Professional Documents

Culture Documents

dESIGN OF MC ELEMENTS PDF

Uploaded by

logeshboy007Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

dESIGN OF MC ELEMENTS PDF

Uploaded by

logeshboy007Copyright:

Available Formats

ANNA UNIVERSITY Chennai-25. Syllabus for B.E.

(Full Time) Mechanical Engineering

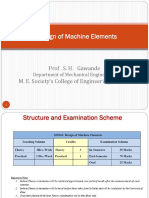

ME331 Design of Machine Elements 1. FUNDAMENTALS OF DESIGN 3 0 0 100 8

Design Process - Computer aided design - Optimum design - Mechanical properties of materials - Types of loads - Stresses - Static , varying, thermal, impact and residual - Factors of safety - Theories of failure - Stress concentration factors - Introduction to fracture mechanics. MECHANICAL SYSTEMS AND MANUFACTURING CONSIDERATIONS IN DESIGN Determination of power capacity - Torque levels - Efficiency of various transmission elements - Preferred numbers - Fits and tolerances - Surface finish - Standards. 3. DESIGN OF FASTENERS AND JOINTS: 2. 7

11

Screwed fasteners - Design of Pin joints - Design of welded joints. Riveted joints (Elementary treatment only - Not for examination purposes) 4. DESIGN OF BASIC MACHINE ELEMENTS 11 Design of shafts - keys - splines coupling - journal bearings - crank shafts - connecting rods - pistons - flywheels - selection of antifriction bearings. 5. DESIGN OF SPRINGS 8

Design of Helical springs - Compression and tension - Concentric torsion springs - Belleville springs - Leaf springs. Note : Approved Design Data Book is permitted in the examination. Total No of periods: 45

Page 1

ME331 Design of Machine Elements Text Books:

100

1. S.G.Kulkarni, " Machine Design - Solved Problems ", Tata McGraw-Hill Publishing Company Ltd., 1998. 2. William Orthein, " Machine Component Design (Vol. I & II) ", M/s. Jaico Publishing 1998 - 99. References: 1. Joseph Edward Shigley and Charles R.Mischke, " Mechanical Engineering Design ", McGraw-Hill International Edition, 1989. 2. Gitin M.Maitra and LN Prasad, " Hand Book of Mechanical Design ", Tata McGraw Hill, 1985. 3. V.B.Bhandari, " Design of Machine Elements ", Tata McGraw Hill Publishing Company Ltd., 1998.

Page 2

ME332 Measurements and Controls 1. MEASUREMENTS

100 6

General Concepts - Units and Standards - Measuring instruments - Sensitivity, readability, range of accuracy, precision - Static and dynamic response - Repeatability hystersis - Systematic and random errors - Correction calibration. 2. INSTRUMENTS 12 Transducer, modifying (intermediate) and terminal stages - Mechanical and Electrical transducers Preamplifiers-Charge amplifiers-Filters-Attenuators-D'arsonval-CRO-Oscillographs-Recorders-Microprocessor based data logging, processing and output. 3. PARAMETERS FOR MEASUREMENT 18 Dimensions, displacement, velocity, acceleration, impact - Force, torque, power-Strain - Pressure - Humidity Temperature - Flow-Time, frequency and phase angle - Noise and sound level; Radio tracer techniques-Flow visualization-Shadow graph, interferometer, schlieren, laser - Doppler - Anemometer. 4. AUTOMATIC CONTROL SYSTEMS 6 Basic elements - Feedback principle, implication of measurements - Error detectors - Final actuating Elements Two Position, multiposition, floating proportional controls - Relays - Servo amplifiers - Servo motors Mechanical, Electrical, magnetic, electronic, hydraulic, pneumatic systems. 5. APPLICATION OF CONTROL SYSTEMS 3 Governing of speed - Kinetic and Process Control - Pressure, temperature, fluid level, flow - Thrust and flight control - Photoelectric controls. Total No of periods: 45

Page 3

ME332 Measurements and Controls Text Book:

100

1. T.G.Beckwith and N. Lewis Buck, " Mechanical Measurements ", Addison Wesley, 1991. References: 1. J.P.Holman, " Experimental Methods for Engineers ", McGraw Hill Book Company, 1971. 2. L.F.Adams, " Measurement and Instrumentation ", The English Language Book Society, 1975. 3. R.S.Sirhi and H.C.Radhakrishna, " Mechanical Measurements ", Wiley Eastern Limited, 1983. 4. Pearson, Bric B, " Technology of Instrumentation ", English University Press Ltd., 1957. 5. Donald P. Eckman, " Industrial Instrumentation ", Wiley Eastern, 1985.

Page 4

ME333 Gas Dynamics and Space Propulsion 1. BASIC CONCEPTS AND ISENTROPIC FLOWS

100 9

Energy and momentum equations of compressible fluid flows - Stagnation states, Mach waves and Mach cone Effect of Mach number on compressibility - Isentropic flow through variable area ducts - Nozzle and Diffusers Use of Gas tables. 2. FLOW THROUGH DUCTS 10 Flow through constant area ducts with heat transfer (Rayleigh flow) and Friction (Fanno flow) - Variation of flow properties - Use of tables and charts - Generalised gas dynamics. 3. NORMAL AND OBLIQUE SHOCKS 10

Governing equations - Variation of flow parameters across the normal and oblique shocks - Prandtl - Meyer relations - Use of table and charts - Applications. 4. JET PROPULSION 10

Theory of jet propulsion - Thrust equation - Thrust power and propulsive efficiency - Operation principle, cycle analysis and use of stagnation state performance of ram jet, turbojet, turbofan and turbo prop engines - Aircraft combustors. 5. SPACE PROPULSION 6 Types of rocket engines - Propellants - Ignition and combustion - Theory of rocket propulsion - Performance study - Staging - Terminal and characteristic velocity - Applications - Space flights. Total No of periods: 45

Page 5

ME333 Gas Dynamics and Space Propulsion Text Book:

100

1. S.M. Yahya, " Fundamentals of Compressible Flow ", New Age International (P) Limited, New Delhi, 1996. References: 1. P.Hill and C. Peterson, " Mechanics and Thermodynamics of Propulsion ", Addison Wesley Publishing Company, 1992. 2. N.J. Zucrow, " Aircraft and Missile Propulsion, Vol. I & II ", John Wiley , 1975. 3. N.J. Zucrow, " Principles of Jet Propulsion and Gas Turbines ", John Wiley, New York, 1970. 4. H.Cohen, G.E.C.Rogers and Saravanamuttoo, " Gas Turbine Theory ", Longman Group Ltd., 1980. 5. G.P.Sutton, " Rocket Propulsion Elements ", John Wiley, 1986, New York. 6. A.H.Shapiro, " Dynamics and Thermodynamics of Compressible Fluid Flow Vol.kl ", John Wiley , 1953, New York. 7. V.Ganesan, " Gas Turbines ", Tata McGraw Hill Publishing Co., New Delhi, 1999.

