Formats

WELL CONTROL TOOLKIT

2002

For more information . . .

Common Data Input 1. Kick Tolerance Calculator 3. Kill Sheet - Surface BOPs 5. Volumetric Control Sheets Unit Converter

Quit Excel

2. Pressure Loss Calculator 4. Kill Sheet - Subsea BOPs 6. Casing Pressure Profile User Guide

Quit Toolki

Version 2002.1 Released January 2002

166347034.xls.ms_office

8/22/2013 9:11 AM

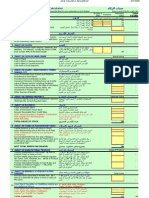

COMMON DATA INPUT

Version 2002.1 Released January 2002 Well No: Rig Name: OD (inch) Casing: Liner 1: Liner 2: Openhole Size (inch): Shut-in Time (h:m): Bit MD (m): Bit TVD (m): Shut-in DP Pres (psi): Shut-in Csn Pres (psi): Shut-in Pit Gain (bbl): Liner Size (inch) Pump 1: Pump 2: Pump 3: 5.5 5.5 5.5 12.25 9:30 AM 4400 3190 100 100 20 Max Pres (psi) 5000 5000 5000 4400 13.625 9808 249 ID (inch) 12.415 Date: Time: Depth (m) 1430 7 09 07 1:09 PM

Units (UK/US):

UK

SurFace or Subsea BOP Stack (F/S) ? f Surface BOP Setup.

Casing / Hole Configuration

Surface Input Pipe

ID (in): Len (m): ID (in): Len (m): 3 150 3 100 1.070 30 20 800 1000 1000 Pump SPM 20 30 40

Drillstring Configuration

OD (inch) Drillpipe 1: Drillpipe 2: HWDP: DC: 7 8 4 2.8 50 200 2650 2650 1.120 1.180 5000 5000 5 ID (inch) 4.8 Length (m) 4150

Choke Line

Well Shut-in Data

Drilling Mud

Mud Weight (sg): PV (cP): YP (lbf/100sqft): Surf Active Vol (bbl): Reserve Vol (bbl): Baryte on Site (MT): Vol Eff % 97 97 97 1.03 1.07 80 120 180 100% bbl/stk 0.088 0.088 0.088 Bit Nozzles (inch^2) 0.451

Formation / Equipment Integrity

Openhole Weak Point MD (m): Openhole Weak Point TVD (m): Min Leak-off /FIT EMW (sg): Max Leak-off /FIT EMW (sg): Casing Burst Pressure (psi): Max Allowable Surf Pres (psi):

Mud Pump Data

SCR Data (mud return via flowline)

Pump 1: bbl/min 1.707 2.561 3.414 Pscr (psi) 350 500 700 Pump 2: bbl/min 1.707 2.561 3.414 Pscr (psi) 360 515 720 100 100 100 100

Formation Pressure / Temperature

Min Pore Pressure (sg): Max Pore Pressure (sg): Surface Temperature (deg.F): Weak Point Temperature (deg.F): Kick Zone Temperature (deg.F): MD (m) Surface: Kick-Off 1: End-Built 1: DP Cross-Over: Kick-off 2: End-Built /Drop 2: Bit: 0 0 0 0 0 0 4400 3190

Pressure Safety Factors:

Surf Pres Safety Factor for Kick Toler (psi): Minimum Bottom Hole Over-B During Kill (psi): Operating Margin for Vol Control (psi): Operating Margin for Lubrication (psi):

Well Profile

TVD (m) 0 0 MD 0 0 0 0 0 0 4400 X Y Horizontal Departure 0 0 1000 2000 0 0 0 0 0 0 3030 0 0 0 0 3190

3000

4000

0

500

Vertical Depth

1000 1500

2000

2500 3000 3500

For Kick Tolerance only: Angle below Weak Point (deg): Angle at Bit Depth (deg): Angle above Horizontal (deg): Horizontal Section Length (m):

Surface BOPs: Keep Following Green Cells Blank !

0 0 0

166347034.xls.ms_office

Page 3 of 2

8/22/2013 9:11 AM

KICK TOLERANCE CALCULATOR

For Vertical, Deviated or Horizontal Wells

Version 2002.1 Released January 2002

Well:

9808

Units (UK/US):

us

Kick Zone Parameters:

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 Openhole Size ? Measured Depth ? Vertical Depth ? Horizontal Length (>87 deg) ? Tangent Angle Above Horizontal ? Min Pore Pressure Gradient ? Max Pore Pressure Gradient ? Kick Zone Temperature ? (inch) (ft) (ft) (ft) (deg) (ppg) (ppg) (deg.F) (ft) (ft) (deg) (ppg) (ppg) (deg.F) (inch) (ft) (inch) (psi) (ppg) (bbl/ft) (bbl/ft) 8.5 6405 6405

Input Error Messages:

Non-Horizontal 10.000 10.000 100 1800 1800 20.000 20.000 100 6.25 200 5.5 0 9.500 0.03224 0.04080 Comments:

Weak Point Parameters:

Measured Depth ? Vertical Depth ? Section Angle (<87 deg) ? Min Fracture Gradient / EMW ? Max Fracture Gradient / EMW Weak Point Temperature ?

Other Parameters:

Drill Collar OD ? Drill Collar Length ? Drillpipe OD ? Surface Pressure Safety Factor ? Mud Weight in Hole ? Annular Capacity Around BHA: Annular Capacity Around DP:

At least 100 psi !

At Min Fracture Gradient:

Circulating MAASP Gas Gradient at Weak Point For Min Pore Pressure: Max Allowable Gas Height: Kick Tolerance: For Max Pore Pressure: Max Allowable Gas Height: Kick Tolerance: (psi) (psi/ft) (ft) (bbl) (ft) (bbl) 981 0.0416 1804 33.3 1804 33.3

At Max Fracture Gradient:

Circulating MAASP Gas Gradient at Weak Point For Min Pore Pressure: Max Allowable Gas Height: Kick Tolerance: For Max Pore Pressure: Max Allowable Gas Height: Kick Tolerance:

Min Fracture Grad

(psi) (psi/ft) (ft) (bbl) (ft) (bbl)

981 0.0416 1804 33.3 1804 33.3

Max Fracture Grad

35

30 Kick Tolerance (bbl)

25

20

Min Fracture Grad Max Fracture Grad 10.00 33 33 10.00 33 33 10.00 33 33

15

10

5

0 0.00

2.00

4.00

6.00

Pore Pressure Gradient

8.00

10.00

12.00

APPENDIX:

Maximum Allowable Gas Influx Volume

Based on Casing Burst & Surface Equipment Rating

Max Allowable Surface Pressure ? Near Surface Casing ID ? Near Surface Annular Temperature ? Gas Gradient at Max Surface Pres: Near Surface Annular Capacity:

(psi) (inch) (deg.F) (psi/ft) (bbl/ft) (ft) (bbl) (ft) (bbl)

5000 12.8 80 0.100 0.12976 12300 infinite 12300 infinite Comments: Extends to hole TD

At Minimum Pore Pressure Gradient:

Max Allowable Gas Height at Surface: Max Allowable Gas Vol. on Shut-in:

At Maximum Pore Pressure Gradient:

Max Allowable Gas Height at Surface: Max Allowable Gas Vol. on Shut-in:

2500

Max Allowable Gas Volume (bbl) 2000 1500

Extends to hole TD

10.00 10.00 10.00

2205 2205 2205

1000

500 0 0.00

2.00

4.00

6.00 Pore Pressure Gradient

8.00

10.00

12.00

166347034.xls.ms_office

8/22/2013 9:11 AM

PRESSURE LOSS CALCULATOR

Version 2002.1 Released January 2002

UK Units (UK/US):

UK

Original Mud: Kill Weight Mud:

Weight (sg) 1.100 1.120

PV (cP) 30 30

YP (lbf/100sqft) 20 20

Mud SCR Range (bbl/min) Minimum: 1 Maximum: 5

CHOKE LINE DIMENSION:

