Professional Documents

Culture Documents

Pressure Parts Weld Schedule

Uploaded by

Kerem İnanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Parts Weld Schedule

Uploaded by

Kerem İnanCopyright:

Available Formats

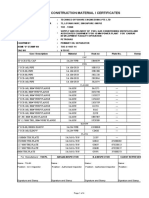

PRESSURE PARTS ERECTION WELD SCHEDULE BOILER NO: BJ-026

01 ERECTION WELD NO EW 01 02 DESCRIPTION COMBUSTOR MAIN DOWN COMERS (DRUM NOZZLE TO PIPE) COMBUSTOR MAIN DOWN COMERS (PIPE TO PIPE) W.C.CYCLONE & LOOP SEAL DOWN COMERS (DRUM NOZZLE TO PIPE ) DOWN COMER FOR R.W.W EVAPORATER SA 105+SA106 GR B (DRUM NOZZLE TO PIPE ) COMBUSTER BRANCH DOWN COMERS DOWNCOMER FOR WATER COOLED CYCLONE, RADIANT WING WALL EVAPORATOR &COMBUSTER BRANCH DOWNCOMERS (PIPE TO PIPE/ STUB/ ELBOW/ HEADER) DOWNCOMER FOR WATER COOLED CYCLONE,CYCLONE INLET DUCT,LOOP SEAL PARTITION PANEL(PIPE TO PIPE/STUB/EQUAL TEE/ELBOW & HEADER TO EXPANDER) 03 NO OF WELD / BOILER 4 04 PIPE / TUBES size (mm) 09 10 INTER PREHEAT PASS POST HEAT MATERIAL WELDING ELECTRODE O O O COMBINATION PROCESS C (MIN) C C (MAX) O O O SA105 + GTAW + ER70SA1 + 100 C 300 C 100 C for 1 SA106 GR B SMAW E7018-1 hour 05 06 07 08 11 PWHT OC 61010 OC 12 APPLICABLE WPS CVL/WPS/296 REV 01 13 NDE METHOD & EXTENT % 100%

