Professional Documents

Culture Documents

3.4.b.01 Air Blower

Uploaded by

Gohar KhokharCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3.4.b.01 Air Blower

Uploaded by

Gohar KhokharCopyright:

Available Formats

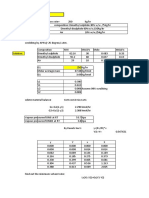

DOCUMENT No.

PAGE

OF

REV.

DATE

Equipment Data Sheet

SI UNITS

REV*

PROJECT No. CLIENT PROJECT SERVICE MODEL INSTALLATION AMBIENT TEMPERATURE DESIGN CASE 1 DESIGN CASE 2

RFQ/RFP NO. LOCATION VENDOR TAG SIZE SERIAL QTY

AIR BLOWER

1 MANUFACTURER 2 3 ENVIRONMENT 4 ELEVATION 5 CAUSE OF CORROSION/EROSION 6 7

PERFORMANCE / OPERATING CONDITIONS

MIN. MAX. DESIGN CASE 3

0 0

C DESIGN CASE 4

DESIGN CASES kPa(abs) kg-mol m /h kg/h % kg/s

0 0 3

GUARANTEED

8 GAS HANDLED (ANALYSIS ATTACHED) 9 ATMOSPHERIC PRESSURE 10 MOLECULAR WEIGHT 11 STD. FLOW SCMH @ 150C & 101.325 12 ACTUAL FLOW @ SUCTION CONDITIONS 13 MASS FLOW 14 RELATIVE HUMIDITY 15 WATER VAPOUR 16 SUCTION TEMPERATURE 17 DISCHARGE TEMPERATURE (EST.) 18 SUCTION PRESSURE 19 DISCHARGE PRESSURE 20 DIFFERENTIAL PRESSURE 21 GAS COMPRESSIBILITY 22 23 24 25 POLYTROPIC HEAD 26 POWER ( + / - 4%) 27 SPEED 28 ESTIMATED SURGE 29 30 31 STEAM 32 33 34 35 36 37 38 39 ELECTRIC POWER 40 41 42 43 44 45 46 47 REMARKS 48 49 50 51 52 53 54 55 56 57

C kPag kPag kPag k=Cp/Cv k=Cp/Cv k=Cp/Cv k=Cp/Cv bhp rpm % m3/h

SUCTION DISCHARGE SUCTION DISCHARGE

UTILITIES

INLET

0 0 0

EXHAUST

COOLING WATER TYPE PRESSURE TEMP MAX. ALLOW. TEMP. RISE kPag

0 0

NORMAL TEMP1 MAX. TEMP MIN. TEMP

C C

NORMAL PRESSURE1 MAX. PRESSURE kPag MIN. PRESSURE kPag

C kPag

C C

REMARKS MAIN AUXILIARY V Hz ft

VOLTAGE PHASE FREQUENCY ENCLOSURE ELEVATION

NOTE:

INDICATES INFORMATION TO BE COMPLETED BY PURCHASER 0: INDICATES AN ORDER REVISION

BY VENDOR 1, 2, 3, : INDICATES A POST-ORDER REVISION

* A, B, C, : INDICATES A PRE-ORDER REVISION

REV

DATE

BY

CK'D

APP.

DESCRIPTION

REV

DATE

BY

CK'D

APP.

DESCRIPTION

\\vboxsrv\conversion_tmp\scratch_6\[152154039.xls.ms_office.xls]PAGE 1

ISO 9001 DATA SHEET

DOCUMENT No.

PAGE

OF

REV.

