Professional Documents

Culture Documents

Subchannel Analysis Method at A Glance

Uploaded by

Syeilendra PramudityaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Subchannel Analysis Method at A Glance

Uploaded by

Syeilendra PramudityaCopyright:

Available Formats

Subchannel Analysis Method at A Glance

Lecture Note on Nuclear Reactor Thermal Hydraulics

Syeilendra Pramuditya Department of Nuclear Engineering Tokyo Institute of Technology December 2012

1

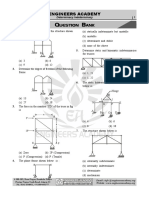

Subchannel Analysis Method

Estimation of:

Fuel temperature (conduction eq.) Clad temperature (heat transfer & conduction eq.) Coolant temperature (transport eqs.) Flow field (transport eqs.)

Fuel Subassembly

Subchannel Analysis Method

Governing equations: time-averaged transport equations

c + c v = J + cv t

unsteady term + convection term = diffusion term + source term + fluctuation term

c Mass Linear momentum Internal energy 1

v

J 0

pI + q 1

( q p v + )

Subchannel Analysis Method

The basic equations are discretized based on 2D nonorthogonal subchannel geometry Basically it is a finite volume coarse grid CFD

Three types of control volume (CV)

l axial plane i subchannel number under consideration

Three types of subchannel

mk adjacent subchannel number (k = 1, 2,3) k gap number between subchannel i and mk

Subchannel Analysis Method

Internal energy Vi ,l

n +1 i ,l

n +1 i ,l

n i ,l

n i ,l n + E = Qcn,+,1l + Qw,+i1l i ,

Discretized equations

t 3 n +1 n +1 n +1 p i ,l {w A} {w A} + k {u n +1 A} Qtn,i ,l i ,l +1/ 2 i ,l 1/ 2 k ,l k =1

Axial momentum Vi ,l +1/ 2

Need modeling

w i ,l +1/ 2 t

n +1

n i ,l +1/ 2

+ Mz = { p n +1} A + Rz

i ,l +1

({ p } A )

n +1

i ,l

n i ,l +1/ 2

n +1/ 2 i ,l +1/ 2

Vi ,l +1/ 2

Transverse momentum Vi ,l +1/ 2

n k ,l

Need modeling

n k ,l

n +1 k ,l

+ Mx = k { p n +1} A + Rx

mk ,l

({ p } A )

n +1

i ,l

n +1/ 2 k ,l

Need modeling

Subchannel Analysis Method

Four equations and twelve unknowns (unsolvable)

Subchannel Analysis Method

Subchannel Analysis Method

Axial flow resistance Rz =

(

A fs

Az w2 pn + n dA = pz = fz V 2 De

Pipe models Engel/Novendstern models Rehme model Cheng-Todreas model

Transverse flow resistance Rx =

(

A fs

Ax u 2 pn + n dA = px = fx V 2 DV

Gunter-Shaw

Subchannel Analysis Method

Inter-channel mixing of energy

Turbulent term of the internal energy equation Qt =

A ff

ev n dA = Wij*, H C p Ti T j

COBRA model Cheng-Todreas model

Wij*, H = Wij*, M = i Sij Gk

i =

Cmix DV ,k

ij Re

0.125 k

Subchannel Analysis Method

Substituting the two momentum equations into mass and energy equations: win,l++11/ 2 = a0 + a1 ( pin,l+1 pin,l++11 ) win,l+11/ 2 = b0 + b1 ( pin,l+11 pin,l+1 )

n+ ukn,+1 = c0 + c1 ( pmk1l pin,l+1 ) l ,

10

We obtain: Two equations and two unknowns (solvable)

Subchannel Analysis Method

To solve this algebraic equation system, the mass and energy equations can be considered as zero-valued non-linear functions:

11

Fmass Fmass ( p, T ) = 0 Fenergy Fenergy ( p, T ) = 0

This system is then solved by using the multivariable Newton-Raphson method:

