Professional Documents

Culture Documents

Wastegate Check

Uploaded by

raquettelaker2Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wastegate Check

Uploaded by

raquettelaker2Copyright:

Available Formats

2. Engine\Turbocharger system Adjustment/Replacement - Chec...

Checking the wastegate valve, 4-cyl.

Warning

Take care if the car is warm. The coolant is hot and

there is also a risk of burning yourself on the exhaust

manifold.

If it is not possible to adjust the basic charging pressure, check the wastegate valve as

follows:

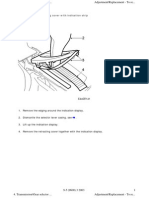

1. Undo the hose clip on the turbocharger pressure pipe and bend the bypass pipe

aside.

2. Remove the exhaust manifold heat shield. The heat shield is attached with a nut and

two clips on the underside.

3. Undo the nuts securing the front exhaust system to the turbo unit.

Important

9-5 (9600) 1 2001 1

2. Engine\Turbocharger system Adjustment/Replacement - Chec...

The flexible section at the front of the exhaust

system should not be bent out of line by more

than 7°, i.e. if the front exhaust system is

allowed to hang, it must not bend more than the

sag caused by its own weight.

If the pipe is overloaded, permanent deformation

of the components will result. This can cause

noise and leakage, and damage at a later stage.

Note

Apply motor oil or the like to the nuts and

carefully undo them.

4. Remove the clip and unhook the pushrod from the control arm on the valve.

5. Observe whether the flap valve abuts firmly against the turbine housing. Check for

carbon deposits, etc.

6. Check that the arm moves easily.

7.

Hook on the pushrod and fit the lock clip.

9-5 (9600) 1 2001 2

2. Engine\Turbocharger system Adjustment/Replacement - Chec...

8. Attach the front exhaust system to the turbo. Grease the studs with Molycote 1000,

part No. 30 20 971.

9-5 (9600) 1 2001 3

2. Engine\Turbocharger system Adjustment/Replacement - Chec...

Tightening torque: 24 Nm (18 lbf ft)

Important

When fitting the front exhaust system to the

turbo, the nuts should be tightened alternately to

avoid distorting the flange. The flange must not

abut against the turbo connection flange.

9. Fit the heat shield. Press on the left-hand holder first. Apply Molycote 1000, part no.

30 20 971, to the stud.

Tightening torques:

Locknut 20 Nm (15 lbf ft)

10. Mount the bypass valve with pipe. Fit a new O-ring, greased with non-acidic

vaseline.

Tightening torque: 8 Nm (6 lbf ft)

9-5 (9600) 1 2001 4

You might also like

- Important: Turbocharger, V6 To RemoveDocument13 pagesImportant: Turbocharger, V6 To Removeraquettelaker2No ratings yet

- Fault Diag ProcedureDocument6 pagesFault Diag Procedureraquettelaker2No ratings yet

- Manual de Motor Elantra-Tiburón 1998 G4GRDocument6 pagesManual de Motor Elantra-Tiburón 1998 G4GRRodolfo SilvaNo ratings yet

- Radiator Fan, V6: WarningDocument7 pagesRadiator Fan, V6: Warningraquettelaker2No ratings yet

- Engine CoolingDocument50 pagesEngine CoolingBenz Aio Calachua AraujoNo ratings yet

- Unit Description SpecificationDocument20 pagesUnit Description SpecificationLuis AlfonsoNo ratings yet

- Manual Taller ARN 125 CC (Idioma Ingles)Document85 pagesManual Taller ARN 125 CC (Idioma Ingles)Cordobessa50% (2)

- Installation Guide: Dellorto Induction Kit for 1984-85 Mazda RX-7Document7 pagesInstallation Guide: Dellorto Induction Kit for 1984-85 Mazda RX-7Brent Z. BaileyNo ratings yet

- UntitledDocument1,003 pagesUntitledsharon100% (1)

- A3 2009 2.0L Cbfa CctaDocument300 pagesA3 2009 2.0L Cbfa CctaJ VallejoNo ratings yet