DATE

Equipment Data Sheet

SI UNITS

REV*

PROJECT No. CLIENT PROJECT SERVICE MODEL

RFQ/RFP NO. LOCATION VENDOR TAG SIZE NOZZLE CONNECTIONS SIZE INLET DISCHARGE DRAIN VENT IMPELLERS TYPE FORGED WELDED mm RIVETED CAST mm m/s SERIAL QTY

AIR BLOWER

1 MANUFACTURER 2 3 MAX. SPEED 4 OVERSPEED TEST 6 CRITICAL SPEED 7 8 CASING 9 10 11 12 13 14 15 16 17 BEARING HOUSING 18 19 20 21

CONSTRUCTION

rpm rpm FIRST SECOND MODEL CASING SPLIT MATERIAL THICK. DESIGN PRESSURE HYDROTEST PRESS OPERATING TEMP. MAX.

0

TRIP SPEED MAXIMUM CW rpm rpm CCW

rpm rpm

ANSI RATING

FACING

POSITION

5 ROTATION VIEWED FROM COUPLING END

mm

CORROSION ALLOW.

mm kPag kPag

MATERIAL DIAMETER MAX. DIAMETER MAX. TIP SPEED MAX. MACH NO. @ IMPELLER EYE SHAFT MATERIAL DIAMETER @ IMPELLER DIAMETER @ COUPLING mm mm

MIN.

TYPE MATERIAL BOLTED ON OTHER JOURNAL BEARINGS TYPE MATERIAL DIAMETER THRUST BEARINGS TYPE MATERIAL SURFACE LOADING m2 kPa mm INTEGRAL W/ CASING

LABYRINTHS IMPELLER LABYRINTH MATERIAL SHAFT SLEEVES UNDER LABYRINTH SHAFT SEAL TYPE BUFFER GAS TYPE FLOW m 3/h @ SEALING LIQUID TYPE FLOW m 3/h @ kPag

0

22 BEARINGS 23 24 25 26 27 28 29 30 31 32 33 TESTS 34 35 36 37 38 39 40 41 OIL SYSTEM 42 43 44 45 46 ACCESSORIES 47 48 49 50 51 52 53 54 55 56 57 REMARKS 58 59 60 61

LABYRINTH

CARBON RING

LIQUID SEAL

kPag

BASE PLATE & ASSEMBLY REQUIRED REQUIRED REQUIRED REQUIRED REQUIRED REQUIRED WITNESSED WITNESSED WITNESSED WITNESSED WITNESSED WITNESSED WEIGHTS & DIMENSIONS COMPRESSOR (L x W x H) WEIGHT INSTALLED SHIPPING HEAVIEST PART FOR MAINTENANCE TYPE MAKE MODEL REMARKS kg kg kg m BASEPLATE SOLE PLATES SS PIPING FEED SS PIPING DRAIN COMMON W/ DRIVER

HYDROSTATIC PERFORMANCE MECHANICAL RUN SHOP INSPECTION DRIVER W/ COMPRESSOR DISMANTLE-INSPECTION

FURNISHED BY COMMON WITH SEE OIL SYSTEM DATA SHEET

AXIAL PROBES VIBRATION PROBES VIBRATION READOUT VIBRATION MONITOR COUPLING COUPLING SPACER

INSTRUMENT

NOTE:

INDICATES INFORMATION TO BE COMPLETED BY PURCHASER 0: INDICATES AN ORDER REVISION

BY VENDOR 1, 2, 3, : INDICATES A POST-ORDER REVISION

ISO 9001 DATA SHEET

* A, B, C, : INDICATES A PRE-ORDER REVISION

\\vboxsrv\conversion_tmp\scratch_6\[152154039.xls.ms_office.xls]PAGE 1

You might also like

- Liquid Valve CV CalcDocument4 pagesLiquid Valve CV Calcamit_kt1973No ratings yet

- Flare Modeling ParametersDocument25 pagesFlare Modeling Parametersf3byz100% (1)

- Figure 1: Coordinate of Plant LocationDocument11 pagesFigure 1: Coordinate of Plant LocationJonathon John100% (1)

- Tank Pressure Vacuum ReliefDocument1 pageTank Pressure Vacuum ReliefalmadhagiNo ratings yet