J r X = F r

r Fmass pi ,l r J = r F energy pi ,l r Fmass Ti ,l r Fenergy r Fmass pi ,l 1 r Fenergy r Fmass pi ,l +1 r Fenergy r Fmass pm1,l r Fenergy r Fmass pm 2,l r Fenergy r Fmass pm 3,l r Fenergy pm 3,l T

Ti ,l

pi ,l 1

pi ,l +1

pm1,l

pm 2,l

X = pi ,l

r

Ti ,l pi ,l 1 pi ,l +1 pm1,l pm 2,l

pm3,l

r Fmass F = r Fenergy

Subchannel Analysis Method

With some matrix manipulation:

pi ,l c11 c12 + Ti ,l c21 c22 c13 c23 c14 c24 pi ,l 1 pi ,l +1 g c15 pm1,l = 1 c25 g pm 2,l 2 p m 3,l

12

pi ,l + c11 pi ,l 1 + c12 pi ,l +1 + c13 pm1,l + c14 pm 2,l + c15 pm3,l = g1

Ti ,l = g 2 ( c21 pi ,l 1 + c22 pi ,l +1 + c23 pm1,l + c24 pm 2,l + c25 pm3,l )

Discrete Poisson equation for pressure correction:

2 ( p ) =

Subchannel Analysis Method

A1,1 A2,1 A1,2 A2,2 A3,2 A2,3 A3,3 A3,4 Al ,l 1 Al ,l Al ,l +1 AL 1, L 2 AL 1, L 1 AL , L 1 P B 1 1 P2 B2 P3 B3 = B Pl l AL 1, L PL 1 BL 1 AL , L PL BL

13

a11 Al ,l = Pl = p1,l

Bl = b1,l

aI , I

p I ,l

T

p2,l pi ,l

b2,l bi ,l bI ,l

Subchannel Analysis Method

The Block Tridiagonal Matrix system is then solved either by direct or iterative methods. Solution procedures: - Gaussian elimination (direct) - Gauss-Seidel (iterative)

14

Subchannel Analysis Method

PRE-PROCESSOR Translating the problem under consideration into appropriate input files (e.g. tabular data of SC, rod, gap numbering, power density at each cell, form friction factor at arbitrary locations, etc). START

15

SOLVER

POST-PROCESSOR Displaying the calculation result into something meaningful to the user (e.g. nice fancy colorful images and graphs).

Initialize

Steady state

FINISH time = stop time

Time counter time = print time Output Newton-Rhapson Poisson solver

Subchannel Analysis Method

Pre-processor

16

Subchannel Analysis Method

Example of problem specification

17

Rod radial nodalization

Axial Power Profile (EOC) 1.8 1.6 1.4 Relative power 1.2 1.0 0.8 0.6 0.4 0.2 0.0 -500

500

Bundle axial nodalization

1000 1500 z [mm]

2000

2500

3000

Subchannel Analysis Method

Velocity vector

18

100% power & flow Re 16200 Radial skew 3.0 Wall heat loss 0%

500 480 460 440 420 400 380 360 340 320 300 280 z [cm] 260 240 220 200 180 160 140 120 100

Po we r

80

Sk e

60

w

He los at s

40 20 -2 -1 0 x [cm] 1 2

Subchannel Analysis Method

Flow recirculation

Velocity vector

19

1% power & flow Re 162 Radial skew 3.0 Wall heat loss 10%

500 480 460 440 420 400 380 360 340 320 300 280 z [cm] 260 240 220 200 180 160 140 120 100