Page 6

ME334 Machine Tools 1. TURNING MACHINES

100 8

Lathe: Specification - Types - Mechanisms - Operations - Calculations - Capstan and turret lathe - Tooling with examples - Copy turning lathe. 2. OTHER BASIC MACHINES 14

Shaper: Specification - Types - Mechanism - Calculations Planer: Specification - Types - Mechanism - Calculations. Drilling: Specification - Types - Feed Mechanism - Operations - Drill tool nomenclature - Mounting - Reamer and tap tools - Calculations. Broaching: Specification - Types - Tool nomenclature - Broaching process. Boring: Specification - Types - Operations - Boring tool - Jig Boring machine. Grinding: Types of grinding machine - Designation and selection of grinding wheel - Bonds - Reconditioning of grinding wheel - Grinding of various machine elements - Lapping honing and super finishing. 3. GEAR CUTTING MACHINES 12 Milling: Specification - Types - Cutter nomenclature - Types of cutter - Milling processes - Indexing - Cam and thread milling. Kinematics of gear shaping and gear hobbing - Gear generation principles specifications - Cutters - Bevel gear generator - Gear finishing methods. 4. AUTOMATS 5 Classification - Cam controlled automats, single spindle and multi spindle automats - Swiss type, automatic screw mechanism - Feeding mechanism - Transfer mechanism, Tracer controller mechanism. 5. THEORY OF METAL CUTTING 6

Mechanism of metal cutting - Cutting forces - Chip formation - Merchant's circle diagram - Calculations - Tool geometry - Machineability - Tool wear - Tool life - Cutting tool materials - Cutting fluids. Total No of periods: 45

Page 7

ME334 Machine Tools Text Books:

100

1. S.K. Hajra Choudry, S.K.Bose, " Workshop Technology Vol II ". 2. P.C.Sharma, " A Text Books of Production Engineering ", S.Chand and Co. Ltd., IV Edition, 1993. References: 1. De Garmo et al., " Materials and Processes in Manufacturing ", Prentice Hall of India, Eight Edition, 1998. 2. Richara R. Kibbe, John E.Neely, Roland O. Meyer and Warrent T. White, " Machine Tool Practices ", VI Edition, Prentice Hall of India, 1999. 3. N.K.Mehia, " Machine Tool Design and NC ", Tata McGraw Hill Publishing Co. Ltd., 1999.

Page 8

ME335 Computer Aided Design 1. THE DESIGN PROCESS

100 4

The design process Morphology of design - Product cycle - Sequential and concurrent engineering - Role of computers - Computer Aided Engineering - Computer Aided Design - Design for Manufacturability - Computer Aided Manufacturing - Benefits of CAD. 2. INTERACTIVE COMPUTER GRAPHICS 10 Creation of Graphic Primitives - Graphical input techniques - Display transformation in 2-D and 3-D - Viewing transformation - Clipping - hidden line elimination - Mathematical formulation for graphics - Curve generation techniques - Model storages and Data structure - Data structure organisation - creation of data files - Accessing data files - Concepts of data processing and information system. Data Bank Concepts - Data bank information storage and retrieval - Data life cycle - Integrated data processing - Information system. Engineering Data Management System. Hierarchical data structure. Network data structure - Relational data structure. Data storage and search methods. 3. SOLID MODELING 3 Geometric Modeling - Wireframe, Surface and Solid models - CSG and B-REP Techniques - Features of Soild Modeling Packages - Parametric and features - Interfaces to drafting, Design Analysis. 4. FINITE ELEMENT ANALYSIS 13

Introduction - Procedures - Element types - Nodal approximation - Element matrices, vectors and equations Global connectivity - Assembly - Boundary conditions - Solution techniques - Interfaces to CAD - Introduction packages - Software development for design of mechanical components. Total No of periods: 30

Page 9

ME335 Computer Aided Design Text Book:

100

1. Sadhu Singh, " Computer Aided Design and Manufacturing ", Khanna Publishers, New Delhi, 1998. References: 1. D.F. Rogers and J.A.Adams, " Mathematical Elements in Computer Graphics ", McGraw-Hill Book Company, New York, 1976. 2. P.Radhakrishnan and C.P.Kothandaraman, " Computer Graphics and Design ", Dhanpat Rai and Sons, New Delhi, 1991. 3. E.Dieter George, " Engineering Design ", McGraw-Hill International Edition, 1991. 4. P.Radhakrishnan and S.Subramanyan, " CAD / CAM / CIM ", Wiley Eastern Ltd., New Age International Ltd., 1994. 5. Groover and Zimmers, " CAD / CAM : Computer Aided Design and Manufacturing ", Prentice Hall of India, New Delhi, 1994. 6. V.Ramamurthi, " Computer Aided Mechanical Design and Analysis ", Tata McGraw Hill Publishing Co Ltd., 1998. 7. Ibrahim Zeid, " CAD - CAM Theory and Practice ", Tata McGraw Hill Publishing Co. Ltd., 1991.

Page 10

MF331 Engineering Metrology 1. BASIC CONCEPTS OF MEASUREMENTS

100 2

Need for measurement - Precision and Accuracy - Reliability - Errors in Measurements - Causes - Types.

2.

LINEAR AND ANGULAR MEASUREMENTS

Measurement of Engineering Components - Comparators, Slip gauges, Rollers, Limit gauges - Design and Applications - Auto collimator - Angle dekkor - Alignment telescope - Sine bar - Bevel protractors - Types Principle - Applications. 3. FORM MEASUREMENTS 7 Measurement of Screw thread and gears - Radius measurement - Surface finish measurement - Straightness, Flatness and roundness measurements - Principles - Application. 4. LASER METROLOGY 7

Precision instrument based on Laser - Use of Lasers - Principle - Laser Interferometer - Application in Linear and Angular measurements - Testing of machine tools using Laser Interferometer. 5. ADVANCES IN METROLOGY 7

Co-ordinate measuring machine - Constructional features - Types - Applications of CMM - CNC CMM applications - Computer Aided Inspection - Machine Vision - Applications in Metrology. 6. LABORATORY EXERCISE 30

i) Straightness measurement using Autocollimator. ii) Measurement of Taper angle using Tool Makers Microscope. iii) Measurement of various elements of screw thread using Tools Makers Microscope. iv) Measurement of composite error using gear tester. v) Calibration of optical comparator and measurement of dimension vi) Determining the accuracy of electrical and optical comparator. vii) Measurement of taper angle using sine bar. viii) Measurement of various angles using Bevel Protractor. ix) Measurement of dimensions using Vernier Height Gauge. Total No of periods: 60

Page 11

MF331 Engineering Metrology Text Book: 1. R.K.Jain, " Engineering Metrology ", Khanna Publishers, 1994. References:

100

1. Gaylor, Shotbolt and Sharp, " Metrology for Engineers ", O.R.Cassel, London, 1993. 2. Thomas, " Engineering Metrology ", Butthinson & Co., 1984. 3. Books an Workshop Technology and Manufacturing Processes.

Page 12

ME336 Dynamics Lab .

100 60

1. MESUREMENTS 1.1 Measurement of Shaft Speed-Counters, Techometers, Tachogenerators Digital Tachometers Stroboscopes. 1.2 Measurement of Frequency, Amplitude, Acceleration, Vibration pick ups Accelerometers - Recorders. 2. KINEMATICS 2.1 Kinematics of four bar machanisms - Slider Crank, Crank Rocker Mechanism. 2.2 Kinematics of Universal Joints. 2.3 Kinematics of Gears - Spur, Helical, Bevel, Worm. 2.4 Kinematics of Gear trains - Simple, Compound, Epicyclic, Differential and Worm Wheel Reducers. 3. DYNAMICS 3.1 Inertia Systems: Experiments on 3.1.1 Turn table apparatus - Determination of M.I. 3.1.2 Motorized Gryoscope - Verification of Laws. 3.1.3 Connecting Rod and Flywheel - Determination of M.I. by oscillation. 3.2 Transmission Systems 3.2.1 Gear reducers - Determiantion of Transmission efficiency. 3.2.2 Governors - Watts, Porter, Proell and Hartnell - Determination of Sensitivity, effort etc. 3.2.3 Cam-study of Jump phenomenon - Determination of Critical Speeds. 3.3 Vibrating Systems 3.3.1 Spring mass system - Determination of damping Coefficient of single degree of freedom system. 3.3.2 Multidegree freedom suspension system determination of influence coefficients. 3.3.3 Vibrating table - Determination of transmissibility ratio. 3.3.4. Compound Pendulum - Determination of torsional natural frequencies - system with lumped moment of inertia. 3.3.5. Flywheel and Axis system - Determination of torsional natural frequencies - system with lumped moment of inertia. 3.3.6. Transverse vibration - Free - Free Beam. 3.3.7. Whirling of shaft - Determination of critical speed of shaft with concentrated loads. 3.4. Balancing 3.4.1. Balancing of rotating masses. 3.4.2. Balancing of reciprocating masses. . Students will be given ten to twelve experiments from the list of experiments given in the list, depending upon the facilities available in the laboratory, during that semester. Total No of periods: 60

Page 13

ME336 Dynamics Lab

100

Page 14

ME337 Thermal Engineering Laboratory I .

