Professional Documents

Culture Documents

ISO 10816 Vibration Severity Levels

Uploaded by

gsaiprasathCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ISO 10816 Vibration Severity Levels

Uploaded by

gsaiprasathCopyright:

Available Formats

BAppendix B General Severity Level Guidelines

When considering severity levels, be aware that standards can only provide general guidelines to determine initial alarm settings. Such guidelines should never substitute experience and good judgement. The most reliable method of determining alarm settings is to trend vibration readings over time, establish baseline values and alarm settings above baseline values.

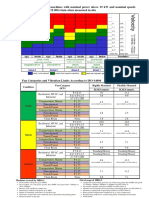

Vibration measured in Velocity

For vibration velocity, ISO standards, such as ISO 10816, First Edition 1995, or VDI 2056 guidelines, are generally accepted. ISO 10816 with the title Mechanical vibration Evaluation of machine vibration by measurements on nonrotating parts consists of six parts. Part 1 (10816-1) determines general guidelines and is followed by the additional parts of ISO 10816, for example Part 2 (108162) for land-based steam turbines and generators in excess of 50 MW with normal operating speeds of 1500 RPM, 1800 RPM, 3000 RPM and 3600 RPM. The following severity chart is in accordance with the ISO 10816-2 guidelines. For exceptions to this guideline and for more information, reference the ISO 10816-2 document.

Machine Condition Transmitter (MCT) User Manual

B-1

General Severity Level Guidelines Vibration measured in Velocity

ISO 10816-2 Speed (RPM) Velocity mm/sec RMS 11.8 10.0 8.5 7.5 5.3 3.8 2.8 1.4 0.0

Steam Turbines and Generators 1500 or 1800 3000 or 3600 Damage occurs

Restricted Unrestricted Newly

Operation Operation Commissioned Machinery

Table B - 1. Vibration Severity Chart ISO 10816-2. Industrial machines with nominal power above 15 kW and nominal speeds between 120 RPM and 15000 RPM when measured in position are covered by ISO 10816-3. The machines are separated into 4 different groups: Group 1: Large machinery and electrical machines with shaft height greater than 315 mm that are normally equipped with sleeve bearings. Group 2: Medium-size machines and electrical machines with shaft height between 160 mm and 315 mm that are normally equipped with rolling element bearings and operate at speeds above 600 RPM. Group 3: Pumps with multivane impellers and separate drivers with rated power above 15 kW. Machines of this

B-2 Machine Condition Transmitter (MCT) User Manual

General Severity Level Guidelines Vibration measured in Velocity

group may be equipped with sleeve or rolling element bearings. Group 4: Pumps with multivane impellers and with integrated drivers that are equipped with sleeve or rolling element bearings. ISO 10816-3 Rated Power Machinery Group 2&4 15 kW 300 kW Machinery Group 1&3 Group 1: 300 kW 50 MW Group 3: above 15 kW occurs

Velocity

mm/sec RMS Damage

11.0 7.1 4.5 3.5 2.8 2.3 1.4 0.7 0.0

Foundation Rigid

Restricted Unrestricted

Operation Operation

Newly

Commissioned

Machinery Flexible

Flexible Rigid Table B - 2. Vibration Severity Chart ISO 10816-3.

Mechanical Condition Transmitter (MCT) User Manual

B-3

General Severity Level Guidelines Vibration Enveloped Acceleration Measurements

Vibration Enveloped Acceleration Measurements

Severity levels for machine vibration and bearing defect detection by means of the enveloping technique are needed to classify the machine condition according to standards and practical guidelines. For enveloped acceleration in all forms, severity levels are related to speed and bearing size. The bearing size is generally related to the load capabilities of the machine. The higher the speed, the higher the energy generated by impacts as elements roll over bearing damage. The relation: Maximum shaft speed times shaft diameter has a maximum, depending on the bearing technology. Notice that for bigger bearings the speed is limited, and therefore, the severity levels are also limited. Carefully select the severity levels for enveloped acceleration using machine knowledge. Sensor location and sensor installation is important for successful machine monitoring. The boundaries between different states of severity conditions are less defined. Comparative and relative judgement methods are preferred above absolute judgement and the application of standards. For creating a comparative measurement, the process control system is able to create a trend of the vibration signal. This signal can be compared against a baseline overall measurement of that measurement point, with the knowledge that the machine is running under normal conditions. In many cases, periodic measurements have been performed on equipment before a permanent monitor (such as the MCT system) is installed. The knowledge of those measurements and the machine behavior provides a good indication of effective alarm level settings.

