Professional Documents

Culture Documents

Rebar Grades

Uploaded by

Gelbert SilotOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rebar Grades

Uploaded by

Gelbert SilotCopyright:

Available Formats

Rebar Grades

[Top]

Our products are made in accordance with Philippine National Standards for Steel Bars for Concrete Reinforcement, under PNS-49:2002.

Specifications and Grading

[Top]

The three grades under this specification namely, Grades PNS 230, 275, and 415 trace their roots to ASTM specifications. And the terms Structural, Intermediate, and Hightensile originated from earlier versions of ASTM-A615 but remained unchanged in deference to custom and familiarity among users. The table below provides a handy reference as to the common understanding in the market regarding these grades.

ASTM vs PNS Codes Popular Nomenclature

Grade 33 / PNS 230 Grade 40 / PNS 275 Grade 60 / PNS 415 Structural Grade Intermediate Grade High-Tensile Grade

Typical Application

Low-rise Buildings and Low Loading Conditions Medium-rise Structures / Infrastructure Work Medium & High-rise Structures / Infrastructure

The three grades are distinguished by the different color markings painted at the ends of each bar, as shown in the following table:

Weldability of a Rebar

[Top]

It must be noted that, in the current PNS 49, rebars are further categorized into weldable and non-weldable grades. The difference between the two categories is primarily rooted in their different chemical compositions and carbon equivalents (CEQ). Despite the different nomenclatures and their connotations, both Weldable and Non-weldable grades can actually be welded. However, the relatively lower carbon content and CEQ of the so-called weldable grade does make it easier to weld without having to worry about pre-heating and

post-heating requirements and procedures, that is a concern highlighted especially in temperate situations.

Rebar Sizes

[Top]

The standard sizes that the Company manufactures and sells are as follows: 10mm, 12mm, 16mm, 20mm, 25mm, 28mm, 32mm, and 36mm. For special orders, it can also make 40mm and 50mm bars.

The Nominal Size of a Rebar

[Top]

For both the plain round bar and the rebar, the word size and nominal diameter are used interchangeably. For a rebar, alternatively known as a deformed steel bar, its size specifically refers to the size of a plain round bar having the same weight per meter as the rebar. A specific size of plain round bar refers to its nominal diameter. This size also refers to the diameter of a circular plain round bar having a certain unit mass or weight per meter. A plain round bar and a rebar of the same size will have the same unit mass or weight per meter of bar.

The Proper Way of Measuring a Plain Round Bar

[Top]

For a plain round bar, determining its 'size' involves simply taking a direct physical measurement of its diameter since its circular cross section should remain quite uniform throughout its length. A plain round bar is considered to be dimensionally acceptable if its diameter, as measured, falls within the dimensional tolerances allowed by the Standard.

The Proper Way of Measuring a Rebar

[Top]

A rebar however is not measured in the same way as a plain round bar. Because of its nonuniform cross section, a rebar must comply with the allowable Variation in Mass (VIM) in lieu of measurement of its diameter. Checking for this VIM involves taking and weighing one meter of rebar and comparing the findings against the standard value.

Weight Tolerance

[Top]

Because variation in cross sectional area occurs during hot rolling, a corresponding variation in linear weight is to be expected. For this reason, PNS-49 provides for an allowable variation in mass (VIM) of 6%, measured using one meter of rebar.

Length Tolerance

[Top]

The cut length of a rebar varies as well because of shrinkage as it cools down. The standard however limits this shrinkage, and the minimum lengths of the finished rebar are shown below.

Std. Length (m)

6.0 7.5 9.0 10.5 12.0

Min. Acceptable Length (m)

5.960 7.453 8.935 10.440 11.940

Our rebar comes in these commercial lengths: 6.0, 7.5, 9.0, 10.5, and 12.0 meters. Special lengths of 13.5 and 15.0 meters are subject to special orders and negotiations.

Mechanical Property Specifications

[Top]

MECHANICAL PROPERTIES Yield Strength, MPa min. Tensile Strength, MPa min. Elongation in 200mm, % min.

