Professional Documents

Culture Documents

Qauntum Scalar I40i80 I4 Maintenance Guide

Uploaded by

Scramble 69Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Qauntum Scalar I40i80 I4 Maintenance Guide

Uploaded by

Scramble 69Copyright:

Available Formats

Maintenance Guide

Quantum Scalar i40 and Scalar i80

6-66548-07 Rev A

Scalar i40 and Scalar i80 Maintenance Guide, 6-66548-07 July 2012, Product of U.S.A. Quantum Corporation provides this publication as is without warranty of any kind, either express or implied, including but not limited to the implied warranties of merchantability or fitness for a particular purpose. Quantum Corporation may revise this publication from time to time without notice. COPYRIGHT STATEMENT Copyright 2012 by Quantum Corporation. All rights reserved. Your right to copy this manual is limited by copyright law. Making copies or adaptations without prior written authorization of Quantum Corporation is prohibited by law and constitutes a punishable violation of the law. TRADEMARK STATEMENT Quantum, the Quantum logo, and Scalar are registered trademarks of Quantum Corporation, registered in the U.S.A. and other countries. Preserving the Worlds Most Important Data. Yours., StorageCare, and Vision are trademarks of Quantum. LTO and Ultrium are trademarks of HP, IBM, and Quantum in the U.S.A. and other countries. All other trademarks are the property of their respective companies. Specifications are subject to change without notice.

ii

Quantum Scalar i40 and Scalar i80 Maintenance Guide

Contents

Preface

xix

Scalar i40 Supported Versions . . . . . . . . . . . . . . . . . . . . . . . xxv

Chapter 1

Common Service Procedures

Receiving Customer Library E-mail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Connecting to the Service Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Logging In With Service Privileges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Service Menu Trees . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Changing Operator Panel Home Screen View . . . . . . . . . . . . . . . . . . . . 9 Changing to Alternate Home Screen. . . . . . . . . . . . . . . . . . . . 11 Returning to Default Home Screen . . . . . . . . . . . . . . . . . . . . . 11 Enabling Remote Service Login . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Logging Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Resetting the Admin Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Shutting Down, Restarting, Turning Off, and Removing Power. . . . . . 14 Shutting Down the Library . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 Restarting the Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Turning Off the Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 Completely Removing Library Power. . . . . . . . . . . . . . . . . . . . 20

Quantum Scalar i40 and i80 Maintenance Guide

iii

Contents

Emergency Power-off Procedure . . . . . . . . . . . . . . . . . . . . . . . 20 Taking the Library Offline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 Taking a Partition Online or Offline . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 Taking a Tape Drive Online or Offline . . . . . . . . . . . . . . . . . . . . . . . . . 23 Unlocking the I/E Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 Releasing Magazines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 Releasing Magazines via the User Interface. . . . . . . . . . . . . . . 29 Releasing Magazines Manually . . . . . . . . . . . . . . . . . . . . . . . . 30 Configuring the Service Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 Saving and Restoring the Library Configuration . . . . . . . . . . . . . . . . . 32 Saving the Library Configuration . . . . . . . . . . . . . . . . . . . . . . 33 Restoring the Library Configuration . . . . . . . . . . . . . . . . . . . . 33 Removing the Y-tray Restraint and Releasing the Y-tray at Initial Install . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 Installing the Y-tray Restraint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 Using Advanced Reporting Control Path Failover and Forced CPF . . . . 38 Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 Configuring CPF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 Forcing CPF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Chapter 2

Lodged Tape Removal Instructions

43

Notes for Service Before Beginning . . . . . . . . . . . . . . . . . . . . . . . . . . . 44 Pulling out the Tape Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . 44 Rotating the Picker Fingers . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 Required Tools and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 Taking ESD Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 Recovering a Cartridge By Removing the Tape Drive . . . . . . . . . . . . . . 49 Recovering a Cartridge by Removing Top Cover of Library . . . . . . . . . 52 Removing the Library from a Rack . . . . . . . . . . . . . . . . . . . . . 53 Removing the Lid of the Desktop Kit. . . . . . . . . . . . . . . . . . . . 55 Removing the Top Cover of the Library. . . . . . . . . . . . . . . . . . 55 Dislodging Tape Using Drive Eject Button (cartridge completely stuck in drive) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

iv Quantum Scalar i40 and i80 Maintenance Guide

Contents

Moving the Picker Carriage Along the Robots Z-axis (Tape Stuck in Magazine) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 Sliding the Picker Along the X-axis (Cartridge Stuck in Drive and Attached to Picker) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63 Swiveling the Picker (Theta Axis) . . . . . . . . . . . . . . . . . . . . . . . 65 Manually Unloading the Tape Drive . . . . . . . . . . . . . . . . . . . . 68 Manually Unloading the HP LTO-4 or LTO-5 Half-Height Tape Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68 Manually Unloading the HP LTO-4 Full-Height Tape Drive. . . . 70 Reinstalling the Top Cover and Final Steps . . . . . . . . . . . . . . . 73

Chapter 3

Installing, Removing, and Replacing CRUs

75

Taking ESD Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 Connecting Library Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77 Installing the Rack Mount Kit (Rail Kit) . . . . . . . . . . . . . . . . . . . . . . . . 79 Supported Rack Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79 Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 Rack Mount Kit Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 Installing the Rack Mount Shelves. . . . . . . . . . . . . . . . . . . . . . 81 Installing the Library In a Rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90 Removing the Library From a Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . 92 Installing the Library in a Desktop Kit . . . . . . . . . . . . . . . . . . . . . . . . . 93 Kit Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95 Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95 Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96 Removing the Library from a Desktop Kit . . . . . . . . . . . . . . . . . . . . . 101 Removing and Replacing the Front Bezel. . . . . . . . . . . . . . . . . . . . . . 102 Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102 Bezel Replacement Kit Contents . . . . . . . . . . . . . . . . . . . . . . 102 Bezel Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . 102 Replacing the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107 Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108 Removing and Installing a Filler Plate . . . . . . . . . . . . . . . . . . . . . . . . 119 Removing and Installing a Tape Drive Filler Plate . . . . . . . . . 119

Quantum Scalar i40 and i80 Maintenance Guide v

Contents

Removing and Installing a Power Supply Filler Plate . . . . . . . 119 Removing and Replacing a Magazine . . . . . . . . . . . . . . . . . . . . . . . . 121 Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121 Magazine Replacement Kit Contents . . . . . . . . . . . . . . . . . . 121 Creating a Backup Map of Cartridge Locations . . . . . . . . . . . 121 Removing the Magazine from the Library . . . . . . . . . . . . . . . 122 Installing the Magazine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123 Removing and Installing a Power Supply. . . . . . . . . . . . . . . . . . . . . . 126 Replacing a Power Supply in a Single-Power-Supply System (Scalar i40 and Scalar i80). . . . . . . . . . . . . . . . . . . . . . . . . . . 127 Adding or Replacing a Redundant Power Supply on the Scalar i80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128 Removing and Replacing the System Control Board . . . . . . . . . . . . . 129 Replacing the System Control Board . . . . . . . . . . . . . . . . . . . 129 Installing Library Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . 131 Restoring the Library Configuration . . . . . . . . . . . . . . . . . . . 133 Manually Reconfiguring the Library . . . . . . . . . . . . . . . . . . . 135 Removing and Replacing a Tape Drive. . . . . . . . . . . . . . . . . . . . . . . . 137 Preparing Partitions and Control Paths . . . . . . . . . . . . . . . . . 137 Removing a Tape Drive from the Library . . . . . . . . . . . . . . . . 138 Installing a Tape Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139 Packaging the Library for Moving or Shipping. . . . . . . . . . . . . . . . . . 143 Packaging Kit Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143 Creating a Backup Map of Cartridge Locations . . . . . . . . . . . 143 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144 Unpacking the Library in its New Location . . . . . . . . . . . . . . 148