B-4

Machine Condition Transmitter (MCT) User Manual

General Severity Level Guidelines Vibration Enveloped Acceleration Measurements

100

To be used with CMSS793, 797 accelerometers CMVA55, CMVA320, filter 3, fmax=30,000 CPM, pk-pk reading.

33.3

10

3600 3000 1800 1500 RPM 1200 900 600 400 200

3.30

100

0.33

0.1 10 100

0.03 1000

Shaft Diameter (mm)

Figure B - 1. Enveloped Acceleration Alarm Guidelines (Fmax = 60,000 CPM). To utilize the above chart, the following parameters must be known: Bearing bore diameter in mm (indicates load) Shaft speed in RPM

Assumptions for using the above chart are necessary as deviations from standardized data collection greatly affect enveloped acceleration readings. Assumptions are as follows: Filter 3 = 500-10,000 Hz Fmax = 60,000 CPM / 1,000 Hz A scaling factor is required for other Fmax values. A scaling equation is provided in Part II. Sensor = CMSS793 or CMSS797 or MCD probe Detection = Peak to Peak

Mechanical Condition Transmitter (MCT) User Manual

Alert Setting (gE) (Scale is 1/3 of Danger Scale)

Danger Setting (gE)

B-5

General Severity Level Guidelines Vibration Enveloped Acceleration Measurements

Perform measurements with the machine operating under normal conditions. For example, when the rotor and the main bearings have reached their normal steady operating temperatures and with the machine running under its normal rated condition (at rated voltage, flow, pressure, and load). To obtain the most accurate readings, enveloped acceleration measurements require probe placement in the maximum load zone, or as close as possible to the maximum load zone within the measured bearing or gear box. Example Bearing bore diameter: Shaft speed: Fmax: 100 mm 1800 RPM 60,000 CPM

Use the chart in Figure B-1 to determine this enveloped acceleration measurements alert and danger alarm settings: Locate 100 mm on the shaft diameter axis. Follow the vertical line representing 100 mm to the point where it intersects the 1800 RPM running speed line. This is your reference point. From your reference point, follow the horizontal lines left to the danger settings axis to determine your initial danger alarm setting (7.5 gE). From your reference point, follow the horizontal lines right to the alert settings axis to determine your initial alert alarm setting (2.5 gE). Use the Scaling Factor chart (Figure B-2).

B-6

Machine Condition Transmitter (MCT) User Manual

General Severity Level Guidelines Vibration Enveloped Acceleration Measurements

1.40 1.20

Scaling Factor

1.00 0.80 0.60 0.40 0.20 0.00 0 500 1000 1500 2000

Fmax (Hz)

Figure B - 2. Scaling Factor for Fmax Compensation for Enveloped Acceleration Measurements. The definition for an alarm condition for the enveloped acceleration transmitter module also depends on the application. Alarms can be a warning that a certain condition has occurred and that further analysis is required. Based upon those results, a decision must be made on further required actions. The MCT is then used as a monitoring device. The alarm condition can also be used to take direct action. In this case the MCT module is fulfilling a protective task together with the process control / relay system. The software CMSW5000 Atlas For Windows features a calculator for enveloped acceleration alarm settings and is based on identical assumptions. For more information please visit our website www.skfcm.com, select News and download Revolution 6, Number 2

Mechanical Condition Transmitter (MCT) User Manual B-7

You might also like

- Condition Monitoring of Centrifugal Blower Using Vibration Analysis PDFDocument10 pagesCondition Monitoring of Centrifugal Blower Using Vibration Analysis PDFJose PradoNo ratings yet

- PeakVue TrainingDocument98 pagesPeakVue TrainingThyagaraju Palisetty100% (5)

- Vibration Standardss ISO10816Document24 pagesVibration Standardss ISO10816Aswartha Technical Services67% (3)

- Ge Severity Chart PDFDocument1 pageGe Severity Chart PDFgsaiprasathNo ratings yet

- Limit Table According To ISO (10816-3 and 14694)Document1 pageLimit Table According To ISO (10816-3 and 14694)Muhammad Haroon67% (3)

- Vibration Analysis Measurement ManualDocument215 pagesVibration Analysis Measurement Manualronfrend100% (1)