- Saab 9-3ss Fuel Tank R& RDocument14 pagesSaab 9-3ss Fuel Tank R& Rraquettelaker2100% (1)

- R90/E LPG Reducer Maintenance GuideDocument15 pagesR90/E LPG Reducer Maintenance GuideBen MuisNo ratings yet

- Engine Fuel System Troubleshooting GuideDocument19 pagesEngine Fuel System Troubleshooting GuidePablo Rojas Valenzuela100% (1)

- Carb Turbo Kit InstructionsDocument11 pagesCarb Turbo Kit InstructionsKevin ShankleNo ratings yet

- Ford Edge 2008-2009 PDFDocument462 pagesFord Edge 2008-2009 PDFEnedine RamirezNo ratings yet

- AVEO 2007-2010/wave - 07-10/engine Mechanical - 1.5L/Repair Instructions - Off VehicleDocument39 pagesAVEO 2007-2010/wave - 07-10/engine Mechanical - 1.5L/Repair Instructions - Off VehicleArley Hernandez100% (1)

- Omvl Reparaturanleitung R90e Verdampfer EngDocument15 pagesOmvl Reparaturanleitung R90e Verdampfer EngbojanNo ratings yet

- Model 45HB-70HB: Instruction ManualDocument12 pagesModel 45HB-70HB: Instruction ManualcarlosNo ratings yet

- OMVL R90 Use and Maintenance Manual - CompressedDocument15 pagesOMVL R90 Use and Maintenance Manual - CompressedAJNo ratings yet

- Banda 2.3 TurboDocument5 pagesBanda 2.3 TurbosergioNo ratings yet

- EFI Installation Manual Rotax 4-1 Rev5Document26 pagesEFI Installation Manual Rotax 4-1 Rev5Esteban POPO ECHEVERRYNo ratings yet

- Bottom Feed Port Fuel InjectorsDocument6 pagesBottom Feed Port Fuel InjectorsdarherreraNo ratings yet

- Exhaust System - Catalytic Converter-1.6L Duratorq-TDCi (74kW-100PS 81kW-110PS) - DV 110 PSDocument12 pagesExhaust System - Catalytic Converter-1.6L Duratorq-TDCi (74kW-100PS 81kW-110PS) - DV 110 PSaalin14No ratings yet

- Sum-Carb InstrDocument14 pagesSum-Carb InstrbobNo ratings yet

- 00M12 PDFDocument6 pages00M12 PDFurania22000No ratings yet

- 199R7948 5rev5 PDFDocument16 pages199R7948 5rev5 PDFbatman2054No ratings yet

- Induction Module Assembly 9.5: GeneralDocument10 pagesInduction Module Assembly 9.5: Generalvette512No ratings yet

- Dodge Ram A/C Compressor ClutchDocument7 pagesDodge Ram A/C Compressor ClutchKkbhuvan KkNo ratings yet

- Holley Carb AdjustmentsDocument8 pagesHolley Carb AdjustmentsAaron SteeleNo ratings yet

- Oilpump4afe PDFDocument7 pagesOilpump4afe PDFhanzhio elNo ratings yet

- Bomba de Alta Precion de CombustibleDocument10 pagesBomba de Alta Precion de Combustiblehamilton mirandaNo ratings yet

- Changing Thermostat in 2002 9-5 V6Document8 pagesChanging Thermostat in 2002 9-5 V6snappydressedotter100% (2)

- Motor Installation and Maintenance ManualDocument23 pagesMotor Installation and Maintenance ManualVenkat CherukuriNo ratings yet

- John Deere Z425 EZtrak Residential Mower (SN.100001 and Up) Service Repair Technical Manual (TM113019)Document15 pagesJohn Deere Z425 EZtrak Residential Mower (SN.100001 and Up) Service Repair Technical Manual (TM113019)zhuangfuqian31No ratings yet

- Cylinder Head InstallDocument2 pagesCylinder Head InstallMiguel Moreno FernándezNo ratings yet

- Repair Guides - Carbureted Fuel System - Rochester 2se - E2se CarburetorDocument5 pagesRepair Guides - Carbureted Fuel System - Rochester 2se - E2se CarburetoreducsalNo ratings yet