Po we r

80 60

Sk e

w

He los at s

40 20 0 -3 -2 -1 0 x [cm] 1 2

Comparison with Experimental Data

Bundle Characteristics

Parameters Fluid Number of rods Heated length [mm] Rod diameter (D) [mm] Pitch (P) [mm] P/D Edge pitch (W) [mm] W/D Wire diameter [mm] Wire axial pitch (H) [mm] H/D Flat-to-flat distance [mm] Power profile Sodium 19 533.4 5.842 7.2644 1.243 7.3914 1.265 1.4224 304.8 52.2 34.1 Uniform Run 020472-1459 020472-1118 020472-0949 020372-1443 020372-1054 012172-1447 012172-1338 022472-1143

20

Experiment Parameters

Flow rate gal/min 0.74 2.1 2.6 4.2 5 32 42 55 Power kW/ft.rod 0.15 0.46 0.54 0.89 0.94 4.8 4.8 9.7 Tin [F] 600 600 600 600 600 600 600 600 dT [F] 193 192 175 190 190 130 97 158

*M.H. Fontana, R.E. MacPherson, P.A. Gnadt and L.F. Parsly, Temperature distribution in the duct wall and at the exit of a 19-rod simulated LMFBR fuel assembly (FFM Bundle 2A), Nuclear Technology, Vol. 24, 1974, pp. 176200.

Comparison with Experimental Data

21

Subchannel and rod numbering

Gap numbering

Calculation domain: 19 pins 42 subchannels 60 gaps 38/74 axial planes

Boundary conditions: Inlet coolant temperature Total mass flow rate Outlet pressure Constant wall heat flux

Comparison with Experimental Data

Mass flow rate 2.86 kg/s 1.6 1.4 Normalized temperature 1.2 1.0 0.8 0.6 0.4 0.2 0.0 -20 -15 -10 -5 0 5 10 Corner-to-corner distance [mm] 15 20

Cold dimensions Hot dimensions Exp. data

22

Max Error: 11.9% RMS error: 6.2%

Max Error: 10.2% RMS error: 6.9%

T* =

Ti Tin , Tout ,avg Tin

Tout ,avg =

T

i =1 N i =1

i wi Ai

,

Max Error: 5.2% RMS error: 3.5%

i i i

w A

Comparison with Experimental Data

Bundle Characteristics

Parameters Fluid Number of rods Heated length [mm] Rod diameter (D) [mm] Pitch (P) [mm] P/D Edge pitch (W) [mm] W/D Wire diameter [mm] Wire axial pitch (H) [mm] H/D Flat-to-flat distance [mm] Power profile Axial power peaking Sodium 37 930 6.50 7.87 1.21 8.003 1.23 1.32 307 47.2 50.4 Chopped cosine 1.21 F37P20 F37P27 G37P22 G37P25 L37P43 2810 1530 7520 2810 1370 80000 88600 20700 81000 130000 1.17 1.17 1.34 1.34 1.34 Run No. B37P02 C37P06 E37P13 E37P17

23

Experiment Parameters

Re 11200 2810 739 7610 Gr 13600 52800 61100 20100 Power skew [max/avrg] 1.00 1.00 1.00 1.17

*F. Namekawa, A. Ito, K. Mawatari, Buoyancy Effects on Wire-Wrapped Rod Bundle Heat Transfer in an LMFBR Fuel Assembly, National Heat Transfer Conference, 1984.

Comparison with Experimental Data

24

L2 HEATED LENGTH 930 mm

915 mm

Subchannel and rod numbering

Gap numbering

Calculation domain: 37 pins 78 subchannels 114 gaps 38 axial planes (dz = 2.583 cm)

Boundary conditions: Inlet coolant temperature Inlet total mass flow rate Outlet pressure Constant wall heat flux

Comparison with Experimental Data

Re 7610, Gr 20100, Skew 1.17

1.6 1.4 1.2 1 0.8 0.6 0.4 0.2 -25

25

Re 11200, Gr 13600, Skew 1.0 1.6 Normalized Temperature 1.4 1.2 1 0.8 0.6 0.4 0.2 -25 Exp. data Case C04 (Hot) Case C04 (Cold) -15 -5 5 15 Flat-to-Flat Distance [mm] 25