- BS 7882 - 2008 PaperDocument25 pagesBS 7882 - 2008 PaperMohamed Naser0% (1)

- Iso 10816-5-2000 7Document1 pageIso 10816-5-2000 7selmir_9No ratings yet

- Proven Method For Specifying Both Six Spectral Alarm Bands As Well As Narrowband Alarm EnvelopesDocument4 pagesProven Method For Specifying Both Six Spectral Alarm Bands As Well As Narrowband Alarm EnvelopesVILLANUEVA_DANIEL2064No ratings yet

- CMOS transistor level schematics and stick diagrams for logic gatesDocument8 pagesCMOS transistor level schematics and stick diagrams for logic gatesDeepak Verma100% (3)

- Coupled Vibration Analysis For PumpDocument0 pagesCoupled Vibration Analysis For Pumpilmu2No ratings yet

- ISO VA DocumentDocument20 pagesISO VA DocumentgsaiprasathNo ratings yet

- Electric Motor Diagnostics Defect Frequencies and Data ColleDocument51 pagesElectric Motor Diagnostics Defect Frequencies and Data ColleSubrata Dubey50% (2)

- Vibration Standards ISO 10816Document33 pagesVibration Standards ISO 10816Geremi Cano Frias100% (7)

- Boq of MEP For FactoryDocument37 pagesBoq of MEP For FactoryLi LiuNo ratings yet

- VDI 2056 RefDocument4 pagesVDI 2056 RefManan Vadher0% (2)

- AMPLITUDE MODULATION Versus BEATSDocument5 pagesAMPLITUDE MODULATION Versus BEATSHaitham YoussefNo ratings yet

- Vibration Limits As Per Iso 10816 StandardsDocument1 pageVibration Limits As Per Iso 10816 StandardsJean-Baptiste Lebegue84% (25)

- Vibration MonitoringDocument67 pagesVibration MonitoringApurv Khandelwal100% (4)

- Iso 10816Document4 pagesIso 10816spbhaskaran28No ratings yet

- Vibration Values Guide Maintenance of Wind TurbinesDocument4 pagesVibration Values Guide Maintenance of Wind TurbinesManel Montesinos100% (1)

- John White Videos of Spooky2 InterfaceDocument24 pagesJohn White Videos of Spooky2 InterfaceTimothy M HallNo ratings yet

- ISO 10816 Vibration Severity LevelsDocument7 pagesISO 10816 Vibration Severity Levelsgsaiprasath100% (2)

- Introduction To PeakvueDocument55 pagesIntroduction To PeakvueAhmed Nazeem100% (4)

- 10816Document6 pages10816Umair MaqboolNo ratings yet

- Bs-Iso-10816-6-1995 A1-2015Document14 pagesBs-Iso-10816-6-1995 A1-2015Alfrett Cabrera100% (1)

- Vibration StandardDocument3 pagesVibration StandardelrajilNo ratings yet

- Vibration Analysis and Acceptance StandardDocument23 pagesVibration Analysis and Acceptance StandardEstebanRivera100% (2)

- NTN Bearing Bpfo&BpfiDocument61 pagesNTN Bearing Bpfo&BpfishantanusamajdarNo ratings yet

- Process Monitoring of Hydro Turbine VibrationsDocument8 pagesProcess Monitoring of Hydro Turbine VibrationsreddyloginNo ratings yet

- ClassDAmps ReviewBook LRDocument58 pagesClassDAmps ReviewBook LRAlejandroVCMXNo ratings yet

- Iso 10816Document2 pagesIso 10816satyandaru100% (3)

- ISO 2372 WithDocument12 pagesISO 2372 WithEcruz Cruz L100% (2)

- Detection of Ski Slopes in Vibration SpectrumsDocument7 pagesDetection of Ski Slopes in Vibration SpectrumsjeyaselvanmNo ratings yet

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionFrom EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionNo ratings yet

- As 1359.114-1997 Rotating Electrical Machines - General Requirements Vibration Measurements and LimitsDocument8 pagesAs 1359.114-1997 Rotating Electrical Machines - General Requirements Vibration Measurements and LimitsSAI Global - APACNo ratings yet

- Analisis de Vibraciones Mecanicas SKFDocument31 pagesAnalisis de Vibraciones Mecanicas SKFJhonathan GarciaNo ratings yet