- Emergency Scrubber DesignDocument36 pagesEmergency Scrubber DesignSurajit das0% (1)

- Output Summary: SI UnitsDocument42 pagesOutput Summary: SI UnitsAkhil JoseNo ratings yet

- Feuille Calcul Gas Pipeline Blowdown TimeDocument6 pagesFeuille Calcul Gas Pipeline Blowdown TimeNic RicNo ratings yet

- PSV Sizing: The Relief Load Can Be Calculated Directly, in Pounds Per Hour, From The Following RelationshipDocument4 pagesPSV Sizing: The Relief Load Can Be Calculated Directly, in Pounds Per Hour, From The Following RelationshipAfees OlajideNo ratings yet

- Reciprocating Compressor Performance Worksheeet USCDocument6 pagesReciprocating Compressor Performance Worksheeet USCTiano BaLajadiaNo ratings yet

- Sizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesDocument5 pagesSizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesJavierNo ratings yet

- Subsea Pipeline Design Report.Document26 pagesSubsea Pipeline Design Report.Luke6nNo ratings yet

- GTL Process Design and Economic AnalysisDocument41 pagesGTL Process Design and Economic AnalysisthuythukopaiNo ratings yet

- Tank Normal Venting (ISO)Document2 pagesTank Normal Venting (ISO)Saeid Rahimi Mofrad0% (1)

- Control Valve Sizing - LiquidDocument4 pagesControl Valve Sizing - Liquidcharro1623No ratings yet

- Indra: SonatrachDocument9 pagesIndra: SonatrachhichamNo ratings yet

- Chemical & Process Technology - Requirements of SDV Bypass Pressurization Line PDFDocument4 pagesChemical & Process Technology - Requirements of SDV Bypass Pressurization Line PDFvenkatrangan2003100% (1)

- Volume Calculation For Pressure Vessel TankDocument2 pagesVolume Calculation For Pressure Vessel Tanksai srikarNo ratings yet

- Perancangan Plate Adn Frame HEDocument36 pagesPerancangan Plate Adn Frame HEDavid LambertNo ratings yet

- Carbon Molecular Sieve DataDocument6 pagesCarbon Molecular Sieve DataShashank RaiNo ratings yet

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Honey TiwariNo ratings yet

- API Data SheetsDocument7 pagesAPI Data SheetsalfruizpNo ratings yet

- TDS For Basket StrainerDocument2 pagesTDS For Basket StrainerRAGHVENDRA PRATAP SINGHNo ratings yet

- Desuperheater Boiler Feed Water RequirementDocument2 pagesDesuperheater Boiler Feed Water RequirementmayurjannuNo ratings yet

- Spreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2Document26 pagesSpreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2hwang2100% (1)

- Bulk Air Eliminator R1Document1 pageBulk Air Eliminator R1hydrothermsNo ratings yet

- Contro Corrosion FactorsDocument10 pagesContro Corrosion Factorsramadoss_alwar7307No ratings yet

- Enhanced Gravity OWS Sizing SpreadsheetDocument1 pageEnhanced Gravity OWS Sizing Spreadsheetdeion29No ratings yet

- Demister SizingDocument3 pagesDemister SizingD K SNo ratings yet

- Tank Venting Requirements (API 2000) 2Document3 pagesTank Venting Requirements (API 2000) 2RubensBoerngenNo ratings yet

- Bundwall SampleDocument1 pageBundwall Samplewawen03No ratings yet

- Vent Sizing MethodsDocument26 pagesVent Sizing Methodsmieiroluiz12No ratings yet

- Spreadsheet-Based Process Group SoftwareDocument10 pagesSpreadsheet-Based Process Group SoftwareHendy ArmantoNo ratings yet

- Filter Separator Revised Feb 19 2004Document1 pageFilter Separator Revised Feb 19 2004motalebyNo ratings yet