Length (m) 1000 0 ID (inch) 3.5 0 160 140 120 100 80 60 40 20 0 0

Original Mud

Kill Mud

Choke Line Pressure Loss: Mud SCR Pressure Loss (psi) (bbl/min) Original Mud Kill Mud 1 91 91 2 98 98 3 106 106 4 113 113 5 142 144

Pressure Loss (psi)

Section 1: Section 2:

Slow Circulation Rate (bbl/min)

ANNULUS DIMENSION:

Length (m) 70.0 250.0 Casing ID (inch) 18.750 17.500 String OD (inch) 5.5 5.5 8.6 Pressure Loss (psi) 8.6 8.6 8.6 8.6 8.6 8.6 8.6 0

Original Mud

Kill Mud

Annulus Pressure Loss: Mud SCR Pressure Loss (psi) (bbl/min) Original Mud Kill Mud 1 8.6 8.6 2 8.6 8.6 3 8.6 8.6 4 8.6 8.6 5 8.6 8.6

2 4 Slow Circulation Rate (bbl/min)

166347034.xls.ms_office

Page 5 of 3

8/22/2013 9:11 AM

KILL SHEET

For Vertical / Deviated Wells with Surface BOPs

Version 2002.1 Released January 2002 Well No: Test Case A1 12.25 5020 OD DP Size 1: DP Size 2: Heavy Weight DP: Drill Collar: Casing/Hole ID Casing: 12.415 12.25 12.25 12.25 Surf Input Line: Choke Line: 5 8 Strg OD 5 5 5 8 OD= OD= 1391 3 2.5 5 ID 4.276 Rig: TVD (ft) Rig Name 13.375 MD (ft) 4000 Date: Shoe TVD (ft): 4000 1000 Depth (ft) 9100 0 600 300 Len (ft) 4000 5100 600 300 ID= ID= 3.00 in 3.00 in 9700 10000 Depth (ft) 4000.00 9100.00 9700.00 10000.00 Length (ft): Length (ft): 800 Vol Eff (%): Vol Eff (%): 22-Jan-02 4000

Units (UK/US):

Time: Shoe MD(ft)

US

1:09 PM 4000 13.50 1000

Hole Size (inch): Csn Burst (psi):

Casing OD (inch):

Openhole Weak Point:

Fracture Grad EMW (ppg): Reserve Mud Vol (bbl): Vol (bbl) 161.7 0.0 5.2 1.8 Vol (bbl) 502.0 619.8 72.9 25.1 150 100 1121.8 1194.7 1219.8 Vol (bbl): Vol (bbl): 161.7 166.9 168.8

Barite on Site (sack) (bbl/ft) 0.01777 0.00000 0.00875 0.00607 Len (ft) 9100

Drill String Contents (From Surface to Bottom)

Cumulative Volume (bbl)

Annulus Contents (From Surface to Bottom)

Capacity (bbl/ft) 0.12549 0.12154 0.12154 0.08364 Cumulative Volume (bbl)

1.3 0.9 2191 0.088 0.088 Total 813 542 407

Total Circ System Vol (bbl): Pump 1 Liner (in): Pump 2 Liner (in): SPM 20 30 40 bbl/min 1.707 2.561 3.414 5.5 5.5 Pscr 350 500 700

Surf Active (bbl):

Total Active Mud Vol (bbl): 97 97 Bit to Shoe 420.5 280.3 210.2 Near vertical well ! 10000 YP (lbf/100ft^2): Shut-in Pit Gain (bbl): 50.4 Total (sack): 100% bbl/stk: 100% bbl/stk: Shoe to Chk 294.0 196.0 147.0

Pumping Data

Max Pres (psi): Max Pres (psi): PUMP 2 bbl/min 1.707 2.561 3.414 Pscr 360 515 720 Pump No Surface to Bit 1 98.9 65.9 49.4 5000 5000

PUMP 1

KILL CIRCULATION TIMES (min)

Kick Data

Time Shut-In: 9:30 AM Mud Weight in Hole (ppg): SIDPP (psi): 400 Kill MW (ppg), MW2= Kill Pump SPM: Kill Rate (bbl/min) SCR Pres (psi): 30 2.561 500 Bit at TD (ft): 12.000 12.769 Bit Nozzles (in^2) 0.451 10000 PV (cP): 30 600

TVD (ft):

20 30 1104.7

Shut-in Casing Pres (psi):

Barite Required (lb/bbl):

Pressure Losses

Circ Pressure Losses (psi): Surf Input Pipe: Inside Drill String: Drill Bit: 6 262 63 Annular Pressure Loss (APL) (psi): APL - Based on SCR Test: APL - Directly Calculated: Accepted APL: 169 142 bbl/stroke: 0.08536

Conventional vertical / high angle kill

166347034.xls.ms_office

Page 6 of 3 Kill Data

8/22/2013 9:11 AM

Kill Start Time: Keep this cell blank: Initial Circ Pres (psi): 100 900 MD (ft) 0

Kill Mud to Reach: Pump Strokes: Pump Pres (psi): TVD (ft) 0 0 0 Vol (bbl) 0.0 0.0 0.0 0.0 0.0 0.0 168.8

Drill Bit: 1977 532 Strokes 0 0 0 0 0 0 1977

Choke: 16268 532 Time (min) 0 0.0 0.0 0.0 0.0 0.0 65.9

MAASPs (psi): Static: Circulating: 312 253

Standpipe Pressure Section Point:

From: Surface:

(For Pumping Down Kill Mud Through Drill String) Standpipe Pressure (psi) 900 ( =Pic )

To: Drill Bit:

10000

10000

532

( =Pfc )

1000 900 Standpipe Pressure (psi) 800 700 600 500 400 300 200 100 0 0

STANDPIPE PRESSURE CHART

500

1000

1500

2000

2500

Pump Strokes to Bit (Stroke)

STANDPIPE PRESSURE TABLE

Pump Stroke 0 110 220 330 440 550 660 770 880 990 1100 1210 1320 1430 1540 1650 Pred. DP Pres (psi) 1500 1486 1472 1458 1445 1435 1425 1415 1405 1395 1385 1375 1368 1361 1355 1348 Actual DP Pressure (psi) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Actual Choke Pressure (psi) 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 Pump Stroke 1760 1870 1980 2090 2200 2310 2420 2530 2640 2750 2860 2970 3080 3190 Pred. DP Pressure (psi) 1342 1336 1329 1323 1317 1310 1304 1298 1291 1285 1279 1272 1266 1260 Actual DP Pressure (psi) 17 18 19 20 21 22 23 24 25 26 27 28 29 30 Actual Choke Pressure (psi) 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 1258 psi

3222 1258 31 Hereafter maintain DP pressure constant @

166347034.xls.ms_office

Page 7 of 3

8/22/2013 9:11 AM

GENERAL KILL PROCEDURE

Pump Start Up Procedure:

~ When the choke pressure gauge starts to respond in each step, manipulate the choke valve to adjust the choke pressure according to the table on the right. ~ Zero the stroke counter when kill mud has reached rig floor. ~ When the pump has reached the kill speed, record the initial circulating pressure and compare with the calculated value. ~ If the recorded and calculated values are close to each other, continue the kill operation. If they are significantly different, stop the pump, shut-in the well and investigate. If choke pressure in the above table is constant, the conventional kill method will be used, which will ignore Annular Pressure Loss (APL) to provide an over-balance pressure. If choke pressure is decreasing during pump start up, the slimhole technique will be used, which will compensate APL during kill. When APL is relatively high however, it may be impossible to fully compensate APL. In this case, the choke pressure will reduce to zero and the choke valve become wide-open during pump start up. Pump Speed (SPM) 0 6 12 18 24 30 Choke Pressure (psi) 600 600 600 600 600 600 Drillpipe Pressure (psi) 400 500 600 700 800 900

Displacing Drillpipe and Annulus with Kill Mud:

Once the pump has reached kill speed, the choke valve should be adjusted to control the DP pressure so that the bottom hole pressure is maintained constant. This means that: ~ During the 1st complete circulation using Driller's method, the DP pressure be maintained constant at the initial circulating pressure. ~ When kill weight mud is being pumped down the drillpipe (using either Driller's or W&W), the DP pressure be adjusted according to the standpipe pressure chart & table shown in the 2nd page of the kill sheet. Once the kill mud has entered into the annulus, the DP pressure should be maintained constant. However, at some point when the annulus is being displaced by kill mud, or after the influx is out of hole, the choke valve may become wide-open. From then on, DP pressure will increase gradually while choke valve is kept at the full open position. This will continue until the kill mud reaches the choke, at which DP pressure should be equal or close to the value shown in the "Kill Data" Section.

