Professional Documents

Culture Documents

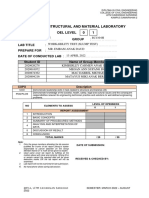

Compression Test

Uploaded by

Joe PhamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compression Test

Uploaded by

Joe PhamCopyright:

Available Formats

INTRODUCTION:

A compression test is a method for determining the behavior of materials under a compressive load. Compression tests are conducted by loading the test specimen between two plates and then applying a force to the specimen by moving the crossheads together. The compression test is used to determine elastic limit, proportionality limit, yield point, yield strength and compressive strength. Compressive Strength: It is the maximum compressive stress that a material is capable of withstanding without fracture. Brittle materials fracture during testing and have a definite compressive strength values. The compressive strength of ductile materials is determined by their degree of distortion during testing.

Result:

Compression test Material Diameter (mm) Cross-sectional area (mm2) Youngs Modulus (GPa) Load at Yield point (N) Yield strength (MPa) Maximum load (N) Ultimate tensile strength (MPa) % Elongation Fracture strength ( kN/m2) Aluminum alloy 5.00 19.63 70 20300 95 50000 110 8.89 10341.3

Discussion:

The compression test is carried out by using an Aluminum specimen in only one time. The specimens are loaded axially up to failure or any other prescribed level whereby the specimen is deformed and the axial and the radial deformation can be measured using equipment. The obtained result could be slightly difference from theoretical case. The concentricity between the specimen and device was not good. Thats why the graph plotted by software was not seemed to be reasonable in comparison with one in book.

After deformation, the shape of specimen was not like our expected one. If we choose a brittle material instead of aluminum, the result will be much different. Generally, the compression test is performed with brittle materials Conclusion: One small aluminum specimen has been successfully tested. Compression strength approaching 10341.3 kN/m2 has been measured. A number of results indicate that failure initiates within or immediately adjacent to the gage section, as intended. The standard deviation of the compression strengths is low, which is consistent with the mechanism of compressive failure. A fortunate characteristic of compression testing is that almost all likely sources of error will lead to a conservative estimate of strength. The most severe error occurs when the specimen is loaded with nonparallel surfaces and is forced to bend.

You might also like

- School of Technology Diploma in Buidling Year 1 Atgb 1363 Building Science & Services ReportDocument12 pagesSchool of Technology Diploma in Buidling Year 1 Atgb 1363 Building Science & Services ReportTan Zhen HuiNo ratings yet

- Defect Liability PeriodDocument2 pagesDefect Liability Periodkumburage pereraNo ratings yet

- Discussion ConcreteDocument7 pagesDiscussion ConcreteBgee LeeNo ratings yet

- Discussion +conclusionDocument2 pagesDiscussion +conclusionJacksparraowNo ratings yet

- Department of Environmental Engineering, UET TAXILADocument4 pagesDepartment of Environmental Engineering, UET TAXILAKashif Ali Jalil100% (2)

- Softening Point Test - MCO PDFDocument8 pagesSoftening Point Test - MCO PDFSusi MulyaniNo ratings yet

- Split Tensile TestDocument5 pagesSplit Tensile Testarijitdey6No ratings yet

- BFC 31901 Structure LabsheetDocument13 pagesBFC 31901 Structure LabsheetMRNo ratings yet

- Project Report Group 4Document28 pagesProject Report Group 4Akame TakashitaNo ratings yet

- Cube Test ReportDocument2 pagesCube Test ReportyapluyiNo ratings yet

- Structure Lab-Strut BucklingDocument7 pagesStructure Lab-Strut BucklingFendi RoonNo ratings yet

- LABSHEET Ukur Aras Terkini PDFDocument6 pagesLABSHEET Ukur Aras Terkini PDFLogarithemNo ratings yet

- Background English BondDocument9 pagesBackground English BondasdqwerNo ratings yet

- ECS416 Ammar Aiman (2020461314)Document1 pageECS416 Ammar Aiman (2020461314)Aniqah RushdaNo ratings yet

- Rational Method Computation Time 30mins: Infravera SDN BHDDocument10 pagesRational Method Computation Time 30mins: Infravera SDN BHDazhar ahmadNo ratings yet

- Rebound Hammer Test - MOSDocument6 pagesRebound Hammer Test - MOSFaizah Sophi100% (1)

- U2 Direct Shear Test Unconfined Compression TestDocument35 pagesU2 Direct Shear Test Unconfined Compression TestazmieNo ratings yet

- Minute Meeting FluidDocument5 pagesMinute Meeting FluidKerol Kerol KerolNo ratings yet

- Aggregate Impact Test: Highway and Traffic Engineering ECG564Document7 pagesAggregate Impact Test: Highway and Traffic Engineering ECG564SyukrinaNo ratings yet

- Question 1-Open EndedDocument4 pagesQuestion 1-Open EndedAshadi HamdanNo ratings yet

- CT2 AssignmentDocument16 pagesCT2 AssignmentCHI YAN KONGNo ratings yet

- Group H Civil Materials Lab 2A ReportDocument21 pagesGroup H Civil Materials Lab 2A ReportLanceNo ratings yet

- FYP1 & FYP2 Forms With Rubrics 2014 v2.1Document33 pagesFYP1 & FYP2 Forms With Rubrics 2014 v2.1redz00No ratings yet

- Method Statement For Mackintosh Probe TestDocument1 pageMethod Statement For Mackintosh Probe TestNurLiyana RasmiNo ratings yet

- Full Report GeofestDocument18 pagesFull Report Geofestmr_sam91100% (1)

