Professional Documents

Culture Documents

ISO22000 - HYG - R - 09 Internal Audit Checklist (Area & Departmental)

Uploaded by

NabilKnouziOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ISO22000 - HYG - R - 09 Internal Audit Checklist (Area & Departmental)

Uploaded by

NabilKnouziCopyright:

Available Formats

Page 1 of 16

Auditee:

Audit Date:

Document No. : ISO22000-HYG-R-09 Implementation Date: 14 Nov 2011 Revision No. 0 Page: 1 of 1

ISO 22000 / SFSMS AUDIT KITCHEN / BAR CHECKLIST

POLICIES

Policy 1 - NN Plastic Cutting Board and Knife

ITEMS TO CHECK

1. Following color coding policy? 2. Staff able to demonstrate proper cleaning and sanitizing procedure? 3. Ask staff when to clean? S: every 30 minutes and after each task 4. D2, D4 and brush available? 5. Knives when not in use placed in the hanging rack or sterilizer? 6. Boards and knives clean? Inspect handle and blade edge. 7. Boards without deep groves, cracks, molds? Knives without engravings? 8. Sanitizer at soaking bin at 200ppm quat solution? 9. Sashimi and other RTE fish prepared with a designated cutting board and knife? 1. No banned products by BFAD consumed by Hotel/Kitchen/Bar? 1. Deviation form raised for any non-compliance by Kitchen? 1. Staff able to demonstrate proper handwashing procedure? 2. Ask staff how long are hands rubbed? S: At least 20 seconds 3. Staff know when to wash hands? Ask staff. 4. Does staff wash hands every 30 minutes, before wearing gloves, after handling raw food or garbage? When returning from a break? 1. HW amenities complete: warm water, hand soap and sanitizer, paper towel, gloves, chained nail brush in 200 ppm sanitizer solution, instructional poster, mechanically operated sink, garbage bin. 2. Nail brush sanitizer at 200 ppm sanitizer solution? Changing records updated? 1. Are gloves used when handling ready-to-eat food or when with wound or sore? 2. Are hands washed before wearing gloves? 3. Paper towel used over hand with glove when touching surfaces? 1. Staff know the chilling hot food policy? 2. Are chilled items covered with cling film? Is enough ice used for water bath? 3. Is blast chiller clean and free from rust? 4. Are SFSMS records available, complete and verified? S: Cool food above 63C to 10C 90 minutes or to 5C in 4 hours.

COMPLIANCE Y N

COMMENTS

Policy 2 - LR Health Hazard Policy 3 - LR Deviation Form Policy 4 - HR Hand Washing

Policy 5 - HR Hand Washing Station Policy 6 - HR Disposable Gloves Policy 8 - HR Chilling Hot Food CCP6

Page 2 of 16

Document No. : ISO22000-HYG-R-09 Implementation Date: 14 Nov 2011

Revision No. 0 Page: 1 of 1

ISO 22000 / SFSMS AUDIT KITCHEN / BAR CHECKLIST

POLICIES

Policy 9 - MR Hygienic Transfer From Receiving Policy 10 - MR First Aid Kit

ITEMS TO CHECK

1. Are high risk items transferred within 20 minutes? 2. Are different food items seperated when transported? 2. Are cleaned and sanitized trolleys and crates used? 1. First aid box available with brightly colored water proof, plasters? 2. Other first aid contents complete based on checklist? 3. Staff with no open wound and wearing colored water proof bandages with glove? 4. Ask staff when to change plasters? S: every 4 hours 1. Is a dedicated ice scooper soaked in sanitizer used for scooping ice? 2. Ice scooper with chain and soaked at 200ppm sanitizer solution? 3. Ice machine interior plastic molder and rubber gasket clean, rust free? 4. SFSMS cleaning and changing records available at each machine? 1. Rotary slicer cleaned and sanitized and dismantled at end of operation? 2. Check functionality: presence of rust, leak, scale, etc. 3. SFSMS cleaning records verified by Sous Chef/Outlet Chef? 1. Records available and verified by Chief Steward? 2. Ask steward temperature and change water requirements. 3. Check functionality: presence of rust, leak, lime scale, etc 4. Dishwashing Machine meeting temperature requirements? S: Main wash-55-65C S: Final rinse-82-86C, Exit plate-71C (thermolabel) 1. No thawing in ambient temperature? 2. Well segregated from other foods, no cross-contamination 3. Frozen items thawed in ref labeled with date and time to indicate second shelf life? 1. Items thawed in running water labeled with date and time? 2. Ask staff secondary shelf life of thawed items. S: 12 hours 3. Ask staff maximum no. of hours for thawing in running water. S: 4 hours 1. Disposable piping bag used labeled with date and time? 2. Ask staff shelf-life. S: 4 hours