406.4 X 27.7

EW 02

28

406.4 X 30.96 SA 106 GR-B +

SA 106 GR-B

GTAW + SMAW GTAW + SMAW

ER70SA1 + E7018-1 ER70SA1 + E7018-1

100

C 300

C 100

C for 1 hour

61010 OC NIL

CVL/WPS/296 REV 01 CVL/WPS/250 REV 00

100%

EW 03

219.1 X 16.55

SA 105 + SA 106 GR-B

15

C 300

C NIL

100%

EW 04

219.1 X 1 6.55

SA 105 + SA 106 GR-B

GTAW + SMAW

ER70SA1 + E7018-1

15

C 300

C NIL

NIL

CVL/WPS/250 REV 00

100%

EW 05

273.1 X 25.4 219.1 X 18.26

EW 06

48

SA106GR-B + SA106GR-B / SA234WPB SA 106 GR B + SA 106 GR B / SA 234 WPB

GTAW + SMAW GTAW + SMAW

ER70SA1 + E7018-1 ER70SA1 + E7018-1

100

C 300

C 100

C for 1 hour

61010 OC NIL

CVL/WPS/296 REV 01 CVL/WPS/250 REV 00

100%

15

C 300

C NIL

100%

EW 07

12

168.3 X 14.27 SA 106 GR B +

SA 106 GR B / SA 234 WPB

GTAW + SMAW

ER70SA1 + E7018-1

15

C 300

C NIL

NIL

CVL/WPS/250 REV 00

10%

Page 1 of 5

PRESSURE PARTS ERECTION WELD SCHEDULE BOILER NO: BJ-026

01 ERECTION WELD NO EW 08 02 DESCRIPTION DOWNCOMER FOR WATER COOLED CYCLONE,LOOP SEAL & LOOP SEAL PARTITION PANEL,CYCLONE I/L DUCT (PIPE TO PIPE/STUB/DRUM NOZZLE/ELBOW/HEADE R/TEE/REDUCER) DOWNCOMER FOR LOOP SEAL PARTITION PANEL (UNEQUALTEE TO REDUCER) COMBUSTOR PANEL TUBES AND OPENING FOR WING WALL BOTTOM GRID PANELS TUBES BED ASH COOLER TUBES BED ASH COOLERS BOTTOM CONNECTING HEADERS WATER COOLED CYCLONE INLET HEADER-1 (RETURN LUG) WATER COOLED CYCLONE LOOP SEAL TUBES & LOOP SEAL PARTITION PANEL TUBES RISER FOR CYCLONE INLET DUCT (PIPE TO PIPE, DRUM NOZZLE, STUB , ELBOW) 03 NO OF WELD / BOILER 52 04 PIPE / TUBES size (mm) 09 10 INTER PREHEAT PASS POST HEAT MATERIAL WELDING ELECTRODE O O O COMBINATION PROCESS C (MIN) C C (MAX) O O SA 106 GR-B + GTAW + ER70SA1 + 15 C 300 C NIL SA 106 GR-B / SMAW E7018-1 SA 234 WPB 05 06 07 08 11 PWHT OC NIL 12 APPLICABLE WPS CVL/WPS/250 REV 00 13 NDE METHOD & EXTENT % 10%

114.3 X 8.56

EW 09

168.3 X 14.27

SA 234 WPB + SA 234 WPB

GTAW + SMAW

ER70SA1 + E7018-1

15

C 300

C NIL

NIL

CVL/WPS/250 REV 00

10%

EW 10

1530

51 X 4.5 51 X 4.5 44.5 X 4.5 219.1 X 28.58 114.3 X 13.49

SA 210 GR A1 + SA 210 GR A1 SA 210 GR A1 + SA 210 GR A1 SA 210 GR A1 + SA 210 GR A1 SA 210 GR A1 + SA 106 GR B SA 210 GR A1 + SA 106 GR B

GTAW

ER70SA1

15

C 300

C NIL

NIL

CVL/WPS/183A REV 01 CVL/WPS/183A REV 01 CVL/WPS/183A REV 01 CVL/WPS/296 REV 01 CVL/WPS/250 REV 00

10%

EW 11

140

GTAW

ER70SA1

15

C 300

C NIL

NIL

10%

EW 12

300

GTAW

ER70SA1

15

C 300

C NIL

NIL

10%

EW 13

GTAW + SMAW GTAW + SMAW

ER70SA1 + E7018-1 ER70SA1 + E7018-1

100

C 300

C 100

C for 1 hour

61010 OC NIL

100%

EW 14

15

C 300

C NIL

10%

EW 15

80

44.5 X 4 44.5 X 4

SA 210 GR A1 + SA 210 GR A1 SA 210 GR A1 + SA 210 GR A1

GTAW

ER70SA1

15

C 300

C NIL

NIL

CVL/WPS/183A REV 01 CVL/WPS/183A REV 01

10%

EW 16

268

GTAW

ER70SA1

15

C 300

C NIL

NIL

10%

EW 17

16

114.3 X 8.56

SA 106 GR B + SA 106 GR B / SA 234 WPB

GTAW + SMAW

ER70SA1 + E7018-1

15

C 300

C NIL

NIL

CVL/WPS/250 REV 00

10%

Page 2 of 5

PRESSURE PARTS ERECTION WELD SCHEDULE BOILER NO: BJ-026

01 ERECTION WELD NO EW 18 02 DESCRIPTION BED ASH COOLER RISERS (PIPE TO PIPE, DRUM NOZZLE, STUB , ELBOW) BED ASH COOLER RISERS (PIPE TO STUB) RISER FOR COMBUSTOR LEFT, RIGHT & ROOF HEADERS, WC CYCLONES, MAIN BRANCH, RADIANT EVOPRATOR, (PIPE TO PIPE, DRUM NOZZLE, STUB, ELBOW) C.O.C POST HEADERS C.O.C CONNECTING LINK (PIPE TO STUB/ELBOW) C.OC BOTTOM,TOP & SIDE WALL TUBES S.C.W.BOTTOM HEADERS(HEADER TO BRANCH HEADER/EQUAL TEE) STEAM COOLED WALL TUBES PRIMARY SUPERHEATER COILS(PSH I/L HEADER STUBS TO BANK-I BOTTOM COILS PRIMARY SUPERHEATER COILS(BANK-I TO TOP COILS TO PSH O/L HEADER STUBS) 03 NO OF WELD / BOILER 22 04 PIPE / TUBES size (mm) 09 10 INTER PREHEAT PASS POST HEAT MATERIAL WELDING ELECTRODE O O O COMBINATION PROCESS C (MIN) C C (MAX) O O SA 106 GR B + GTAW + ER70SA1 + 15 C 300 C NIL SA 106 GR B / SMAW E7018-1 SA 234 WPB 05 06 07 SA 106 GR B + SA 106 GR B / SA 234 WPB SA 106 GR B + SA 106 GR B / SA 234 WPB GTAW ER70SA1 + E7018-1 ER70SA1 + E7018-1 15