Normalized Temperature

Exp. data Simulation

-15 -5 5 15 Flat-to-Flat Distance [mm] 25

Re 7520, Gr 20700, Skew 1.34

1.6 Normalized Temperature 1.4 1.2 1 0.8 0.6 0.4 0.2 -25

ErrorMAX [%] Skew 1.00 Skew 1.17

Exp. data Simulation

-15 -5 5 15 Flat-to-Flat Distance [mm] 25

ErrorRMS [%] 8.5 (Cold) 5.5 (Hot) 3.4 (Hot) 5.6 (Hot)

9.8 (Cold) 8.1 (Hot) 5.4 (Hot) 9.3 (Hot)

Skew 1.34

Subchannel Analysis Method

26

~ Thank You for your Attention ~

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Z Purlin DesignDocument22 pagesZ Purlin DesignGautam PaulNo ratings yet

- 2018 Grade 10 Physics Notes PDFDocument136 pages2018 Grade 10 Physics Notes PDFSalifyanji100% (3)

- AES-Ductwork-System-Design. (Fittings-Friction Loss)Document64 pagesAES-Ductwork-System-Design. (Fittings-Friction Loss)magxstone100% (1)

- Unit III Sliding Contact BearingDocument26 pagesUnit III Sliding Contact BearingSHUBHAM GOVILNo ratings yet

- General PhysicsDocument15 pagesGeneral Physicsmar liaNo ratings yet

- Determinacy and Indeterminacy Questions for Structural Engineering ExamDocument9 pagesDeterminacy and Indeterminacy Questions for Structural Engineering ExamBhagwat BhajipaleNo ratings yet

- Problema 2B.3Document5 pagesProblema 2B.3Shely Cortés PNo ratings yet

- Programming and Computation in Physics - FTCS MethodDocument27 pagesProgramming and Computation in Physics - FTCS MethodSyeilendra PramudityaNo ratings yet

- Computation and Programming in Physics - Numerical Integration MethodsDocument26 pagesComputation and Programming in Physics - Numerical Integration MethodsSyeilendra PramudityaNo ratings yet

- Computation and Programming in Physics - Euler & Runge-Kutta MethodsDocument34 pagesComputation and Programming in Physics - Euler & Runge-Kutta MethodsSyeilendra PramudityaNo ratings yet

- Academic CV SampleDocument5 pagesAcademic CV SampleSyeilendra Pramuditya100% (1)

- Dr. Syeilendra Pramuditya - Lecture Notes On Thermal Hydraulics and Nuclear SafetyDocument105 pagesDr. Syeilendra Pramuditya - Lecture Notes On Thermal Hydraulics and Nuclear SafetySyeilendra PramudityaNo ratings yet

- Computation and Programming in Physics - Root Finding AlgorithmsDocument33 pagesComputation and Programming in Physics - Root Finding AlgorithmsSyeilendra PramudityaNo ratings yet

- Computation and Programming in Physics - Data Representation / GraphicsDocument29 pagesComputation and Programming in Physics - Data Representation / GraphicsSyeilendra PramudityaNo ratings yet

- Basic Thermal-Hydraulics Experiments For Nuclear Engineering StudentsDocument14 pagesBasic Thermal-Hydraulics Experiments For Nuclear Engineering StudentsSyeilendra PramudityaNo ratings yet

- Official Program of The ASME-JSME-KSME Joint Fluids Engineering 2011Document104 pagesOfficial Program of The ASME-JSME-KSME Joint Fluids Engineering 2011Syeilendra Pramuditya100% (1)

- The Story of A Web DesignDocument7 pagesThe Story of A Web DesignSyeilendra PramudityaNo ratings yet

- Revised Cheng-Todreas Correlations - Improvements in The Transition Flow RegionDocument18 pagesRevised Cheng-Todreas Correlations - Improvements in The Transition Flow RegionSyeilendra PramudityaNo ratings yet