100

1.

I.C. ENGINES LAB & FUELS LAB

15

1. Study of I.C. Engines, Components and Loading Devices 2. Valve Timing and Port Timing Diagrams. 3. Performance Test on 4-stroke Diesel Engine. 4. Heat Balance Test on 4-stroke Diesel Engine. 5. Morse Test on Multicylinder Diesel Engine. 6. Retardation Test to find Frictional Power of a Diesel Engine. 7. Determination of Viscosity - Red Wood Viscometer. 8. Determination of Flash Point and Fire Point. 2. STEAM LAB 15 1. Study of Steam Generators and Turbines. 2. Performance and Energy Balance Test on a Steam Generator. 3. Performance and Energy Balance Test on Steam Turbine. Total No of periods: 30

Page 15

ME338 Computer Aided Manufacturing 1. CAD / CAM INTERFACE

100 8

Current trends in Manufacturing Engineering - Group Technology - Design for Manufacturing and Assembly Process Planning Techniques - Total approach to product development - Concurrent Engineering - Rapid prototyping - Introduction to CAD / CAM software packages. 2. FUNDAMENTALS OF CNC MACHINES 10 CNC Technology - Functions of CNC Control in Machine Tools - Classification of CNC systems - Contouring System - Interpolators, open loop and closed loop CNC systems - CNC Controllers, Hardware features - Direct Numerical Control (DNC Systems). 3. CONSTRUCTIONAL FEATURES OF CNC MACHINES 10 Design considerations of CNC machines for improving machining accuracy-Structural members-Slideways Sides linear bearings - Ball screws - Spindle drives and feed drives - work holding devices and tool holding devices -Automatic Tool changers. Feedback devices - Principles of Operation-Machining Centres - Tooling for CNC machines. 4. PART PROGRAMMING FOR CNC MACHINES 10 Numerical control codes - Standards - Manual Programming - Canned cycles and subroutines - Computer Assisted Programming, CAD / CAM approach to NC part programming - APT language, machining from 3D models. 5. PRODUCTION PLANNING AND CONTROL 7 Introduction to production planning and control - Shop Floor Control Systems - Just in time approach Emerging Challenges in CAD / CAM, Product Data Management - Product Modeling - Assembly and Tolerance Modeling. Total No of periods:

45

Page 16

ME338 Computer Aided Manufacturing Text Book:

100

1. Ibrahim Zeid, " CAD - CAM Theory and Practice ", Tata McGraw-Hill Publishing Co. Ltd., 1998. References: 1. Yoram Koren, " Computer Control of Manufacturing Systems ", McGraw-Hill Book Company, 1986. 2. MC Mahon and J. Browne, " CAD / CAM ", Addison - Wesley, 1998. 3. P.Radhakrishnan, " Computer Numerical Control ", New Central Book Agency, 1992. 4. G.T.Smith, " CNC - Machining, Techniques - Vol. 1, 2 & 3 ", verlag, 1992. 5. S.Kant Vajpayee, " Principles of Computer Integrated Manufacturing ", Prentice Hall of India Ltd., 1999.

Page 17

ME339 Design of Jigs, Fixtures and Press Tools 1. LOCATING AND CLAMPING DEVICES

100 8

Principles of Jigs and Fixtures design-Locating principles-Locating elements-Standard parts-Clamping devicesMechanical actuation-Pneumatic & hydraulic actuation-Analysis of clamping forces-Tolerance and error analysis. 2. JIGS 8 Drill bushes-Different types of Jigs-Plate latch, channel, box, post, angle plate, angular post, turnover, pot jigsAutomatic drill jigs-Rack & Pinion Operated, Air operated Jigs Components. 3. FIXTURES 8

General principles of boring, lathe, milling and broaching fixtures-Grinding, planing and shaping fixtures, Assembly, Inspection and Welding fixtures-Modular fixtures. Design and development of Jigs and fixtures for given components. 4. PRESS TOOLS 16 Press working terminology-Presses and Press accessories-Computation of capacities and tonnage requirementsStrip layout-Design and development of various types of cutting, Forming and drawing dies-Blank development for Cylindrical and non cylindrical shells - Compound progressive, combination dies. 5. TERM PROJECT 5 Submission of an Industrial report on observation training in Jigs, Fixture and Press Tools. (Not for end-semester examination; to be considered for internal assessment only). Total No of periods: 45

Page 18

ME339 Design of Jigs, Fixtures and Press Tools Text Books:

100

1. " ASTME Handbook of Fixture Design ". 2. " Design Data complied by the Faculty of Mechanical Engineering ", P.S.G.Tech. Coimbatore. References: 1. 2. 3. 4. " Fundamentals of Tool Design ", ASTME, 1983. A.K. Goroshkin, " Jigs and Fixtures Handbook ", Mix Publishers, Moscow, 1983. " Die Design Handbook ", McGraw Hill Book Co., 1965. P.Eugene Ostergaard, " Basic Die Making " - Mc Graw Hill Book, 1963.

Page 19

ME340 Heat and Mass Transfer 1. CONDUCTION

100 10

Fourier's law of conduction in simple and composite geometries, types of boundary and initial conditions, contact resistance, conduction with heat generation, extended surface heat transfer, transient and periodic heat conduction, application of numerical methods. 2. RADIATION 10 Basic laws of radiation, radiation in ideal and real surfaces, view factor algebra, radiation shields, electrical analogy using radiosity and irradiation, gaseous emission and absorption. 3. CONVECTIVE HEAT TRANSFER 10

Dimensional analysis, boundary layer concept, basic governing equations, laminar and turbulent external and internal flows, forced and free convections, integral methods, semi-empirical correlations, flow over bank of tubes. 4. PHASE CHANGE HEAT TRANSFER AND HEAT EXCHANGERS 10 Modes of boiling, Nusselt theory of condensation, correlations in boiling and condensation, types of heat exchangers, methods of analysis, fouling factor and simple design problems. 5. MASS TRANSFER 5

Rate equations, mass diffusion in binary mixtures, evaporation in a column, forced convective mass transfer, heat and mass transfer analogies. 6. TUTORIALS 15

Total No of periods:

60

Page 20

ME340 Heat and Mass Transfer Text Books:

100

1. R.Yadav, " Heat and Mass Transfer ", Central Publishing House, Allahabad, 1995. 2. R.C.Sachdeva, " Fundamentals of Engineering Heat and Mass Transfer ", New Age International Publishers, New Delhi, 1995. References: 1. Frank P. Incropera and David P. DeWitt, " Fundamentals of Heat and Mass Transfer ", John Wiley and Sons, 1998. 2. A.Bejan, " Heat Transfer ", John Wiley and Sons, 1995. 3. M.N.Ozisik, " Heat Transfer ", Mc Graw Hill Book Co., 1994. 4. C.P.Kothandaraman, " Fundamentals of Heat and Mass Transfer ", New Age International Publishers, New Delhi, 1998. 5. James Sucec , " Heat Transfer ", M/s.Jaico Publishing 1998-99 Edition. 6. Nicholas P.C., " Heat Transfer Hand Book ", M/s Jaico Publishing 1998-99 Edition. 7. Holman J.P; Heat and Mass Transfer, Tata McGraw Hill, 2000.

Page 21

ME341 Hydraulic and Pneumatic Controls 1. BASIC PRINCIPLES

100 10

Hydraulic Principles - Hydraulic pumps - Characteristics - Pump Selection -Pumping Circuits - Hydraulic Actuators - Linear Rotary - Selection -Characteristics - Hydraulic Valves - Pressure - Flow - Direction Controls Applications - Hydraulic Fluids-Symbols. 2. HYDRAULIC CIRCUITS 8 Hydraulic circuits - Reciprocating - Quick return - Sequencing synchronizing - Accumulator circuits - Safety circuits - Industrial circuits - Press - Milling Machine - Planner - Fork Lift, etc. 3. DESIGN & SELECTION 8

Design of Hydraulic circuits - Selection of components.

4.