18 16 10 8 8 7 20 18 16 14 14 12

Class

Grade

Specimen

Bending Angle

Diameter of Pin (d = nominal diameter of specimen)

3d 4d 4d 5d 5d 6d 3d 4d 4d 5d 5d 6d

Hot-Rolled NonWeldable Deformed Steel Bar

230 275 415 230

230 275 415 230 275 415*

390 480 620 390 480 550**

D<25mm D25mm D<25mm D25mm D<25mm D25mm D<25mm D25mm D<25mm D25mm D<25mm D25mm

180 180 180 180 180 180

Hot-Rolled Weldable Deformed Bar

275 415

* Maximum yield strength of Weldable steel bars shall not exceed ** Tensile strength shall not be less than 1.25 times the actual yield strength

540

MPa

Surface Deformations Specifications

[Top]

DEFORMATION REQUIREMENTS Nominal Diameter

10 12 16 20 25 28 32 36

Max. Average Spacing of Lugs

7.0 8.4 11.2 14.0 17.5 19.6 22.4 25.2

Height Tolerance of Lugs Minimum

0.4 0.5 0.7 1.0 1.2 1.4 1.6 1.8

Maximum

0.8 1.0 1.4 2.0 2.4 2.8 3.2 3.6

Max. Summation of Gaps (mm)

7.8 9.4 12.6 15.7 19.6 22.0 25.1 27.5

Table of Standard Weights

[Top]

STANDARD WEIGHT OF DEFORMED ROUND STEEL BARS Bar Diameter mm

10 12 16 20 25 28 32 36

Unit Weight Kg/m

0.616 0.888 1.578 2.466 3.853 4.834 6.313 7.990

Bar Commercial Length 6.0 m

3.696 5.328 9.468 14.796 23.118 29.004 37.878 47.940

7.5 m

4.620 6.660 11.835 18.495 28.898 36.255 47.348 59.925

9.0 m

5.544 7.992 14.202 22.194 34.677 43.506 56.817 71.910

10.5 m

6.468 9.324 16.569 25.893 40.457 50.757 66.287 83.895

12.0 m

7.392 10.656 18.936 29.592 46.236 58.008 75.756 95.880

You might also like

- ANGLE BAR SIZES in The PhilippinesDocument5 pagesANGLE BAR SIZES in The PhilippinesTeodoro Quintana100% (2)

- Metal Roofing Prices: Structural Steel Price ListDocument5 pagesMetal Roofing Prices: Structural Steel Price ListRizza Salde100% (1)

- DPWH Min. Pavement Thickness & Width of Nat'l. Road With DESIGN COMPUTATION PDFDocument8 pagesDPWH Min. Pavement Thickness & Width of Nat'l. Road With DESIGN COMPUTATION PDFRandy CernaNo ratings yet

- Estimate Guide-Dry WallsDocument1 pageEstimate Guide-Dry WallsVholts Villa Vitug100% (5)

- TemfacilDocument9 pagesTemfacilBernard100% (1)

- Lecture 3.a Analysis and Design of One-Way SlabDocument50 pagesLecture 3.a Analysis and Design of One-Way SlabMary Dominique OnateNo ratings yet

- Item 311Document85 pagesItem 311MewnEProwt100% (2)

- ASEP Steel Handbook PDFDocument261 pagesASEP Steel Handbook PDFMark Arboleda Gumamela100% (7)

- Plan For Bacani Bridge (RCDG)Document15 pagesPlan For Bacani Bridge (RCDG)Glyn A. BrinquezNo ratings yet

- Timber Design of A Two Storey HouseDocument92 pagesTimber Design of A Two Storey HouseEmmanuel Lazo80% (5)

- Philippines C Purlins SpecsDocument2 pagesPhilippines C Purlins SpecsChris Cmecs Magadia80% (10)

- Computation of Dead Load Structural Elements Dead LoadsDocument7 pagesComputation of Dead Load Structural Elements Dead LoadsKyle KuzmaNo ratings yet

- Rebar Cutting ListDocument20 pagesRebar Cutting Listleo dumapi100% (2)