O

08

11 PWHT OC NIL

12 APPLICABLE WPS CVL/WPS/250 REV 00

13 NDE METHOD & EXTENT % 10%

168.3 X 14.27

EW 19

60.3 X 5.54 168.3 X 14.27

C 300

C NIL

NIL

CVL/WPS/250 REV 00 CVL/WPS/250 REV 00

10%

EW 20

106

GTAW + SMAW

15

C 300

C NIL

NIL

10%

EW 21 EW 22

8 20

219.1 X 25.4 114.3 X 11.13 44.5 X 4.5 273 X 28.58

EW 23

528

SA 106 GR B + SA 106 GR B SA 106 GR B + SA 106 GR B / SA 234 WPB SA 21O GRA1 + SA 21O GRA1 SA 106 GR B + SA 106 GR B / SA 234 WPB SA 21O GRA1 + SA 21O GRA1 SA 21O GRA1 + SA 21O GRA1

GTAW + SMAW GTAW + SMAW GTAW

ER70SA1 + E7018-1 ER70SA1 + E7018-1 ER70SA1

100 15

C 300 C 300

C 100 C NIL

C for 1 hour

61010 OC NIL

CVL/WPS/296 REV 01 CVL/WPS/250 REV 00 CVL/WPS/183A REV 01 CVL/WPS/296 REV 01

100% 10%

15

C 300

C NIL

NIL

10%

EW 24

GTAW + SMAW

ER70SA1 + E7018-1

100

C 300

C 100

C for 1 hour

61010 OC

100%

EW 25

630

44.5 X 6 44.5 X 4.5

GTAW

ER70SA1 + E7018-1 ER70SA1

15

C 300

C NIL

NIL

CVL/WPS/250 REV 00 CVL/WPS/183A REV 01

10%

EW 26

188

GTAW

15

C 300

C NIL

NIL

10%

EW 27

358

44.5 X 4.5

SA 213 T11 + SA 213 T11

GTAW

ER80SB2

150

C 300

C NIL

NIL

CVL/WPS/184 REV 00

10%

Page 3 of 5

PRESSURE PARTS ERECTION WELD SCHEDULE BOILER NO: BJ-026

01 ERECTION WELD NO EW 28 02 DESCRIPTION FINAL SUPERHEATER COILS(I/L HEADER STUBS TO BANK-I COILS) FINAL SUPERHEATER COILS(BANK-I COILS TO FSH O/L HEADER STUBS) INTEGRAL ECONOMISER COILS HANGER TUBES 03 NO OF WELD / BOILER 147 04 PIPE / TUBES size (mm) 09 10 INTER PREHEAT PASS POST HEAT MATERIAL WELDING ELECTRODE O O O COMBINATION PROCESS C (MIN) C C (MAX) O O O SA 213 T22 + GTAW ER90SB3 220 C 350 C 80 C for SA 213 T91 TO 15 100 Minutes followe SA 213 T91 + GTAW ER90SB9 220 OC 300 OC d by SA 213 T91 wrap with mineral SA 21O GRA1 + GTAW ER70SA1 15 OC 300 OC NIL SA 21O GRA1 05 06 07 SA 21O GRA1 + SA 21O GRA1 SA 105 + SA 234 WPB GTAW + SMAW GTAW + SMAW ER70SA1 + E7018-1 ER70SA1 + E7018-1 15

O

08

11 PWHT OC 74515 OC

12 APPLICABLE WPS CVL/WPS/233 REV 00

13 NDE METHOD & EXTENT % 10%

44.5 X 4

EW 29

294

44.5 X 4

76010 OC

CVL/WPS/230A REV 00

10%

EW 30

520

38.1 X 3.66 44.5 X 6 219.1 X 16.55

NIL

CVL/WPS/183A REV 01 CVL/WPS/250 REV 00 CVL/WPS/250 REV 00

10%

EW 31

478

C 300

C NIL

NIL

10%

EW 32

EW 33

ECONOMISER TO DRUM INLET LINK(DRUM NOZZLE TO EXPANDER) ECONOMISER TO DRUM INLET LINK (PIPE TO PIPE/ELBOW) ECONOMISER TO DRUM INLET LINK(HEADER TO REDUCER) DRUM TO STEAM COOLED WALL INLET LINK(PIPE TO DRUM NOZZLE/STUB) DRUM TO STEAM COOLED WALL INLET LINK (PIPE TO PIPE) DRUM TO STEAM COOLED WALL INLET LINK (PIPE TO REDUCER/STUB/ELBO W)