PNEUMATIC SYSTEMS

Pneumatic fundamentals - Control Elements - Logic Circuits - Position - Pressure Sensing - Switching - Electro Pneumatic - Electro Hydraulic Circuits - Robotic Circuits. 5. DESIGN & SELECTION 10

Design of Pneumatic circuits - Classic-Cascade-Step counter - Combination -Methods - PLC-Microprocessors Uses - Selection criteria for Pneumatic components - Installation and Maintenance of Hydraulic and Pneumatic power packs - Fault finding - Principles of Low Cost Automation - Case studies Total No of periods: 45

Page 22

ME341 Hydraulic and Pneumatic Controls Text Books:

100

1. J.Michael, Pinches and John G.Ashby, " Power Hydraulics ", Prentice Hall, 1989. 2. Andrew Parr, " Hydraulics and Pnematics (HB) ", Jaico Publishing House, 1999. References: 1. Dudleyt, A. Pease and John J. Pippenger, " Basic Fluid Power ", Prentice Hall, 1987. 2. Anthony Esposite, " Fluid Power with Applications ", Prentice Hall, 1980.

Page 23

ME342 Design of Transmission Systems 1. DESIGN OF FLEXIBLE POWER TRANSMISSION SYSTEMS

100 10

V belts and pulleys - Flat belts and pulleys - Wire ropes and pulleys - Link chains and pulleys - Transmission chains and Sprockets-Silent chains - Ribbed V belts. 2. SPUR GEARS 8

Force analysis -Tooth stresses - Dynamic effects - Estimating gear size - Fatigue strength - Factor of safety - Gear materials - Gear blank design. 3. HELICAL BEVEL AND WORM GEARS 10

Parallel Helical Gears - Kinematics - Force analysis crossed helical gears - Worm Gearing - Force Analysis Straight Bevel Gears - Kinematics Bevel Gear - Force Analysis. Gear Blank Design. 4. DESIGN OF GEAR BOXES 7

Geometric progression - Standard step ratio - Ray diagram, kinematic layout -Design of sliding mesh gear box Constant mesh gear box. 5. CLUTCHES AND BRAKES 10

Internal Expanding Rim Clutches and Band Brakes - External - Contracting Rim Clutches and Band Brakes Type Clutches and Brakes. Frictional contact Axial clutches, cone clutches and brakes - Energy Considerations. Temperature Rise - Friction Materials. Total No of periods: 45

Page 24

ME342 Design of Transmission Systems References:

100

1. Joseph Edward Shigley and Charles, R. Mischke, " Mechanical Engineering Design ", McGraw Hill International Editions, 1989. 2. Gitin M.Maitra and L.V.Prasad, " Hand book of Mechanical Design ", II Edition, Tata Mc Graw Hill, 1985. 3. V.B. Bhandari, " Design of Machine Elements ", Tata McGraw Hill Publishing Company Ltd., 1994. 4. T.V.Sundarajamoorthy and N.Shanmugam, " Machine Design ", Khanna Publishers, Delhi-6, 1989.

Page 25

ME343 CAM Laboratory . 1. Manual Part Programming for CNC Machines using Stand G and M Code Machining praticals on Trainer Type CNC Machines.

100 60

Simulation of tool path -

2. Computer Assisted Part Programming - APT Programming Language Part Programming using APT and other NO Programming languages. 3. Exposure to Component Modeling and CL data generation using CAD / CAM Software like Unigraphics Pro/E Smart CAM etc. 4. NC code generation using CAD / CAM software - Post processing for stsndard CNC control like FANUCSINUMERIC etc. 5. Introduction to Surface Machining - Multi-Axis Machining. 6. Study of Rapid proto typing and tooling processes (Not for examination purposes) Total No of periods: 60

Page 26

ME344 Thermal Engineering Laboratory II . LIST OF EXPERIMENTS REFRIGERATION AND AIRCONDITIONING 1. Study of refrigeration system, charging and troubleshooting 2. Determination of COP of a refrigeration system. 3. Study of airconditioning system, charging and trouble shooting. 4.. Study of year - round air conditioning system. (not included for examination) 5. Performance test on a LPG refrigerator system. 6. Study of LPG Refrigerator system. (not included for examination purposes) HEAT TRANSFER 1. Heat transfer studies in a pinfin. 2. Parallel flow & counter flow heat exchanger. 3. Determination of stefan boltzmann constant. 4. Determination of flash point and fire point of the given oil sample.

100 60

Total No of periods:

60

Page 27

CE071 Principles of Environmental Science and Engineering 1. COMPONENTS OF ENVIRONMENT

100 9

Components - Water, air and land - Inter-relationship between components - Subcomponents; Ecosystem Structure and functional components of ecosystem - Development and evolution of ecosystem - Energy flow and material cycling in ecosystem - Natural and man made impacts on water, air and land; Environment and development - Concept of sustainable development. 2. SCIENCE OF ENVIRONMENT 9 Chemistry, Physics and biology of water, air and land; Stress on the Chemistry, Physics and Biology of water, air and land owing to the impacts; Environmental quality objective and goals - Policies on development projects and their impacts, with emphasis on the branch of engineering of the student. 3. CURRENT ENVIRONMENTAL ISSUES 9 Current Environmental issues at Country level - management of municipal sewage, municipal solid waste, Hazardous waste and Bio-medical waste - Air pollution due to industries and vehicles; Global issues Biodiversity, Climatic change, Ozone layer depletion. 4. ENGINEERING INTERVENTIONS TO REDUCE THE ENVIRONMENTAL STRESSES 9

Minimisation of Stress - Principles of Physics, chemistry and biology in engineering interventions such as waste treatment - Flow sheets of engineering interventions relevant to the Engineering discipline of the student - Waste minimisation techniques - Clean technology options - Standards of performance of the interventions. 5. (A) TOOLS FOR ENVIRONMENTAL MANAGEMENT 9 9

Environmental impact assessment; Precautionary Principle and Polluter Pays Principle; Constitutional provisions, Legal and economic instruments in Environmental Management; Role of Non-government organisations - Community participation environmental management works; International conventions and protocols; Pollution Control Boards and Pollution Control Acts. (B) FIELD STUDY In-depth study of environmental issues at least one environmentally sensitive site relevant to the discipline of the student and preparation of a report thereupon. Total No of periods: 45

Page 28

CE071 Principles of Environmental Science and Engineering Text Books:

100

1 G.M.Masters, Introduction to Environmental Engineering & Science, Prentice Hall, New Delhi, 1997 2. J.G. Henry and G. W. Heike, Environmental Science & Engineering", Prentice Hall International Inc., New Jersy, 1996. References: 1. S. K. Dhameja, Environmental Engineering and Management, S. K. Kataria and Sons, New Delhi, 1999. 2. State of India's Environment - A Citizen's Report, Centre for Science and Environment and Others, 1999 3. Shyam Divan and Armin Rosancranz, Environmental Law and Policy in India, Cases, Materials and Statutes, Oxford University Press, 2001.