- AMS Suite: Machinery Health Manager Data & MonitoringDocument39 pagesAMS Suite: Machinery Health Manager Data & MonitoringrharaksiNo ratings yet

- Machine Vibration Standards and Acceptance LimitsDocument66 pagesMachine Vibration Standards and Acceptance Limitssuper2274100% (2)

- Extracto ISO 10816Document10 pagesExtracto ISO 10816clroyo9475No ratings yet

- Detect Machinery Faults by Using Peak VueDocument13 pagesDetect Machinery Faults by Using Peak VueHarold Alconz100% (2)

- Mobility Trends Whats Ahead For Automotive SemiconductorsDocument11 pagesMobility Trends Whats Ahead For Automotive SemiconductorsLarryNo ratings yet

- Vibration Key ChartsDocument12 pagesVibration Key ChartsgsaiprasathNo ratings yet

- ISO 10816 ChartDocument1 pageISO 10816 Chartgsaiprasath100% (3)

- ISO 10816-1 - Vibration at Load ConditionDocument2 pagesISO 10816-1 - Vibration at Load ConditionAZZAF ChannelNo ratings yet

- Iso 2372Document10 pagesIso 2372WulaNda Rika75% (4)

- ISO 10816 Standards - Vibration Monitoring Non Rotating MachinesDocument1 pageISO 10816 Standards - Vibration Monitoring Non Rotating MachinesJoe SmithNo ratings yet

- ISO 7919-1 Mechanical Vibration Standard Measurements On Rotating Parts PDFDocument24 pagesISO 7919-1 Mechanical Vibration Standard Measurements On Rotating Parts PDFLuis RomeroNo ratings yet

- ISO 10816 Vibration Severity StandardsDocument1 pageISO 10816 Vibration Severity StandardsDhi Adhi67% (3)

- 37.vibration Chart Appendix)Document3 pages37.vibration Chart Appendix)Petroen100% (3)

- 303mills PDFDocument32 pages303mills PDFfaisalNo ratings yet

- Figure 1 - Typical FFT Showing Gear MisalignmentDocument4 pagesFigure 1 - Typical FFT Showing Gear MisalignmentDario SesarNo ratings yet

- Mech Vibrartion Lab2Document13 pagesMech Vibrartion Lab2Edryna AntasyaNo ratings yet

- High-Side Motor Current Monitoring For Over-Current ProtectionDocument3 pagesHigh-Side Motor Current Monitoring For Over-Current Protectionbookreader1968No ratings yet

- Iso TC 108 SC 2 N 666Document58 pagesIso TC 108 SC 2 N 666Rahul B. WaghaleNo ratings yet

- Machine Evaluator Series: Advanced Handheld Condition Monitoring InstrumentDocument12 pagesMachine Evaluator Series: Advanced Handheld Condition Monitoring InstrumentMohd Bahruddin Ab GhaparNo ratings yet

- Analysis Techniques: TrendingDocument5 pagesAnalysis Techniques: TrendingVasile RaduNo ratings yet

- A 837 eDocument2 pagesA 837 eKhalida MuddasserNo ratings yet

- 10816-3 GuidelinesDocument1 page10816-3 GuidelinesThyagaraju PalisettyNo ratings yet

- Data Acquisition: Detectors: TransducersDocument11 pagesData Acquisition: Detectors: TransducersVasile RaduNo ratings yet

- 3G3RV V1Document76 pages3G3RV V1Omiga HatemNo ratings yet

- Ways To Measure The Force Acting On A Rotating Shaft: What Is Torque?Document5 pagesWays To Measure The Force Acting On A Rotating Shaft: What Is Torque?chandununnaNo ratings yet

- Familiarization With and Performance Check Of, Vibration Testing & Measuring EquipmentDocument33 pagesFamiliarization With and Performance Check Of, Vibration Testing & Measuring EquipmentOmar Saleem100% (1)

- Banco DresserDocument8 pagesBanco DresserEder Alonso Cardenas CepedaNo ratings yet

- Monarch 1000 ManualDocument10 pagesMonarch 1000 ManualABRIL19No ratings yet

- Expt. 1 Experimental Verification of Dynamic Balancing of Rotating MassesDocument7 pagesExpt. 1 Experimental Verification of Dynamic Balancing of Rotating MassesPranjalNo ratings yet

- Computerised Universal Testing Machine for Materials TestingDocument12 pagesComputerised Universal Testing Machine for Materials TestingEr Hemant Kumar SahNo ratings yet