Complete Kill Operation:

~ When the kill mud has returned to surface, stop the pump and close the choke valve to check drillpipe and choke pressures. ~ If both drillpipe and choke pressures are zeros, open the BOP and further flow-check the annulus. ~ A further complete circulation should be carried out. In the mean time, a suitable overbalance should be added to the mud weight.

166347034.xls.ms_office

Page 8 of 3

8/22/2013 9:11 AM

KILL SHEET

For Vertical / Deviated Wells with Subsea BOPs

Version 2002.1 Released January 2002 Well No: WFC 17.5 Rig: Rig Name 20 Date: Shoe TVD (m) 2650 1000 Depth (m) 3050 0 50 90 Len (m) 1990 660 400 50 90 3100 3190 Depth (m) 1990.0 2650.0 3050.0 3100.0 3190.0 Length (m): 800 02.oct.2003 2650

Units (UK/US):

Time: Shoe MD (m)

UK

1:09 PM 2650 1.15 1000

Hole Size (inch):

Casing OD (inch):

Openhole Weak Point: TVD (m) 2650 MD (m) Csn Burst (psi): 5000 Baryte on Site (MT): OD DP Size 1: DP Size 2: Heavy Weight DP: Drill Collar: Casing/Hole ID Riser: Casing: 18.75 18.75 17.5 17.5 17.5 7 8 Strg OD 5.5 5.5 5.5 7 8 4 2.8 5.5 ID 4.8 (bbl/m) 0.07342 0.00000 0.05099 0.02498 Len (m) 3050

Fracture Grad EMW (sg): Reserve Mud Vol (bbl): Vol (bbl) 223.9 0.0 2.5 2.2 Vol (bbl) 2037.6 675.8 351.8 41.0 69.5 2713.4 3065.3 3106.2 3175.7 223.9 226.5 228.7

Drill String Contents (From Surface to Bottom)

Cumulative Volume (bbl)

Annulus Contents (From Surface to Bottom)

Capacity (bbl/m) 1.02394 1.02394 0.87954 0.81979 0.77199 3409 Kill Line ID (in) Len (m) 1990 Cumulative Volume (bbl)

Surf Input Line: OD= Total Circ System Vol (bbl): Choke Line Section Subsea: Surface: Pump 1 Liner (in): Pump 2 Liner (in): ID (in) Len (m) 1990

ID= 3.00 in Surf Active (bbl):

150 Vol (bbl): Total Active Mud Vol (bbl): 2000 Air Gap (m) Density (sg): Density (sg):

4.3 4209 -10

Subsea Choke / Kill Line Setup

Sea Water Depth (m) Fluid in Choke Line: Fluid in Kill Line:

Pumping Data

5.5 5.5 Max Pres (psi): Max Pres (psi): PUMP 2 bbl/min 1.707 2.561 3.414 Pscr 360 515 720 Total 801 534 400 5000 5000 Vol Eff (%): Vol Eff (%): 97 97 1 Bit to Shoe 270.8 180.5 135.4 Shoe to BOP 395.9 263.9 197.9 BOP to Chk 0.0 0.0 0.0 100% bbl/stk: 100% bbl/stk: 0.088 0.088

SCR Tests (Return from Riser) PUMP 1 SPM 20 30 40 bbl/min 1.707 2.561 3.414 Pscr 350 500 700

Kill Using Pump No.: Surface to Bit 134.0 89.3 67.0

KILL CIRCULATION TIMES (min)

Kick Data

Time Shut-In: 9:30 AM Mud Weight in Hole (sg): SIDPP (psi): 100 Kill MW (sg), MW2= Kill Pump SPM: Kill Rate (bbl/min) SCR Pres (psi): 30 2.561 500 Bit at TD (m): 1.070 3190 PV (cP):

Near vertical well ! TVD (m): 3190 30 YP (lbf/100ft^2): Shut-in Pit Gain (bbl): 10.4 Total (MT): 20 20 19.9

Shut-in Casing Pres (psi): 100 1.092 Barytes Required (lb/bbl):

Pressure Losses

Bit Nozzles (in^2) 0.451 Circ Pressure Losses (psi): Surf Input Pipe: Inside Drill String: Drill Bit: 0 0 SCR Pressure Through Choke (psi): 500 20 220 47 Annular Pressure Loss (APL) (psi): APL - Based on SCR Test: APL - Directly Calculated: User Accepted APL: 214 32 bbl/stroke: 0.08536

Calculated Choke Line Loss (CLL) (psi): User Accepted CLL (psi):

166347034.xls.ms_office

Page 9 of 3 Conventional vertical / high angle Kill Kill Data

8/22/2013 9:11 AM

Kill Start Time: Keep this cell blank: Initial Circ Pres (psi): 100 600 MD (m) 0 2000

Kill Mud to Reach: Pump Strokes: Pump Pres (psi): TVD (m) 0 2000 Vol (bbl) 0.0 146.8 #VALUE! 0.0 #VALUE! 0.0 228.7

Drill Bit: 2680 510 Strokes 0 1720 #VALUE! 0 #VALUE! 0 2680

Choke: 16012 510 Time (min) 0 57.3 #VALUE! 0.0 #VALUE! 0.0 89.3

MAASPs (psi): Static: Circulating: 301 285

Standpipe Pressure Section Point:

From: Surface:

(For Pumping Down Kill Mud Through Drill String) Standpipe Pressure (psi) 600 544 ( =Pic )

To: Drill Bit:

3190

3190

510

( =Pfc )

STANDPIPE PRESSURE CHART

610 600 590 580 570 560 550 540 530 520 510 500 0 500 1000 1500 2000 2500 3000 3500 Pump Strokes to Bit (Stroke)

Standpipe Pressure (psi)

STANDPIPE PRESSURE TABLE

Pump Stroke (psi) 0 90 180 270 360 450 540 630 720 810 900 990 1080 1170 1260 1350 Pred. DP Pres (psi) 600 597 594 591 588 585 582 579 576 574 571 568 565 562 559 556 Actual DP Pressure (psi) 1 2 3 4 5 6 7 8 9 0 1 2 3 4 5 6 Actual Choke Pressure (psi) 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 Pump Pred. DP Actual DP Stroke Pressure Pressure (psi) (psi) (psi) 1440 553 7 1530 550 3 1620 547 9 1710 544 0 1800 541 1 1890 538 2 1980 535 3 2070 532 4 2160 528 5 2250 525 6 2340 522 7 2430 519 8 2520 516 9 2610 513 0 2680 510 1 Hereafter maintain DP pressure constant @ Actual Choke Pressure (psi) 5 4 3 2 1 0 9 8 7 6 5 4 3 2 1 510 psi

166347034.xls.ms_office

Page 10 of 3

8/22/2013 9:11 AM

GENERAL KILL PROCEDURE

Shut-in surface choke pressure is Surface choke pressure will become Shut-in surface kill line pressure is: Kill line pressure becomes 100 100 -2926 100 (pis) with 0 in choke line.