- Is 14164 2008Document45 pagesIs 14164 2008Pukhraj DagaNo ratings yet

- Waste Heat Recovery UnitDocument15 pagesWaste Heat Recovery UnitEDUARDONo ratings yet

- Compressor SizeDocument3 pagesCompressor SizeSubhash KumarNo ratings yet

- Design of LPG Refigeration System: 1. Copper TubesDocument20 pagesDesign of LPG Refigeration System: 1. Copper TubesJeevan Landge PatilNo ratings yet

- Expansión de la Refinería LA TEJA de ANCAPDocument27 pagesExpansión de la Refinería LA TEJA de ANCAPgrabettyNo ratings yet

- Gas Pipeline FlowDocument12 pagesGas Pipeline FlowGRANRICKYNo ratings yet

- Spreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2Document26 pagesSpreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2venkatesh801No ratings yet

- RTN - Ttu-V-2154-001-Ste-Cal-007 - 3B Capacity Calculation Sheet For PRV & VRVDocument15 pagesRTN - Ttu-V-2154-001-Ste-Cal-007 - 3B Capacity Calculation Sheet For PRV & VRVroronoa_zorro11No ratings yet

- Volume of Water for Test SectionDocument2 pagesVolume of Water for Test SectionFerinoviardi100% (1)

- Fired Heater ComponentsDocument5 pagesFired Heater Componentsahmed atwaNo ratings yet

- Sonic VelocityDocument2 pagesSonic Velocityganeshdhage100% (1)

- Heat Exhanger Individual ReportDocument16 pagesHeat Exhanger Individual ReportMusa OtoNo ratings yet

- Vent Sizing - SpreadsheetDocument2 pagesVent Sizing - SpreadsheetPradip ShindeNo ratings yet

- A Guide To Assist in Evaluating Liquid Fuel FlamesDocument16 pagesA Guide To Assist in Evaluating Liquid Fuel FlamestinuvalsapaulNo ratings yet

- 7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksDocument2 pages7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksJatin Vadhera VCSPNo ratings yet

- Two Phase Flow RegimeDocument8 pagesTwo Phase Flow RegimecitramuaraNo ratings yet

- GCI Storage Tank Data SheetDocument4 pagesGCI Storage Tank Data SheetAlvin Smith60% (5)

- TCE Consulting Engineers Process Data Sheet for Ammonia Storage and Compression VesselsDocument59 pagesTCE Consulting Engineers Process Data Sheet for Ammonia Storage and Compression Vesselsrotatic_engineerNo ratings yet

- HD Api610Document5 pagesHD Api610Venkat RanganNo ratings yet

- API 675 Data Sheet SIDocument2 pagesAPI 675 Data Sheet SIhappale2002100% (3)

- V383773001X00 PDFDocument4 pagesV383773001X00 PDFSIVANo ratings yet

- General purpose steam turbine specification sheetDocument1 pageGeneral purpose steam turbine specification sheetSAKDA MAPRADITKULNo ratings yet

- SEO-Optimized Title for Pig Receiver Datasheet DocumentDocument6 pagesSEO-Optimized Title for Pig Receiver Datasheet Documenthai_solincvnNo ratings yet

- SVSW 004110 G16 0001 Rev.a Datasheet For PumpDocument6 pagesSVSW 004110 G16 0001 Rev.a Datasheet For Pumpnguyenquoc1988No ratings yet

- API STD 676-2009 - Hoja de RequisiciónDocument28 pagesAPI STD 676-2009 - Hoja de RequisiciónRicardo CastroNo ratings yet

- Check List of 6.6kv PanelDocument22 pagesCheck List of 6.6kv Panelsantoshkumar100% (1)

- Large Eddy SimulationDocument43 pagesLarge Eddy SimulationGohar KhokharNo ratings yet

- Couette Flow Reynold Stress PDFDocument11 pagesCouette Flow Reynold Stress PDFGohar KhokharNo ratings yet