Chapter 4

Installing, Removing, and Replacing FRUs

149

Replacing the Y-tray with Robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149 Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150 Y-tray FRU Kit Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150 Taking ESD Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150 Removing the Y-tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150 Installing the Y-tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162 Packing and Shipping the Removed Y-tray . . . . . . . . . . . . . . 174 Moving the Picker Into Proper Position For Shipping . . . . . . 174 Swiveling the Picker (Theta Axis) . . . . . . . . . . . . . . . . . . . . . . 175 Moving the Picker Along the Robot X-axis . . . . . . . . . . . . . . 178

vi

Quantum Scalar i40 and i80 Maintenance Guide

Contents

Chapter 5

Getting Information About the Library

181

Viewing Library Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182 Viewing System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182 Viewing the Location of the Robot . . . . . . . . . . . . . . . . . . . . . . . . . . 183 Viewing the Library Configuration Report . . . . . . . . . . . . . . . . . . . . . 186 Saving and E-mailing the Library Configuration Record. . . . . . . . . . . 188 Saving the Configuration Record . . . . . . . . . . . . . . . . . . . . . 189 E-mailing the Configuration Record . . . . . . . . . . . . . . . . . . . 189 Viewing the Network Settings Report . . . . . . . . . . . . . . . . . . . . . . . . 190 Viewing the Logged in Users Report . . . . . . . . . . . . . . . . . . . . . . . . . 191 Viewing the All Slots Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192 Viewing, Saving, and E-mailing Library Logs . . . . . . . . . . . . . . . . . . . 193 Cleaning Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193 Diagnostic Tickets Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194 SKM Encryption Key Import Warning Log . . . . . . . . . . . . . . . 194 Tape Drive Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195 Viewing Library Information on the Operator Panel . . . . . . . . . . . . . 197 Viewing Partition Information. . . . . . . . . . . . . . . . . . . . . . . . 197 Viewing Tape Drive Information . . . . . . . . . . . . . . . . . . . . . . 197 Viewing Network Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . 198 Viewing the Date, Time, and Time Zone . . . . . . . . . . . . . . . . 198 Viewing Licenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198 Using Advanced Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Chapter 6

Troubleshooting and Diagnostics

201

Capturing Snapshots of Library Information . . . . . . . . . . . . . . . . . . . 202 Troubleshooting Library Not Ready Messages . . . . . . . . . . . . . . . . 203 Not Ready Messages on the Operator Panel . . . . . . . . . . . 203 Not Ready Messages on the Web Client . . . . . . . . . . . . . . 203 Retrieving Tape Drive Logs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205 Interpreting LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206 Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206 System Control Board LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Quantum Scalar i40 and i80 Maintenance Guide vii

Contents

Tape Drive/Sled LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208 Power Supply LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210 Running the Installation and Verification Test (IVT). . . . . . . . . . . . . . 211 Running the IVT Diagnostic Subtests Individually Robotics, Tape Drive, and Magazine Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213 Running the Random Move Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215 Performing Library Diagnostics Tests . . . . . . . . . . . . . . . . . . . . . . . . . 216 Entering the Diagnostics Menu . . . . . . . . . . . . . . . . . . . . . . . 216 Resetting a Tape Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217 Robotics Get/Put Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218 Resetting Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219 EKM Path Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221 Failure Scenarios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221 Running Manual EKM Path Diagnostics . . . . . . . . . . . . . . . . 222 If Failure appears in the Progress Window, the diagnostics were not able to be performed. Enabling Automatic EKM Path Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222 Troubleshooting Diagnostic Ticket Display Issue . . . . . . . . . . . . . . . . 223

Chapter 7

Diagnostic Tickets and Resolutions

225

Ticket Priority Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226 Viewing, Closing, and Resolving Diagnostic Tickets. . . . . . . . . . . . . . 227 Viewing Diagnostic Tickets . . . . . . . . . . . . . . . . . . . . . . . . . . 228 Closing Diagnostic Tickets Automatically . . . . . . . . . . . . . . . 229 Diagnostic Ticket Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230 DT000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231 DT001 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232 DT002 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233 DT010 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234 DT011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235 DT012 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236 DT013 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237 DT014 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238 DT015 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239 DT016 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240 DT017 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

viii Quantum Scalar i40 and i80 Maintenance Guide

Contents

DT018 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242 DT019 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243 DT020 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244 DT021 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245 DT022 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246 DT023 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247 DT024 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248 DT030 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249 DT040 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250 DT041 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251 DT042 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252 DT045 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253 DT046 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254 DT050 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255 DT051 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256 DT052 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257 DT055 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258 DT057 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259 DT058 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260 DT059 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261 DT060 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262 DT065 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263 DT067 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264 DT068 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265 DT070 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266 DT071 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267 DT072 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268 DT073 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269 DT074 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270 DT080 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271 DT082 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272 DT085 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273 DT086 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274 DT087 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275 DT088 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276 DT089 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277 DT090 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278 DT091 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279 DT092 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280 DT093 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281 DT094 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282 DT095 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283 DT096 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Quantum Scalar i40 and i80 Maintenance Guide ix

Contents

DT097 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285 DT101 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286 DT103 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287 DT104 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288 DT105 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289 DT106 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290 DT109 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291 DT112 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292 DT113 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293 DT115 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294 DT116 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295 DT118 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296 DT119 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297 DT120 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298 DT121 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299 DT122 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300 DT123 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301 DT130 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302 DT131 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303 DT133 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304 DT136 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305 DT151 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306 DT153 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307 DT155 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308 DT156 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309 DT158 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310 DT159 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311 DT165 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312 DT166 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313 DT167 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 314 DT170 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315 DT171 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316 DT172 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317 DT173 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318 DT174 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319 DT175 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320 DT176 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321 DT177 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322 DT178 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323 DT179 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324 DT180 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325 DT181 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326 DT182 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

x Quantum Scalar i40 and i80 Maintenance Guide

Contents

DT183 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328 DT184 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329 DT185 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330 DT186 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331 DT187 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332 DT188 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333 DT189 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334 DT190 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335 DT191 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336 DT192 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337 DT195 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338 DT196 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339 Diagnostic Resolutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340 DR000 - Contact Quantum Service . . . . . . . . . . . . . . . . . . . . 340 DR001 - PS Power Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340 DR002 - PS Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341 DR010 - RCS Firmware Image Error. . . . . . . . . . . . . . . . . . . . 342 DR011 - RCS Auto-Level Failure. . . . . . . . . . . . . . . . . . . . . . . 343 DR012 - RCS Initialization Error. . . . . . . . . . . . . . . . . . . . . . . 344 DR013 - RCS Calibration Failure . . . . . . . . . . . . . . . . . . . . . . 345 DR014 - RCS Communication Error . . . . . . . . . . . . . . . . . . . . 346 DR015 - RCS Move Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . 347 DR016 - RCS Motion Failure . . . . . . . . . . . . . . . . . . . . . . . . . 348 DR017 - RCS Imager Error . . . . . . . . . . . . . . . . . . . . . . . . . . . 350 DR018 - RCS Component Failure . . . . . . . . . . . . . . . . . . . . . . 350 DR019 - RCS Put Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351 DR020 - RCS Get Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352 DR021 - RCS Put Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . 353 DR022 - RCS Get Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . 354 DR023 - RCS Cartridge Presence . . . . . . . . . . . . . . . . . . . . . . 355 DR024 - RCS Cartridge Loss. . . . . . . . . . . . . . . . . . . . . . . . . . 356 DR030 - I/E Unlock Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . 357 DR031 - I/E Unlock Warning . . . . . . . . . . . . . . . . . . . . . . . . . 358 DR040 - VPD Information Missing. . . . . . . . . . . . . . . . . . . . . 359 DR041 - VPD Information Warning . . . . . . . . . . . . . . . . . . . . 359 DR042 - VPD Information Changed. . . . . . . . . . . . . . . . . . . . 360 DR045 - Chassis Component Failure . . . . . . . . . . . . . . . . . . . 361 DR046 - Chassis Magazine Unlocked . . . . . . . . . . . . . . . . . . 362 DR050 - SCB Hardware Failure . . . . . . . . . . . . . . . . . . . . . . . 363 DR051 - SCB Clock Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . 364 DR052 - New Library Control Firmware Available . . . . . . . . . 365 DR055 - E-Mail Notification Error . . . . . . . . . . . . . . . . . . . . . 365 DR057 - Cartridge Inventory Error. . . . . . . . . . . . . . . . . . . . . 366