(psi) when choke line is displaced to mud in hole. (psi) with 0 in kill line. with (sg) = Choke Pressure (psi) -2926 -2926 -2926 -2926 -2926 -2926 Kill Line Pressure (psi) 100 100 100 100 100 100 Drillpipe Pressure (psi) 100 200 300 400 500 600

(psi) when displaced to Pump Speed (SPM) 0 6 12 18 24 30

Pump Start Up Procedure:

~ Start the pump and increase its speed in small steps. ~ When choke pressure gauge starts to respond in each step, manipulate choke valve to adjust choke/kill line pressure according to the table on the right. ~ Zero stroke counter when kill mud reaches rig floor. ~ When pump has reached kill speed, record the initial circulating pressure and compare with calculated value. ~ If the recorded and calculated values are close to each

other, continue the kill operation. If they are significantly different, stop pump, shut-in the well and investigate. If the choke pressure in above table is constant, the conventional kill method will be used, which will ignore both Choke Line Loss (CLL) and Annular Pressure Loss (APL) to provide an over-balance pressure. If the choke pressure is decreasing during pump start up, the deep water and/or slimhole techniques will be used, which will compensate CLL and/or APL during kill. When the shut-in surface choke pressure is relatively low however, it may be impossible to fully compensate CLL and/or APL. In this case, the choke pressure will reduce to zero and the choke valve become wide-open during pump start up.

Displacing Drillpipe and Annulus with Kill Mud:

Once the pump has reached kill speed, the choke valve should be adjusted to control the drillpipe pressure so that the bottom hole pressure is maintained constant. This means that: ~ During the 1st complete circulation using Driller's method, the drillpipe pressure be maintained constant at the initial circulating pressure. ~ When kill weight mud is being pumped down the drillpipe (using either Driller's or W&W), the drillpipe pressure be adjusted according to the standpipe pressure chart & table shown in the 2nd page of the kill sheet. Once the kill mud has entered into the annulus, the drillpipe pressure should be maintained constant. However, at some point when the annulus is being displaced by kill mud, or after the influx is out of hole, the choke valve may become wide-open. From then on, drillpipe pressure will increase gradually while choke valve is kept at the full open position. This will continue until the kill mud reaches the choke, at which drillpipe pressure should be equal or close to the value shown in the "Kill Data" Section.

Complete Kill Operation:

~ When the kill mud has returned to surface, stop the pump and close the choke valve to check the drillpipe and choke pressures. ~ If both drillpipe and choke pressures are zeros, start to implement procedures for removing the gas possibly trapped in BOP stack. Then displace the riser annulus to kill mud. ~ Open the BOP and further flow-check the annulus. ~ A further complete circulation should be carried out. In the mean time, a suitable overbalance should be added to the mud weight.

166347034.xls.ms_office

Page 11 of 2

8/22/2013 9:11 AM

VOLUMETRIC CONTROL SHEET

For Controlling Gas Expansion During Well Shut-in

Version 2002.1 Released January 2002

Units (UK/US):

US

Well No: Test Case A1 Rig: Rig Name Date: 22-Jan-02 Time Well Shut-in: 1:09 PM Open Hole Size (inch): 12.25 TD (ft): 10000 TVD (ft): 10000 Open Hole Weak Point: TD (ft): 4000 TVD (ft): 4000 Frac Gradient (ppg): 13 Shut-in DP Pres (psi): 500 Shut-in Csn Pres (psi): 750 MW in Hole (ppg): 12 Bottom Hole Pres on Shut-in (psi): 6734 = Pres Gradient (ppg): 12.962 Shut-in Pit Gain (bbl) Weak Point Pressure on Shut-in (psi): 3244 = Pres Gradient (ppg): 15.609 20 Upper or Average Annular Capacity (bbl/ft): 0.12549 Annular Mud Hydrostatic (psi/bbl) 4.97 O-B Safety Factor (psi): 100 Operating Margin (psi): 100 = Equi Mud Vol (bbl): 20.13 Can drillpipe pressure gauge be used to monitor bottom hole pressure (Y/N) ? y

Volumetric Control Log

For Controlling Gas Expansion Before Reaching BOP Stack

Time (hr:min)

Operation

Shut-in Condition Add Over-B Safety Facotr: Add operating margin Bleed DP pres back to: Add operating margin

Drillpipe Pressure (psi)

Change in DP Pres (+/- psi)

Mud Bled at Choke (bbl)

Hydrostatic Loss (psi)

Total Mud Bled (bbl)

Over-B Pressure (psi)

500 600 700 600

~ 100 100 -100 0 0 0 0 0 0 0 0 0 0 0

~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~

~ ~ ~ 0 ~ 0 ~ 0 ~ 0 ~ 0 ~ 0 ~ 0 ~ 0 ~ 0 ~ 0 ~ 0 ~ 0

~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~

0 100 200

166347034.xls.ms_office

Page 12 of 2

8/22/2013 9:11 AM

LUBRICATION LOG

For Venting Gas From Beneath BOP Stack

Version 2002.1 Released January 2002

Upper Annulus Casing ID (inch) : Lubricating MW (ppg) : 12

12.415

String OD:

5 4.97

Annular Cap (bbl/ft): Operating Margin (psi):

0.12549 100

Hydrostatic (psi/bbl):

Choke Time (hr:min) Before lubrication start Operation Pressure (psi)

Change in (+/- psi)

Mud Vol (bbl)

Mud Vol Bled out (bbl)

Total Mud Pumped in (bbl)

Hydrostatic Gain /Loss (+/-psi)

Choke Pres Pumped in

~ ~

~ ~ ~

~ ~ ~ ~

~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~

~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

166347034.xls.ms_office

8/22/2013 9:11 AM

CASING PRESSURE PROFILE

During Circulating out a Gas Influx

Version 2002.1 Released January 2002

Units (UK/US):

UK 2650 2650 80 180 0.0313

Annular Capacity (bbl/m)

Mud Weight in Hole (sg) Shut-in Gas Influx Vol (bbl) Shut-in Drillpipe Pressure (psi) B'hole Over-Balance (psi) Formation Pore Pressure (psi)

Annular Section No. Hole/Csg ID (inch) String OD (inch)

1.07 20 100 100 4950

Section Bottom TD TVD (m) (m)

Openhole Weak Point MD (m) TVD (m) Surface Temp (deg.F): Bottom Hole Temp (deg.F): Temp Gradient (deg.F/m)

Section Length (m) Section Volume bbl Total Volume (bbl)

Surface: 1 2 3 4 5

18.750 18.750 18.750 17.500 17.500 17.500

5.500 5.500 5.500 5.500 7.000 8.000

0 0 ~ ~ 1990.0 1990.0 1990.0 2037.6 2650.0 2650.0 660.0 675.8 3050.0 3050.0 400.0 351.8 3100.0 3100.0 50.0 41.0 3190.0 3190.0 90.0 69.5 Weighted Average Annular Capacity

~ 3175.7 1138.1 462.3 110.5 69.5 (bbl/m):

~ 1.02394 1.02394 0.87954 0.81979 0.77199 0.99553

Max Pit Gain Volume (bbl) = 16.1 Max Weak Point Pres (psi) = 5050

Max Surf Casing Pres (psi) = 5045 Max Weak Point EMW (sg) = 1.341

Surface Casing & Weak Point Pressure Profiles

5100 5000 4900 Weak Point Pressure (psi) 4800 4700 4600 4500 4400 4300 4200 4100 0 500 1000

Weak Point Pressure Surface Casing Pressure

6000

5000

4000

3000

2000

1000

1500

2000

2500

3000

3500

0 4000

Mud Volume Pumped (bbl)

Surface Casing Pressure (psi)

166347034.xls.ms_office

8/22/2013 9:11 AM

UNIT CONVERTER

Version 2002.1 Released January 2002

Conversion To SI Units

1 1 1 1 1 1 1 1 100 100 100 1 1 100 100 100 1 0.7 Length inch = 25.4 mm ft = 0.3048 m mile = 1.60934 km Weight lbf = 0.45359 kg MT = 1000 kg Volume US gal = 3.78541 litre bbl = 158.987 litre ft^3 = 28.3168 litre Velocity ft/min = 0.508 m/s ft/min = 30.48 m/min Volumetric Flow Rate gal/min = 6.30902 L/s bbl/min = 2.64978 L/s MMscf/day = 327.774 L/s Pressure psi = 6.89476 bar psi = 689.476 kPa psi = 7.0307 kgf/cm^2 Pressure Gradient psi/ft = 22.6206 kPa/m psi/ft = 1.61305 sg Density lbm/US gal = 119.826 lbm/US gal = 0.11983 lbm/ft^3 = 0.01602

