Professional Documents

Culture Documents

LTS Plant

Uploaded by

Ahmed NahrawyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LTS Plant

Uploaded by

Ahmed NahrawyCopyright:

Available Formats

L.P.

Sales Gas

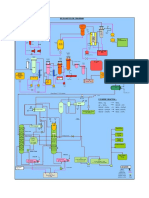

Main Feed 14 S/L 18 S/L C-3 Dehydration Unit A-201 D-202 Z-601 LPG Plant P-201 D-201 A/B/C

E-201 A/B D-203 A/B JT Glycol Reg. Unit E-202 A/B D-204 A/B Fuel D-205

P-201 E-204

Condensate Loading ST 1/2/3/4 E-203 T-201 Condensate From LPG plant P-13 A/B

H-201

P-205

WEPCO : A/Q Gas Field Tittle LTS Plant

Drawn by Date

Rev. No

Sea line from platforms enter first to the primary separator "three parallel separators called slug catcher" D-201 its job is to separate gas from liquid . Gas line goes into two directions: A/Q Production Div. 1. Pipeline to LPG.

/var/www/apps/conversion/tmp/scratch_2/138802058.doc

2. Pipeline to LTS plant. Gas line from D-201 to E-201 loss heat through E-201 from 25c to 6 c then pass through JT valve to reduce its temperature and pressure so condensate start to build up until reaching D-203 to separate three mean components: 1. Rich glycol injected before in the line. 2. Condensate goes to E-202 to rise its temperature. 3. Low pressure sales gas that firstly heated and compressed to the national natural gas network P, T. After the glycol has been regenerated in the glycol regeneration Unit "D-210" it pass through a closed loop in D-203 to reduce its temperature before injection. Condensate from E-202 goes through D-205 "surge drum". Liquid line from D-201 goes to D-204 at low pressure to help gas separation from liquid then this liquid goes to surge drum D-205 at 10 bar and gas goes to D-203. D-205 separate three phase water, condensate and gas. 1. Gas goes to (Fuel gas package and Flair). 2. Condensate to E-203 cools down before distillation tower T-201. T-201 separate condensate component by using temperature distribution on the tower. Up products goes into a loop (first to air cooler A-201then to D-202 "Accumulator" which then goes in two directions reflux pump then tower again OR to dehydration unit ). Down products goes to 1. To pump P-205 then to heater H-201 to help in vaporization and maintaining tower temperatures. 2. To E-204 then to storage tank Gas from D-202 goes to Dehydration unit "MEG liquid desiccant unit" then to C-3 compressor to increase pressure from 6 to 18 Kg/cm2 then to LPG plant.

/var/www/apps/conversion/tmp/scratch_2/138802058.doc

You might also like

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Metric Tons Day Ammonia PlantDocument34 pagesMetric Tons Day Ammonia PlantEleonoraNo ratings yet

- Static & Rotating EquipmentDocument6 pagesStatic & Rotating EquipmentAnonymous ZPV7AKaBANo ratings yet

- Ammonia Equvments DrawingDocument43 pagesAmmonia Equvments DrawingSaad KhanNo ratings yet

- Operation 300 (Crude Methanol Distillation Unit)Document2 pagesOperation 300 (Crude Methanol Distillation Unit)Shoaib AliNo ratings yet

- 200 AREA: OxyhydrochlorinationDocument2 pages200 AREA: OxyhydrochlorinationAnderson de Campos PaimNo ratings yet

- Process Flow Diagram of "Ammonia Feedstock Changeover Project"Document34 pagesProcess Flow Diagram of "Ammonia Feedstock Changeover Project"mohammedNo ratings yet

- Operation of A Distillate Hydrot UnitDocument18 pagesOperation of A Distillate Hydrot UnitFranklin RevillNo ratings yet

- Multi Heat Plumbing Schematic PDFDocument2 pagesMulti Heat Plumbing Schematic PDFParameswararao BillaNo ratings yet

- Quench Tower (Gcu-2), ZeeshanDocument18 pagesQuench Tower (Gcu-2), ZeeshanAnkit Mehrotra100% (1)

- Fault List of Unit-I Emd-IDocument5 pagesFault List of Unit-I Emd-IMCR RGTPP Khedar, HisarNo ratings yet

- Ethylene UnitsDocument20 pagesEthylene UnitsLindah Turson100% (3)

- Chennai Petroleum Corporation LimitedDocument1 pageChennai Petroleum Corporation Limitedv.murugesanNo ratings yet

- Indirect Fired HeaterDocument3 pagesIndirect Fired Heatermatteo2009No ratings yet

- Air Blue UFC ChillerDocument130 pagesAir Blue UFC ChillerAashanram SayeeramNo ratings yet

- RG Plant Flow DiagramDocument1 pageRG Plant Flow DiagramAmit KatiyarNo ratings yet

- HPC Stage II 23417Document18 pagesHPC Stage II 23417HarryBouterNo ratings yet

- Vdocuments - MX 1620 Ethylene Recovery Unitpptx 1601970425506Document31 pagesVdocuments - MX 1620 Ethylene Recovery Unitpptx 1601970425506Shabir MansuriNo ratings yet

- Module ID Equipment Tag NoDocument7 pagesModule ID Equipment Tag NovinodNo ratings yet

- LPG RecoveryDocument5 pagesLPG RecoverymusaveerNo ratings yet

- Air Products Model Number Reference GuideDocument20 pagesAir Products Model Number Reference GuideIgnatius ReillyNo ratings yet

- Versati Hydrobox Type GRS-CQ /I: AccessoriesDocument3 pagesVersati Hydrobox Type GRS-CQ /I: Accessoriesdino_pNo ratings yet