Page 29

GE035 Professional Ethics 1. ENGINEERING ETHICS

100 9

Senses of 'Engineering Ethics' - variety of moral issues - types of inquiry - moral dilemmas - moral autonomy kohlberg's theory -giligan's theory - consensus and controversy - professions and professionalism - professional ideals and virtues - theories about right action - self-interest-customs and religion - uses of ethical theories 2. ENGINEERING AS SOCIAL EXPERIMENTATION 9 Engineering as experimentation - engineers as responsible experimenters - codes of ethics-a balanced outlook on law-the challenger case study 3. ENGINEER'S RESPONSIBILITY FOR SAFETY 9

Safety and risk - assessment of stafety and risk - risk benefit analysis-reducing risk-the three mile island and chernobyI case studies. 4. RESPONSIBILITIES AND RIGHTS 9

Collegiality and loyalty - respect for authority - collective bargaining - confidentiality - conflicts of interest occupational crime - professional rights - employee rights - intellectual property rights (ipr)-discrimination. 5. GLOBAL ISSUES 9

Multinational corporations - environmental ethics-computer ethics-weapons development-engineers as managers-consulting engineers-engineers as expert witnesses and advisors-moral leadership-sample code of conduct. Total No of periods: 45

Page 30

GE035 Professional Ethics Text Book:

100

1. Mike Martin and roland Schinzinger, "Ethics in Engineering", McGraw Hill, New York 1996. References : 1. Charles D.Fleddermann, "Engineering Ethics", prentice Hall, New Mexico, 1999. 2. Laura Schlesinger, "How Could You Do That: The Abdication of Character, Courage, and Conscience", Harper Collins, New York, 1996. 3. Stephen Carter, "Integrity", Basic Books, New York, 1996. 4. Tom Rusk, "The Power of Ethical Persuasion: From Conflict to Partership at Work and in Private Life", Viking, New York, 1993

Page 31

ME432 Power Plant Engineering 1. LAYOUT OF POWER PLANT

100 6

Layouts of Steam, hydel, diesel, MHD, nuclear and gas turbine power plants - Combined power cycles Comparison and selection 2. STEAM BOILER AND CYCLES 14

Modern high pressure and supercritical boilers - Analysis of power plant cycles - modern trends in cycle improvement - Waste heat recovery, Fluidized bed boilers. FUEL AND ASH HANDLING, COMBUSTION CHAMBER, DRAUGHT, AIR 10 POLLUTION Preparation and handling of coal - Pulveriser - Dust collector - Ash removal; Stokers - Different types Pulverised fuel burning ; Draught - Different types - Chimney design - Selection of blowers, Cooling towers Different types - Analysis of pollution from thermal power plants - Pollution controls. 4. INSTRUMENTATION, TESTING OF BOILERS, POWER PLANT ECONOMICS 10 CO2 recorders - Automatic controls for feedwater, steam, fuel,air supply and combustion, Boiler testing and trails - Inspection and safety regulations. Economics of power plant - Actual load curves, fixed costs - Operating costs - Variable load operation. 5. NUCLEAR AND MHD POWER GENERATION 5 Elementary treatment - Nuclear fission, chain reaction - Pressurised water reactors, boiling water reactors, gas cooled reactors - Fast breeder reactors, MHD power cycle principles. Total No of periods: 45 3.

Page 32

ME432 Power Plant Engineering Text Books:

100

1. S.C. Arora and S. Domkundwar, "A Course in Power Plant Engineering", Dhanpat Rai and Sons, Tata McGraw Hill, 1998. 2. P.K.Nag, " Power Plant Engineering ", Tata McGraw Hill Publishing Co. Ltd., 1998. 3. G.R. Nagpal, " Power Plant Engineerig ", Khanna Publishers, 1998. References: 1. Joel Weisman and Roy Eckart, " Modern Power Plant Engineering ", Prentice Hall International Inc., 1985. 2. Bernhardt G. Askrotzki & William A. Vopat, " Power Station Engineering and Economy ", Tata McGraw Hill Publishing Co. Ltd., 1972. 3. Frederick T. Mores, " Power Plant Engineering ", Affiliated East-West Press Private Ltd., 1953.

Page 33

ME433 Mechatronics 1. INTRODUCTION

100 3

Introduction to Mechantronics-Systems-Measurement Systems-Control Systems-Mechatronics Approach.

2.

SENSORS AND TRANSDUCERS

12

Introduction-Performance Terminology-Displacement, Position and Proximity-Velocity and Motion-Fluid Pressure-Temperature Sensors-Light Sensors-Selection of Sensors-Signal Processing. 3. 8055 MICROPROCESSOR 15

Introduction-Architecture-Pin Configuration-Instruction set-Programming of Microprocessors using 8085 instructions-Interfacing input and output devices-Interfacing D/A converters and A/D converters-ApplicationsTemperature control-Stepper motor control-Traffic light controller. 4. PROGRAMMABLE LOGIC CONTROLLERS 8 Introduction-Basic structure-Input/Output Processing-Programming-Mnemonics-Timers, Internal relays and counters-Data handling-Analog Input/Output-Selection of a PLC. 5. DESIGN AND MECHATRONICS 7

Stages in Designing mechatronic systems - Traditional and Mechatronic design -Possible design solutions-Case studies of mechatronic systems - Pick and place robot - automatic car park system -engine management system. Total No of periods: 45

Page 34

ME433 Mechatronics Text Book: 1. W.Bolton, Mechatronics,Longman,Second Edition, 1999. References:

100

1. Michael B. Histand and David G.Alciatore, " Introduction to Mechatronics and Measurement Systems ", McGraw Hill International Editions, 1999. 2. HMT Ltd., " Mechatronics ", Tata McGraw Hill Publishing Co. Ltd., 1998. 3. D.A.Bradley, D.Dawson, N.C.Buru and A.J.Loader, " Mechatronics ", Chapman and Hall, 1993. 4. K.Ram, " Fundamentals of Microprocessors and Microcomputers ", Dhanpat Rai Publications, Fourth Revised Edition, 1999. 5. Ramesh S. Gaonkar, " Microprocessor Architecture ", Programming and Applications, Wiley Eastern, 1997. 6.Dan Necsulescu, "Mechatronics",Pearson Education Asia,2002(Indian reprint).

Page 35

MF441 Process Planning and Cost Estimation 1. PROCESS PLANNING

100 9

Types of Production - Standardization, Simplification - Production design and selection - Process planning, selection and analysis - Process planning, selection and analysis - Steps involved in manual experience based planning and computer aided process planning - Retrieval, generative - Selection of processes analysis Breakeven analysis. 2. ESTIMATING AND COSTING 5 Importance and aims of Cost estimation - Functions of estimation - Costing - Importance and aims of Costing Difference between costing and estimation - Importance of realistic estimates - Estimation procedure. 3. ELEMENT OF COST 12

Introduction - Material Cost - Determination of Material Cost Labour Cost - Determination of Direct Labour Cost - Expenses - Cost of Product (Ladder of cost) - Illustrative examples. Analysis of overhead expenses Factory expenses - Depreciation - Causes of depreciation - Methods of depreciation - Administrative expenses Selling and Distributing expenses - Allocation of overhead expenses. 4. PRODUCT COST ESTIMATION 10 Estimation in forging shop - Losses in forging - Forging cost - Illustrative examples. Estimation in welding shop - Gas cutting - Electric welding - illustrative examples. Estimation in foundry shop - Estimation of pattern cost and casting cost - Illustrative examples. 5. ESTIMATION OF MACHINING TIME 9 Estimation of machining time for Lathe operations - Estimation of machining time for drilling, boring, shaping, planning, milling and grinding operations - Illustrative examples. Total No of periods: 45

Page 36

MF441 Process Planning and Cost Estimation Text Books:

100

1. M.Adithan and B.S. Pabla, " Estimating and Costing ", Konark Publishers Pvt. Ltd., 1989. 2. A.K. Chitale and R.C. Gupta, " Product Design and Manufacturing ", Prentice Hall Pvt. Ltd., 1997. References: 1. Nanua Singh, " System approach to Computer Integrated Design and Manufacturing ", John Wiley & Sons, Inc., 1996. 2. Joseph G. Monks, " Operations Management, Theory & Problems ", McGraw Hill Book Company, 1982. 3. G.B.S. Narang and V.Kumar, " Production and Costing ", Khanna Publishers, 1995. 4. T.R. Banga and S.C. Sharma, " Estimating and Costing ", Khanna Publishers, 1986.

Page 37

ME434 Microprocessor Lab . 1. PROGRAMMING

100 60

1. Addition of Two 8-bit numbers, Sum of 8-bits and 16bits. 2. Decimal addition of two 8-bit numbers Sum: 16 bits. 3. 8-bit sudraction . 4. 8-bit Decimal subraction 5. Additional of Two 16-bit numbers, Sum: 16 bits or more. 6. Multibyte Sudraction. 7. Multibyte Subraction. 8. To arrange a series of numbers in Ascending order. 9. To arrange a series of numbers in Descending order. 10. 8-bit Multiplication. 11. 8-bit Division. 12. Decimal to hexadecimal conversion and Hexadecimal number to Decimal number conversion. 2. INTERFACING 1. Anlog to Digital Conversion. 2. Digital to Anlog Conversion. 3. Stepper Motor Controller. Total No of periods: 60

Page 38

ME439 Comprehension 1.