COMPLIANCE Y N

COMMENTS

Policy 11 - NN Ice Machine

Policy 12 - HR Rotary Slicer Policy 13 - HR Dishwashing Machine

O'PRP 9 Policy 14 - MR Thawing in Ref O'PRP 7 Policy 16 - MR Thawing in Running Water O'PRP 7 Policy 18 - LR Piping Bag

Page 3 of 16

Document No. : ISO22000-HYG-R-09 Implementation Date: 14 Nov 2011

Revision No. 0 Page: 1 of 1

ISO 22000 / SFSMS AUDIT KITCHEN / BAR CHECKLIST

POLICIES

Policy 20 - HR Holding of Hot & Cold Food CCP 5 CCP 8 Policy 22 - MR Prep Table Policy 23 - MR Hamburger Cooking & Service CCP 4 Policy 24 - NN Secondary Shelf Life Policy 25 - NN FIFO Policy 27- MR Whipped Cream Machine Policy 28/29 - LR Freezer Storage Freezer Temp

ITEMS TO CHECK

1. Ask staff temperature requirements for hot and cold holding of food. 2. Are Service Holding Records available, complete and verified? 3. Records were available S: Hot food: 63C and above S: Cold food: 8C and below 1. Preparation tables cleaned and sanitized? Spilled food cleaned? 2. Raw and ready-to-eat item preparation separate? 1. Ask staff about cooking temperature requirements. 2. Ask service staff esp IRD the hamburger phraseology: "The hotel prefers to serve your hamburgers cooked well done. However we will be delighted to prepare your hamburger as you may have prefered?" 3. Are Hamburger cooking records available, complete and verified? S: 70C and above 1. Check chillers and freezers for out of date/expired products? S: Cold Items - 48 hours; Hot Items - 72 hours; Vacuum pack chilled: 72 hours; Processed frozen items: 30 days 1. Check chillers, freezers, dry storage and stocked shelves. FIFO practiced? 2. No out of dated or expired product? 1. Cream covered and at 8C or less? 2. Nozzle sanitized at least every 4 hours? Records for sanitizing nozzle available, complete and verified? 1. Freezer following proper clearance in food storage: 6 inches - from floor and ceiling 2 inches - walls 12 inches - from evaporator 1 inch - stacked crates 2. Check functionality: No rust in shelves, leak, busted lights, frost build up, door, walls, shelves and gaskets clean. No gaps/cracked tiles. 3. Chiller and freezer following standard temperature: S: -18C and below

COMPLIANCE Y N

COMMENTS

Not applicable Not applicable Not applicable

O'PRP 4

Page 4 of 16

Document No. : ISO22000-HYG-R-09 Implementation Date: 14 Nov 2011

Revision No. 0 Page: 1 of 1

ISO 22000 / SFSMS AUDIT KITCHEN / BAR CHECKLIST

POLICIES

Policy 30 - NN Refrigerator Stocking

ITEMS TO CHECK

1. RTE above or separate from raw food? 2. Fish above meat, meat above poultry. Poultry always at bottom shelf. 3. Items wrapped / covered? Stacked properly? 4. No dirty outer cartons in chiller? No dirty crates or containers? 5. Chiller following proper clearance in food storage: 6 inches - from floor and wall 2 inches - walls 12 inches - from evaporator 1 inch - stacked crates 1. Are cooking and reheating temp requirements known and followed by staff? 2. Ask Chef to demonstrate how to take cooking temperature. 3. Cooking and Reheating Records available, complete and verified. S: 74C and above - Poultry, Stuffing, Foods cooked in Microwave S: 70C and above - Hamburger, ground and processed meat, flaked fish S: 63C and above - Fish, seafood, pork, beef, eggs, vegetables, rice S: 75C and above - Reheating (any food) 1. Chiller: clean, rust free, gaskets in good condition, no frost condensation or leak, no exposed wires, lights covered, clean and rust free shelves, no gaps in floors and walls. 2. Gauges in good condition and calibrated with sticker tags? 3. Are Chiller and Freezer Records available, complete and verified? S: Air temp (gauge) at 1C - 4C so that food temp is at less than 5C 1. Ask staff what are the common food allergens? S: Gluten, eggs, dairy, poultry, fish and seafood, nuts, cereals and legumes. 2. Ask Chef and Service staff what to do when guest has a food allergy? S: Service staff to give clear instructions on allergen and Chef to separate preparation and avoid using products with allergen.