- Manual Taller Superlight 125 CCDocument83 pagesManual Taller Superlight 125 CCDoc Moto100% (1)

- Portable Cargo Pump TK80 Simillar To Marflex Portable PPDocument18 pagesPortable Cargo Pump TK80 Simillar To Marflex Portable PPSubramoniam MarineNo ratings yet

- Motovario MaintenanceDocument72 pagesMotovario Maintenancearachman297988No ratings yet

- Camry Solara SEV6Document13 pagesCamry Solara SEV6arturmikieNo ratings yet

- Audi A3-2006-2.0LDocument250 pagesAudi A3-2006-2.0LluisNo ratings yet

- b20z1 OverhaulDocument40 pagesb20z1 Overhaulvladimir hernandezNo ratings yet

- Orbitrol Desarmado y ArmadoDocument9 pagesOrbitrol Desarmado y Armadojulio cesarNo ratings yet

- Jet Kit InstallDocument2 pagesJet Kit InstallmihaisimoNo ratings yet

- Installing camshaft and unit injectorsDocument4 pagesInstalling camshaft and unit injectorsDomonique BermanNo ratings yet

- Fuel Tank Removal and InstallationDocument3 pagesFuel Tank Removal and Installationhockeyman111No ratings yet

- QuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de ServicioDocument5 pagesQuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de Serviciohamilton mirandaNo ratings yet

- Remove Install Overhaul Turbo PDFDocument3 pagesRemove Install Overhaul Turbo PDFOskars ŠtālsNo ratings yet

- John Deere Fuel Injection Pump Repair & Installation PDFDocument8 pagesJohn Deere Fuel Injection Pump Repair & Installation PDFscheisshandy33% (3)

- Subaru - Impreza - Workshop Manual - 1999 - 2002Document8,373 pagesSubaru - Impreza - Workshop Manual - 1999 - 2002bart3omiej3boguszewiNo ratings yet

- 8011 Ford Intake Manifold InstallationDocument2 pages8011 Ford Intake Manifold InstallationFabio Luis ArgentaNo ratings yet

- Camry Solara SLEV6Document13 pagesCamry Solara SLEV6arturmikieNo ratings yet

- Weber ManualDocument28 pagesWeber ManualMedardo SilvaNo ratings yet

- Oil Pump: Removal ProcedureDocument40 pagesOil Pump: Removal Proceduremiguelx69No ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Ford Manual for Owners and Operators of Ford Cars and Trucks (1919)From EverandFord Manual for Owners and Operators of Ford Cars and Trucks (1919)No ratings yet

- Windscreen Wiper Assembly To RemoveDocument4 pagesWindscreen Wiper Assembly To Removeraquettelaker2No ratings yet

- Saab 9-3ss Fuel Tank R& RDocument14 pagesSaab 9-3ss Fuel Tank R& Rraquettelaker2100% (1)

- GSCI Climate Change PagesDocument7 pagesGSCI Climate Change Pagesraquettelaker2No ratings yet

- 2010 Saab 9-5 Informational BrochureDocument15 pages2010 Saab 9-5 Informational Brochureraquettelaker2No ratings yet

- Saab MaintenanceDocument1 pageSaab Maintenanceraquettelaker2No ratings yet

- Before Replacing TurboDocument4 pagesBefore Replacing Turboraquettelaker2No ratings yet

- C Program Files Wis Work Doc19310Document4 pagesC Program Files Wis Work Doc19310raquettelaker2100% (1)

- JalouiseDocument2 pagesJalouiseraquettelaker2No ratings yet

- Selector Lever Casing To RemoveDocument4 pagesSelector Lever Casing To Removeraquettelaker2No ratings yet

- Wastegate AdjustmentDocument5 pagesWastegate Adjustmentraquettelaker2No ratings yet

- Saab Front Fender Replacement.Document10 pagesSaab Front Fender Replacement.raquettelaker2No ratings yet

- Saab 9-5 Sedan Rear BumperDocument6 pagesSaab 9-5 Sedan Rear Bumperraquettelaker2No ratings yet