- Workshop Apc01 2006 eDocument29 pagesWorkshop Apc01 2006 eRogério PereiraNo ratings yet

- Aopen Laptop Motherboard Schematic DiagramDocument47 pagesAopen Laptop Motherboard Schematic DiagrampukymottoNo ratings yet

- Honeywell Stt3000Document106 pagesHoneywell Stt3000zakaria_hsnNo ratings yet

- Multiplexing: Techniques in Optical Networks: WDMDocument28 pagesMultiplexing: Techniques in Optical Networks: WDMSahil SinghNo ratings yet

- APP 751A: SEL-751A Feeder Protection RelayDocument5 pagesAPP 751A: SEL-751A Feeder Protection RelayBouazzaNo ratings yet

- SXTWL2WH-17/17-65/65V-iVT Multi-band Base Station AntennaDocument4 pagesSXTWL2WH-17/17-65/65V-iVT Multi-band Base Station Antennakai tangNo ratings yet

- MSD - 2-MSD 6 Series Ignition InstructionsDocument24 pagesMSD - 2-MSD 6 Series Ignition InstructionsJessie O.BechaydaNo ratings yet

- Ferroresonance in Power SystemsDocument9 pagesFerroresonance in Power Systems_FlyMan_No ratings yet

- Autonomous Car, Seminar Reports - PPT - PDF - DOC - Presentation - Seminar Report, PDF, PPT, Doc, TopicsDocument5 pagesAutonomous Car, Seminar Reports - PPT - PDF - DOC - Presentation - Seminar Report, PDF, PPT, Doc, Topicsകൂട്ടുകാരിയെ സ്നേഹിച്ച കൂട്ടുകാരൻ100% (1)

- Lesson 2-FM Transmitter TerbaruDocument52 pagesLesson 2-FM Transmitter TerbaruRasyid To HomeworkNo ratings yet

- Spec 2018-02 A00Document17 pagesSpec 2018-02 A00vikasamitabhNo ratings yet

- Design of Mini Tesla Coil: A Industrial Oriented Mini Project Report OnDocument42 pagesDesign of Mini Tesla Coil: A Industrial Oriented Mini Project Report OnKarthik VanamNo ratings yet

- TDA9302H: Vertical Deflection Output CircuitDocument5 pagesTDA9302H: Vertical Deflection Output Circuittecnico1069No ratings yet

- Construction of DC MachineDocument7 pagesConstruction of DC MachineAnonymous MAit3mlYm0% (1)

- 2021 SSN Combo Spa 28462 Control Base Repair GuideDocument46 pages2021 SSN Combo Spa 28462 Control Base Repair Guidekawon871No ratings yet

- Banshee AC To DC ConversionDocument2 pagesBanshee AC To DC ConversiondannoxyzNo ratings yet

- Speaker Lab ReportDocument2 pagesSpeaker Lab Reportapi-456993701No ratings yet

- Dimensions: OBS4000-18GM60-E5-V1Document3 pagesDimensions: OBS4000-18GM60-E5-V1Vikas JainNo ratings yet

- 1.5KE Series: 1500W Transient Voltage SuppressorDocument6 pages1.5KE Series: 1500W Transient Voltage SuppressorjefriNo ratings yet

- From 2340 To 7200 kVA: Medium Voltage Inverter Station, Customized Up To 7.2 MvaDocument2 pagesFrom 2340 To 7200 kVA: Medium Voltage Inverter Station, Customized Up To 7.2 Mvaanon_b186No ratings yet

- Condition Monitoring Methods, Failure Identification and Analysis For Induction MachinesDocument8 pagesCondition Monitoring Methods, Failure Identification and Analysis For Induction MachinesRamya DeviNo ratings yet

- BodeRules (Rules 4 Drawing Bode Diagrams)Document4 pagesBodeRules (Rules 4 Drawing Bode Diagrams)pardeepkumarrocksNo ratings yet

- Sensors and Actuators: ELEC 483-001Document9 pagesSensors and Actuators: ELEC 483-001Nouman MemonNo ratings yet

- Electronics RegularDocument169 pagesElectronics RegularNazeerNo ratings yet

- Erico TGB TMGBDocument4 pagesErico TGB TMGBrechtman1289No ratings yet

- LV CapacitorsDocument22 pagesLV CapacitorsFlo MircaNo ratings yet