15

C 300

C NIL

NIL

100%

10

168.3 X 14.27

SA 106 GR B + SA 234 WPB

GTAW + SMAW

ER70SA1 + E7018-1

15

C 300

C NIL

NIL

CVL/WPS/250 REV 00

10%

EW 34

273 X 21.44

SA106GR-B + SA234WPB

GTAW + SMAW

ER70SA1 + E7018-1

100

C 300

C 100

C for 1 hour

61010 OC

CVL/WPS/296 REV 01

100%

EW 35

16

114.32 X 8.56

SA 106 GR-B + SA 106 GR-B

GTAW + SMAW

ER70SA1 + E7018-1

15

C 300

C NIL

NIL

CVL/WPS/250 REV 00

10%

EW 36

12

219.1 X 18.26 168.3 X 14.27

SA 106 GR-B + SA 106 GR-B SA 106 GR-B + SA 106 GR-B / SA 234 WPB

GTAW + SMAW GTAW + SMAW

ER70SA1 + E7018-1 ER70SA1 + E7018-1

15

C 300

C NIL

NIL

CVL/WPS/250 REV 00 CVL/WPS/250 REV 00

100%

EW 37

10

15

C 300

C NIL

NIL

10%

Page 4 of 5

PRESSURE PARTS ERECTION WELD SCHEDULE BOILER NO: BJ-026

01 ERECTION WELD NO EW 38 02 DESCRIPTION P.S.H OUTLET TO RADIANT WING WALL SEC.SUPER HEATERS INLET LINK (HEADER TO REDUCER) P.S.H OUTLET TO RADIANT WING WALL SEC.SUPER HEATERS INLET LINK(PIPE TO PIPE/ELBOW/HEADER/ DE-SH REDUCER & EXPANDER) SEC.S.H O/L TO RADIANT WING FINAL SUPERHEATER INLET LINK(PIPE TO PIPE / HEADER / ELBOW / DESH -EXPANDER & REDUCER) SEC.S.H O/L TO RADIANT WING FINAL SUPERHEATER INLET LINK(HEADER TO REDUCER) RADIANT WING SEC SUPER HEATER INLET BRANCH HEADER RADIANT WING SEC SUPER HEATER O/L BRANCH HEADER ECO FEED WATER PIPING (PIPE TO PIPE, PIPE TO VALVE) 03 NO OF WELD / BOILER 1 04 PIPE / TUBES size (mm) 09 10 INTER PREHEAT PASS POST HEAT MATERIAL WELDING ELECTRODE O O O COMBINATION PROCESS C (MIN) C C (MAX) O O O SA 335 GR P11 GTAW + ER80SB2 + 150 C 300 C 150 C for 1 + SA 234 SMAW E8018-B2 TO hour WP11 CL1 200 05 06 07 08 11 PWHT OC 66510 OC 12 13