Conversion To Customary Units

100 1 1 1 1000 1 619 1 1 1 1 1 100 1 29.9 1 100 1 10 1000 1 1 1 1 1 165 1 Length = 3.93701 inch = 3.28084 ft = 0.62137 mile Weight kg = 2.20462 lb kg = 1 MT Volume litre = 0.26417 US gal litre = 3.8934 bbl litre = 0.03531 ft^3 Velocity m/s = 196.85 ft/min m/min = 3.28084 ft/min Volumetric Flow Rate L/s = 15.8503 gal/min L/s = 0.37739 bbl/min bbl/min = 0.8085 MMscf/day Pressure bar = 14.5038 psi kPa = 4.33663 psi kgf/cm^2 = 14.2233 psi Pressure Gradient kPa/m = 4.42075 psi/ft sg = 0.43396 psi/ft ppg = 0.52 psi/ft Density kg/m^3 = 8.34543 lbm/US gal g/cm^3 = 8.34543 lbm/US gal g/cm^3 = 62.4278 lb/ft^3 ppg = 7.48052 lb/ft^3 Concentration kg/m^3 = 0.35051 lbm/bbl g/L = 0.35051 lbm/bbl Temperature deg.C = 329.9 deg.F Temperature Gradient deg.C/m = 0.54864 deg.F/ft mm m km

1 1 1

kg/m^3 g/cm^3 g/cm^3

1 1 100 1

Concentration lbm/bbl = 2.85301 kg/m^3 lbm/bbl = 2.85301 g/L Temperature deg.F = 37.2778 deg.C Temperature Gradient deg.F/ft = 1.82269 deg.C/m

* Conversion factors are based on "The SI Metric System of Units and SPE Metric Standard", API, June 1984

166347034.xls.ms_office

Page 15 of 6

8/22/2013 9:11 AM

WELL CONTROL TOOLKIT 2002

Version 2002.1 Released January 2002

Well Control Toolkit 2000 is a collection of Excel worksheets designed for drilling engineers and rig-site personnel to record data and perform calculations related to well control. Hardware & software requirement: A PC running under the BP Common Operating Environment (COE3) with Excel 2000. To run Toolkit: ~ To open Toolkit: Same way as you would do with an Excel file. ~ When you first open Toolkit, the Main Menu will appear on the screen. ~ Click on a button in Main Menu to open a worksheet. ~ Upon finishing a worksheet, click on "Return to Menu" button in the worksheet. All the worksheets have the following common features: 1. User can choose to use either UK (m, sg) or US (ft, ppg) units. The ability to convert units has been added to the Common Data Input Sheet, however UK and US units cannot be mixed. 2. Easy to use: Just open a worksheet and input data into green cells, the results will be updated automatically. 3. Data input is flexible: It can be done either in each of the worksheets directly, or imported from "Common Data Input" sheet, or imported from a saved data file. 4. Some input cells have help-notes describing the input requirement. These cells have red triangle on their top-right hand corners. Position and keep the prompt on the cell, the help-notes should appear. 5. Critical inputs are automatically checked. If found unreasonable, error messages will appear. 6. Results are presented in both tabulated data and plots. 7. All data and plots are laid out such that they can be easily printed on letter-sized papers. 8. All plots are re-scaled automatically to fit input /output data range.

Common Data Input

"Common Data Input" (CDI) sheet is designed for entering well data, which can be then imported to other worksheets. Use of this sheet to input data has following advantages: 1. It provides a single data input sheet for all other worksheets in Toolkit. So once this is filled in, it takes only seconds to get results on kick tolerance, kill sheet, or casing pressure profiles, etc. 2. CDI sheet can be saved or imported separately from the Toolkit (top of sheet). 3. It is easier to input data into CDI. For example, there is no need to mentally work out how many annular sizes based on casing and drillstring data. This will be done automatically when importing data into kill sheets or casing annular pressure profile. 4. It allows visual checks on well profiles once MD/TVD data have been inputted at kick-off, end-build, etc. 5. The ability to convert units has been added, however UK and US units cannot be mixed. 6. The ability to save data from all the sheets (workbook) has been added (right side). This feature will save or reimport data directly to the worksheets (includes data not included in the CDI).

1. KICK TOLERANCE CALCULATOR

Kick Tolerance Calculator (KTC) is designed to determine kick tolerance volumes, given well geometry

166347034.xls.ms_office

Page 16 of 6

8/22/2013 9:11 AM

drilling parameters and hole condition. It can be used for vertical, deviated or horizontal wells. The principles used in KTC are similar with those described in BP Well Control Manuals (Volume 1). However, KTC includes the effects of bottom hole pressure / temperature on gas density (for methane gas based on Hall & Yarborough's Equation of State). So it is more accurate, usually less conservative. It can cope with many scenarios (e.g. shut-in influx length is longer or shorter than BHA, etc.). Kick tolerance is defined as the maximum volume of kick influx that can be shut-in and circulated out without breaking down the weak point formation. Therefore, kick tolerance volume is determined based on two critical conditions: ~ When the influx is at the hole bottom under the initial shut-in condition. ~ When the influx top is displaced to the openhole weak point with the original mud weight. It should be pointed out that, the pressure losses through annulus / choke lines and the possible choke error are considered by assuming a Surface Pressure Safety Factor. Therefore, this surface pressure safety factor should be the sum of: 1. A choke operator error margin (say 100 psi) 2. Pressure loss through the choke line. For subsea BOPs, if the choke line pressure loss is to be compensated during kill by using the kill sheet in this Toolkit, then it can be totally or partially ignored. 3) Pressure loss through the annulus above the openhole weak point. In HPHT & ERD wells where there is a long casing & liner section, its annular pressure loss (APL) can be high. If it is included in the pressure safety factor, kick tolerance volume will be significantly reduced. In this case, APL should be compensated during kill by using the Kill Sheets in this Toolkit. In the mean time, APL can be totally or partially ignored in kick tolerance calculations. In some cases, the calculated volume extends from bottom hole to above the casing shoe, which implies that the well can tolerate an unlimited volume of kick without breaking down the weak point formation. This often occurs when the vertical height of the openhole section is relatively short. If this occurs in a high angle or horizontal hole section where potential kick volume can be high, it is important to check the maximum allowable gas volume based on the casing burst strength and pressure ratings of BOP stack & choke manifold. This can be done in the 2nd page of the calculator.

2. PRESSURE LOSS CALCULATOR

Pressure Loss Calculator is designed to calculate pressure losses through choke lines and openhole / casing annuli. The methods are based on the simple models as described in "Applied Drilling Engineering", SPE Textbook, 1986. The calculator can be used for: ~ Estimating the pressure safety factor in Kick Tolerance Calculator. This has been described in the previous section. ~ Estimating the over-pressure during a conventional kill operation. If a conventional method is used in a kill operation, the pressure loss through annulus is ignored to provide an over-pressure at the kick zone to prevent further influx from coming into the wellbore. This calculator can be used to estimate the magnitude of this over-pressure. ~ Estimating the annular pressure loss in small hole drilling. When hole size is relatively small (e.g. < 6"), the annular pressure loss may be high. If ignored as in a conventional kill method, the high annular pressure loss may cause formation breaking down. In this case, the special well control technique should be used, which will compensate the annular pressure loss. The kill sheets as described in the following will facilitate the implementation of the technique.