Quantum Scalar i40 and i80 Maintenance Guide xi

Contents

DR058 - Insert Assignment Warning . . . . . . . . . . . . . . . . . . . 367 DR059 - Auto-Cleaning Failure . . . . . . . . . . . . . . . . . . . . . . . 367 DR060 - Cartridge Return Failure . . . . . . . . . . . . . . . . . . . . . 368 DR065 - Missing Magazine . . . . . . . . . . . . . . . . . . . . . . . . . . 369 DR067 - Magazine Unlock Failure . . . . . . . . . . . . . . . . . . . . . 370 DR068 - Magazine Unlock Warning . . . . . . . . . . . . . . . . . . . 371 DR070 - Missing Cleaning Media . . . . . . . . . . . . . . . . . . . . . 372 DR071 - Unknown Cleaning Media . . . . . . . . . . . . . . . . . . . . 372 DR072 - Invalid Cleaning Media . . . . . . . . . . . . . . . . . . . . . . 373 DR073 - Unassigned Tape Cartridge . . . . . . . . . . . . . . . . . . . 374 DR074 - Unlabeled Tape Cartridge . . . . . . . . . . . . . . . . . . . . 375 DR080 - Tape Drive Type Changed . . . . . . . . . . . . . . . . . . . . 376 DR082 - Tape Drive FW Invalid . . . . . . . . . . . . . . . . . . . . . . . 376 DR085 - Drive Removal Unexpected . . . . . . . . . . . . . . . . . . . 377 DR086 - Drive Power Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . 378 DR087 - Drive Communication Error . . . . . . . . . . . . . . . . . . . 379 DR088 - Drive FW Update Failure . . . . . . . . . . . . . . . . . . . . . 380 DR089 - Drive Sled Fan Failure . . . . . . . . . . . . . . . . . . . . . . . 381 DR090 - Drive Load Failure . . . . . . . . . . . . . . . . . . . . . . . . . . 382 DR091 - Drive Unload Failure . . . . . . . . . . . . . . . . . . . . . . . . 383 DR092 - Drive Unload Prevented . . . . . . . . . . . . . . . . . . . . . . 384 DR093 - Drive Control Failure . . . . . . . . . . . . . . . . . . . . . . . . 385 DR094 - Drive Encryption Warning . . . . . . . . . . . . . . . . . . . . 386 DR095 - Drive Encryption Failure. . . . . . . . . . . . . . . . . . . . . . 387 DR096 - Drive Control Path Loss . . . . . . . . . . . . . . . . . . . . . . 387 DR097 - Drive Unload Timeout . . . . . . . . . . . . . . . . . . . . . . . 388 DR101 - Drive Tape Alert 1 . . . . . . . . . . . . . . . . . . . . . . . . . . 389 DR103 - Tape Drive Alert 3 . . . . . . . . . . . . . . . . . . . . . . . . . . 391 DR104 - Drive Tape Alert 4 . . . . . . . . . . . . . . . . . . . . . . . . . . 391 DR105 - Drive Tape Alert 5 . . . . . . . . . . . . . . . . . . . . . . . . . . 392 DR106 - Drive Tape Alert 6 . . . . . . . . . . . . . . . . . . . . . . . . . . 393 DR109 - Drive Tape Alert 9 . . . . . . . . . . . . . . . . . . . . . . . . . . 394 DR112 - Drive Tape Alert 12 . . . . . . . . . . . . . . . . . . . . . . . . . 395 DR113 - Drive Tape Alert 13 . . . . . . . . . . . . . . . . . . . . . . . . . 396 DR115 - Drive Tape Alert 15 . . . . . . . . . . . . . . . . . . . . . . . . . 397 DR116 - Drive Tape Alert 16 . . . . . . . . . . . . . . . . . . . . . . . . . 397 DR118 - Drive Tape Alert 18 . . . . . . . . . . . . . . . . . . . . . . . . . 398 DR119 - Drive Tape Alert 19 . . . . . . . . . . . . . . . . . . . . . . . . . 399 DR120 - Drive Tape Alert 20 . . . . . . . . . . . . . . . . . . . . . . . . . 399 DR121 - Drive Tape Alert 21 . . . . . . . . . . . . . . . . . . . . . . . . . 400 DR122 - Drive Tape Alert 22 . . . . . . . . . . . . . . . . . . . . . . . . . 402 DR123 - Drive Tape Alert 23 . . . . . . . . . . . . . . . . . . . . . . . . . 402 DR130 - Drive Tape Alert 30 . . . . . . . . . . . . . . . . . . . . . . . . . 404

xii Quantum Scalar i40 and i80 Maintenance Guide

Contents

DR131 - Drive Tape Alert 31 . . . . . . . . . . . . . . . . . . . . . . . . . 405 DR133 - Drive Tape Alert 33 . . . . . . . . . . . . . . . . . . . . . . . . . 405 DR136 - Drive Tape Alert 36 . . . . . . . . . . . . . . . . . . . . . . . . . 406 DR151 - Drive Tape Alert 51 . . . . . . . . . . . . . . . . . . . . . . . . . 407 DR153 - Drive Tape Alert 53 . . . . . . . . . . . . . . . . . . . . . . . . . 408 DR155 - Drive Tape Alert 55 . . . . . . . . . . . . . . . . . . . . . . . . . 408 DR156 - Drive Tape Alert 56 . . . . . . . . . . . . . . . . . . . . . . . . . 409 DR158 - Drive Tape Alert 58 . . . . . . . . . . . . . . . . . . . . . . . . . 410 DR159 - Drive Tape Alert 59 . . . . . . . . . . . . . . . . . . . . . . . . . 410 DR165 - Library Control Path Failover . . . . . . . . . . . . . . . . . . 411 DR166 - Library Control Path Warning . . . . . . . . . . . . . . . . . 412 DR167 - Library Control Path Failure . . . . . . . . . . . . . . . . . . . 413 DR170 - EKM License Expiring. . . . . . . . . . . . . . . . . . . . . . . . 414 DR171 - EKM License Expired . . . . . . . . . . . . . . . . . . . . . . . . 415 DR172 - EKM Primary Failover. . . . . . . . . . . . . . . . . . . . . . . . 416 DR173 - EKM Request Failure . . . . . . . . . . . . . . . . . . . . . . . . 416 DR174 - EKM Secondary Failover . . . . . . . . . . . . . . . . . . . . . 418 DR175 - EKM Communication Warning . . . . . . . . . . . . . . . . 418 DR176 - EKM Mirror Warning . . . . . . . . . . . . . . . . . . . . . . . . 419 DR177 - EKM Server Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . 420 DR178 - EKM Key Unknown . . . . . . . . . . . . . . . . . . . . . . . . . 421 DR179 - EKM Key Set Depleted . . . . . . . . . . . . . . . . . . . . . . . 422 DR180 - EKM Software Mismatch . . . . . . . . . . . . . . . . . . . . . 423 DR181 - EKM Key Corrupted . . . . . . . . . . . . . . . . . . . . . . . . . 423 DR182 - EKM Key Set Exhausted . . . . . . . . . . . . . . . . . . . . . . 424 DR183 - EKM Key Set Missing . . . . . . . . . . . . . . . . . . . . . . . . 425 DR184 - EKM Key Server Sync Warning . . . . . . . . . . . . . . . . . 426 DR185 - EKM Server HTTP Access . . . . . . . . . . . . . . . . . . . . . 427 DR186- Resolve EKM Server Key Generation . . . . . . . . . . . . . 428 DR187 - EKM Server Certificate Expiring . . . . . . . . . . . . . . . . 428 DR188 - Library Certificate Expiring . . . . . . . . . . . . . . . . . . . 429 DR189 - Library Certificate Expired . . . . . . . . . . . . . . . . . . . . 430 DR 190 - Expiring AR License . . . . . . . . . . . . . . . . . . . . . . . . 430 DR 191 - Expired AR License . . . . . . . . . . . . . . . . . . . . . . . . . 431 DR 192 - Hitachi License Activation. . . . . . . . . . . . . . . . . . . . 431 DR 195 - Media Removal Notification . . . . . . . . . . . . . . . . . . 432 DR 196 - Media Security Warning . . . . . . . . . . . . . . . . . . . . . 432