- Turbulent Pipe FlowDocument30 pagesTurbulent Pipe FlowGohar Khokhar100% (1)

- Turbulence ConceptsDocument79 pagesTurbulence ConceptsGohar KhokharNo ratings yet

- CFD Numerical ErrorsDocument52 pagesCFD Numerical ErrorsGohar KhokharNo ratings yet

- An Introduction To AeroacousticsDocument64 pagesAn Introduction To Aeroacousticslax_doraNo ratings yet

- Transonic FlowDocument3 pagesTransonic FlowGohar KhokharNo ratings yet

- Turbulence KolmogorovDocument5 pagesTurbulence KolmogorovGohar Khokhar100% (1)

- Refinery and SealsDocument67 pagesRefinery and Sealsapi-3702021100% (3)

- CFD NotesDocument155 pagesCFD NotesAjit ChandranNo ratings yet

- Rotary CompressorsDocument59 pagesRotary Compressorsguru_519572100% (3)

- Oblique ShocksDocument5 pagesOblique ShocksaeroacademicNo ratings yet

- LNG TerminalsDocument19 pagesLNG TerminalsEric Sullivan100% (2)

- Shock DetonationDocument92 pagesShock Detonationpamos1111No ratings yet

- Compressible Flow-AerothermodynamicsDocument44 pagesCompressible Flow-AerothermodynamicsGohar KhokharNo ratings yet

- Reynolds Stress Models: Deriving The EquationDocument12 pagesReynolds Stress Models: Deriving The EquationWaqar A. KhanNo ratings yet

- Introduction To Differential Analysis of Fluid MotionDocument34 pagesIntroduction To Differential Analysis of Fluid MotionGohar KhokharNo ratings yet

- Aerodynamic Analysis of Sailing ShipDocument12 pagesAerodynamic Analysis of Sailing ShipGohar KhokharNo ratings yet

- Basic Bluff-Body Aerodynamics I: Wind Loading and Structural Response Lecture 8 Dr. J.D. HolmesDocument24 pagesBasic Bluff-Body Aerodynamics I: Wind Loading and Structural Response Lecture 8 Dr. J.D. HolmesGohar KhokharNo ratings yet

- Introduction To Hydrodynamic StabilityDocument35 pagesIntroduction To Hydrodynamic StabilityGohar KhokharNo ratings yet

- Finite Volume MethodsDocument237 pagesFinite Volume MethodsGohar KhokharNo ratings yet

- Grid Generated TurbulenceDocument11 pagesGrid Generated TurbulenceGohar KhokharNo ratings yet

- Boundary Layers Thickness-Displacement-MomentumDocument30 pagesBoundary Layers Thickness-Displacement-MomentumGohar Khokhar67% (3)

- Boundary Layer SeparationDocument20 pagesBoundary Layer SeparationGohar KhokharNo ratings yet

- Chapter 4: Fluid Kinematics: Eric G. PatersonDocument34 pagesChapter 4: Fluid Kinematics: Eric G. PatersonGohar KhokharNo ratings yet

- Boundary Layer Flat PlateDocument27 pagesBoundary Layer Flat PlateGohar KhokharNo ratings yet

- Potential Flow TheoryDocument11 pagesPotential Flow TheoryGohar KhokharNo ratings yet

- Hyper Sonic Planetary Entry Flight MechanicsDocument370 pagesHyper Sonic Planetary Entry Flight MechanicsGohar Khokhar100% (1)

- Vortices in The Wake of CylinderDocument67 pagesVortices in The Wake of CylinderGohar KhokharNo ratings yet

- Mechanical Operations Mixing: Shardul Kale Harshad ShiwankarDocument28 pagesMechanical Operations Mixing: Shardul Kale Harshad ShiwankarKhushbuChemical RautNo ratings yet

- Centrifugal Pump Final Lab ReportDocument14 pagesCentrifugal Pump Final Lab Reportcracking khalifNo ratings yet