- Steel Asia Rebar Shape CodesDocument2 pagesSteel Asia Rebar Shape CodesIya Nicole Lo100% (3)

- Covered Court EstimateDocument31 pagesCovered Court EstimateLizabelleNo ratings yet

- Unit Weight of Rectangular Tubular SteelDocument2 pagesUnit Weight of Rectangular Tubular Steelaj100% (5)

- Estimates Table (Construction)Document3 pagesEstimates Table (Construction)Joe A. Cagas86% (114)

- Fire Ladder DetDocument1 pageFire Ladder Detjay100% (1)

- Boysen PricelistDocument24 pagesBoysen PricelistMike Alar33% (3)

- Defining The NSCP Requirements For The Section Properties of Structural Members of RC BuildingDocument5 pagesDefining The NSCP Requirements For The Section Properties of Structural Members of RC BuildingGinelle Marvida100% (1)

- PNS 49 2020 Rev Std. For Steel Bars For Concrete Reinforcement - SpecificationDocument19 pagesPNS 49 2020 Rev Std. For Steel Bars For Concrete Reinforcement - SpecificationStandpro Testing Center100% (1)

- PNS 49 2019 (Preview) PDFDocument3 pagesPNS 49 2019 (Preview) PDFFrancis Bernales25% (4)

- Standard CHB Sizes Are From Thicknesses of 100mm (4"), 150mm (6") and 200mm (8") X Height of 200mm (8") X Length of 400mm (16")Document7 pagesStandard CHB Sizes Are From Thicknesses of 100mm (4"), 150mm (6") and 200mm (8") X Height of 200mm (8") X Length of 400mm (16")kennysaweg100% (1)

- The NBCP Referral Code SubDocument4 pagesThe NBCP Referral Code SubArcon Solite BarbanidaNo ratings yet

- Philippine Material Prices ReferenceDocument69 pagesPhilippine Material Prices Referencestygwygyr86% (7)

- Minimum Roof Live Loads (NSCP) .Document1 pageMinimum Roof Live Loads (NSCP) .mhergonzales75% (4)

- Angle Bar Steel Weight TableDocument2 pagesAngle Bar Steel Weight Tableyzza88% (17)

- NSCP 2015Document6 pagesNSCP 2015mikollim67% (3)

- DPWH Standard Specification On Aggregate Sub-Base CourseDocument4 pagesDPWH Standard Specification On Aggregate Sub-Base CourseStevenAron100% (4)

- Technical SpecificationsDocument17 pagesTechnical Specificationslarry0lao0iiiNo ratings yet

- Construction Materials Price ListDocument12 pagesConstruction Materials Price ListChristian Gudino0% (1)

- Septic Tank Section DetailsDocument1 pageSeptic Tank Section DetailsKit100% (2)

- Slab Canopy Design SpreadsheetDocument3 pagesSlab Canopy Design Spreadsheetankit kadamNo ratings yet

- Timber Design Project - Design of A Two Storey House (Word File)Document92 pagesTimber Design Project - Design of A Two Storey House (Word File)Emmanuel Lazo90% (20)

- DPWH Blue Book Item ListDocument3 pagesDPWH Blue Book Item ListJan Lawrence Alberto100% (3)

- Covered Court (16m X 30m)Document6 pagesCovered Court (16m X 30m)Engr. D I Y100% (1)

- Vitali Retng Wall (Dupa Format)Document61 pagesVitali Retng Wall (Dupa Format)Bert Eng50% (2)

- Microsoft PowerPoint - ASEP - NSCP 2015 Chapter6 - WOODDocument75 pagesMicrosoft PowerPoint - ASEP - NSCP 2015 Chapter6 - WOODRay Ramilo67% (9)

- General SpecsDocument12 pagesGeneral SpecsKelvene Boy Bravo Silva100% (1)

- SpecificationsDocument7 pagesSpecificationsGaray Atchas100% (1)

- Detail Detail Detail: Schedule of Truss MembersDocument6 pagesDetail Detail Detail: Schedule of Truss MembersSharmane BurlazaNo ratings yet