355.6 X 27.79

NDE APPLICABLE METHOD & WPS EXTENT % CVL/WPS/222A 100% REV 01

EW 39

11

323.8 X 25.4

SA 335 GR P11 + SA 234 WP11 CL1 / SA 234 WP11 CL1

GTAW + SMAW

ER80SB2 + E8018-B2

150

C 300

C 150 TO 200

C for 1 hour

66510 OC

CVL/WPS/222A REV 01

100%

EW 40

323.8 X 33.32

SA 335 GR P11 + SA 335 GR P11 / SA 234 WP11 CL1

GTAW + SMAW

ER80SB2 + E8018-B2

150

C 300

C 150 TO 200

C for 1 hour

66510 OC

CVL/WPS/222A REV 01

100%

EW 41

355.6 X 35.71

SA 335 GR P11 + SA 234 WP11 CL1

GTAW + SMAW

ER80SB2 + E8018-B2

150

C 300

C 150 TO 200

C for 1 hour

66510 OC

CVL/WPS/222A REV 01

100%

EW 42

219.1 X 25.4

SA 335 GR P11 + SA 335 GR 11 SA 335 GR P11 + SA 335 GR 11 SA106 GR-B + SA 216 WCB

GTAW + SMAW GTAW + SMAW GTAW + SMAW

ER80SB2 + E8018-B2 ER80SB2 + E8018-B2 ER70SA1 + E7018-1

150

C 300

C 150 TO 200

C for 1 hour C for 1 hour C for 1 hour

66510 OC

CVL/WPS/222A REV 01 CVL/WPS/222A REV 01 CVL/WPS/296 REV 01

100%

EW 43

219.1 X 32 273.1 X 25.4

150

EW 44

100

C 150 TO 200 O C 300 OC 100

C 300

66510 OC 61010 OC

100%

100%

Page 5 of 5

You might also like

- Rei Vol IDocument297 pagesRei Vol IDineshNo ratings yet

- Time and Cost Overrun in Construction PR PDFDocument43 pagesTime and Cost Overrun in Construction PR PDFCassio ManoelNo ratings yet

- Version 7: One Program For All TasksDocument3 pagesVersion 7: One Program For All Tasksأحمد صبحىNo ratings yet

- WelderPOT 2009finalDocument160 pagesWelderPOT 2009finalMayo de la PazNo ratings yet

- Selected Welding Application in Offshore IndustryDocument38 pagesSelected Welding Application in Offshore IndustryzuudeeNo ratings yet

- The NEW Company ProfileDocument26 pagesThe NEW Company ProfilewisandhaNo ratings yet

- GS P&D Archsd 2012Document127 pagesGS P&D Archsd 2012Andy Lee100% (1)

- Distortions WeldingDocument34 pagesDistortions Welding^passwordNo ratings yet

- PipingDocument54 pagesPipingakhilsyam21No ratings yet

- Joining and AssemblingDocument138 pagesJoining and AssemblingAmjad AliNo ratings yet

- Dai SeminarDocument36 pagesDai SeminardocrafiNo ratings yet

- Purging Brochure PDFDocument19 pagesPurging Brochure PDFjustinctlNo ratings yet

- Asme B16.36 Int PDFDocument3 pagesAsme B16.36 Int PDFRuben Dario Mamani ArellanoNo ratings yet

- Copia de EPCDocument32 pagesCopia de EPCPeter RodriguezNo ratings yet

- EIL IOCL Baroda ScopeDocument6 pagesEIL IOCL Baroda ScopeSairaj KaleNo ratings yet

- GTAW Chapter 1Document4 pagesGTAW Chapter 1Renold ElsenNo ratings yet

- Cladding PDFDocument6 pagesCladding PDFlibid_rajNo ratings yet

- PO # 025 N1091 Fire Fighting Materials - AL BILADDocument7 pagesPO # 025 N1091 Fire Fighting Materials - AL BILADAsad Maher100% (1)

- 16 0 en Wet Welding ExplainedDocument4 pages16 0 en Wet Welding ExplainedcuxuanchieuNo ratings yet

- PQRDocument2 pagesPQRRavi KumaranNo ratings yet

- Guideline For Welding P91Document44 pagesGuideline For Welding P91Howo4DieNo ratings yet

- Specific Size Agitator Selection Process & Specification PDFDocument310 pagesSpecific Size Agitator Selection Process & Specification PDFParth ThakarNo ratings yet

- List of Welding ProcessesDocument4 pagesList of Welding ProcessesspahicdaniloNo ratings yet

- EIL - Bolt SelectionDocument1 pageEIL - Bolt SelectionAndroidNo ratings yet

- Enll/ (-, 1.-I LL LLL ,: I L I (' J IDocument1 pageEnll/ (-, 1.-I LL LLL ,: I L I (' J ISalman KhanNo ratings yet

- 2017 03436 01 002 - Bom 320Document8 pages2017 03436 01 002 - Bom 320sundyaNo ratings yet

- Weld RepireDocument91 pagesWeld RepireKapil ManloiNo ratings yet

- GTAW and Power SourcesDocument18 pagesGTAW and Power SourcesRavi Kumar SinghNo ratings yet

- Consumable LasDocument35 pagesConsumable LasAfifYantoMutuHNo ratings yet

- Checklist - HRSG Ducting - Non Pressure Parts Drgs.Document3 pagesChecklist - HRSG Ducting - Non Pressure Parts Drgs.Ramalingam PrabhakaranNo ratings yet

- Place of Posting: NTPC VindhyachalDocument16 pagesPlace of Posting: NTPC Vindhyachalscentpcbarauni BARAUNINo ratings yet