3. KILL SHEET

166347034.xls.ms_office

Page 17 of 6

8/22/2013 9:11 AM

For Vertical / Deviated Wells With Surface BOPs

The Kill Sheet is designed to record data during drilling operations and to perform kill calculations when a well has been shut-in on a kick. This kill sheet can be used for: ~ Land or offshore rigs with surface BOPs. ~ Vertical, deviated or horizontal wells (Straight, L- or S-shaped holes). ~ Conventional or small hole sizes ~ Single- or dual-sized drillpipe strings (plus HWDPs and DCs). ~ Gas, oil or water kicks. Kill Techniques This kill sheet incorporates both the conventional kill techniques (Drillers or W&W), where annular pressure loss (APL) is ignored, and the special kill technique where APL will be compensated. The advantage of the special kill technique is that it will result in lower wellbore pressures during kill , thus minimising the risk of formation breakdown at the weak point. This is particularly important in ERD, HPHT or small hole wells where APL can be high due to long / small casing annulus. Before deciding on which kill technique to use, APL is calculated using two alternative methods: ~ Based on SCR test data, where APL is obtained by subtracting the string and bit losses from the SCR pump pressure. This method is often more accurate when APL is relatively high (e.g. in small holes). ~ Direct calculation, where APL is calculated based on annular sizes and mud properties. This is often more accurate when APL is relatively low (e.g. in conventional hole sizes). Based on the above APL values, user can input an "Accepted APL" in the "Pressure Losses" section. A suitable kill technique will then be selected: ~ If APL <= 150 psi, the conventional technique will be used where APL is ignored; You can choose to ignore APL in any case by keeping the "Accepted APL" cell blank. ~ If APL > 150 psi and SICP is sufficiently high, then the special kill technique will be used to compensate APL during kill. User will be required to select an over-balance safety factor in the "Kill Data" section. ~ If APL > 150 psi but SICP is low, then APL can only be partially compensated. The actual kill technique to be used will be displayed below the "Pressure Losses" section. Kill Procedures: At the end of the kill sheet (page 3), some guidance is also given on kill procedures and how to use the kill sheet, etc.

4. KILL SHEET

For Vertical / Deviated Wells With Subsea BOPs

This kill sheet is designed for deep water drilling with subsea BOPs. It can be used to record data during drilling operations, and to perform kill calculations. The kick sheet is designed for: ~ Offshore floating rigs where there are long choke /kill lines from the subsea BOP to rig floor. ~ Vertical, deviated or horizontal wells (Straight, L- or S-shaped holes). ~ Conventional or small hole sizes ~ Single- or dual-sized drillpipe strings (plus HWDPs and DCs). ~ Gas, oil or water kicks. The major difference between kill calculations for surface and subsea BOPs is in the choke line loss (CLL). On a land or an offshore fixed rig with surface BOPs, CLL is usually low at kill pump rates and can be ignored during kill operations. On a floating rig with subsea BOPs however, CLL can be

166347034.xls.ms_office

Page 18 of 6

8/22/2013 9:11 AM

significantly higher. If ignored, it can result in excessive pressures in the wellbore and the consequence of formation breaking down at the open hole weak point. The deep water kill technique should be used in this case to compensate the CLL. In this kill sheet, CLL is first calculated. Based on the calculated value and perhaps other rig-site tests, user can then input an accepted CLL for compensation during kill. This is done in the "Pressure Losses" section of the kill sheet. The Annular pressure loss (APL) can also be compensated if it is high. This is done in a similar way as in the previous kill sheet for Surface BOPs. Kill Techniques: Once user has defined the accepted choke line loss (CLL) and annular pressure loss (APL) in "Pressure Losses" section, a suitable kill technique will be selected: A. If CLL <=100psi and APL <= 100psi, both CLL and APL will be ignored. In this case, the conventional vertical / high angle kill technique will be used. You can choose to ignore both APL and CLL in any case by keeping the "Accepted APL" and "Accepted CLL" cells blank. B. If CLL > 100psi but APL <= 100psi, the deep water kill technique will be used to compensate CLL and APL will be ignored. When SICP is low (after choke line has been displaced to mud), however, CLL may be only partially compensated. C. If CLL <= 100psi but APL > 100 psi, the slimhole kill technique will be used to compensate APL and CLL will be ignored. When SICP is low (after choke line has been displaced to mud), however, APL may be only partially compensated. D. If CLL > 100 psi and APL > 100psi, the combination of deep water and slimhole kill techniques will be used to compensate both CLL and APL. User will be required to select an over-balance safety factor in the "Kill Data" section. If SICP is low (after choke line has been displaced to mud), however, CLL and APL will be only partially compensated. The actual kill technique to be used will be displayed above the "Kill Data" section. Kill Procedures: At the end of the kill sheet (page 3), some guidance is also given on kill procedures and how to use the kill sheet, etc.

5. VOLUMETRIC CONTROL SHEETS

The volumetric control techniques are used during well shut-in period to control gas expansion due to migration. The purposes of the techniques are to: 1) Maintain the bottom hole pressure above the formation pressure to prevent further influx, and 2) Control the bottom hole pressure below a preset limit to prevent formation breakdown. For swabbed kicks, the techniques can be used as the final kill. For under-balanced kicks, however, the techniques only provide a temporary measure to control the wellbore pressure. The final kill can only be achieved by circulating kill mud into the hole. Therefore the techniques are only used when circulating kill is impossible due to pumps breakdown, string washout, plugged bit nozzles or string off-bottom, etc. Also it is worthwhile to mention that volumetric control of an influx is only necessary when the influx contains free-gas which is migrating up the annulus. Three techniques are included in the Toolkit: 1) Volumetric control using drillpipe pressure gauge This is a relatively simple and accurate technique to control gas expansion. It should be used when there is communication between drillpipe pressure gauge and the wellbore annulus. 2) Volumetric control using choke pressure gauge This technique is a less reliable technique for controlling gas expansion. So it is only used when use of DP pressure is impossible due to string washout, plugged nozzles or string off-bottom, etc. 3) Static Lubrication The technique is used to vent gas from beneath BOP stack (both surface and subsea).

166347034.xls.ms_office

Page 19 of 6

8/22/2013 9:11 AM

For more detailed information about the volumetric control techniques, please refer to: BP Well Control Manuals, Vol.I, Chapter 6, Section 2.

6. CASING PRESSURE PROFILES

This spreadsheet program is designed to calculate the casing pressure profiles at the casing shoe and surface when displacing a given volume of gas influx to surface. The calculations are based on the following assumptions: 1) The influx is free gas. For mixed influxes (gas/oil/water), only the gas component is considered. 2) The influx is a single gas bubble. Calculations based on this assumption usually give higher pressures and thus, it is conservative. 3) The mud displacing the influx has the original mud weight (Driller's method). If kill mud weight was used (Wait & Weight method), the casing shoe and surface pressures may be lower. Therefore, the pressure predictions from this program will be conservative.

UNIT CONVERTER

All the worksheets in this Toolkit have been designed for both the UK (m.sg) and US (ft.ppg) oil industry units. This should cover most of the world-wide operations within BP. However, if you find any units used in your local operations are different from those in the worksheets, then this unit Converter can be used to convert your local units into either the UK or US units.

166347034.xls.ms_office

8/22/2013 9:11 AM

DISCLAIMER

This Toolkit has been developed by BP Exploration Operating Company Limited ("BP") for internal use only. The calculations are based on the latest well control techniques and procedures. Every effort has been made to ensure their correctness as well as their field applicability. However, BP makes no warranty of any kind, express or implied, with respect to this Toolkit including, but not limited to, the implied warranties of mechantability and fitness for any purpose. BP shall have no liability for any loss or damage, however caused and of whatever nature, arising directly or indirectly from the use of this Toolkit. No tool, however powerful and accurate, can ever replace sound professional judgement in the field to ensure that safe and sound techniques and procedures are followed in a well control event.