- Section 418Document17 pagesSection 418mhiiikeeeNo ratings yet

- 4.2 - Design of Singly Reinforced Rectangular Beams Based On NSCP 2015 and Aci 318-14Document24 pages4.2 - Design of Singly Reinforced Rectangular Beams Based On NSCP 2015 and Aci 318-14Marcelo AbreraNo ratings yet

- Concrete Strength ProjectionDocument2 pagesConcrete Strength ProjectionKai de Leon0% (1)

- Typical Detail of Stiffener Column & Beam For Masonry: If More Than 3000 Mm. Span Provide Stiffener Column 3000 3000 3000Document1 pageTypical Detail of Stiffener Column & Beam For Masonry: If More Than 3000 Mm. Span Provide Stiffener Column 3000 3000 3000RRCDC JEEFRY100% (3)

- Purlin & Sagrod Design (NSCP 2015)Document4 pagesPurlin & Sagrod Design (NSCP 2015)Jake Cortez100% (2)

- Revised Plumbing Code of The Philippines - Part16Document2 pagesRevised Plumbing Code of The Philippines - Part16MBA103003No ratings yet

- Estimates 2Document11 pagesEstimates 2Lorna BacligNo ratings yet

- Detailed Unit Price AnalysisDocument1 pageDetailed Unit Price AnalysisRafael Santiago100% (1)

- Pag-Asa Steel Products & Services - Product GuideDocument3 pagesPag-Asa Steel Products & Services - Product GuideroldskiNo ratings yet

- RebarsDocument5 pagesRebarsJohny Lou LuzaNo ratings yet

- Rebar SpecificationsDocument5 pagesRebar SpecificationsJeffrey James AvenidoNo ratings yet

- Rebar SpecificationsDocument5 pagesRebar SpecificationsJeffrey James AvenidoNo ratings yet

- Preheat Ions For A 514 Grade B MaterialDocument2 pagesPreheat Ions For A 514 Grade B Materialjrod64No ratings yet

- PNS Rebars PDFDocument4 pagesPNS Rebars PDFAnthony AngelesNo ratings yet

- Reinforcement SteelDocument7 pagesReinforcement SteelNavneet SoniNo ratings yet

- Reinforcing Steel BarsDocument17 pagesReinforcing Steel BarsRonald BilogNo ratings yet

- Ruukki Hot Rolled Steels Processing of Material Flanging Raex and Optim QCDocument9 pagesRuukki Hot Rolled Steels Processing of Material Flanging Raex and Optim QCM R PatraputraNo ratings yet

- Structural FabricationDocument46 pagesStructural FabricationmithileshNo ratings yet

- Bar STDDocument8 pagesBar STDtushk20100% (1)

- Reinforcing Steel Bars Price List: StructuralDocument1 pageReinforcing Steel Bars Price List: StructuralGelbert SilotNo ratings yet

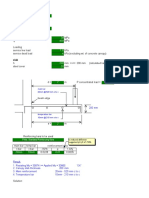

- 2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsDocument26 pages2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsGelbert SilotNo ratings yet

- Social Security System: SSS SeminarsDocument2 pagesSocial Security System: SSS SeminarsGelbert Silot100% (2)

- (ANALYSIS) Why Filipinos Need To Stay at Home Until June (Or Even Longer) PDFDocument13 pages(ANALYSIS) Why Filipinos Need To Stay at Home Until June (Or Even Longer) PDFGelbert SilotNo ratings yet

- Latest FormDocument27 pagesLatest FormGelbert SilotNo ratings yet

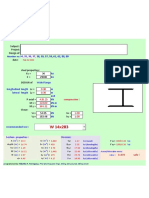

- SFB 2Document1 pageSFB 2Gelbert SilotNo ratings yet

- Columnsteel 1Document1 pageColumnsteel 1Gelbert SilotNo ratings yet

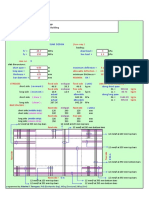

- Design of Angular Member: Top CHPRDDocument2 pagesDesign of Angular Member: Top CHPRDGelbert SilotNo ratings yet