Appendix A

Tape Alert Flag Descriptions

435

Quantum Scalar i40 and i80 Maintenance Guide

xiii

Contents

Index

445

xiv

Quantum Scalar i40 and i80 Maintenance Guide

Figures

Figure 1 Figure 2 Figure 3 Figure 4 Figure 5 Figure 6 Figure 7 Figure 8 Figure 9 Figure 10 Figure 11 Figure 12 Figure 13 Figure 14 Figure 15 Figure 16 Figure 17

Service Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Operator Panel Service Menu . . . . . . . . . . . . . . . . . . . . . . . 7 Web Client Service Menu . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Alternate Home Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Shutdown in Progress Message . . . . . . . . . . . . . . . . . . . . 16 Ready to Power Down Message . . . . . . . . . . . . . . . . . . . . 16 Ready to Power Down Message . . . . . . . . . . . . . . . . . . . . 16 Series of Restart Messages . . . . . . . . . . . . . . . . . . . . . . . . 18 I/E Station Unlocked Message. . . . . . . . . . . . . . . . . . . . . . 26 I/E Station Locked Message . . . . . . . . . . . . . . . . . . . . . . . 27 Magazine Unlocked Message . . . . . . . . . . . . . . . . . . . . . . 29 Magazine Locked Timer Message . . . . . . . . . . . . . . . . . . . 29 Magazine Release Latch Access . . . . . . . . . . . . . . . . . . . . 31 Pushing Down on Thumbscrews to Release Y-tray (GA Libraries Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 Removing the Y-tray Restraint . . . . . . . . . . . . . . . . . . . . . 37 Setup - Drive Settings Screen . . . . . . . . . . . . . . . . . . . . . . 39 Setup - Control Path Screen . . . . . . . . . . . . . . . . . . . . . . . 40

Quantum Scalar i40 and Scalar i80 Maintenance Guide

xv

Figures

Figure 18 Figure 19 Figure 20 Figure 21 Figure 22 Figure 23 Figure 24 Figure 25 Figure 26 Figure 27 Figure 28 Figure 29 Figure 30 Figure 31 Figure 32 Figure 33 Figure 34 Figure 35 Figure 36 Figure 37 Figure 38 Figure 39 Figure 40 Figure 41 Figure 42 Figure 43

Tools - Drive Operations Screen for CPF . . . . . . . . . . . . . . 41 Force CPF Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 Picker Fingers Horizontal, Grasping Cartridge. . . . . . . . . . 46 Picker Fingers Vertical, Releasing Cartridge. . . . . . . . . . . . 47 LTO Tape Cartridge Inspection . . . . . . . . . . . . . . . . . . . . . 51 Plug in Magazine Bezel to Allow Access to Thumbscrews . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54 Top Cover Screw Locations . . . . . . . . . . . . . . . . . . . . . . . . 56 HP LTO-4 Eject Button . . . . . . . . . . . . . . . . . . . . . . . . . . . 58 Picker Fingers Horizontal, Grasping Cartridge. . . . . . . . . . 60 Carriage Release Button in Normal Operating Position (Flush With Top of Card). . . . . . . . . . . . . . . . . . . . . . . . . . 61 Depressing the Carriage Release Button . . . . . . . . . . . . . . 62 Acceptable Locations for Sliding the Picker Along the X-axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64 Normal Position of Theta Gear . . . . . . . . . . . . . . . . . . . . . 66 Raising the Gear to Swivel the Picker . . . . . . . . . . . . . . . . 67 Manual Unload - HP LTO-4 and LTO-5 Half-Height Tape Drive70 Manual Unload - HP LTO-4 Full-Height Tape Drive . . . . . . 72 Connection Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78 Rack Mount Shelf Depth Requirements . . . . . . . . . . . . . . 82 Assembling the Left and Right Rack Mount Shelves . . . . . 83 Rail Adapter Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84 Assembling the Left-Hand Rack Mount Shelf . . . . . . . . . . 85 Installing the Rack Mount Shelves . . . . . . . . . . . . . . . . . . 87 Tightening the Rack Mount Shelves . . . . . . . . . . . . . . . . . 88 Location for Installing the Clip Nut or Cage Nut . . . . . . . . 90 Magazine Release Latch Access Holes . . . . . . . . . . . . . . . . 91 Securing the Scalar i40 and Scalar i80 in the Rack . . . . . . 92

xvi

Quantum Scalar i40 and Scalar i80 Maintenance Guide

Figures

Figure 44 Figure 45 Figure 46 Figure 47 Figure 48 Figure 49 Figure 50 Figure 51 Figure 52 Figure 53 Figure 54 Figure 55 Figure 56 Figure 57 Figure 58 Figure 59 Figure 60 Figure 61 Figure 62 Figure 63 Figure 64 Figure 65 Figure 66 Figure 67 Figure 68 Figure 69 Figure 70 Figure 71

Desktop Kit, Scalar i40 and Scalar i80. . . . . . . . . . . . . . . . 94 Magazine Release Latch Access Holes . . . . . . . . . . . . . . . . 96 Location of Rubber Feet on Bottom of Library . . . . . . . . . 98 Installing the side panels . . . . . . . . . . . . . . . . . . . . . . . . 100 Installing the Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . 101 Bezel Screw Locations on Bottom of Library . . . . . . . . . . 104 Bezel Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105 Scalar i80 Pull/Push Locations . . . . . . . . . . . . . . . . . . . . . 106 Components to Remove . . . . . . . . . . . . . . . . . . . . . . . . . 110 Removing the Y-tray Restraints. . . . . . . . . . . . . . . . . . . . 112 Restraining the Y-tray . . . . . . . . . . . . . . . . . . . . . . . . . . . 113 Reinstalled Components . . . . . . . . . . . . . . . . . . . . . . . . . 117 Filler Plates Installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 Magazine Release Latch Access Holes . . . . . . . . . . . . . . . 123 Proper Orientation (Right-Side Magazine) . . . . . . . . . . . 124 Removing/Installing the Magazine Bezel. . . . . . . . . . . . . 125 Single Power Supply System . . . . . . . . . . . . . . . . . . . . . . 126 Redundant Power Supply System . . . . . . . . . . . . . . . . . . 127 Ethernet Port Locations on the SCB . . . . . . . . . . . . . . . . 131 Acceptable Installation Locations for Full-Height Tape Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140 Installing a Tape Drive . . . . . . . . . . . . . . . . . . . . . . . . . . 141 Restraining the Y-tray . . . . . . . . . . . . . . . . . . . . . . . . . . . 146 Scalar i40 Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147 Scalar i80 Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148 Top Cover Screw Locations . . . . . . . . . . . . . . . . . . . . . . . 154 Y-tray in Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155 Bulkhead Inside Library, Y-axis Flex Cable . . . . . . . . . . . . 157 Y-axis Flex Cable Connection on Library Back Plane . . . . 158