- Rfi Request FormDocument1 pageRfi Request Formvishnu300022No ratings yet

- 1319 3 Guidelines For WeldingDocument64 pages1319 3 Guidelines For Weldingg_sanchetiNo ratings yet

- ASTM - Valve, Material Specifications PDFDocument8 pagesASTM - Valve, Material Specifications PDFmourinho2No ratings yet

- Short List of Applied Piping Standard PDFDocument3 pagesShort List of Applied Piping Standard PDFmohamad3010No ratings yet

- Company Profile COES Jun 2015Document21 pagesCompany Profile COES Jun 2015magnito77No ratings yet

- Fuel SystemDocument8 pagesFuel SystemManoj UpadhyayNo ratings yet

- Visual Inspection of Weld Joints Welding and NDTDocument7 pagesVisual Inspection of Weld Joints Welding and NDTALFA ENGINEERING100% (2)

- Crosby Style HL Low Pressure Steel Full Nozzle Safety Valves Installation, Maintenance and Adjustment InstructionsDocument17 pagesCrosby Style HL Low Pressure Steel Full Nozzle Safety Valves Installation, Maintenance and Adjustment InstructionsTarek MohamedNo ratings yet

- Dissimilar Metal Weldingv2 HERBST PDFDocument23 pagesDissimilar Metal Weldingv2 HERBST PDFAnonymous q2HC0zyfa2No ratings yet

- List of Construction Material / CertificatesDocument4 pagesList of Construction Material / CertificatesHanuman RaoNo ratings yet

- Leak Testing & Plugging Procedure For SYN. Loop Waste Heat BoilerDocument3 pagesLeak Testing & Plugging Procedure For SYN. Loop Waste Heat BoilerBESTINNo ratings yet

- Ei2303 Ii Ii 4&5Document23 pagesEi2303 Ii Ii 4&5Ramanathan SunderNo ratings yet

- Welding and Fabrication NoteDocument54 pagesWelding and Fabrication NoteluminiousNo ratings yet

- Comparison Table For Pipes and Fittings PDFDocument1 pageComparison Table For Pipes and Fittings PDFrcpretoriusNo ratings yet

- Boiler Inspection Tips 1Document146 pagesBoiler Inspection Tips 1SenakeNo ratings yet

- Plugging of Boiler Tubes - AQ9 PDFDocument6 pagesPlugging of Boiler Tubes - AQ9 PDFВиталий РунцивNo ratings yet

- Pipeline Welding InspectionDocument4 pagesPipeline Welding InspectionRizky TrianandaNo ratings yet

- D LevelDocument26 pagesD LevelhussnainreflectNo ratings yet

- Welding Facilities WDFDocument30 pagesWelding Facilities WDFpaaryNo ratings yet

- 5 Units Separator BOQ Pipe, Flange and Fitting 25-8-15Document24 pages5 Units Separator BOQ Pipe, Flange and Fitting 25-8-15Engr Khurram Jaan RamayNo ratings yet

- Boiler ManualDocument178 pagesBoiler ManualJay LawsonNo ratings yet

- Technofac: Welding Inspector CSWIP 3.1 Non Destructive Examination (NDE), ASNT Level-IIDocument9 pagesTechnofac: Welding Inspector CSWIP 3.1 Non Destructive Examination (NDE), ASNT Level-IIElankumaran PeriakaruppanNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- How To Order Alfa ValveDocument0 pagesHow To Order Alfa ValveZoebairNo ratings yet

- Ehp-3164439xxx AssyDocument3 pagesEhp-3164439xxx Assysantos_gurrolaNo ratings yet

- Wiring Diagram Schema Electrique: 30RA 100 B0921 PEE 0000269480Document13 pagesWiring Diagram Schema Electrique: 30RA 100 B0921 PEE 0000269480Dinu Muralidharan MNo ratings yet

- Singhania-CO2 INERTISATION SYSTEM DataDocument12 pagesSinghania-CO2 INERTISATION SYSTEM DataAnandharaj .KNo ratings yet

- 064126-S-LIS-100-A Valve List - Boiler Pressure PartsDocument6 pages064126-S-LIS-100-A Valve List - Boiler Pressure PartsYusuf Feri FeriansyahNo ratings yet

- Balance RT Joint For Vwha053Document6 pagesBalance RT Joint For Vwha053Manikandan elumalaiNo ratings yet

