Professional Documents

Culture Documents

Hazop Study Template

Uploaded by

Lunga Dan PatsoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hazop Study Template

Uploaded by

Lunga Dan PatsoCopyright:

Available Formats

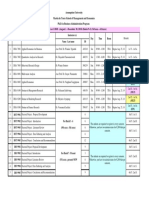

Hazard & Operability Assessment (HAZOP) Process Unit: Ammonia Separation and Storage P&ID No.

Section/Node: Study Date: Property Pressure Guide Word No More of Less of Part of Deviations No Pressure More Pressure Less pressure ? Process Parameters: Pressure Consequences Causes Suggested Controls

Process Parameters: Temperature Property Temperature Guide Word No More of Less of Part of Deviations Consequences Causes Suggested Controls

Process Parameters: Flow Property Flow Guide Word No More of Less of Part of Deviations No Flow Consequences Causes Suggested Controls

Process Parameters: Level Property Level Guide Word No More of Less of Part of Deviations Consequences Causes Suggested Controls

Process Parameters: Concentration Property Concentration Guide Word No More of Less of Part of Deviations Consequences Causes Suggested Controls

Team members:

Scope of work The HAZOP study will be carried out on area 5. The HAZOP study should consider the following: 1. Initial start-up 2. Normal operation 3. Maintenance shut down 4. Emergency shut down 5. Start up after shut downs

Evaluating causes and consequences (Chevron) Causes Brainstorm all possible causes related to human factors and equipment performance Dont analyse during brainstorming Stay within section during brainstorming (Special note: feed nodes from off-plots, it is acceptable to identify causes from the node) Dont criticize during brainstorming Discuss all realistic causes in detail

o Develop Consequences Without Safeguards o Check that all consequences take system out of design envelope, i.e. outside the intended range of operation o Must identify ALL consequences (immediate and delayed both inside and outside section of analysis, injury, fire, damage, environmental or economic impact), eg compressor failure will result in shutdown of plant will eventually result in total facility shutdown o Note how consequences develop, ie how deviation will trigger alarms/ trips, etc, to trigger operator intervention Considerations: o Operator is not available or is not paying attention o Control valve are in manual o Alarm and safety interlocks do not function o Procedures are not followed or are not understood

Part of only some of the design intention achieved

You might also like

- No-Flow Process Deviations GuideDocument5 pagesNo-Flow Process Deviations GuideAnonymous QqE5tcEa100% (5)

- Template Hazid ReportDocument17 pagesTemplate Hazid ReportJagan Bose75% (4)

- HAZOP ExerciseDocument8 pagesHAZOP Exercisekefeinzel0% (1)

- Chapter 7 HazopDocument11 pagesChapter 7 HazopMohd Azman Suwandi50% (2)

- HAZOP ExerciseDocument12 pagesHAZOP Exerciseshawalina07No ratings yet

- HAZOP ProcedureDocument10 pagesHAZOP Proceduresharjeel39100% (3)

- Hazard and Operability (HAZOP) Study: Dr. AADocument75 pagesHazard and Operability (HAZOP) Study: Dr. AAjoenediath9345No ratings yet

- Process Safety - Handbook - 2011 PDFDocument129 pagesProcess Safety - Handbook - 2011 PDFpnrao2p67% (3)

- Introduction to Hazardous Evaluation TechniquesDocument21 pagesIntroduction to Hazardous Evaluation TechniquesMalak HindiNo ratings yet

- HazopDocument4 pagesHazopbaaziz2015No ratings yet

- Hazard and Operability (HAZOP) & Hazard Analysis TrainingDocument106 pagesHazard and Operability (HAZOP) & Hazard Analysis TrainingShainu Govindankutty100% (8)

- Hazop StudyDocument7 pagesHazop StudyAnderson JoeNo ratings yet

- FMEA Process GuideDocument31 pagesFMEA Process Guideinder_sandhuNo ratings yet

- Design FMEA of Radiator Endplate LeaksDocument5 pagesDesign FMEA of Radiator Endplate LeaksLeonardoViannaNo ratings yet

- HazopDocument66 pagesHazopBlack WidowNo ratings yet

- HAZOP Study Methodology - 2 IEDOSH JB - StudentDocument116 pagesHAZOP Study Methodology - 2 IEDOSH JB - StudentAhmad Fauzie Ibrahim IsmailNo ratings yet