100 30

The objective of "Comprehension" is to provide opportunity for the student to apply the knowledge acquired during the earlier semesters to real-life problems which he/she may have to face in future as an engineer. While learning as to how to solve real life problems, the student will receive guidance from teachers and also review various courses (subjects) learnt earlier. 2. The comprehension assessment will consist of 3 to 5 tests in each Thermal, Desgin and Manufacturing Streams covering all the subject of study in the respective streams under B.E. Mechanical Engineering Course. Total No of periods: 30

Page 39

GE406 1.

TOTAL QUALITY MANAGEMENT INTRODUCTION

3 0 0 100 9

Definition of Quality, Dimensions of Quality, Quality Planning, Quality costs - Analysis Techniques for Quality Costs, Basic concepts of Total Quality Management, Historical Review, Principles of TQM, Leadership Concepts, Role of Senior Management, Quality Council, Quality Statements, Strategic Planning, Deming Philosophy, Barriers to TQM Implementation. 2. TQM PRINCIPLES 9

Customer satisfaction Customer Perception of Quality, Customer Complaints, Service Quality, Customer Retention, Employee Involvement Motivation, Empowerment, Teams, Recognition and Reward, Performance Appraisal, Benefits, Continuous Process Improvement Juran Trilogy, PDSA Cycle, 5S, Kaizen, Supplier Partnership Partnering, sourcing, Supplier Selection, Supplier Rating, Relationship Development, Performance Measures Basic Concepts, Strategy, Performance Measure. 3. STATISTICAL PROCESS CONTROL (SPC) 9

The seven tools of quality, Statistical Fundamentals Measures of central Tendency and Dispersion, Population and Sample, Normal Curve, Control Charts for variables and attributes, Process capability, Concept of six sigma, New seven Management tools. 4. TQM TOOLS 9

Benchmarking Reasons to Benchmark, Benchmarking Process, Quality Function Deployment (QFD) House of Quality, QFD Process, Benefits, Taguchi Quality Loss Function, Total Productive Maintenance (TPM) Concept, Improvement Needs, FMEA Stages of FMEA. 5. QUALITY SYSTEMS 9

Need for ISO 9000 and Other Quality Systems, ISO 9000:2000 Quality System Elements, Implementation of Quality System, Documentation, Quality Auditing, QS 9000, ISO 14000 Concept, Requirements and Benefits. TEXT BOOK: 1. Dale H.Besterfiled, et at., Total Quality Management, Pearson Education Asia, 1999. (Indian reprint 2002). REFERENCES: 1. 2. 3. 4. 5. James R.Evans & William M.Lidsay, The Management and Control of Quality, (5th Edition), South-Western (Thomson Learning), 2002 (ISBN 0-324-06680-5). Feigenbaum.A.V. Total Quality Management, McGraw-Hill, 1991. Oakland.J.S. Total Quality Management Butterworth Hcinemann Ltd., Oxford. 1989. Narayana V. and Sreenivasan, N.S. Quality Management Concepts and Tasks, New Age International 1996. Zeiri. Total Quality Management for Engineers Wood Head Publishers, 1991.

ME435 Engineering Management 1. ENGINEERING ECONOMICS

100 10

Introduction - Demand and Revenue Analysis - Demand Forecasting - Production Analysis - Cost and Supply Analysis, Price and output Determination - Investment Analysis - Plant Location - Economic Optimization. 2. MANAGEMENT OF WORK 8

Types of Business Organisation, Forms, Planning - Organising - Designing effective organisations Coordination. 3. THE MANAGEMENT OF ENGINEERS 10

Human Resource Development - Motivating individuals and workgroups - Leadership for Managerial Effectiveness - Team working and Creativity - Managerial Communication - Personal Management - Time Management - Stores Management - Career Planning. 4. THE MANAGEMENT OF ENGINEERING 10 Financial Management - Product development - Management techniques in product development - Nature of controlling - Operations Management - Just-in-Time. 5. CONTEMPORARY MANAGEMENT ISSUES 7

Managing World Economic Change - The global environment - Multinational Strategies - Economic Cycles and Director Investment - Change and Organisation Development - Managerial Ethics and Social responsibilities. Total No of periods: 45

Page 41

ME435 Engineering Management Text Books:

100

1. Gail Freeman - Bell and Janes Balkwill, " Management in Engineering - Principles and Practive ", Prentice Hall of India Pvt.Ltd., 1998. 2. Gene Burton and Manab Thaker, " Management Today Principles and Practice ", Tata McGraw Hill, 1995. References: 1. M. Joesph, Putti Management - " A Functional Approach ", McGraw Hill, 1999. 2. R.R. Barathwal, " Engineering Economics ", McGraw Hill, 1997.

Page 42

ME436 Operations Research 1. LINEAR MODELS

100 15

The phases of operations research study- Linear programming - Graphical method - Simplex algorithm - Duality - Transportation problems - Assignment problems - Applications to problems with discrete variables. 2. NETWORK MODELS 6

Network models - Shortest route - Minimal spanning tree - Maximum flow models - Project network - CPM and PERT networks - Critical path scheduling - Sequencing models. 3. INVENTORY MODELS 6

Inventory models - Economic order quantity models - Quantity discount models - Stochastic Inventory models Multi product models - Inventory control models in practice. 4. QUEUEING THEORY 8

Queueing models - Queueing systems and structures - Notation - parameter - Single Server and multi server models - Poisson input - Exponential service - Constant rate service - Infinite population - Simulation. 5. DECISION MODELS 10

Decision models - Game theory - Two person zero sum games - Graphical solution - Algebric solution - Linear programming solution - Replacement models - Models based on service life - Economic life - Single/ Multi variable search technique - Application of OR models - Case studies. 6. TUTORIALS 15

Total No of periods:

60

Page 43

ME436 Operations Research Text Books:

100

1. H.A.Taha, " Operations Research ", Prentice Hall of India, 1999, Sixth Edition. 2. S.Bhaskar, " Operations Research ", Anuradha Publishers, Tamil Nadu, 1999. References: 1. Shennoy, Srivastava, " Operation Research for Management ", Wiley Eastern, 1994. 2. M.J. Bazara, Jarvis, H. Sherali, " Linear Programming and Network Flows ", John Wiley, 1990. 3. Philip and Ravindran, " Operational Research ", John Wiley, 1992. 4. Hillier and Lieberman, " Operations Research ", Holden Day, 1986. 5. Frank, S.Budnick, Dennis, McLeavy, " Principles of Operation Research for Management ", Richard D Irwin, 1990.

Page 44

ME437 Automobile Engineering 1. VEHICLE STRUCTURE AND ENGINES

100 10

Vehicle construction, Chassis, Frame and Body, Engine types, Construction, Operation, Performance and Balance Engine Trouble Shooting, Gas Turbines, Air pollution, Pollution standards. 2. ENGINE AUXILIARY SYSTEMS 10

Carburetors, Electronic Fuel Injection System - Monopoint and Multipoint Systems, Electrical Systems - Battery Generator, Starting Motor, Lighting and Ignition (Battery and Electronic Types) 3. TRANSMISSION SYSTEMS 10

Clutch - Types and Construction, Fluid Flywheel, Gear Boxes, Manual and Automatic - Overdrives - Propeller Shaft - Differential and Rear Axle. 4. RUNNING SYSTEMS 8

Wheels and Tyres, Steering Geometry and Types, Types of front axle, Suspension systems, Braking systems.

5.

ALTERNATIVE FUELS/ POWER PLANTS

Use of Natural Gas, LPG and Hydrogen in Automobiles as fuels, Electric and Hybrid vehicles, Fuel cells

6.