Original Author - Yuejin Luo For more information or help, please contact: Jonny Gent, E-mail: gentjl@bp.com Alan Billard, E-mail: billarda@bp.com

Version 2002.1 Released January 2002 FOR USE WITH EXCEL 2000

You might also like

- Well DataDocument16 pagesWell DatascrbdgharaviNo ratings yet

- Casing CementingDocument8 pagesCasing CementingscrbdgharaviNo ratings yet

- Ilker Drilling ProgrammeDocument71 pagesIlker Drilling Programmerıdvan duranNo ratings yet

- Dir PlanDocument2 pagesDir PlanscrbdgharaviNo ratings yet

- Well Name: Horizontal Demo Well CLF 0: Surface BOP ? 1Document58 pagesWell Name: Horizontal Demo Well CLF 0: Surface BOP ? 1bohog39663No ratings yet

- Coiled Tubing Drilling ManualDocument140 pagesCoiled Tubing Drilling ManualjdmacbookNo ratings yet

- 07 Circulation Times and Volumes - QuartzDocument1 page07 Circulation Times and Volumes - QuartzRebarNo ratings yet

- Well Control Data Sheet: Directional WellsDocument1 pageWell Control Data Sheet: Directional WellsscrbdgharaviNo ratings yet

- SDU Ver142beta1 - Demo Print 1 PDFDocument12 pagesSDU Ver142beta1 - Demo Print 1 PDFreza khNo ratings yet

- AFEDocument2 pagesAFER NilandNo ratings yet

- Dew CalculationDocument6 pagesDew CalculationHaykal Yuqdha0% (1)

- 29 - Well Control Data Sheet For Directional Wells Wt. & Wt. MethodDocument1 page29 - Well Control Data Sheet For Directional Wells Wt. & Wt. MethodJunaid MateenNo ratings yet

- Omnibus CVD Risk EstimatorDocument6 pagesOmnibus CVD Risk EstimatorXigentNo ratings yet

- IWCF Kick SheetDocument3 pagesIWCF Kick SheetKathryn SmithNo ratings yet

- HPHT Lessons - SLBDocument39 pagesHPHT Lessons - SLBSuresh100% (1)

- How To Stabilize and Strengthen The Wellbore During Drilling Operations" by DR Fred GrowcockDocument16 pagesHow To Stabilize and Strengthen The Wellbore During Drilling Operations" by DR Fred Growcockrıdvan duranNo ratings yet

- Well Control For Drilling EngineersDocument26 pagesWell Control For Drilling EngineersJairo Cortes100% (1)

- Acid CalculationsDocument4 pagesAcid CalculationsjoensameNo ratings yet

- Recent Advances in Complex Well DesignDocument26 pagesRecent Advances in Complex Well DesignForex FxTraderNo ratings yet

- 12.25 Hole KTDocument30 pages12.25 Hole KTchaeqqNo ratings yet

- Bit Hyd Program - 1 1Document19 pagesBit Hyd Program - 1 1Heris SitompulNo ratings yet

- Daily Drilling Progress Report: Mud PropertiesDocument1 pageDaily Drilling Progress Report: Mud PropertiesMarcoNo ratings yet

- Chapter 16IT Controls Part IIDocument10 pagesChapter 16IT Controls Part IIChene Soriano100% (1)

- Completion Fluid ProgramDocument8 pagesCompletion Fluid ProgramMessaoud Amr100% (1)

- Bit HydraulicsDocument1 pageBit HydraulicsstevebeardsleyNo ratings yet

- 31 - Well Control Data Sheet For Vertical Wells Wt. & Wt. MethodDocument1 page31 - Well Control Data Sheet For Vertical Wells Wt. & Wt. MethodJunaid MateenNo ratings yet

- Solids CalculationsDocument17 pagesSolids Calculationsmohamed4874No ratings yet

- Evening Report HH 83-1 CDocument1 pageEvening Report HH 83-1 CMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Well Control Data Sheet: Vertical WellsDocument2 pagesWell Control Data Sheet: Vertical WellsscrbdgharaviNo ratings yet

- Balance of Materials: Density of A Mixture of Fluids, Knowing Volume and Density of Its ComponentsDocument2 pagesBalance of Materials: Density of A Mixture of Fluids, Knowing Volume and Density of Its ComponentsRebarNo ratings yet

- Casing Design CalculationDocument10 pagesCasing Design CalculationNurul Aishah100% (3)

- Cement CalcDocument6 pagesCement Calcmmohsinaliawan100% (1)

- Well Control Data Sheet: Vertical WellsDocument2 pagesWell Control Data Sheet: Vertical WellsscrbdgharaviNo ratings yet

- CementingDocument47 pagesCementingKarwan DilmanyNo ratings yet

- Cement PlannerDocument6 pagesCement PlannerscrbdgharaviNo ratings yet

- 14 Balanced Plug Calculations & Procedure - QuartzDocument2 pages14 Balanced Plug Calculations & Procedure - QuartzRebarNo ratings yet

- Integrated Wellbore Stability Analysis For Well Trajectory Optimization and Field DevelopmentDocument162 pagesIntegrated Wellbore Stability Analysis For Well Trajectory Optimization and Field DevelopmentkikimixplusNo ratings yet

- Primary and Remedial CementingDocument108 pagesPrimary and Remedial CementingPablo Santo100% (2)

- 20 in Surf - 94 PPFDocument12 pages20 in Surf - 94 PPFAnonymous XbmoAFtINo ratings yet

- 671 - BP Well Control Tool Kit 2002Document20 pages671 - BP Well Control Tool Kit 2002gplese0No ratings yet

- Critical Success Factors For The Implementation of Enterprise Resource Planning (Erp) : Empirical ValidationDocument10 pagesCritical Success Factors For The Implementation of Enterprise Resource Planning (Erp) : Empirical ValidationiacikgozNo ratings yet

- Under Balanced OperationsDocument104 pagesUnder Balanced OperationsJavier Ignacio Meriles100% (1)

- SSA 11 Kes Evoy - Workover Well KillDocument7 pagesSSA 11 Kes Evoy - Workover Well KillDavide Boreaneze100% (1)

- @@@@API Technical Data Book Tanques Bombas y Tuberías PDFDocument78 pages@@@@API Technical Data Book Tanques Bombas y Tuberías PDFjorge pajonNo ratings yet

- Guidelines For Volumetric Stripping Rev.1 Feb.2004Document27 pagesGuidelines For Volumetric Stripping Rev.1 Feb.2004Yuri KostNo ratings yet

- CSG CMT CalculationsDocument5 pagesCSG CMT Calculationsfrancisryan4519No ratings yet

- Hidraulica ExelDocument339 pagesHidraulica ExelJose RuedaNo ratings yet

- Techniques To Reduce Timing Violations Using Clock Tree Optimizations in Synopsys ICC2Document10 pagesTechniques To Reduce Timing Violations Using Clock Tree Optimizations in Synopsys ICC2Pardhasaradhi Damarla100% (1)

- BP WellControlToolkitDocument3 pagesBP WellControlToolkitJuan Pablo CassanelliNo ratings yet

- Salamat-1 Mud Report 54-28092012Document4 pagesSalamat-1 Mud Report 54-28092012mega87_2000No ratings yet

- Slimhole Coiled Tubing DrillingDocument131 pagesSlimhole Coiled Tubing DrillingTran Dang Sang100% (2)

- Well Program Bangko # 317Document21 pagesWell Program Bangko # 317Ryan SinagaNo ratings yet

- TUBEMOVEDocument2 pagesTUBEMOVEChristian MatteoNo ratings yet

- Enerplus Resources Inc.: Proposed Drilling Wellbore SchematicDocument1 pageEnerplus Resources Inc.: Proposed Drilling Wellbore SchematiclaaliautoNo ratings yet

- Drilling Engineering - PE 311: Hydraulics of Drilling FluidsDocument29 pagesDrilling Engineering - PE 311: Hydraulics of Drilling FluidsDeepak RanaNo ratings yet

- DrlgFldsAwarenessWorkshop1 June 09Document167 pagesDrlgFldsAwarenessWorkshop1 June 09Mahmoud Ahmed Ali Abdelrazik100% (1)

- Casing CalculationsDocument10 pagesCasing CalculationsKimiko ShopNo ratings yet

- 35 - Casing CementingDocument8 pages35 - Casing CementingAseem PandeyNo ratings yet

- DST BhaDocument1 pageDST Bhajairaso2950No ratings yet

- Enerplus Resources Inc - Drilling Diagram OurwellDocument4 pagesEnerplus Resources Inc - Drilling Diagram OurwellHeris SitompulNo ratings yet

- Calculate Leak Off TestDocument5 pagesCalculate Leak Off Testmt59cool2089No ratings yet