- Introduction To HAZOPDocument39 pagesIntroduction To HAZOPapi-19846338100% (1)

- Hazop MethodDocument75 pagesHazop Methodfairus100% (11)

- HAZOP TrainingDocument131 pagesHAZOP Trainingtamilnaduchennai100% (14)

- Appendix-1 (HAZOPWorksheets)Document37 pagesAppendix-1 (HAZOPWorksheets)zohaib_farooq100% (1)

- Sample HAZOP Study Worksheet (P&ID 100-002)Document5 pagesSample HAZOP Study Worksheet (P&ID 100-002)Mikee Felipe88% (8)

- Process Hazards Analysis MethodsDocument1 pageProcess Hazards Analysis MethodsRobert MontoyaNo ratings yet

- HazopDocument75 pagesHazopavanish.v100% (1)

- Hazop Hazard & Operability StudiesDocument19 pagesHazop Hazard & Operability StudiesAppajiNo ratings yet

- HAZOPDocument35 pagesHAZOPRiyadh Saleh100% (1)

- Hazop.1092475 Appendix 30.hazopDocument67 pagesHazop.1092475 Appendix 30.hazopAudrey Patrick Kalla50% (2)

- Basics of HAZOPDocument26 pagesBasics of HAZOPNg JoshuaNo ratings yet

- Hazop Procedures Kenny SampleDocument178 pagesHazop Procedures Kenny Sampleayuzme123100% (1)

- Safety LOPADocument28 pagesSafety LOPAnandorg1113100% (1)

- HAZOP Study (Part II)Document18 pagesHAZOP Study (Part II)Saad Ahmed100% (14)

- HAZOP GuidelinesDocument43 pagesHAZOP GuidelinesKhan Lala100% (3)

- Techniques of Hazard IdentificationDocument19 pagesTechniques of Hazard Identificationforzama100% (4)

- Hazop StudyDocument49 pagesHazop Studychempraveen4u100% (1)

- Process Hazard Analysis MethodsDocument61 pagesProcess Hazard Analysis Methodsjcv235100% (1)

- HAZOP Study (Part I)Document4 pagesHAZOP Study (Part I)Saad Ahmed100% (1)

- HAZOP Study Guide for Engineering SafetyDocument8 pagesHAZOP Study Guide for Engineering SafetyliamsiNo ratings yet

- Sensorselection and PlacementDocument4 pagesSensorselection and Placementnirbhay111No ratings yet

- HazopDocument75 pagesHazopSaima Saima89% (9)

- HAZOP STUDY PLANNING AND LOGISTICSDocument21 pagesHAZOP STUDY PLANNING AND LOGISTICSMohd HisammudinNo ratings yet

- 7 Important Step of Process Hazard Analysis - Process SafetyDocument8 pages7 Important Step of Process Hazard Analysis - Process SafetypritiNo ratings yet

- HAZOP Study Training CourseDocument55 pagesHAZOP Study Training CourseDobrescu Cristian100% (1)

- HAZOP Implementation and Evaluation ProceduresDocument29 pagesHAZOP Implementation and Evaluation Proceduresamidi5555913No ratings yet

- ProcessSafetyManagement AuditApproachDocument8 pagesProcessSafetyManagement AuditApproachismailayarNo ratings yet

- HAZID Worksheet FORM Rev 25 May 2012 Timas Premier Oil IndonesiaDocument15 pagesHAZID Worksheet FORM Rev 25 May 2012 Timas Premier Oil IndonesiaMatthew BennettNo ratings yet

- Hazop: Hazard & Operability StudiesDocument51 pagesHazop: Hazard & Operability StudiesFSBollNo ratings yet

- Hazard and Operability Study (Hazop) : Dr. M. Azam SaeedDocument39 pagesHazard and Operability Study (Hazop) : Dr. M. Azam SaeedMuhammad Bilal100% (1)

- Hazop Basic ConceptsDocument14 pagesHazop Basic ConceptsClaudio Sobarzo100% (1)

- HAZOPDocument18 pagesHAZOPMark GuevarraNo ratings yet

- 12 Steps Engineering Safe Oil Gas FacilitiesDocument22 pages12 Steps Engineering Safe Oil Gas FacilitiesrobigedNo ratings yet

- Hazop RequirementDocument43 pagesHazop RequirementTheVirus Papa100% (2)