- A Ultimate Load CombinationsDocument1 pageA Ultimate Load CombinationsGelbert SilotNo ratings yet

- Two Way SlabDocument1 pageTwo Way SlabGelbert SilotNo ratings yet

- Column Design/Analysis Software: (Based On The NSCP 2015 Code)Document2 pagesColumn Design/Analysis Software: (Based On The NSCP 2015 Code)Gelbert SilotNo ratings yet

- Column Design/Analysis Software: (Based On The NSCP 2015 Code)Document2 pagesColumn Design/Analysis Software: (Based On The NSCP 2015 Code)Gelbert SilotNo ratings yet

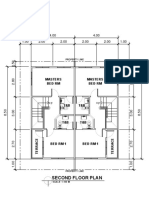

- Masters Bed RM Masters Bed RM: Second Floor PlanDocument1 pageMasters Bed RM Masters Bed RM: Second Floor PlanGelbert SilotNo ratings yet

- Laundry Laundry: Ground Floor PlanDocument1 pageLaundry Laundry: Ground Floor PlanGelbert SilotNo ratings yet

- 12 Date:: 20 Footing Dimension: 230 97.5 16Document1 page12 Date:: 20 Footing Dimension: 230 97.5 16Gelbert SilotNo ratings yet

- Application Special Member PDFDocument20 pagesApplication Special Member PDFGelbert SilotNo ratings yet

- AIA1800 Operator ManualDocument184 pagesAIA1800 Operator ManualZain Sa'adehNo ratings yet

- E Flight Journal Aero Special 2018 Small PDFDocument44 pagesE Flight Journal Aero Special 2018 Small PDFMalburg100% (1)

- Lec 33 - Householder MethodDocument11 pagesLec 33 - Householder MethodMudit SinhaNo ratings yet

- Chronic Kidney DiseaseDocument15 pagesChronic Kidney Diseaseapi-270623039No ratings yet

- ME Eng 8 Q1 0101 - SG - African History and LiteratureDocument13 pagesME Eng 8 Q1 0101 - SG - African History and Literaturerosary bersanoNo ratings yet

- Farmer Producer Companies in OdishaDocument34 pagesFarmer Producer Companies in OdishaSuraj GantayatNo ratings yet

- Lesson PlanDocument2 pagesLesson Plannicole rigonNo ratings yet

- Costbenefit Analysis 2015Document459 pagesCostbenefit Analysis 2015TRÂM NGUYỄN THỊ BÍCHNo ratings yet

- Oracle - Prep4sure.1z0 068.v2016!07!12.by - Lana.60qDocument49 pagesOracle - Prep4sure.1z0 068.v2016!07!12.by - Lana.60qLuis AlfredoNo ratings yet

- The Mantel Colonized Nation Somalia 10 PDFDocument5 pagesThe Mantel Colonized Nation Somalia 10 PDFAhmad AbrahamNo ratings yet

- Equivalent Fractions Activity PlanDocument6 pagesEquivalent Fractions Activity Planapi-439333272No ratings yet

- C C C C: "P P P P PDocument25 pagesC C C C: "P P P P PShalu Dua KatyalNo ratings yet

- Recommendations For Students With High Functioning AutismDocument7 pagesRecommendations For Students With High Functioning AutismLucia SaizNo ratings yet

- PLC Laboratory Activity 2Document3 pagesPLC Laboratory Activity 2Kate AlindajaoNo ratings yet

- Benevisión N15 Mindray Service ManualDocument123 pagesBenevisión N15 Mindray Service ManualSulay Avila LlanosNo ratings yet

- How Drugs Work - Basic Pharmacology For Healthcare ProfessionalsDocument19 pagesHow Drugs Work - Basic Pharmacology For Healthcare ProfessionalsSebastián Pérez GuerraNo ratings yet

- All You Need To Know About Egg YolkDocument7 pagesAll You Need To Know About Egg YolkGolden Era BookwormNo ratings yet

- Theories of International InvestmentDocument2 pagesTheories of International InvestmentSamish DhakalNo ratings yet

- ISO 9001 2015 AwarenessDocument23 pagesISO 9001 2015 AwarenessSeni Oke0% (1)

