Professional Documents

Culture Documents

The Knock Ic Engines

Uploaded by

muthupecmec4908Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

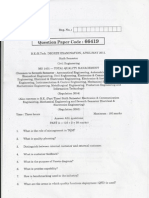

The Knock Ic Engines

Uploaded by

muthupecmec4908Copyright:

Available Formats

THE PHENOMENON OF KNOCK IN CI ENGINES

In CI engines the injection process takes place over a definite interval of time. Consequently, as the first few droplets to be injected are passing through the ignition delay period, additional droplets are being injected into the chamber.

If the ignition delay of the fuel being injected is short, the first few droplets will commence the actual burning phase in a relatively short time after injection and a relatively small amount offuel will be accumulated in the chamber when actual burning commences

As a result, the mass rate of mixture burned will be such as to produce a rate of pressure rise that will exert a smooth force on the piston.

If, on the other hand, the ignition delay is longer, the actual burning of the first few droplets is delayed and a greater quantity of fuel droplets gets accumulated in the chamber. When the actual burning commences, the additional fuel can cause too rapid a rate of pressure rise , resulting in a jamming of forces against the piston and rough engine operation

If the ignition delay is quite long, so much fuel can accumulate that the rate of pressure rise is almost instantaneous, as shown in Fig.12.17(c). Such a situation produces the extreme pressure differentials and violent gas vibrations known as knocking and is evidenced by audible knock.

The phenomenon is similar to that in the SI engine. However, in the SI engine, knocking occurs near the end of combustion whereas in the 01 engine, knocking occurs near the beginning of combustion.In order to decrease the tendency of knock it is necessary to start the actual burning as early as possible after the injection begins. In

You might also like

- QP 2010 May (2 Files Merged)Document4 pagesQP 2010 May (2 Files Merged)muthupecmec4908No ratings yet

- Faqs On CoconutDocument85 pagesFaqs On CoconutRanjith KumarNo ratings yet

- T Q M - 5 Yrs Univ Question Papers (Up-To 2011)Document14 pagesT Q M - 5 Yrs Univ Question Papers (Up-To 2011)Aravind100% (3)

- Ge 2111: Engineering Graphics: Unit V - Perpective ProjectionsDocument1 pageGe 2111: Engineering Graphics: Unit V - Perpective Projectionsmuthupecmec4908No ratings yet

- GE 2111: Engineering Graphics:: Unit IV - Development of SolidsDocument1 pageGE 2111: Engineering Graphics:: Unit IV - Development of Solidsmuthupecmec4908No ratings yet

- Mg-1401 Total Quality Management Question PaperDocument2 pagesMg-1401 Total Quality Management Question Papersubhaz100% (5)

- TQM Class NotesDocument12 pagesTQM Class NotesMOHAMMED ALI CHOWDHURY100% (4)

- TQM Unit 1Document26 pagesTQM Unit 1Muthuvel M100% (4)

- Total Quality Management Dec09 Jan10Document1 pageTotal Quality Management Dec09 Jan10muthupecmec4908No ratings yet

- Phase TransformationsDocument78 pagesPhase Transformationsmuthupecmec4908No ratings yet

- IV SectionsDocument2 pagesIV Sectionsmuthupecmec4908No ratings yet

- V IsometricDocument1 pageV Isometricmuthupecmec4908No ratings yet

- 2MARKSDocument21 pages2MARKSmuthupecmec4908No ratings yet

- PlanesDocument2 pagesPlanesmuthupecmec4908No ratings yet

- III SolidsDocument2 pagesIII Solidsmuthupecmec4908No ratings yet

- Common Features and Shapes in Historic BridgesDocument22 pagesCommon Features and Shapes in Historic Bridgesmuthupecmec4908No ratings yet

- Proj Points & LinesDocument3 pagesProj Points & Linesmuthupecmec4908No ratings yet

- Engineering Graphics Plane Curves ProblemsDocument1 pageEngineering Graphics Plane Curves Problemsmuthupecmec4908No ratings yet

- Bridg SeDocument28 pagesBridg Semuthupecmec4908No ratings yet

- Anna University Chennai SyllabusDocument95 pagesAnna University Chennai SyllabusRAAM MECHNo ratings yet

- Engine SpeedDocument2 pagesEngine Speedmuthupecmec4908No ratings yet

- Engineering MechanicsDocument2 pagesEngineering Mechanicsmuthupecmec4908No ratings yet

- C.I Delay PeriodDocument21 pagesC.I Delay Periodmuthupecmec4908No ratings yet

- Bridges Dusseau (EDocFind - Com)Document37 pagesBridges Dusseau (EDocFind - Com)muthupecmec4908No ratings yet

- Lesson 6 Powerpointv02Document39 pagesLesson 6 Powerpointv02muthupecmec4908No ratings yet

- Bridge Engineering: From Rome to Modern DesignDocument18 pagesBridge Engineering: From Rome to Modern Designmuthupecmec4908No ratings yet

- FES Bridges LectureDocument22 pagesFES Bridges LecturePranesh Gr100% (1)

- BridgesDocument23 pagesBridgesmuthupecmec4908No ratings yet

- Bridges: Discover Engineering ENGR 096Document22 pagesBridges: Discover Engineering ENGR 096muthupecmec4908No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)