- Tobee® TH Slurry PumpsDocument6 pagesTobee® TH Slurry PumpsCentrifugal Slurry PumpNo ratings yet

- Chapter 8Document7 pagesChapter 8Ali BasheerNo ratings yet

- Jockey Pump Balsam (Grundfosh) PDFDocument11 pagesJockey Pump Balsam (Grundfosh) PDFm khaeronNo ratings yet

- DWP0327 D42 D53 Sump DatasheetDocument2 pagesDWP0327 D42 D53 Sump Datasheetabet_4No ratings yet

- 44.question Bank-Mee322Document17 pages44.question Bank-Mee322Prashant AwasthiNo ratings yet

- Ms Megachem A2740 8e 3Document23 pagesMs Megachem A2740 8e 3nata siagianNo ratings yet

- Dke672 ch2Document44 pagesDke672 ch2Siraj MohammedNo ratings yet

- KSB Prirucnik - Odabir PumpeDocument92 pagesKSB Prirucnik - Odabir PumpeНебојша РадићNo ratings yet

- Manual Bomba Alta Presion (Osmosis FEDCO)Document46 pagesManual Bomba Alta Presion (Osmosis FEDCO)gastoks83% (6)

- Hemanth Karmali & Deepak Pai - FomentoDocument46 pagesHemanth Karmali & Deepak Pai - FomentoNileshNo ratings yet

- Full Pump InductionDocument94 pagesFull Pump InductionPrathmesh LoharNo ratings yet

- MINNOVEX Fixed Gap Manual 2003Document8 pagesMINNOVEX Fixed Gap Manual 2003Edwing William Salhuana MendozaNo ratings yet

- Volute CasingDocument8 pagesVolute CasingRafael Leonardo GomezNo ratings yet

- Centrigual Compressors Course - Very Good PDFDocument91 pagesCentrigual Compressors Course - Very Good PDFVILLANUEVA_DANIEL2064100% (1)

- Spandau Pumpen Centrifugal Pumps SKF Vogel Schmiertechnik 1 6667 ENDocument72 pagesSpandau Pumpen Centrifugal Pumps SKF Vogel Schmiertechnik 1 6667 ENsf w0% (1)

- Design & Fabrication of a Portable Mixer for Low Viscosity FluidsDocument34 pagesDesign & Fabrication of a Portable Mixer for Low Viscosity FluidsmohtasimNo ratings yet

- Bladegen ToturialsDocument83 pagesBladegen ToturialsmistrycsNo ratings yet

- Impeller Volute and Diffuser Interaction: G. PavesiDocument29 pagesImpeller Volute and Diffuser Interaction: G. PavesiashokrangasamyNo ratings yet

- Solvent Extraction Pump Mixers - Where to From HereDocument20 pagesSolvent Extraction Pump Mixers - Where to From HereclaudioNo ratings yet

- PC 12Document8 pagesPC 12Gopinath Srinivasan100% (1)

- ASGP Training ReportDocument46 pagesASGP Training ReportjaiminNo ratings yet

- Unit 4Document23 pagesUnit 4eyobNo ratings yet

- Amacan S 60HzDocument40 pagesAmacan S 60HzRicardo BarrosNo ratings yet

- Fermenter Design PDFDocument41 pagesFermenter Design PDFAngel Mah Xin Yee100% (1)

- LIGHTNIN - Mud Mixers CatalogDocument4 pagesLIGHTNIN - Mud Mixers CatalogIsaurovNo ratings yet

- Backflush Pump Capacity & Rated CurrentDocument7 pagesBackflush Pump Capacity & Rated Currentsaikat_das_meNo ratings yet

- Water Jet TrusmasterDocument5 pagesWater Jet TrusmasterSagita WidyatamaNo ratings yet

- Bungartz Mos Umos - enDocument10 pagesBungartz Mos Umos - enabasakNo ratings yet