- Daily Drilling Report: Bha Tally Bit Record Mud Report Mud Pump Drilling InformationDocument25 pagesDaily Drilling Report: Bha Tally Bit Record Mud Report Mud Pump Drilling InformationHamed NazariNo ratings yet

- Fishing Diagram - Stabilizer Jar Pony Collar - BHA#10Document10 pagesFishing Diagram - Stabilizer Jar Pony Collar - BHA#10abhijitrathiNo ratings yet

- BP-KILL-SHEET - Contoh Latihan Soal-DikonversiDocument9 pagesBP-KILL-SHEET - Contoh Latihan Soal-Dikonversiwindaru kusumaNo ratings yet

- Title ListDocument6,834 pagesTitle ListMD ABUL KHAYERNo ratings yet

- InventoryDocument34 pagesInventorypvwanderNo ratings yet

- Interactvie Spreadsheets Form+ControlsDocument64 pagesInteractvie Spreadsheets Form+ControlsUok RitchieNo ratings yet

- Safe Braking Zone (SBZ)Document4 pagesSafe Braking Zone (SBZ)Uok RitchieNo ratings yet

- Tier-2 Load Rating File SummaryDocument1 pageTier-2 Load Rating File SummaryUok RitchieNo ratings yet

- CtrypremDocument68 pagesCtrypremUok RitchieNo ratings yet

- In The Green CellsDocument10 pagesIn The Green CellsUok RitchieNo ratings yet

- FTE CalculationDocument4 pagesFTE CalculationUok RitchieNo ratings yet

- Formula WT CalculatorDocument50 pagesFormula WT CalculatorUok RitchieNo ratings yet

- Ie DataDocument74 pagesIe DataUok RitchieNo ratings yet

- Sita Cue SheetDocument6 pagesSita Cue SheetUok RitchieNo ratings yet

- Ie DataDocument74 pagesIe DataUok RitchieNo ratings yet

- Hemispherical HeadDocument4 pagesHemispherical HeadAscanio BarbosaNo ratings yet

- Bec-Exercises 4-3 & 5-6Document5 pagesBec-Exercises 4-3 & 5-6Uok RitchieNo ratings yet

- Excel Beta ExampleDocument5 pagesExcel Beta ExamplebhaveshvmlNo ratings yet

- Wireless Power CalculatorDocument1 pageWireless Power CalculatorUok RitchieNo ratings yet

- GFRDocument4 pagesGFRUok RitchieNo ratings yet

- Tutorial Excel IRRDocument1 pageTutorial Excel IRRUok RitchieNo ratings yet

- CUDA Occupancy CalculatorDocument48 pagesCUDA Occupancy CalculatorUok RitchieNo ratings yet

- MS Excel FormulasDocument223 pagesMS Excel FormulasUok RitchieNo ratings yet

- Expense Share Calculator 1.0.5Document6 pagesExpense Share Calculator 1.0.5Uok RitchieNo ratings yet

- BMI Group Calculator EnglishDocument5 pagesBMI Group Calculator EnglishMcarl MatelNo ratings yet

- Kick Detection - Drilling Process SafetyDocument3 pagesKick Detection - Drilling Process SafetyUok RitchieNo ratings yet

- Heating Fuel Cost Comparison CalcDocument13 pagesHeating Fuel Cost Comparison CalcrscottcochraneNo ratings yet

- Ie DataDocument74 pagesIe DataUok RitchieNo ratings yet

- Auto Loan CalculatorDocument5 pagesAuto Loan CalculatorUok RitchieNo ratings yet

- برنامج حساب زكاه المالDocument3 pagesبرنامج حساب زكاه المالnewlife4me100% (10)

- Cellulite Treatment London - The Cellulite Experts - Cellulite - Fat Removal and Skin Tightening - Lifting With Radiofrequency, Ultrasound Cavitation & Needle-Free MesotherapyDocument3 pagesCellulite Treatment London - The Cellulite Experts - Cellulite - Fat Removal and Skin Tightening - Lifting With Radiofrequency, Ultrasound Cavitation & Needle-Free MesotherapyUok RitchieNo ratings yet

- Beginner's Guide To Using Slack: How To Download and SetupDocument10 pagesBeginner's Guide To Using Slack: How To Download and Setupapi-438333796No ratings yet

- Rechargeable Laptop Battery User ManualDocument1 pageRechargeable Laptop Battery User ManualVintonius Raffaele PRIMUSNo ratings yet

- Dwi Hadianti, S.E: Mypersonal Profile Work ExperienceDocument1 pageDwi Hadianti, S.E: Mypersonal Profile Work ExperienceBumn Kuala Tungkal HebatNo ratings yet

- GSA 3GPP Roadmap 1693182705Document11 pagesGSA 3GPP Roadmap 1693182705Hamza BouchebbahNo ratings yet

- Steganography PresentationDocument15 pagesSteganography PresentationhiraL_patel936No ratings yet

- IPsec - GNS3Document9 pagesIPsec - GNS3khoantdNo ratings yet

- Apd Summer Institute ApplicationDocument3 pagesApd Summer Institute ApplicationFNo ratings yet

- RAN3308: Flexi RFM 3T6R 2100Document2 pagesRAN3308: Flexi RFM 3T6R 2100Reza BordbarNo ratings yet

- 2020 - A Revisit of Navier-Stokes EquationDocument12 pages2020 - A Revisit of Navier-Stokes EquationAshutosh SharmaNo ratings yet

- Investigation of The Condominium Building Collapse in Surfside, Florida: A Video Feature Tracking ApproachDocument27 pagesInvestigation of The Condominium Building Collapse in Surfside, Florida: A Video Feature Tracking ApproachSparkly DraigNo ratings yet

- Chapters 1 - 6: - Chapter 6Document51 pagesChapters 1 - 6: - Chapter 6Delasdriana WiharjaNo ratings yet

- Stock Price Prediction Using Machine Learning and LSTM-Based Deep Learning ModelsDocument18 pagesStock Price Prediction Using Machine Learning and LSTM-Based Deep Learning ModelsYONG POH YEN STUDENTNo ratings yet

- Semi-Automatic Digital Micro Vickers Hardness Testing Machine (Tester) DVS-1XYDocument8 pagesSemi-Automatic Digital Micro Vickers Hardness Testing Machine (Tester) DVS-1XY周记伟No ratings yet

- System Imaging and SW Update Admin v10.6Document102 pagesSystem Imaging and SW Update Admin v10.6tseiple7No ratings yet

- Visual Foxpro Bsamt3aDocument32 pagesVisual Foxpro Bsamt3aJherald NarcisoNo ratings yet

- Auto Power ManualDocument97 pagesAuto Power ManualAngel100% (1)

- TraceDocument318 pagesTraceJonathan EvilaNo ratings yet

- Aadhaar Update Form: Aadhaar Enrolment Is Free & VoluntaryDocument4 pagesAadhaar Update Form: Aadhaar Enrolment Is Free & VoluntaryShankar HirekarNo ratings yet

- How To Register The HospitalDocument55 pagesHow To Register The HospitalAkhilesh Dwivedi0% (1)

- Assignment Cyber Law E.N 54Document6 pagesAssignment Cyber Law E.N 54Tajamul IslamNo ratings yet

- Tc14.0.0.0 ActiveWorkspace6.2.2 READMEDocument5 pagesTc14.0.0.0 ActiveWorkspace6.2.2 READMEgyuregabiNo ratings yet

- Chapter 12Document34 pagesChapter 12Thanh Van DaoNo ratings yet

- Criteria For Classifying Forecasting Me - 2020 - International Journal of Foreca PDFDocument11 pagesCriteria For Classifying Forecasting Me - 2020 - International Journal of Foreca PDFcrackendNo ratings yet

- CP3000S BomDocument14 pagesCP3000S BommundomusicalmeriaNo ratings yet

- Sap MM PDFDocument2 pagesSap MM PDFMurali TungaNo ratings yet

- PLCDocument936 pagesPLCjulio cidNo ratings yet

- Architectural Design Case Studies: Useful Online ResourcesDocument3 pagesArchitectural Design Case Studies: Useful Online Resourcesnysidlibrary100% (1)