LAB PRACTICE (FOR INTERNAL ASSESSMENT ONLY)

15

Study of Automotive Transmission Systems, Study of Automotive Electric Circuits, Callibration of Fuel Pump for Multi Cylinder Automotive Engine,Testing of Automotive Shock Absorbers. Total No of periods: 60

Page 45

ME437 Automobile Engineering Text Book: 1. R.B. Gupta, " Automobile Engineering ", Satya Prakashan, 1993. References:

100

1. William Crouse, " Automobile Engineering Series ", McGraw-Hill, 1988. 2. Newton and Steeds, " Motor Vehicles ", ELBS, 1985 3. Duffy Smith, " Auto Fuel Systems ", The Good Heat Willcox Company Inc., 1987 4. Osamu Hirao and Richard K. Pefley, " Present and Future Automotive Fuels ", John Wiley and Sons, 1988.

Page 46

You might also like

- Kumar Saurabh Resume (SAP IBP)Document6 pagesKumar Saurabh Resume (SAP IBP)SaurabhSinhaNo ratings yet

- Chapter-6 Motivation PDFDocument21 pagesChapter-6 Motivation PDFericacadagoNo ratings yet

- Mechatronics Unit III and IV Question and AnswersDocument6 pagesMechatronics Unit III and IV Question and AnswersSaravanan MathiNo ratings yet

- Procedure Checklist For Fm200 InstallationDocument2 pagesProcedure Checklist For Fm200 InstallationJibril Lamai0% (1)

- Engineering Management: Reference: Engineeringmanagement by RobertomedinaDocument15 pagesEngineering Management: Reference: Engineeringmanagement by RobertomedinaZchary SkyNo ratings yet

- 01 KDOM Course HandoutDocument14 pages01 KDOM Course HandoutBhimsen ShresthaNo ratings yet

- PDF 9 1 PDFDocument208 pagesPDF 9 1 PDFCatherine RockyNo ratings yet

- 604 I.c.engine (Me-604) Exp. ManualDocument35 pages604 I.c.engine (Me-604) Exp. Manualnavaneet gupta100% (1)

- Design of Machine Elements2Document14 pagesDesign of Machine Elements2Satwik PriyadarshiNo ratings yet

- Design 2 1 PDFDocument255 pagesDesign 2 1 PDFAjayNo ratings yet

- Power Plant Chapter 2Document24 pagesPower Plant Chapter 2Harp Yq100% (1)

- Applied Thermodynamics QBDocument12 pagesApplied Thermodynamics QBapi-25999517100% (1)

- Machine Design IDocument19 pagesMachine Design Inauman khanNo ratings yet

- Kinematics of Machinery NotesDocument65 pagesKinematics of Machinery NotesVenkatesh Rajamani100% (1)

- Engineering Dynamics Lecture 1Document33 pagesEngineering Dynamics Lecture 1Anokha LadlaNo ratings yet

- Atd Questions and AnswersDocument18 pagesAtd Questions and AnswersPraba Karan DNo ratings yet

- Module 3 - Ideal Models of Engine CyclesDocument37 pagesModule 3 - Ideal Models of Engine CyclesMuhammad BilalNo ratings yet

- Unit I DME I 13 09 2021Document68 pagesUnit I DME I 13 09 2021Vaibhav JainNo ratings yet

- Me8792 - Power Plant EngineeringDocument48 pagesMe8792 - Power Plant EngineeringPalanivel Rajan A RNo ratings yet

- Unit 1. Fundamentals of Design Master b5Document20 pagesUnit 1. Fundamentals of Design Master b5S VNo ratings yet

- MECN 4110 - Mechanisms Design - Fall 2012 - Lecture 01Document59 pagesMECN 4110 - Mechanisms Design - Fall 2012 - Lecture 01florenceprasadNo ratings yet

- FALLSEM2020-21 MEE3001 TH VL2020210101665 Reference Material I 31-Aug-2020 Module 4 Design of Riveted Joint 8 PDFDocument53 pagesFALLSEM2020-21 MEE3001 TH VL2020210101665 Reference Material I 31-Aug-2020 Module 4 Design of Riveted Joint 8 PDFAK PRODUCTIONSNo ratings yet

- Machine Design Lab ManualDocument28 pagesMachine Design Lab ManualEr Raghvendra Singh100% (1)

- Inversion of Four BarDocument2 pagesInversion of Four BarDinesh SharmaNo ratings yet

- A Review On Revolution of Flat Plate Collector For Solar Water HeaterDocument17 pagesA Review On Revolution of Flat Plate Collector For Solar Water HeaterIJRASETPublications100% (1)

- Questions On Mechanical-Electrical AnalogyDocument2 pagesQuestions On Mechanical-Electrical Analogyparth bhardwaj100% (1)

- IEEE Citation Guidelines2 PDFDocument5 pagesIEEE Citation Guidelines2 PDFShahAyzdiiNo ratings yet

- Mechanical Engineering Syllabus 2013Document94 pagesMechanical Engineering Syllabus 2013Subash Gerrard DhakalNo ratings yet

- Keys, Shafts and CouplingsDocument26 pagesKeys, Shafts and CouplingsNauman KhanNo ratings yet

- Power Plant EngineeringDocument6 pagesPower Plant EngineeringMahalingam Nanjappan100% (1)

- Univ Lab Set - 1 Me8711 Sa LabDocument5 pagesUniv Lab Set - 1 Me8711 Sa LabAsst.Prof MECH100% (1)

- rr10302 Engineering MechanicsDocument12 pagesrr10302 Engineering MechanicsSRINIVASA RAO GANTANo ratings yet

- 28 Patriotic Bollywood Movies - Top Hindi Desh Bhakti Films PDFDocument14 pages28 Patriotic Bollywood Movies - Top Hindi Desh Bhakti Films PDFsukushNo ratings yet

- DME Lesson Plan As Per NBADocument3 pagesDME Lesson Plan As Per NBASabareesan Subramanian0% (1)

- Scrubbing Line PaperDocument8 pagesScrubbing Line PaperAndiNo ratings yet

- Sample Question Paper Mechanical Engineering MeasurementsDocument4 pagesSample Question Paper Mechanical Engineering MeasurementsAbhishek SakatNo ratings yet

- DOME-I Unit 1 - GDocument17 pagesDOME-I Unit 1 - GGautam GunjanNo ratings yet

- Me Laws and Code ChichuDocument25 pagesMe Laws and Code ChichuMark julius garciaNo ratings yet

- Classification of CompositesDocument2 pagesClassification of CompositesViswanathan SrkNo ratings yet

- PHY203Document237 pagesPHY203MitrabhanuNo ratings yet

- Question Paper For RACDocument2 pagesQuestion Paper For RACSDvidyaNo ratings yet

- Me Law Me SyllabiDocument12 pagesMe Law Me SyllabiVon A. DamirezNo ratings yet

- Project Study 2Document41 pagesProject Study 2James AlcariaNo ratings yet

- 1.1 Significance of MeasurementsDocument16 pages1.1 Significance of MeasurementsManikandan SNo ratings yet

- What Is Machine DesignDocument54 pagesWhat Is Machine DesignPavan KishoreNo ratings yet

- Mech-V-Design of Machine Elements I (10me52) - AssignmentDocument10 pagesMech-V-Design of Machine Elements I (10me52) - AssignmentArunNo ratings yet

- MEIM0111 Mechanical Engineering Profession Lecture 1Document10 pagesMEIM0111 Mechanical Engineering Profession Lecture 1Jethro Marco V. VicenteNo ratings yet

- M.E BooksDocument5 pagesM.E BooksPrasoon SurendranNo ratings yet

- Machine Design Report 1Document15 pagesMachine Design Report 1WaqasNo ratings yet

- Mechanical MeasurementsDocument3 pagesMechanical MeasurementsneerubandaNo ratings yet

- Introduction To Design of Machine ElementsDocument11 pagesIntroduction To Design of Machine Elementssakali aliNo ratings yet

- AE 2202 THERMOdynamics - 2 Mark QuestionsDocument56 pagesAE 2202 THERMOdynamics - 2 Mark QuestionsthanikavelNo ratings yet