- Saab 9-5 Wagon Subwoofer REmovalDocument8 pagesSaab 9-5 Wagon Subwoofer REmovalraquettelaker2100% (3)

- GPZ Turbo Training Manual - Part1Document13 pagesGPZ Turbo Training Manual - Part1dasdaserdNo ratings yet

- 5134645-Spare Parts Catalog-51994950001-2Document163 pages5134645-Spare Parts Catalog-51994950001-2BobNo ratings yet

- Unknown 6Document380 pagesUnknown 6Tina TinaNo ratings yet

- I C Engine Lab ManualDocument46 pagesI C Engine Lab Manualمحمد رأفتNo ratings yet

- Cat.# 90-8M0079939 Parts Manual Oil SumpDocument103 pagesCat.# 90-8M0079939 Parts Manual Oil Sumpமுத்து தேவேந்திரன்No ratings yet

- Brake System Overhaul Lab: PossibleDocument4 pagesBrake System Overhaul Lab: PossibleMujeres Virglius PabliusNo ratings yet

- MC 10121462 9999Document367 pagesMC 10121462 9999DirkNo ratings yet

- June New 19Document67 pagesJune New 19vinaysoni1987No ratings yet

- 2006 LEXUS GX470 Fuse SchematicDocument6 pages2006 LEXUS GX470 Fuse Schematicstummel6636No ratings yet

- Page 47-54 Immobiliser and DiagnosisDocument13 pagesPage 47-54 Immobiliser and DiagnosisDaniel Mamani Paredez100% (1)

- Diesel Engine v1Document7 pagesDiesel Engine v1Cendolz IssZulNo ratings yet

- C9 Disassembly AssemblyDocument126 pagesC9 Disassembly AssemblyRami Dal100% (15)

- CUMMINS 4B3.9-G2 ENGINE DATASHEETDocument5 pagesCUMMINS 4B3.9-G2 ENGINE DATASHEETHerbert IrahetaNo ratings yet

- Banda 2.3 TurboDocument5 pagesBanda 2.3 TurbosergioNo ratings yet

- DPD Feature and OperationDocument34 pagesDPD Feature and Operationsneddonrobin2No ratings yet

- 164 TWSM0814R 4M5 enDocument71 pages164 TWSM0814R 4M5 enClaudio Rene Silva HernandezNo ratings yet

- Fast Moving ItemsDocument224 pagesFast Moving ItemsMr. BatesNo ratings yet

- Thermodynamics Fundamentals for Powerplant SystemsDocument32 pagesThermodynamics Fundamentals for Powerplant SystemsJason M AdvinculaNo ratings yet

- 854 Fe 34 TaDocument27 pages854 Fe 34 TapepppeNo ratings yet

- BBPP MPV BMTI/Automotive Reskilling & Upskilling 2020Document10 pagesBBPP MPV BMTI/Automotive Reskilling & Upskilling 2020KaiZen PuTra MiddleNo ratings yet

- GM Car CatalogDocument3 pagesGM Car CatalogTayfun SezişNo ratings yet

- In-line six cylinder diesel engine specificationsDocument15 pagesIn-line six cylinder diesel engine specificationsRicardo MarmoNo ratings yet

- Chevrolet Vehicle Coverage PDFDocument5 pagesChevrolet Vehicle Coverage PDFAim Mobil JayaNo ratings yet

- Irjet V7i3447 PDFDocument9 pagesIrjet V7i3447 PDFURVASHI PATILNo ratings yet

- 6bta g1Document6 pages6bta g1Yè WințNo ratings yet

- 507 - ssp603 - A6 AvantDocument60 pages507 - ssp603 - A6 Avantsezio81100% (2)

- NodizDocument23 pagesNodiztudor_patrutoiuNo ratings yet

- Maintenance plan excavator tracksDocument2 pagesMaintenance plan excavator tracksEmcosermax SacNo ratings yet

- Saito Gas Engines-ManualDocument36 pagesSaito Gas Engines-ManualPERSONAL arlojiNo ratings yet

- cpc4 Tier4 Eu6 Manual sw34 v1 0Document338 pagescpc4 Tier4 Eu6 Manual sw34 v1 0vlad100% (2)