- Lecture 8Document36 pagesLecture 8ashrfNo ratings yet

- Lecture-4 &5Document99 pagesLecture-4 &5Anusha DesaiNo ratings yet

- La Técnica Del HazOpDocument13 pagesLa Técnica Del HazOpEugenio DuranNo ratings yet

- 2 4 HazopDocument14 pages2 4 HazopIMPG077080No ratings yet

- Root Cause Failure Analysis Rev 2Document69 pagesRoot Cause Failure Analysis Rev 2clcoolleo100% (1)

- CHAPTER 8 Hazop StudyDocument7 pagesCHAPTER 8 Hazop StudyNethiyaa50% (2)

- Fault Tracing IntroductionDocument4 pagesFault Tracing IntroductionjgkuchhadiyaNo ratings yet

- SUPPLI 4 JDocument69 pagesSUPPLI 4 JkvasudevinK123No ratings yet

- ChE 534 - Module 3Document34 pagesChE 534 - Module 3Precious JamesNo ratings yet

- Function:: Yield Fatigue Material Instability Creep Wear Corrosion Cracked Deformed LeakingDocument16 pagesFunction:: Yield Fatigue Material Instability Creep Wear Corrosion Cracked Deformed LeakingAnita SinghNo ratings yet

- Biodigester PDFDocument3 pagesBiodigester PDFLunga Dan PatsoNo ratings yet

- Biodigester PDFDocument3 pagesBiodigester PDFLunga Dan PatsoNo ratings yet

- Biodigester PDFDocument3 pagesBiodigester PDFLunga Dan PatsoNo ratings yet

- Biodigester PDFDocument3 pagesBiodigester PDFLunga Dan PatsoNo ratings yet

- Biodigester PDFDocument3 pagesBiodigester PDFLunga Dan PatsoNo ratings yet

- Biodigester PDFDocument3 pagesBiodigester PDFLunga Dan PatsoNo ratings yet

- SmelterDocument28 pagesSmelterLunga Dan PatsoNo ratings yet

- Task 1: Process SummaryDocument3 pagesTask 1: Process SummarylungapatsoNo ratings yet

- Mineral ProcessingDocument28 pagesMineral ProcessinglungapatsoNo ratings yet

- Biodigester PDFDocument3 pagesBiodigester PDFLunga Dan PatsoNo ratings yet

- Biodigester PDFDocument3 pagesBiodigester PDFLunga Dan PatsoNo ratings yet

- Biodigester PDFDocument3 pagesBiodigester PDFLunga Dan PatsoNo ratings yet

- Biodigester PDFDocument3 pagesBiodigester PDFLunga Dan PatsoNo ratings yet

- Biodigester PDFDocument3 pagesBiodigester PDFLunga Dan PatsoNo ratings yet

- Leaching: Acid LeachingDocument2 pagesLeaching: Acid LeachingLunga Dan PatsoNo ratings yet

- Leaching: Acid LeachingDocument2 pagesLeaching: Acid LeachingLunga Dan PatsoNo ratings yet

- Leaching: Acid LeachingDocument2 pagesLeaching: Acid LeachingLunga Dan PatsoNo ratings yet

- Biodigester PDFDocument3 pagesBiodigester PDFLunga Dan PatsoNo ratings yet

- Final Sotho DialogueDocument1 pageFinal Sotho DialogueLunga Dan PatsoNo ratings yet

- Language LearningDocument2 pagesLanguage LearningLunga Dan PatsoNo ratings yet

- Naming of Basothp and Xhosa PeopleDocument3 pagesNaming of Basothp and Xhosa PeopleLunga Dan PatsoNo ratings yet

- Final DialogueDocument2 pagesFinal DialogueLunga Dan PatsoNo ratings yet

- ComminutionDocument14 pagesComminutionLunga Dan PatsoNo ratings yet

- Comminution 1Document13 pagesComminution 1Lunga Dan PatsoNo ratings yet

- ComminutionDocument14 pagesComminutionLunga Dan PatsoNo ratings yet

- FluidisationDocument6 pagesFluidisationLunga Dan PatsoNo ratings yet

- List of TablesDocument11 pagesList of TablesLunga Dan PatsoNo ratings yet

- ComminutionDocument14 pagesComminutionLunga Dan PatsoNo ratings yet

- In This Essay PDFDocument2 pagesIn This Essay PDFLunga Dan PatsoNo ratings yet

- PH.D BA - Class Schedule 1-2018Document1 pagePH.D BA - Class Schedule 1-2018Adnan KamalNo ratings yet