- MRBR ATR 72 Rev18Document424 pagesMRBR ATR 72 Rev18Juan Forero OrtizNo ratings yet

- Ito Na Talaga Yung FinalDocument22 pagesIto Na Talaga Yung FinalJonas Gian Miguel MadarangNo ratings yet

- LetrasDocument9 pagesLetrasMaricielo Angeline Vilca QuispeNo ratings yet

- Lecturenotes Data MiningDocument23 pagesLecturenotes Data Miningtanyah LloydNo ratings yet

- Chemistry: Crash Course For JEE Main 2020Document18 pagesChemistry: Crash Course For JEE Main 2020Sanjeeb KumarNo ratings yet

- Duavent Drug Study - CunadoDocument3 pagesDuavent Drug Study - CunadoLexa Moreene Cu�adoNo ratings yet

- Digital MetersDocument47 pagesDigital MetersherovhungNo ratings yet

- Gemini Dollar WhitepaperDocument7 pagesGemini Dollar WhitepaperdazeeeNo ratings yet

- Arnold Ventures Letter To Congressional Social Determinants of Health CaucusDocument7 pagesArnold Ventures Letter To Congressional Social Determinants of Health CaucusArnold VenturesNo ratings yet

- Spesifikasi PM710Document73 pagesSpesifikasi PM710Phan'iphan'No ratings yet

- UC 20 - Produce Cement Concrete CastingDocument69 pagesUC 20 - Produce Cement Concrete Castingtariku kiros100% (2)

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyFrom EverandSodium Bicarbonate: Nature's Unique First Aid RemedyRating: 5 out of 5 stars5/5 (21)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlFrom EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlRating: 4 out of 5 stars4/5 (4)

- An Applied Guide to Water and Effluent Treatment Plant DesignFrom EverandAn Applied Guide to Water and Effluent Treatment Plant DesignRating: 5 out of 5 stars5/5 (4)

- Chemical Engineering Design: Principles, Practice and Economics of Plant and Process DesignFrom EverandChemical Engineering Design: Principles, Practice and Economics of Plant and Process DesignRating: 4 out of 5 stars4/5 (16)

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksFrom EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- The Perfumed Pages of History: A Textbook on Fragrance CreationFrom EverandThe Perfumed Pages of History: A Textbook on Fragrance CreationRating: 4 out of 5 stars4/5 (1)

- Distillation Design and Control Using Aspen SimulationFrom EverandDistillation Design and Control Using Aspen SimulationRating: 5 out of 5 stars5/5 (2)

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- A New Approach to HAZOP of Complex Chemical ProcessesFrom EverandA New Approach to HAZOP of Complex Chemical ProcessesNo ratings yet

- Handbook of Cosmetic Science: An Introduction to Principles and ApplicationsFrom EverandHandbook of Cosmetic Science: An Introduction to Principles and ApplicationsH. W. HibbottRating: 4 out of 5 stars4/5 (6)

- Pulp and Paper Industry: Emerging Waste Water Treatment TechnologiesFrom EverandPulp and Paper Industry: Emerging Waste Water Treatment TechnologiesRating: 5 out of 5 stars5/5 (1)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Coulson and Richardson’s Chemical Engineering: Volume 2B: Separation ProcessesFrom EverandCoulson and Richardson’s Chemical Engineering: Volume 2B: Separation ProcessesAjay Kumar RayNo ratings yet

- Cathodic Protection: Industrial Solutions for Protecting Against CorrosionFrom EverandCathodic Protection: Industrial Solutions for Protecting Against CorrosionNo ratings yet

- Bioinspired Materials Science and EngineeringFrom EverandBioinspired Materials Science and EngineeringGuang YangNo ratings yet

- Transport Phenomena in Heat and Mass TransferFrom EverandTransport Phenomena in Heat and Mass TransferJ.A. ReizesRating: 5 out of 5 stars5/5 (1)

- Fundamentals of Risk Management for Process Industry EngineersFrom EverandFundamentals of Risk Management for Process Industry EngineersNo ratings yet