Quantum Scalar i40 and Scalar i80 Maintenance Guide

xvii

Figures

Figure 72 Figure 73 Figure 74 Figure 75 Figure 76 Figure 77 Figure 78 Figure 79 Figure 80 Figure 81 Figure 82 Figure 83 Figure 84 Figure 85 Figure 86 Figure 87 Figure 88 Figure 89 Figure 90 Figure 91

Flex Cable on Robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159 Y-tray Lift Tabs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161 Removing Thumbscrews and Plastic Strips from Bottom of Y-tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162 Y-tray Adapter Board . . . . . . . . . . . . . . . . . . . . . . . . . . . 164 Connecting the Flex Cable . . . . . . . . . . . . . . . . . . . . . . . 164 Strain Relief on Y-tray Adapter Board . . . . . . . . . . . . . . . 165 Strain Relief on Y-tray Adapter Board . . . . . . . . . . . . . . . 166 Y-climber Gear in Proper Position . . . . . . . . . . . . . . . . . . 167 Y-climber Gear in Proper Position and Y-axis Transmission Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168 Y-axis Flex Cable Connection on Library Back Plane . . . . 170 Y-axis Flex Cable and Strain Relief Installed on Bulkhead 171 X-axis Encoder on Robot - Front Inside of Library and Robot Directional Movement . . . . . . . . . . . . . . . . . . . . . 173 Normal Position of Theta Gear . . . . . . . . . . . . . . . . . . . . 176 Raising the Gear to Swivel the Picker . . . . . . . . . . . . . . . 177 Acceptable Locations for Sliding the Picker Along the X-axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179 Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206 System Control Board LEDs. . . . . . . . . . . . . . . . . . . . . . . 207 Fibre Channel Tape Drive LEDs . . . . . . . . . . . . . . . . . . . . 209 Power Supply LED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210 Enabling Automatic EKM Path Diagnostics. . . . . . . . . . . 223

xviii

Quantum Scalar i40 and Scalar i80 Maintenance Guide

Preface

This manual discusses service-related procedures for the Quantum Scalar i40 and Scalar i80.

Audience

This manual is written for field service engineers.

Document Organization

Following is a brief description of chapter contents. Chapter 1, Common Service Procedures explains how to perform standard service procedures/ Chapter 2, Lodged Tape Removal Instructions provides instructions on how to remove a lodged tape cartridge. Chapter 3, Installing, Removing, and Replacing CRUs provides detailed instruction on how to install, remove, and replace all the customer-replaceable physical components of the library. Chapter 4, Installing, Removing, and Replacing FRUs provides detailed instruction on how to install, remove, and replace all the field replaceable components on the library. Chapter 5, Getting Information About the Library describes all of the reporting features on the library.

Quantum Scalar i40 and Scalar i80 Maintenance Guide

xix

Preface

Chapter 6, Troubleshooting and Diagnostics describes the librarys troubleshooting tools, including LEDs and tests. Chapter 7, Diagnostic Tickets and Resolutions provides a listing of every diagnostic ticket and resolution available on the library. Appendix A, Tape Alert Flag Descriptions lists all the Tape Alerts you may encounter in a diagnostic ticket. The document concludes with an Index.

Notational Conventions

This manual uses the following conventions: Convention File and directory names, menu commands, button names, and window names are shown in bold font. Menu names separated by arrows indicate a sequence of menus to be navigated. Example /data/upload

Utilities > Firmware

The following formats indicate important information: Note: Note emphasizes important information related to the main topic. Caution: Caution indicates potential hazards to equipment or data. WARNING: Warning indicates potential hazards to personal safety. Right side of the system Refers to the right side as you face the component being described. Left side of the system Refers to the left side as you face the component being described.

xx

Quantum Scalar i40 and Scalar i80 Maintenance Guide

Preface

Product Safety Statements

Quantum will not be held liable for damage arising from unauthorized use of the product. The user assumes all risk in this aspect. This unit is engineered and manufactured to meet all safety and regulatory requirements. Be aware that improper use may result in bodily injury, damage to the equipment, or interference with other equipment. The System, Safety, and Regulatory Information Guide is located on the Scalar i40 and Scalar i80 documentation and training CD. WARNING: Before operating this product, read all instructions and warnings in this document and in the System, Safety, and Regulatory Information Guide.

Quantum Scalar i40 and Scalar i80 Maintenance Guide

xxi

Preface

Related Documents

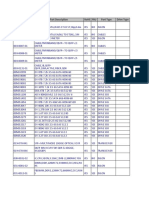

The following Quantum documents are also available for Scalar i40 and Scalar i80 systems: Document No. 6-66545-xx 6-66546-xx 6-66547-xx 6-00618-xx 6-66773-xx 6-00423-xx

Document Title

Scalar i40 and Scalar i80 Users Guide Scalar i40 and Scalar i80 Quick Start Guide Scalar i40 and Scalar i80 Release Notes System, Safety, and Regulatory Information Scalar i40 and Scalar i80 Basic SNMP Reference Guide Quantum Intelligent Libraries SCSI Reference Guide

xxii

Quantum Scalar i40 and Scalar i80 Maintenance Guide

Preface

Document No. 6-01317-xx

Document Title

Quantum Intelligent Libraries SMI-S Reference Guide

For the most up to date product information and documentation, see: http://www.quantum.com/ServiceandSupport/Index.aspx

SCSI-2 Specification

The SCSI-2 communications specification is the proposed American National Standard for information systems, dated March 9, 1990. Copies may be obtained from: Global Engineering Documents 15 Inverness Way, East Englewood, CO 80112 (800) 854-7179 or (303) 397-2740

Contacts

Quantum company contacts are listed below.

Quantum Corporate Headquarters

To order documentation on the Scalar i40 or Scalar i80 or other products, contact: Quantum Corporation (Corporate Headquarters) 1650 Technology Drive, Suite 700 San Jose, CA 95110-1382

Technical Publications

To comment on existing documentation send e-mail to: doc-comments@quantum.com

Quantum Scalar i40 and Scalar i80 Maintenance Guide

xxiii

Preface

Quantum Home Page

Visit the Quantum home page at: http://www.quantum.com

Getting More Information or Help

StorageCare, Quantums comprehensive service approach, leverages advanced data access and diagnostics technologies with crossenvironment, multi-vendor expertise to resolve backup issues faster and at lower cost. Accelerate service issue resolution with these exclusive Quantum StorageCare services: Service and Support Web site - Register products, license software, browse Quantum Learning courses, check backup software and operating system support, and locate manuals, FAQs, firmware downloads, product updates and more in one convenient location. Benefit today at: http://www.quantum.com/ServiceandSupport/Index.aspx Telephone Support - Find contact information for your location at: http://www.quantum.com/ServiceandSupport/Contacts/ ProductSelect/Index.aspx eSupport - Submit online service requests, update contact information, add attachments, and receive status updates via e-mail. Online Service accounts are free from Quantum. That account can also be used to access Quantums Knowledge Base, a comprehensive repository of product support information. Sign up today at: http://www.quantum.com/osr StorageCare Guardian - Securely links Quantum hardware and the diagnostic data from the surrounding storage ecosystem to Quantum's Global Services Team for faster, more precise root cause diagnosis. StorageCare Guardian is simple to set up through the internet and provides secure, two-way communications with Quantums Secure Service Center. More StorageCare Guardian information can be found at: http://www.quantum.com/ServiceandSupport/Services/ GuardianInformation/Index.aspx

xxiv

Quantum Scalar i40 and Scalar i80 Maintenance Guide

Preface

Worldwide End-User Product Warranty

For more information on the Quantum Worldwide End-User Standard Limited Product Warranty: http://www.quantum.com/pdf/QuantumWarranty.pdf

Scalar i40 Supported Versions

Quantum provides support for the current release and the two previous major releases. For example, since i4 is the latest release, Quantum supports releases i4, i3 and i2. Releases earlier than i2 are not supported.