- Official Program of NURETH-14 Conference (September 2011)Document64 pagesOfficial Program of NURETH-14 Conference (September 2011)Syeilendra PramudityaNo ratings yet

- ANSYS Workbench 13 Tutorial - 2D Meshing With Prism Layers (Or Boundary Layers) On Wall BoundariesDocument13 pagesANSYS Workbench 13 Tutorial - 2D Meshing With Prism Layers (Or Boundary Layers) On Wall BoundariesSyeilendra Pramuditya0% (1)

- Web Development WorkshopDocument10 pagesWeb Development WorkshopSyeilendra PramudityaNo ratings yet

- Problem Solving Series - Laminar Velocity Profile Between Infinite Parallel PlatesDocument3 pagesProblem Solving Series - Laminar Velocity Profile Between Infinite Parallel PlatesSyeilendra PramudityaNo ratings yet

- FORTRAN77 Code - NECTARDocument2 pagesFORTRAN77 Code - NECTARSyeilendra PramudityaNo ratings yet

- Basic Thermal-Hydraulics Experiments For Nuclear Engineering StudentsDocument9 pagesBasic Thermal-Hydraulics Experiments For Nuclear Engineering StudentsSyeilendra PramudityaNo ratings yet

- (PDF) NECTAR Code: A Sample CalculationDocument5 pages(PDF) NECTAR Code: A Sample CalculationSyeilendra PramudityaNo ratings yet

- FORTRAN77 Subroutine For Matrix InversionDocument2 pagesFORTRAN77 Subroutine For Matrix InversionSyeilendra Pramuditya100% (2)

- (PDF) NECTAR Code: A Sample CalculationDocument5 pages(PDF) NECTAR Code: A Sample CalculationSyeilendra PramudityaNo ratings yet

- A Numerical Method For Thermo-Fluid-Dynamics Analyses of Fast Nuclear Reactors Fuel Assemblies - Single-Phase Flow Formulation (Subchannel Analysis Method)Document27 pagesA Numerical Method For Thermo-Fluid-Dynamics Analyses of Fast Nuclear Reactors Fuel Assemblies - Single-Phase Flow Formulation (Subchannel Analysis Method)Syeilendra PramudityaNo ratings yet

- Thermal Hydraulics of Single Phase Flow in Multi Channel SystemsDocument11 pagesThermal Hydraulics of Single Phase Flow in Multi Channel SystemsSyeilendra PramudityaNo ratings yet

- Syeilendra Pramuditya - Example of Motivation LetterDocument1 pageSyeilendra Pramuditya - Example of Motivation LetterSyeilendra PramudityaNo ratings yet

- FORTRAN77 Function To Calculate Matrix DeterminantDocument2 pagesFORTRAN77 Function To Calculate Matrix DeterminantSyeilendra PramudityaNo ratings yet

- NECTAR Code - A Steady State Thermal Hydraulics SolverDocument9 pagesNECTAR Code - A Steady State Thermal Hydraulics SolverSyeilendra PramudityaNo ratings yet

- FORTRAN77 Code - Thermal-Hydraulics of Single Phase Flow in A Heated ChannelDocument7 pagesFORTRAN77 Code - Thermal-Hydraulics of Single Phase Flow in A Heated ChannelSyeilendra PramudityaNo ratings yet

- FORTRAN77 Subroutine To Calculate Matrix DeterminantDocument1 pageFORTRAN77 Subroutine To Calculate Matrix DeterminantSyeilendra PramudityaNo ratings yet

- Thermal-Hydraulics of Single Phase Flow in A Heated ChannelDocument12 pagesThermal-Hydraulics of Single Phase Flow in A Heated ChannelSyeilendra Pramuditya100% (1)