- Welding DefectsDocument8 pagesWelding DefectssbmmlaNo ratings yet

- Basic InstrumentDocument85 pagesBasic InstrumenthaseebmonNo ratings yet

- Basic Valve and Testing Method - 1Document37 pagesBasic Valve and Testing Method - 1Fouad OudinaNo ratings yet

- Types of Pressure TermsDocument10 pagesTypes of Pressure TermssbmmlaNo ratings yet

- PSV Calculation and PhilosophyDocument33 pagesPSV Calculation and PhilosophysbmmlaNo ratings yet

- RT Hand Written BookDocument22 pagesRT Hand Written BooksbmmlaNo ratings yet

- PT 3 Types of Cleaning, Equipment's and MaterialsDocument13 pagesPT 3 Types of Cleaning, Equipment's and MaterialssbmmlaNo ratings yet

- Sample Editable WPSDocument2 pagesSample Editable WPSsbmmlaNo ratings yet

- Site Inspection ChecklistDocument3 pagesSite Inspection ChecklistsbmmlaNo ratings yet

- Film Defects - AMERONDocument94 pagesFilm Defects - AMERONER RaviNo ratings yet

- Basic Exam Qustion SetDocument20 pagesBasic Exam Qustion SetsbmmlaNo ratings yet

- Set-Up Tack Welding Procedure For Drum Long & Cirseam Butt Welds Control No. Revision No.: 0 Date: Page: 1 of 1Document1 pageSet-Up Tack Welding Procedure For Drum Long & Cirseam Butt Welds Control No. Revision No.: 0 Date: Page: 1 of 1sbmmlaNo ratings yet

- Pamphlet On Safety Precautions For Steel Erection WorkDocument4 pagesPamphlet On Safety Precautions For Steel Erection WorksbmmlaNo ratings yet

- BGas MaterialDocument65 pagesBGas Materialslxanto100% (4)

- SOP NM ReportingDocument2 pagesSOP NM ReportingsbmmlaNo ratings yet

- Quality Control ManualDocument77 pagesQuality Control ManualsbmmlaNo ratings yet

- Static Equipment AwarenessDocument137 pagesStatic Equipment AwarenessZeshan100% (1)

- Standard Operating Procedure (Coils / Tubes) : Prepared By: Checked by Approved byDocument4 pagesStandard Operating Procedure (Coils / Tubes) : Prepared By: Checked by Approved bysbmmla100% (1)

- API 510-Kuwait Petroleum TrainingDocument160 pagesAPI 510-Kuwait Petroleum Trainingsbmmla100% (1)

- Piping Dimension Chart UsefulDocument1 pagePiping Dimension Chart UsefulrizkiNo ratings yet

- Sop Duplex MCDocument3 pagesSop Duplex MCsbmmlaNo ratings yet

- Swaged End - NormalisingDocument1 pageSwaged End - NormalisingsbmmlaNo ratings yet

- Tube To Tube Welding Procedure Control No.:Revision No.: 0 Date: Page: 1 of 1 1.0 ScopeDocument1 pageTube To Tube Welding Procedure Control No.:Revision No.: 0 Date: Page: 1 of 1 1.0 ScopesbmmlaNo ratings yet

- DNV Os-E403Document38 pagesDNV Os-E403ReadersmoNo ratings yet

- Sop Piping Tubes Standard Repair ProcedureDocument3 pagesSop Piping Tubes Standard Repair ProceduresbmmlaNo ratings yet

- Pre-Heating Procedure For Nozzle and Downcomer: Control No. Revision DateDocument1 pagePre-Heating Procedure For Nozzle and Downcomer: Control No. Revision DatesbmmlaNo ratings yet

- Nozzle To Drum Welding Procedure Control No.: Revision No.: 0 Date: Page: 1 of 1Document1 pageNozzle To Drum Welding Procedure Control No.: Revision No.: 0 Date: Page: 1 of 1sbmmlaNo ratings yet

- Standard Operating Procedure (Headers) : Prepared By: Checked by Approved byDocument5 pagesStandard Operating Procedure (Headers) : Prepared By: Checked by Approved bysbmmlaNo ratings yet

- Downcomer Nozzle To Drum Welding Procedure: 1.0 ScopeDocument1 pageDowncomer Nozzle To Drum Welding Procedure: 1.0 ScopesbmmlaNo ratings yet

- Standard Operating Procedure (Membrance Panels) : Prepared By: Checked by Approved byDocument5 pagesStandard Operating Procedure (Membrance Panels) : Prepared By: Checked by Approved bysbmmlaNo ratings yet