Quantum Scalar i40 and Scalar i80 Maintenance Guide

xxv

Preface

xxvi

Quantum Scalar i40 and Scalar i80 Maintenance Guide

Common Service Procedures

Chapter 1

This chapter explains how to perform common service procedures, including: Receiving Customer Library E-mail Connecting to the Service Port Logging In With Service Privileges Service Menu Trees Changing Operator Panel Home Screen View Logging Out Resetting the Admin Password Shutting Down, Restarting, Turning Off, and Removing Power Emergency Power-off Procedure Taking the Library Offline Taking a Partition Online or Offline Taking a Tape Drive Online or Offline Unlocking the I/E Station Releasing Magazines Configuring the Service Port Saving and Restoring the Library Configuration

Quantum Scalar i40 and Scalar i80 Maintenance Guide

Chapter 1: Common Service Procedures Receiving Customer Library E-mail

Removing the Y-tray Restraint and Releasing the Y-tray at Initial Install Using Advanced Reporting Control Path Failover and Forced CPF

Receiving Customer Library E-mail

The following procedures are described in detail in the users guide. They are outlined here in case you need to instruct a customer to set up their library e-mail account to automatically send you notifications and snapshots. Please see the users guide if you need more details. Set the customer contact information (name, phone number, and e-mail address). It is recommended that the customer fill this out before sending automatic e-mail notifications. From the Web client, click Setup > Notification > Contact Information. Configure the library e-mail account to enable the library to send e-mails. You can elect to automatically send a snapshot with the e-mails, and configure authentication, from this screen. From the Web client, click Setup > Notification > E-mail Account. Create, modify, delete, enable, disable, and set priority levels for e-mail accounts (including techsup@quantum.com) to receive automatic notifications from the library. Note: The e-mail account techsup@quantum.com is disabled by default and cannot be deleted, although you can modify the priority level. From the Web client, click Setup > Notification > Setup.

Quantum Scalar i40 and Scalar i80 Maintenance Guide

Chapter 1: Common Service Procedures Connecting to the Service Port

Connecting to the Service Port

The system control board (SCB) provides an Ethernet port that is reserved for use by service personnel. The service port is the RIGHT side port (see Figure 1 on page 4). The default IP address for the service port is 192.168.177.001. When servicing a library, connect your laptop to the service port to access the remote Web client (do not use the customer port). Use the Web client when servicing the library. You must use the remote Web client to perform some tasks that are not available on the local operator panel. These tasks include saving and restoring library configurations and downloading firmware. 1 Directly connect your laptop to the service port located on the SCB. You can connect to the service port using either a cross-over or a straight Ethernet cable. Note: The service port should never be connected to the LAN infrastructure. The service port should only be direct connected to the service users laptop. 2 Open a Web browser on your laptop. Supported browsers include Microsoft Internet Explorer versions 6.0 and 7.0, and Firefox version 1.0.6 and later. 3 Access IP address 192.168.177.001. The library login page opens. Note: If the login page does NOT appear, the customer may have changed the service port subnet because it conflicted with the customer port network subnet. To view the service port IP address, select Tools > Service Network on the operator panel.

Quantum Scalar i40 and Scalar i80 Maintenance Guide

Chapter 1: Common Service Procedures Connecting to the Service Port

Note: In firmware version 100G.GS004, the Tools > Service Network screen on the operator panel displays an incorrect default service port IP address of 192.168.177.000. The correct default IP address is really 192.168.177.1. If the customer changed the subnet (third octet), the final octet will still be 1, even though it displays as 000. 4 Log in to the library.

Figure 1 Service Port

Customer port

Service port

Quantum Scalar i40 and Scalar i80 Maintenance Guide

Chapter 1: Common Service Procedures Logging In With Service Privileges

Logging In With Service Privileges

The service menu is available only to service personnel. There are not too many differences between the service menu and the normal admin menu, except for: Operator Panel Web Client If passwords are enabled, only service users can reset factory defaults (Tools > Reset Factory Defaults). When a service user logs on (either to the Web client or operator panel), all other Web client users are automatically logged off. Only service users can Reset Factory Defaults (Tools > Reset Factory Defaults) Service users can perform drive and robotics tests without entering Diagnostics mode. To access the service menu, log on to the operator panel or the Web client using your service name and password. Service user name: service Service password: 10101100 For security reasons, an administrator can configure the library to prevent a remote service user from logging in through either the Ethernet port or the library service port. This setting is configured only from the operator panel using Setup > Security Services > Service User. You can always log on to the operator panel with service privileges, even when remote service user access is disabled, so you can change this setting if necessary. See Select Exit twice to return to the default home screen. on page 11 for more information.

Quantum Scalar i40 and Scalar i80 Maintenance Guide

Chapter 1: Common Service Procedures Service Menu Trees

Service Menu Trees

Figure 2 on page 7 shows the operator panel service menu with service items highlighted. Figure 5 on page 16 shows the Web client service menu.

Quantum Scalar i40 and Scalar i80 Maintenance Guide

Chapter 1: Common Service Procedures Service Menu Trees

Figure 2 Operator Panel Service Menu

Operator Panel Main Menu Bar

Setup

Network Configuration Date & Time License Installation Dedicated Slots Cleaning I/E Tape Drives (FC) Configure Partitions View Current Partitions Auto-Create Partitions Delete Partitions Account Settings Password Settings Session Timeout Modify Password* System Settings Unload Assist Logical SN Addr Man Cart Assign SNMP SMI-S Power Save Alternate Home Auto DT Close Security Services Network IF SSH Services ICMP Web client Service User SNMP V1/V2 SSL

Actions

I/E Unlock I/E Station Import Tape Import Cleaning Tape Export Tape Export Cleaning Tape Magazine Release Tape Drive Change Mode Unload Manual Cleaning Reset Change Partition Mode Shutdown Shutdown Library

Tools

IVT Diagnostics Robotics Test Tape Drive Test Magazine Test Random Move Test Robotics View Service Network Modify Subnet Reset Factory Defaults

Reports

Diagnostic Tickets Library Tape Drives Media Close ALL About Library Partitions Tape Drives Network Settings Date/Time Licenses Copyright Statement

ACCESS KEY Restart Library NOTE: If passwords are not enabled on the operator panel, all users have access to all menus and functions. All Users Admin Privileges Only * Only Available if LUI Passwords are enabled

Quantum Scalar i40 and Scalar i80 Maintenance Guide

Chapter 1: Common Service Procedures Service Menu Trees

Figure 3 Web Client Service Menu

Web Client Main Menu Bar

Setup

Setup Wizard Partitions Cleaning Slots I/E Station Slots Drive Settings Control Path License Notification E-mail Configuration Advanced Reporting Receiver Addresses Media Security

Operations

Media Move Import Export Cleaning Media Import Export Partitions Change Mode Drive Load Unload