COMPLIANCE Y N

COMMENTS

Policy 31 - HR Cooking Temp Requirements & Reheating Food CCP 4 CCP 7 Policy 32 - HR Freezer & Chiller Maintenance

CCP 2 Policy 34 - MR Awareness of Food Allergens

Page 5 of 16

Document No. : ISO22000-HYG-R-09 Implementation Date: 14 Nov 2011

Revision No. 0 Page: 1 of 1

ISO 22000 / SFSMS AUDIT KITCHEN / BAR CHECKLIST

POLICIES

Policy 35 - HR Cooling & Drying Animals For Asian BBQ Policy 36 - LR Mayonnaise Awareness Policy 37 - MR Can Opener Policy 38 - NN Bar Counter Inspection

ITEMS TO CHECK

1. Is resticted area provided to hang animals for Asian BBQ? 2. Are game birds stored separately from poultry items? 3. Are BBQ labeled with both date and time of cooking and drying? 4. Are containers available to prevent drip / cross contamination? 5. Are foods reheated to 75C before service? 1. Recommended brands only used: S: Chef, Krafts, Heinz, Hellmann's, QP and Best Foods. 2. Ask staff if hotel made mayonniase can be used? 3. Are pasteurized eggs used for items such as holandaise sauce? 1. Clean and well maintained. Blade sharp and mount clean. No rust. 2. Records available, complete and verified? 1. Bar area and bar counter tidy, organized, clean and sanitized? 2. Food and food containers stored 6 in above the floor? 3. Ice bin clean and kept closed when not in use. 4. Ice scooper kept in container with sanitizer. Sanitizer at 200ppm. 5. Green colored cutting board and knife clean and without deep grooves? 6. D2, D4 , gloves available at all times? D2 and D4 kept in chemical kit? 7. Refuse bin clean and refuse properly segregated? 8. Chiller: clean, rust free, gaskets in good condition, no frost condensation or leak, no exposed wires, lights covered, clean and rust free shelves, no gaps in floors and walls. 9. Items wrapped / covered? Stacked properly? 10. In-house made juices labeled with date and time? 11. No expired items. Refer to Secondary shelf life of common bar products. 12. Chiller air temp (gauge) at 1C - 4C so that food temp is at less than 5C

COMPLIANCE Y N

COMMENTS

CCP 2

Page 6 of 16

Document No. : ISO22000-HYG-R-09 Implementation Date: 14 Nov 2011

Revision No. 0 Page: 1 of 1

ISO 22000 / SFSMS AUDIT KITCHEN / BAR CHECKLIST

POLICIES

Policy 40 - MR Receiving of Freshly Slaughtered Meat O'PRP 2 Policy 41 - MR Vacuum Packaging Policy 42 - NN Dry Storage

ITEMS TO CHECK

COMPLIANCE Y N

COMMENTS

1. Purchased from approved suppliers. 2. Meat received within 6 hours of slaughter ideally before 11am? 3. Meat labeled with date and time of slaughtering? 4. Meat cooked within 4 hours or stored to reach 8C within 4 hours? 5. Freshly slaughtered meat delivered with slaughter time permit? 1. Vacuum packaging machine clean and well maintained? 2. Vacuum packaging of raw and RTE items separate? 3. Ask Chef secondary shelf life of raw chilled vacuum packed meats? S: 3 days or less 1. Dry store clean and organized. 2. Products with production label or date of expiration. FIFO followed. 3. Cans - no dent, rust or bloating. No open package. 4. Glass items stored at bottom shelves. 5. No evidence of pest infestation. 6. Dry store following proper clearance in food storage: 6 inches - from floor and ceiling 2 inches - walls 7. Temperature at <24C ; Humidity at 65%. O'PRP 6 Policy 43 - NN 1. Check staff grooming: hair, fingernails, uniform, watch, jewelry. Personal Hygiene 2. Staff wearing clean clothing and apron. No wiping of hands in apron. Habit 3. Staff to wear hair restraint. Female chefs: hairnet and toque 4. Proper tasting praticed. Single use tasting spoon used. No eating. 5. No personal belongings inside the kitchen. 6. No wearing of aprons in toilet, during meals and when on break. Policy 45 - NN 1. Floors, walls, ceiling, sink, shelves, cleaning cabinet, drainages clean. Pot Wash 2. PWS amenities complete: Supply of warm water, instruction (wash, rinse, sanitize), Station supply of detergent and sanitizer, cleaning tools, waste bin with lid and non wood shelving. No steel wool. 3. Check functionality: presence of rust, leak, drainage gaps. 4. Segregation of clean and dirty items done. Clean items turn down to dry.