- 5 Days To Improve Your Pronunciation Day 1: BBC Learning EnglishDocument3 pages5 Days To Improve Your Pronunciation Day 1: BBC Learning EnglishKelly AliagaNo ratings yet

- KYC - FidelityDocument2 pagesKYC - FidelityMohammad Munazir AliNo ratings yet

- Enterprise System Engineering: Course Code: SWE - 304Document8 pagesEnterprise System Engineering: Course Code: SWE - 304syed hasnainNo ratings yet

- Synd - 7 Business Eco EMBA 59A Decision Time at The Aromatic Coffee CoDocument18 pagesSynd - 7 Business Eco EMBA 59A Decision Time at The Aromatic Coffee CoTiwi Movita FitrianaNo ratings yet

- Greek Labour LawDocument3 pagesGreek Labour LawSerban MihaelaNo ratings yet

- CSR TrainingDocument12 pagesCSR Trainingskdwivediindia0% (1)

- Kevin Kato Fischer Swot AnalysisDocument17 pagesKevin Kato Fischer Swot AnalysisKevin Kato Fischer100% (2)

- Women Entrepreneurs in IndiaDocument33 pagesWomen Entrepreneurs in Indiaritesh1991987No ratings yet

- Segmenting Global MarketsDocument12 pagesSegmenting Global MarketsJenny YadvNo ratings yet

- Group 6 - Mid-Term - PNJ PosterDocument1 pageGroup 6 - Mid-Term - PNJ PosterMai SươngNo ratings yet

- Chapter 10 Cost Planning For The ProductDocument44 pagesChapter 10 Cost Planning For The ProductMuhamad SyofrinaldiNo ratings yet

- BSC Hospital 1Document24 pagesBSC Hospital 1sesiliaNo ratings yet

- Summary of BRC Global Food Safety Standard Issue 6 Changes Landscape 110111Document28 pagesSummary of BRC Global Food Safety Standard Issue 6 Changes Landscape 110111Poulami DeNo ratings yet

- MKT 412 Lecture 12 - Crafting The Service EnvironmentDocument34 pagesMKT 412 Lecture 12 - Crafting The Service EnvironmentEhsan Karim100% (1)

- SM MCQDocument30 pagesSM MCQWoroud Quraan100% (3)

- Viner Cost Curves and Supply CurvesDocument25 pagesViner Cost Curves and Supply CurvesZenobio FarfNo ratings yet

- Promo Pricing Strategies Reduce Prices Attract CustomersDocument20 pagesPromo Pricing Strategies Reduce Prices Attract CustomersMarkDePazDiazNo ratings yet

- Allianz PNB Life Peso Dynasty Equity Fund detailsDocument2 pagesAllianz PNB Life Peso Dynasty Equity Fund detailsHihihiNo ratings yet

- Isaca Cisa CoursewareDocument223 pagesIsaca Cisa Coursewareer_bhargeshNo ratings yet

- 7 Logistics - WarehousingDocument20 pages7 Logistics - Warehousingashish.bms9100% (4)

- 80957667-Dissertation MSC DFSMDocument98 pages80957667-Dissertation MSC DFSMSanjay JamwalNo ratings yet

- Frequently Asked Questions Transition From UL 508C To UL 61800-5-1Document6 pagesFrequently Asked Questions Transition From UL 508C To UL 61800-5-1nomeacueroNo ratings yet

- Auditing bank reconciliation proceduresDocument2 pagesAuditing bank reconciliation procedureshsjhsNo ratings yet

- Final Internship ReportDocument58 pagesFinal Internship ReportKrishna SahuNo ratings yet

- Business Studies Glossary PDFDocument8 pagesBusiness Studies Glossary PDFAbdulaziz SaifuddinNo ratings yet

- Consumer Satisfaction of Aircel NetworkDocument5 pagesConsumer Satisfaction of Aircel NetworkSaurabh KumarNo ratings yet

- Operation and Product Management: LT Col Tauhidul IslamDocument23 pagesOperation and Product Management: LT Col Tauhidul IslamOptimistic EyeNo ratings yet

- Lambo v. NLRCDocument17 pagesLambo v. NLRCPatrisha AlmasaNo ratings yet

- Solutions To All Assigned Practice Problems (W502)Document27 pagesSolutions To All Assigned Practice Problems (W502)donjazonNo ratings yet