Tools

All Diagnostic Tickets Capture Snapshot Save/Restore Configuration E-mail Configuration Record Save Configuration Record Drive Operations Download SNMP MIB EKM Path Diagnostics EKM Management Import Communication Certificates Encryption Certificate Import Export

Reports

System Information Library Configuration Network Settings Logged In Users All Slots Log Viewer Advanced Reporting Drive Resource Utilization Media Integrity Analysis About Scalar i40/i80 Open Source Licenses

Diagnostic Tickets Change Mode Receiver Addresses Contact Information Network Management System Shutdown Network SNMP SNMP Trap Registrations User Management User Accounts Remote Authentication Reset Operator Panel Passwords Encryption System Configuration Partition Configuration Date & Time Register Library Log Out

Encryption Key I/E Station Unlock Import Release Magazines Export Retrieve SKM Logs Update Library Firmware Reset Factory Defaults

ACCESS KEY All Users Admin Privileges Only Services Privileges Only

Drives

Drive Tests Drive Reset

Robotics

Robotics Get/Put Test

Quantum Scalar i40 and Scalar i80 Maintenance Guide

Chapter 1: Common Service Procedures Changing Operator Panel Home Screen View

Changing Operator Panel Home Screen View

From the operator panel, you may choose to change the default home screen to an alternate home screen that facilitates easy I/E unlock access, displays the number of I/E slots and the number of I/E slots that are full. Changes to the home screen can be made only from the operator panel.

Quantum Scalar i40 and Scalar i80 Maintenance Guide

Chapter 1: Common Service Procedures Changing Operator Panel Home Screen View

Figure 4 Alternate Home Screen

Number of occupied I /E slots Number of configured I /E slots

Unlock I/E Station

Scalar i80

Number of occupied I /E slots Number of configured I/E slots

Unlock bottom I/E Station

Unlock top I/E Station

10

Quantum Scalar i40 and Scalar i80 Maintenance Guide

Chapter 1: Common Service Procedures Enabling Remote Service Login

Changing to Alternate Home Screen

1 Select Setup > System Settings and press Select. 2 Select Alternate Home and press Modify. 3 Select Up to choose Unlock I/E, and press Apply. 4 Select Exit twice to return to the alternate home screen. Note: From the alternate home screen, selecting Menu returns you to the default home screen. To return to the alternate home screen, select Actions > Alternate Home, and press Select. Unlocking the I/E is described in Unlocking the I/E Station on page 25.

Returning to Default Home Screen

1 From the alternate home screen, select Menu to return to the default home screen. The default home screen is displayed temporarily, however upon power cycle will display the alternate home screen until reset permanently. 2 To reset to view the default home screen permanently, select Setup > System Settings and press Select. 3 Select Alternate Home and press Modify. 4 Select Down and press Apply. Select Exit twice to return to the default home screen.

Enabling Remote Service Login

For security reasons, a user with administrator privileges can configure the library to prevent the remote service user from logging in through either the Ethernet port or the library service port. If a customer disabled remote service login, you may need to enable it during your session. Remember to disable it again when you are finished.

Quantum Scalar i40 and Scalar i80 Maintenance Guide

11

Chapter 1: Common Service Procedures Logging Out

Operator Panel

Note: If you are viewing the alternate home screen, select Menu to return to default home screen. 1 Select Setup > Security Services > Service User. 2 Press Modify. 3 Scroll to select Enabled or Disabled and press Apply.

Logging Out

Remember to log out if you are logged on as service. Logging out secures the library from being accessed by unauthorized users. Log out whenever you have finished accessing the library. You will only be able to log out of the operator panel if passwords are enabled on the operator panel. To check if passwords are enabled, select Setup > Account Settings > Password Settings on the operator panel. Note: Clicking the close button (X) in the upper-right corner of the Web client closes the browser window but does not log you out.

Operator Panel

Note: If you are viewing the alternate home screen, select Menu to return to default home screen. 1 Select Actions > Logout. 2 Press Yes to confirm.

12

Quantum Scalar i40 and Scalar i80 Maintenance Guide

Chapter 1: Common Service Procedures Resetting the Admin Password

Web Client

1 Click the Logout button in the upper right corner of the screen, or select Operations > Log Out. 2 Click OK to confirm.

Resetting the Admin Password

Operator Panel Passwords

If a customer forgets their operator panel passwords and cannot log in, they can reset the passwords. Resetting the passwords disables them and deletes both the admin and user passwords. This means that no login is required to access the operator panel. They can re-create the passwords again as needed. You can only reset operator panel passwords via the Web client. The customer can do this themselves, logged in with Admin privileges (you do not need to be logged in as Service to do this). 1 From the Web client, select Setup > User Management > Reset Operator Panel Passwords. 2 Press Apply.

Web Client Password

The default customer Admin password is password, but the customer can change it. If they forget what they changed it to, they can either reset factory defaults (which deletes all the user accounts, so they may not wish to do this) or you can reset it for them via the Service login on the Web client. To change the Admin password, you will change the password the same way a customer would, only via the service menu. 1 Using the Web client, log in as a Service user using the default Service login and password (see Logging In With Service Privileges on page 5).

Quantum Scalar i40 and Scalar i80 Maintenance Guide

13

Chapter 1: Common Service Procedures Shutting Down, Restarting, Turning Off, and Removing Power

2 From the Web client, select Setup > User Management > User Accounts. 3 Select admin and click Modify. 4 In the Enter your Admin Password text box, enter the service password. 5 Enter the new password twice, in the Enter new password for selected user name and Confirm new password for selected user name text boxes. 6 Click Apply.

Shutting Down, Restarting, Turning Off, and Removing Power

It is important to shut down the library properly before turning off the library or completely removing library power. Caution: You should always perform a shutdown before turning off the library or completely removing power. Otherwise, the following could occur: The library may not complete closing all data and log files. If you turn off power or unplug the power cord while writing to tape, the data on the tape could become corrupted. If you unplug the power cord, the robot may become frozen in the middle of an operation and unable to move once library power is restored, possibly requiring a service call. The steps for shutting down, turning off, and completely removing library power are: 1 Make sure the connected host applications are not sending commands to the library and that all library operations have stopped.

14

Quantum Scalar i40 and Scalar i80 Maintenance Guide

Chapter 1: Common Service Procedures Shutting Down, Restarting, Turning Off, and Removing Power

2 Shut down the library using the operator panel or Web client (see Shutting Down the Library on page 15). 3 Turn OFF the library by pressing the power button on the front panel (see Turning Off the Library on page 19). 4 Remove library power by disconnecting the power supply cord from the power supply on the back of the library. If there are two power supplies, remove the cords to both. See Completely Removing Library Power on page 20.

Shutting Down the Library

Shutdown shuts down the librarys operating system and firmware, closes data and log files, and retracts the picker so that a tape cartridge or the picker fingers are not stuck part way into a tape drive or magazine slot. If the robot was in the middle of a get or put operation, it will attempt to complete the operation before shutting down, by either pushing the cartridge into the destination slot, or removing it completely from the slot and stopping in a safe location from which it can move again once power is restored. Once the shutdown is complete, you can safely turn off the library by pressing the power button on the front panel (see Turning Off the Library on page 19).

Operator Panel

1 Make sure the connected host applications are not sending commands to the library and that all library operations have stopped. Note: If you are viewing the alternate home screen, select Menu to return to default home screen. 2 Press Actions > Shutdown > Shutdown Library. 3 Press Yes to confirm. A shutdown in progress message appears on the operator panel (see Figure 5).