- Performance Analysis of Backward Curved Centrifugal Fan in Heating Ventilation and Air-ConditioningDocument3 pagesPerformance Analysis of Backward Curved Centrifugal Fan in Heating Ventilation and Air-ConditioningIjsrnet Editorial100% (1)

- Golden Gate Colleges: IILO 1 - Spiritually and IILO 2 - AcademicallyDocument7 pagesGolden Gate Colleges: IILO 1 - Spiritually and IILO 2 - AcademicallyHindi Ka MAHALNo ratings yet

- Ogdcl Test, Correct Answers Are Not Provided, Errors / Spelling Mistakes / Revisions Are AcceptedDocument2 pagesOgdcl Test, Correct Answers Are Not Provided, Errors / Spelling Mistakes / Revisions Are AcceptedAmjad AliNo ratings yet

- Muthayammal Engineering College,: RasipuramDocument6 pagesMuthayammal Engineering College,: RasipuramVarun CharavananNo ratings yet

- The Me Profession-2Document2 pagesThe Me Profession-2Narfred EgarNo ratings yet

- GDJP Important 2 Marks and 16 Marks With AnswerDocument18 pagesGDJP Important 2 Marks and 16 Marks With AnswerMechanical Engg DeptNo ratings yet

- DTS Syllabus12122011Document1 pageDTS Syllabus12122011ntsdharmaNo ratings yet

- Anna University Coimbatore REGULATIONS 2007-08 B.E - Mechanical EngineeringDocument28 pagesAnna University Coimbatore REGULATIONS 2007-08 B.E - Mechanical EngineeringRaajeshkrishnaNo ratings yet

- ManfDocument34 pagesManfAnantha NarayananNo ratings yet

- Me 6401 Kom - Uti Ans KeyDocument11 pagesMe 6401 Kom - Uti Ans Keylogeshboy007100% (1)

- Som Lab Manual NnceDocument39 pagesSom Lab Manual Nncelogeshboy007No ratings yet

- ME 6401 KOM - Unit Test-I Question PaperDocument1 pageME 6401 KOM - Unit Test-I Question Paperlogeshboy007No ratings yet

- A Study On Sales Penetration of New Holland Brand in Ramnad and Sivagangai Dist Kalaiarasi.V VMM-997 MBADocument14 pagesA Study On Sales Penetration of New Holland Brand in Ramnad and Sivagangai Dist Kalaiarasi.V VMM-997 MBAlogeshboy007No ratings yet

- List of Experiments: Ce6411 Strength of Materials LaboratoryDocument2 pagesList of Experiments: Ce6411 Strength of Materials Laboratorylogeshboy007No ratings yet

- Syllabus R2013 PDFDocument105 pagesSyllabus R2013 PDFlogeshboy007No ratings yet

- Me 2035 Entrepreneurship DevelopmentDocument2 pagesMe 2035 Entrepreneurship Developmentlogeshboy007No ratings yet

- Case Study 1Document3 pagesCase Study 1logeshboy007No ratings yet

- Cycle Test 1 Set2Document2 pagesCycle Test 1 Set2logeshboy007No ratings yet

- Ce 1252 - Strength of Materials: Two Mark Question & AnswersDocument23 pagesCe 1252 - Strength of Materials: Two Mark Question & Answerslogeshboy007No ratings yet

- Cycle Test 1 Set1Document6 pagesCycle Test 1 Set1logeshboy007No ratings yet

- Corrosion Engineering: Presented by M.LogeshDocument19 pagesCorrosion Engineering: Presented by M.Logeshlogeshboy007No ratings yet

- Corrosion: Presented by M.LogeshDocument4 pagesCorrosion: Presented by M.Logeshlogeshboy007No ratings yet

- Introduction To Surface EngineeringDocument31 pagesIntroduction To Surface Engineeringlogeshboy007No ratings yet

- EDMDocument20 pagesEDMlogeshboy007No ratings yet

- Course Objectives: Course Mapping Programme: B.E. Mechanical Engineering Course: Engineering Physics IIDocument2 pagesCourse Objectives: Course Mapping Programme: B.E. Mechanical Engineering Course: Engineering Physics IIlogeshboy007No ratings yet

- ME2303-Design of Machine ElementsDocument36 pagesME2303-Design of Machine Elementslogeshboy007No ratings yet

- Automatic Pneumatic Vulcanizing Machine Using Heat SensorDocument3 pagesAutomatic Pneumatic Vulcanizing Machine Using Heat Sensorlogeshboy007No ratings yet

- Minimisation of Interlaminar Stress in Composite Wind Turbine BladesDocument6 pagesMinimisation of Interlaminar Stress in Composite Wind Turbine Bladeslogeshboy007No ratings yet

- Manual Bombas Pozo e ImpulsionDocument112 pagesManual Bombas Pozo e ImpulsionFernando PuentesNo ratings yet

- CV hll3220cw Uke PSGDocument17 pagesCV hll3220cw Uke PSGczarownikivanovNo ratings yet

- GSPDocument27 pagesGSPVirgil Titimeaua100% (1)

- CeldekDocument2 pagesCeldekPK SinghNo ratings yet

- Mitac 6120N ManualDocument141 pagesMitac 6120N ManualLiviu LiviuNo ratings yet

- G249 MXBDocument8 pagesG249 MXBAndres SorinNo ratings yet

- Acid CleaningDocument32 pagesAcid Cleaningsekhar_ntpcNo ratings yet

- Scan 0001Document1 pageScan 0001ochiroowitsNo ratings yet

- Technical Manual Operator'S and Unit Maintenance Manual FOR Firing Device, Demolition. M122 (NSN 1375-01-021-0606) (EIC: 2NA)Document7 pagesTechnical Manual Operator'S and Unit Maintenance Manual FOR Firing Device, Demolition. M122 (NSN 1375-01-021-0606) (EIC: 2NA)Михаил НаумовNo ratings yet

- Øyvind H. Johansen Et Al - Qualification of An Enhanced Blast Explosive (DPX-6) : According To STANAG 4170Document25 pagesØyvind H. Johansen Et Al - Qualification of An Enhanced Blast Explosive (DPX-6) : According To STANAG 4170MallamaxNo ratings yet

- R10 On XPDocument182 pagesR10 On XPadenihun Adegbite100% (1)

- What Is NoSQLDocument4 pagesWhat Is NoSQLDulari Bosamiya BhattNo ratings yet

- MIL-W-22759 Rev E - Part34Document1 pageMIL-W-22759 Rev E - Part34David WongNo ratings yet

- GSM RF Interview QuestionsDocument26 pagesGSM RF Interview QuestionsmohammedelrabeiNo ratings yet

- Using Gelatin For Moulds and ProstheticsDocument16 pagesUsing Gelatin For Moulds and Prostheticsrwong1231100% (1)

- Short Notes On Building ConstructionDocument20 pagesShort Notes On Building Constructionlarnz0% (1)

- Manual de TallerDocument252 pagesManual de TallerEdison RodriguezNo ratings yet

- ATM Storage TankDocument10 pagesATM Storage TanksameerpecNo ratings yet

- 7GCBC PohDocument75 pages7GCBC PohEyal Nevo100% (1)

- A White Paper On IExpense Features in R12Document17 pagesA White Paper On IExpense Features in R12Balaji ShindeNo ratings yet

- St3133 Reading Dancing ManualDocument2 pagesSt3133 Reading Dancing ManualdfsaNo ratings yet

- Strategic Management MBA (GTU)Document639 pagesStrategic Management MBA (GTU)keyur0% (2)

- cm6800 48x8 NewDocument98 pagescm6800 48x8 Newvijayakumar3661No ratings yet

- Decline Curve AnalysisDocument37 pagesDecline Curve AnalysisAshwin VelNo ratings yet

- EN - 61558 - 2 - 4 (Standards)Document12 pagesEN - 61558 - 2 - 4 (Standards)RAM PRAKASHNo ratings yet

- S7-1200 DataSheetDocument14 pagesS7-1200 DataSheetperuhayaNo ratings yet

- Sa 449Document8 pagesSa 449Widya widya100% (1)