- Production of AnilineDocument16 pagesProduction of AnilineNaixt Cabudz100% (2)

- Brema C150Document5 pagesBrema C150Queno QuenoNo ratings yet

- PIP Accepted IdeasDocument9 pagesPIP Accepted IdeasSuresh RamakrishnanNo ratings yet

- Alweiller Pump BrochureDocument20 pagesAlweiller Pump BrochureHector MaldonadoNo ratings yet

- Cat - Dcs.sis - Controller 953DDocument2 pagesCat - Dcs.sis - Controller 953DAlberto CrespoNo ratings yet

- 325dl Electric PDFDocument4 pages325dl Electric PDFaeylxdNo ratings yet

- 2GR FE CoolingDocument36 pages2GR FE CoolingLuks FernandezNo ratings yet

- 15 & 16 Equipment ListDocument29 pages15 & 16 Equipment Listhekayat71No ratings yet

- Amine Treating UnitDocument3 pagesAmine Treating UnitAGPNo ratings yet

- Carlyle Semi HermeticsDocument38 pagesCarlyle Semi Hermeticscolive.pt100% (1)

- Industrial Training Presentation: PETRONAS Chemicals Methanol Labuan Sdn. BHDDocument9 pagesIndustrial Training Presentation: PETRONAS Chemicals Methanol Labuan Sdn. BHDAbdul AzizNo ratings yet

- SD 110 Step 1 Training EngineDocument62 pagesSD 110 Step 1 Training Enginemliugong97% (34)

- Gas Plant - 3Document67 pagesGas Plant - 3viettanctNo ratings yet

- P&id AmoniacoDocument2 pagesP&id AmoniacodiexboyNo ratings yet

- Art 11 PDFDocument3 pagesArt 11 PDFantonkiryushinNo ratings yet

- Operation 100 (Steam Reforming Unit)Document5 pagesOperation 100 (Steam Reforming Unit)Shoaib AliNo ratings yet

- (Project Eco) Latest Semifull Half Without Part RogerDocument35 pages(Project Eco) Latest Semifull Half Without Part RogerRoger FernandezNo ratings yet

- 04 Actuator EnglDocument14 pages04 Actuator Englsumantabal_uceNo ratings yet

- Script RavenDocument2 pagesScript RavenravenNo ratings yet

- GHE (Gas Heat Exchanger) LT ECO PDFDocument37 pagesGHE (Gas Heat Exchanger) LT ECO PDFMallinatha PNNo ratings yet

- Parameters of Different Heat ExchangersDocument2 pagesParameters of Different Heat ExchangersCuando la dictadura es un hecho, la Revolución es un derechoNo ratings yet

- Export Pricelist 2013Document80 pagesExport Pricelist 2013Ion VasileNo ratings yet

- Plano Electrico 330CL DKYDocument2 pagesPlano Electrico 330CL DKYAnonymous Dq7m7Hq7ar50% (2)

- Equipment List & Design Pressure-TemperatureDocument2 pagesEquipment List & Design Pressure-Temperatureaike_5No ratings yet

- D10T Track-Type Tractor Power Train System: Rjg1-UpDocument2 pagesD10T Track-Type Tractor Power Train System: Rjg1-UpJHOSMAR_22No ratings yet

- ExcavatorDocument2 pagesExcavatorHelar W. Cutipa Machaca50% (2)

- HiluxDocument11 pagesHiluxCarlos Eduardo Zelidon100% (2)

- EC313 Valves Test.Document3 pagesEC313 Valves Test.HosseinNo ratings yet

- Plano Electrico RM500Document18 pagesPlano Electrico RM500Pablo Gaspar D'Agostini AmengualNo ratings yet

- Confrimed Equipment Tag Numbers For Butadiene ProjectDocument3 pagesConfrimed Equipment Tag Numbers For Butadiene ProjectDana GuerreroNo ratings yet

- VICOT Pompa de Caldura PDFDocument14 pagesVICOT Pompa de Caldura PDFOarga CalinNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Misalignment of The Exhaust Manifold and BellowsDocument5 pagesMisalignment of The Exhaust Manifold and BellowsAhmed NahrawyNo ratings yet

- Fuel Metering Valve Problem: TroubleshootingDocument2 pagesFuel Metering Valve Problem: TroubleshootingAhmed NahrawyNo ratings yet

- Failures of Cylinder Head Valves On G3500C and G3500E Generator Set Engines (1100, 1105, 1121)Document5 pagesFailures of Cylinder Head Valves On G3500C and G3500E Generator Set Engines (1100, 1105, 1121)Ahmed Nahrawy100% (1)

- AutomotiveDocument124 pagesAutomotiveAhmed Nahrawy100% (9)

- ASME Pressure Transient Flow Forces (Manring and Zhang)Document5 pagesASME Pressure Transient Flow Forces (Manring and Zhang)Ahmed NahrawyNo ratings yet

- 966F Wheel Loader Electrical SystemDocument2 pages966F Wheel Loader Electrical SystemAhmed Nahrawy82% (11)

- 966F Wheel Loader Electrical SystemDocument2 pages966F Wheel Loader Electrical SystemAhmed Nahrawy82% (11)

- Pipeline Construction PDFDocument3 pagesPipeline Construction PDFAhmed Nahrawy100% (1)

- Pitch Diameter, DDocument2 pagesPitch Diameter, DAhmed NahrawyNo ratings yet

- 966F & 966F Series II Wheel Loaders Hydraulic SystemDocument2 pages966F & 966F Series II Wheel Loaders Hydraulic SystemAhmed Nahrawy100% (7)

- K Value of FittingsDocument4 pagesK Value of FittingsJoydip Misra100% (6)

- Well TestingDocument25 pagesWell TestingAhmed Nahrawy100% (3)