- Status of Fast Reactor Development in The WorldDocument12 pagesStatus of Fast Reactor Development in The WorldSyeilendra PramudityaNo ratings yet

- Dxdy Dy DXDZ yDocument8 pagesDxdy Dy DXDZ yLieyna LinaNo ratings yet

- Flow Meter Type DetectorsDocument9 pagesFlow Meter Type DetectorsAli AimranNo ratings yet

- Mechanical Vibration Modeling and AnalysisDocument152 pagesMechanical Vibration Modeling and AnalysisTiago Rodrigues Dos SantosNo ratings yet

- Assignment Fall2018Document2 pagesAssignment Fall2018Frans LoekitoNo ratings yet

- HOL - Instance-Conservation of Momentum3Document6 pagesHOL - Instance-Conservation of Momentum3Martin DelgadoNo ratings yet

- Convective Mass Transfer PDFDocument14 pagesConvective Mass Transfer PDFAnonymous 4XZYsImTW5100% (1)

- Two-Way Slab CalculationDocument10 pagesTwo-Way Slab CalculationJake CortezNo ratings yet

- Mechanics of Machinery: Adapted From Theory of Machine and Mechanisms J.E ShigleyDocument65 pagesMechanics of Machinery: Adapted From Theory of Machine and Mechanisms J.E ShigleyDanialNo ratings yet

- Introduction To Engineering Seismology: Assignment 3 - Hints and SolutionsDocument2 pagesIntroduction To Engineering Seismology: Assignment 3 - Hints and SolutionsSaurabhĶřNo ratings yet

- 5 RudderDocument37 pages5 RudderAamir SirohiNo ratings yet

- Chapter 6: Solving A Conjugate Heat Transfer Problem Using ANSYS FluentDocument34 pagesChapter 6: Solving A Conjugate Heat Transfer Problem Using ANSYS FluentSrijan VermaNo ratings yet

- Innovative Composite Slim Floor Design PDFDocument6 pagesInnovative Composite Slim Floor Design PDFGinoNo ratings yet

- Opti 222 W9Document5 pagesOpti 222 W9Aya HassanNo ratings yet

- Lecture 2 - KinematicsDocument56 pagesLecture 2 - KinematicsJ KimNo ratings yet

- EDrive Actuators E-Tac ET BrochureDocument4 pagesEDrive Actuators E-Tac ET BrochureElectromateNo ratings yet

- ASIE Model - MAS KHAIRULIZA BINTI ABDUL HALIR-4STEM1-Fizik (DLP) - Minggu 42 PDFDocument1 pageASIE Model - MAS KHAIRULIZA BINTI ABDUL HALIR-4STEM1-Fizik (DLP) - Minggu 42 PDF'Izzat NordinNo ratings yet

- Modelling Brittle Failure of Rock: V. Hajiabdolmajid, P.K. Kaiser, C.D. MartinDocument11 pagesModelling Brittle Failure of Rock: V. Hajiabdolmajid, P.K. Kaiser, C.D. MartinKristi GonzalesNo ratings yet

- HSSC G PhysicsDocument78 pagesHSSC G Physicshasnain ghazalaNo ratings yet

- Chapter 07 Entropy-7 PDFDocument35 pagesChapter 07 Entropy-7 PDFMarviandi EkoNo ratings yet

- CH1 Intro&StaticsDocument42 pagesCH1 Intro&Staticsgelber clintonNo ratings yet

- Heat and Mass Transfer by S K Mondal T&Q (1) .0001 PDFDocument110 pagesHeat and Mass Transfer by S K Mondal T&Q (1) .0001 PDFankitgaurav3497No ratings yet

- Lsdyna Lsprepost IntroDocument74 pagesLsdyna Lsprepost IntroBlick ZitaNo ratings yet

- Mixed Mode Crack Propagation in ConcreteDocument45 pagesMixed Mode Crack Propagation in ConcreteAdolfo Gálvez VillacortaNo ratings yet