- Dimensions Weldolet® Size On Size STD MSS SP97Document2 pagesDimensions Weldolet® Size On Size STD MSS SP97Musslih Yulianto100% (1)

- 7.5. Cla-Val E-650-01Document4 pages7.5. Cla-Val E-650-01sigithvacNo ratings yet

- BMMM 2333-Tutorial 1 2020Document2 pagesBMMM 2333-Tutorial 1 2020I-zad MJNo ratings yet

- Parts Manual: HONGHUA Co., LTDDocument51 pagesParts Manual: HONGHUA Co., LTDfreddNo ratings yet

- TC Data Sheet E24NEDocument5 pagesTC Data Sheet E24NEMarlene SalazarNo ratings yet

- Flange Integrity Training: Principles For Ensuring Bolted Joint ReliabilityDocument4 pagesFlange Integrity Training: Principles For Ensuring Bolted Joint ReliabilityDipankar KhawasNo ratings yet

- Cast Steel Comparison ChartDocument1 pageCast Steel Comparison ChartFrancisco Andres Rivas SarabiaNo ratings yet

- Process Engineering Manual 005 IIDocument29 pagesProcess Engineering Manual 005 IIzoeNo ratings yet

- Choked Gas Flow - Milton BeychokDocument8 pagesChoked Gas Flow - Milton BeychokSteve WanNo ratings yet

- Fluid MechanicsDocument8 pagesFluid MechanicsFearless HeroNo ratings yet

- What Is An RTJ Flange - Ring Type Joint Flanges (PDF) - What Is PipingDocument12 pagesWhat Is An RTJ Flange - Ring Type Joint Flanges (PDF) - What Is Pipinghervé louisNo ratings yet

- Discharge Hose DH-20 - Rv04Document1 pageDischarge Hose DH-20 - Rv04Pablo Sanchez AmpueroNo ratings yet

- Eaton 1CE30 Eaton B6743Document4 pagesEaton 1CE30 Eaton B6743Ibrahim AbdElHamidNo ratings yet

- Osborne ReynoldDocument7 pagesOsborne Reynoldmirdza94No ratings yet

- 02 - Calosi Surge Exploration Tests and Second Quadrant Characteristic Dynamic Modeling On High Pressure Ratio CompDocument14 pages02 - Calosi Surge Exploration Tests and Second Quadrant Characteristic Dynamic Modeling On High Pressure Ratio CompseniabenicarloNo ratings yet

- CROSS To Mann 2016Document94 pagesCROSS To Mann 2016Sebastian Ganci0% (1)

- IV.1.38.01 Storage ContainersDocument3 pagesIV.1.38.01 Storage ContainersNestor RodriguezNo ratings yet

- Framo Operational ManualDocument20 pagesFramo Operational ManualViijaay Nehra100% (1)

- 905 Brochure PDFDocument4 pages905 Brochure PDFsergioNo ratings yet

- Fire Pumps SopDocument7 pagesFire Pumps SopPankaj PandeyNo ratings yet

- 1450RPM PDFDocument111 pages1450RPM PDFFulton Xavier ZambranoNo ratings yet

- A9 HBR-01-GSX-MEC-DTS-0002 Rev B2Document9 pagesA9 HBR-01-GSX-MEC-DTS-0002 Rev B2ahmed.njahNo ratings yet

- Condition Monitoring For Centrifugal CompressorsDocument49 pagesCondition Monitoring For Centrifugal CompressorsHmidaNo ratings yet

- PerarEC-EB 0 PDFDocument21 pagesPerarEC-EB 0 PDFadrianioantomaNo ratings yet

- Zupcaste Pumpe 2pfDocument13 pagesZupcaste Pumpe 2pfmilokisrNo ratings yet

- 3406e and 3456 EngineDocument20 pages3406e and 3456 EnginebejoythomasNo ratings yet

- Instrumentation FOR P&ID'sDocument51 pagesInstrumentation FOR P&ID'sEvando Pereira dos SantosNo ratings yet

- 004 Mud Pump PerformanceDocument33 pages004 Mud Pump PerformanceJuan GómezNo ratings yet

- Fina Ponya-Model PDFDocument1 pageFina Ponya-Model PDFNursyarafina Binti SulaimanNo ratings yet

- Ductile Iron FittingsDocument72 pagesDuctile Iron FittingsAhmed TalaatNo ratings yet