Quantum Scalar i40 and Scalar i80 Maintenance Guide

15

Chapter 1: Common Service Procedures Shutting Down, Restarting, Turning Off, and Removing Power

Figure 5 Shutdown in Progress Message

4 Wait until the ready to power down message appears (see Figure 6).

Figure 6 Ready to Power Down Message

5 Turn OFF the library by pressing the power button on the front panel.

Web Client

1 Press Operations > System Shutdown. 2 Select Shutdown and click Apply. 3 Click OK to confirm. 4 Wait until the ready to power down message appears on the operator panel (see Figure 7).

Figure 7 Ready to Power Down Message

16

Quantum Scalar i40 and Scalar i80 Maintenance Guide

Chapter 1: Common Service Procedures Shutting Down, Restarting, Turning Off, and Removing Power

5 Turn OFF the library by pressing the power button on the front panel.

Restarting the Library

Restart shuts down and then reboots the library's operating system and firmware. During the reboot, the library performs an inventory of the tape drives and magazine slots. If any tape drives or partitions were previously taken offline, restarting the library brings them back online. The reboot takes approximately 5 minutes.

Operator Panel

1 Make sure the connected host applications are not sending commands to the library and that all library operations have stopped. Note: If you are viewing the alternate home screen, select Menu to return to default home screen. 2 Press Actions > Shutdown > Restart Library. 3 Press Yes to confirm. 4 Several messages appear on the screen, in the order shown in Figure 8. Do not do anything in response to these messages. The library will restart and initialize on its own.

Quantum Scalar i40 and Scalar i80 Maintenance Guide

17

Chapter 1: Common Service Procedures Shutting Down, Restarting, Turning Off, and Removing Power

Figure 8 Series of Restart Messages

Web Client

1 Make sure the connected host applications are not sending commands to the library and that all library operations have stopped. 2 Press Operations > System Shutdown. 3 Select Restart and click Apply. 4 Press OK to confirm. 5 Several messages appear on the operator panel, in the order shown in Figure 8 on page 18. Do not do anything in response to these messages. The library will restart and initialize on its own.

18

Quantum Scalar i40 and Scalar i80 Maintenance Guide

Chapter 1: Common Service Procedures Shutting Down, Restarting, Turning Off, and Removing Power

Turning Off the Library

Turning OFF the library means pressing the power button on the front panel. It is recommended that you perform a shutdown via the Web client or operator panel before turning off the library. If you do not perform a shutdown, the library attempts to complete all shutdown operations before turning off the library. However, it may not have enough time to shut down completely, and operations could be stopped mid-process. Caution: You should always perform a shutdown before turning off the library or completely removing power. Otherwise, the following could occur: The library may not complete closing all data and log files. If you turn off power while writing to tape, the data on the tape could become corrupted. 1 Make sure the connected host applications are not sending commands to the library and that all library operations have stopped. 2 Shut down the library (see Shutting Down the Library on page 15). 3 Turn OFF the library by physically pressing the power button on the librarys front panel. It can take up to 12 seconds for the power to completely turn off. Note: Turning off the library does not completely remove library power (see Completely Removing Library Power on page 20).

Quantum Scalar i40 and Scalar i80 Maintenance Guide

19

Chapter 1: Common Service Procedures Shutting Down, Restarting, Turning Off, and Removing Power

Completely Removing Library Power

Completely removing library power means disconnecting the power cord from each power supply on the library. Caution: You should always perform a shutdown and then turn off library power before completely removing power. Otherwise, the following could occur: The library may not complete closing all data and log files. If you turn off power or unplug the power cord while writing to tape, the data on the tape could become corrupted. The robot may become frozen in the middle of an operation and unable to move once library power is restored, possibly requiring a service call. 1 Make sure the connected host applications are not sending commands to the library and that all library operations have stopped. 2 Shut down the library (see Shutting Down the Library on page 15). 3 Turn OFF the library by physically pressing the power button on the librarys front panel (see Turning Off the Library on page 19). Make sure the operator panel turns off or the LED on the SCB turns off. 4 Disconnect the power cord(s) from all power supplies on the back of the library. If there are two power supplies, disconnect both cords. Power is completely removed from the library when the LED on each power supply is off.

Emergency Power-off Procedure

In an emergency, you may need to turn off power immediately to stop robot motion, bypassing the normal shutdown process. In an emergency, you can turn off power in one of two ways: Press the power button on the front of the library to turn the library OFF. It may take up to 4 seconds for all motion to completely stop. Note that this does not completely remove library power (you need to disconnect the power cords to do that). Disconnect the power cord from each power supply on the back of the library. It may take 1 to 2 seconds for motion to completely stop.

20

Quantum Scalar i40 and Scalar i80 Maintenance Guide

Chapter 1: Common Service Procedures Taking the Library Offline

Caution: These methods are not recommended except in case of emergency where it is vital that library operations be stopped immediately. If you do not first perform a shutdown as described in the sections above, the following could occur: The library may not complete closing all data and log files. If you turn off power or unplug the power cord while writing to tape, the data on the tape could become corrupted. If you unplug the power cord, the robot may become frozen in the middle of an operation and unable to move once library power is restored, possibly requiring a service call.

Taking the Library Offline

Some maintenance activities require that the entire library be taken offline. To take the library offline, change the mode of all partitions from online to offline. See Taking a Partition Online or Offline on page 21 for instructions.

Taking a Partition Online or Offline

There are two partition modes: online and offline. Online SCSI hosts control the partition. In this mode, all host application SCSI commands are processed. Offline SCSI hosts cannot control the partition. In this mode, library operations can be performed via the local or remote user interface.

Quantum Scalar i40 and Scalar i80 Maintenance Guide

21

Chapter 1: Common Service Procedures Taking a Partition Online or Offline

Changing the partition mode changes whether or not the specified partition is online or offline to the host application. Changing a partition mode using the library interface may affect your host application. See your host application documentation for more information. Note: Some maintenance activities require that the entire library be taken offline. To take the library offline, change the mode of all partitions from online to offline. When you are changing the partition mode, be aware of the following: When you access the Change Partition Mode screen, you will see only partitions to which you have been given access. When changing the partition mode from online to offline, all host application commands in progress at the start of the mode change are completed. You can change partition modes from the operator panel or the Web client.

Operator Panel

Note: If you are viewing the alternate home screen, select Menu to return to default home screen. 1 Select Actions > Change Partition Mode. The partitions are displayed, along with their online/offline status. 2 Use the Up and Down buttons to select a partition. 3 Press Modify. 4 Uses the Up and Down buttons to change the mode. 5 Press Apply.

22

Quantum Scalar i40 and Scalar i80 Maintenance Guide

Chapter 1: Common Service Procedures Taking a Tape Drive Online or Offline

Web Client

1 Select Operations > Partitions > Change Mode. In the partition table under Mode, the Current column indicates the current mode of the partition. The New column contains an Online/Offline button. The button toggles between modes. Note: If a partition is in use, the Online/Offline button is grayed out. 2 In the partition table, identify the partition that requires a mode change. 3 Click the Online/Offline button to toggle to the desired mode. 4 Click Apply. 5 Save the library configuration (see Saving the Library Configuration on page 33).

Taking a Tape Drive Online or Offline

There are two tape drive modes: online and offline. Online Tape drive is available for use. This is the normal operating mode for the tape drive. Offline Tape drive is offline to the host application and is not available for cartridge load and unload (move) operations initiated by the host application, but it remains available for Web client or operator panel initiated move commands. Note: If a cartridge is already in the tape drive when you take the tape drive offline, then the host can still read and write data on the tape. Some operations require that the tape drive be offline. You can take a tape drive offline rather than the entire library or partition so as to minimize disruption of library operations. A drive taken offline will remain offline until you bring it back online, or until the library is rebooted.

Quantum Scalar i40 and Scalar i80 Maintenance Guide 23