- Design Mix Calculation Grade 30NDocument6 pagesDesign Mix Calculation Grade 30NikhwanNo ratings yet

- Testing Polymer ConcreteDocument6 pagesTesting Polymer Concretevoch007No ratings yet

- Density and Porosity of RocksDocument4 pagesDensity and Porosity of RocksTroy HewittNo ratings yet

- Full As Contoh Member AkashahDocument29 pagesFull As Contoh Member AkashahWayen Bulat100% (1)

- Test 1 - Concrete Mix Design DishanDocument20 pagesTest 1 - Concrete Mix Design DishanYasndra AbeygunewardhaneNo ratings yet

- Tensile TestingDocument8 pagesTensile TestingAddrien DanielNo ratings yet

- Physical and Mechanical Properties of Some Common Nigerian Timber Species Based On Limit State Design ApproachDocument8 pagesPhysical and Mechanical Properties of Some Common Nigerian Timber Species Based On Limit State Design ApproachSEP-PublisherNo ratings yet

- Failure of Retaining Wall - Case StudyDocument4 pagesFailure of Retaining Wall - Case StudyRaghavNo ratings yet

- Taking-Off Sheet, BQ Sheet and Concrete Mix Design FormDocument7 pagesTaking-Off Sheet, BQ Sheet and Concrete Mix Design FormiskandarNo ratings yet

- Eat 303 Wastewater Engineering Open Ended Lab Level 3Document1 pageEat 303 Wastewater Engineering Open Ended Lab Level 3Kucing GemukNo ratings yet

- Conclusion Space FrameDocument1 pageConclusion Space FrameHasnolhadi SamsudinNo ratings yet

- Half-Cell Potential Test From The Upper-Side and The Lower-Side of Reinforced Concrete Slabs: A Comparative StudyDocument6 pagesHalf-Cell Potential Test From The Upper-Side and The Lower-Side of Reinforced Concrete Slabs: A Comparative StudyANNADURAINo ratings yet

- Eng MathDocument13 pagesEng MathZaKy ZubaidiNo ratings yet

- 1 Brushbond (M)Document3 pages1 Brushbond (M)marzuki0202No ratings yet

- Compressive Strength of BricksDocument5 pagesCompressive Strength of BricksDharmik Med BabraNo ratings yet

- Ecg354-Aggregate Impact TestDocument7 pagesEcg354-Aggregate Impact TestNurin AdlinaNo ratings yet

- Workability Test (Slump Test) Lab ReportDocument10 pagesWorkability Test (Slump Test) Lab ReportMAC DARREL MICHAEL MAC DARREL MICHAELNo ratings yet

- Chapter 8Document12 pagesChapter 8gilbert850507No ratings yet

- Tutorial 1 - Properties and Section ClassificationDocument20 pagesTutorial 1 - Properties and Section ClassificationCyrus Hong100% (1)

- Problem Statement PDFDocument10 pagesProblem Statement PDFDana Al-YafeiNo ratings yet

- We Are From Group 7 in For Subject BFC31602 CONTRACT and ESTIMATION Section 2Document2 pagesWe Are From Group 7 in For Subject BFC31602 CONTRACT and ESTIMATION Section 2Jacksmith LdreckssonNo ratings yet

- Cube TestDocument10 pagesCube Testridhuanzainal100% (1)

- Assignment 1Document32 pagesAssignment 1sharifah atiqahNo ratings yet

- Reason Why You Choose The Type of Tender For The ProjectDocument4 pagesReason Why You Choose The Type of Tender For The Projectling540No ratings yet

- Cost Effective HousingDocument8 pagesCost Effective HousingPriyankaNo ratings yet

- Chapter 3 Pavement Patching and RepairDocument28 pagesChapter 3 Pavement Patching and RepairCollin Legaspina100% (1)

- Chapter 1B Mat FoundationsDocument17 pagesChapter 1B Mat Foundationsmohamed hassan adenNo ratings yet

- Case Studies in Project Management Semester September 2020Document8 pagesCase Studies in Project Management Semester September 2020faroukalias100% (1)

- Advanced Construction Methods and EquipmentsDocument104 pagesAdvanced Construction Methods and EquipmentsKurtNo ratings yet

- Guide Notes On Site SupervisionDocument11 pagesGuide Notes On Site Supervisionalwil144548No ratings yet

- Penetration Test: Lab ReportDocument6 pagesPenetration Test: Lab ReportbawanlavaNo ratings yet

- 06 Emcm5203 T2Document23 pages06 Emcm5203 T2HASMANIRA100% (1)

- BFC 32302 Tutorial 1 - SolutionDocument5 pagesBFC 32302 Tutorial 1 - SolutionLebya UminNo ratings yet

- Preliminary Works To Do Before Starting ConstructionDocument1 pagePreliminary Works To Do Before Starting ConstructionAbok AduogoNo ratings yet

- Compression TestDocument8 pagesCompression TestKaneki SSSNo ratings yet

- A KissDocument22 pagesA KissJoe PhamNo ratings yet

- Cover Letter - TemplateDocument1 pageCover Letter - TemplateJoe PhamNo ratings yet

- Forte Webinar - Chevron 12-2-08 VCPDocument22 pagesForte Webinar - Chevron 12-2-08 VCPJoe PhamNo ratings yet

- Forte Webinar - Chevron 12-2-08 VCPDocument22 pagesForte Webinar - Chevron 12-2-08 VCPJoe PhamNo ratings yet

- Test Preparing 44apDocument2 pagesTest Preparing 44apJoe PhamNo ratings yet

- Homework 1Document1 pageHomework 1Joe PhamNo ratings yet