Page 7 of 16

Document No. : ISO22000-HYG-R-09 Implementation Date: 14 Nov 2011

Revision No. 0 Page: 1 of 1

ISO 22000 / SFSMS AUDIT KITCHEN / BAR CHECKLIST

POLICIES

Policy 46 - NN Kitchen Waste Bin

ITEMS TO CHECK

COMPLIANCE Y N

COMMENTS

1. Garbage bins with foot pedal, clean and lined with polyethylene bag. 2. Proper segregation practiced. 3. No cardboards should be left inside kitchen or thrown in waste bin. 4. Transported waste must be covered with bin lid esp. during transit. Policy 46 - NN 1. Clean, well lit, ventilated, sealed to prevent entrance of pest. Garbage 2. Cleaning gears hanged in its proper place. Wash point available. Room 3. HWS with complete amenities, sanitizer changing forms up-to-date. 4. Insect killing device and plastic curtain clean and in good condition. 5. No pest at all time. 6. WIC monitored and forms up-to-date. 7. Drainage system to be clean and functional 8. No storage of food containers, racks or idle equipment. 9. Compactor machine clean and functional. Policy 47 - MR 1. Ice cream recipe to state pasteurizing time and temperature. Ice-Cream 2. Clean and in good working condition, sanitized prior to use and dismantled Machine after operation. 3. No rust, peel or foreign matter on ice cream scrapper. Policy 48 - NN 1. Ice-cream freezer used for ice cream only. No raw food. Ice-Cream 2. All products wrapped and labeled. Freezer 3. Check functionality: presence of rust, leak, frost, gasket clean. 4. Ice cream scoop kept under running water and washed and sanitized every 4 hours. Policy 49 - LR 1. Chemicals placed in designated area: chemical cabinet or chemical kit. Chemical Storage 2. Are all chemical spray bottles and dispensers labeled. 3. Stored separately from food, food packaging or operating equipment. 4. Clean, dry, cool, well lit, ventilated and out of sunlight. 5. Material Safety Data Sheets available and updated for all chemicals. 6. Acid, alkaline and chlorine products stored separately. 7. Safety gear (goggles, hand gloves and lab coat) available. 8. Smoking prohibited (signage posted). Access to chemicals restricted.

Page 8 of 16

Document No. : ISO22000-HYG-R-09 Implementation Date: 14 Nov 2011

Revision No. 0 Page: 1 of 1

ISO 22000 / SFSMS AUDIT KITCHEN / BAR CHECKLIST

POLICIES

Policy 50 - MR Color Coding Label Policy 51 - MR Moon Cake Production CCP 4 Policy 52 - HR Management Commitment & Culture

ITEMS TO CHECK

1. Produced, opened and ref thawed food products labeled.

COMPLIANCE Y N

COMMENTS

Policy 53 - HR Receiving Inspection

O'PRP 3 CCP 1, O'PRP 1 O'PRP 5 Vegetable PreWash Room CCP 3

1. Disposable gloves to be worn during packaging. 2. Prep table and equipment clean and sanitized at all times. 3. Secondary shelf life to be indicated (best before date). 4. Mooncakes baked to reach internal core temperature of 75C. 1. Team meeting done at least once per month. 2. SFSMS Orientation done within 2 months after job commencement. 3. SFSMS Policy Training within 3 months after job commencement. 4. Corrective action system in place and signed off by appropriate manager. 5. Team members aware of H, M, L, NN policies and hotel compliance. 6. GM to attend once every 4 months and RM to attend once a month. 7. Management team to demonstrate on going internal audit program. 8. All SFSMS docmentation completed and signed. 9. Pest control audit must be completed and signed off. 10. Preventive Maintenance records to be completed as per schedule. 11. Time and temp records available; checked by calibrated thermometer. 1. Floors, walls, ceiling, pallets, crates, trolleys, insect killing device clean. 2. No high risk food item left for more than 20 minutes. 3. Food received free from rips, tears, rust, dents and with use by or best before label. No wilt veg, fish with strong odor and dead crustaceans. 4. Daily Deliveries Record available, complete and verified. 5. Receiving clerk and food porters with hair restraint and nails cut short. 6. Frozen Food temperature: -12C 7. Chilled Food temperature: 5C 8. Hot food temperature: 63C 1. Floors, walls, ceiling, sink, drainage clean. 2. Ask staff method of washing and disinfecting fruits and vegetables.. 3. Eden sanitizer at correct pH. S: pH 3, Soking time: 60 seconds 4. Records were available

Not applicable Not applicable Not applicable Not applicable

Page 9 of 16

Document No. : ISO22000-HYG-R-09 Implementation Date: 14 Nov 2011

Revision No. 0 Page: 1 of 1

ISO 22000 / SFSMS AUDIT KITCHEN / BAR CHECKLIST

POLICIES ITEMS TO CHECK

COMPLIANCE Y N

COMMENTS

Policy 54 - HR 1. Visitors and contractors in F&B areas must sign in, wear badge and be Visitor & escorted at all times. Contractor Policy 2. Visitors and contractors to observe proper handwashing and personal hygiene and habits. Policy 55 - MR 1. Facilities and equipment was available Off-site Catering 2. Minimal risk on time-temperature abuse 3. Minimal risk on contamination and cross-contamination 4. Checklist (Appendix III) was completed for every event. 5. Food samples were retained for events of more than 50 pax. CCP 3 1. Washing and sanitizing method was understood. 2. Sinks were clean, no cross contamination. 3. Concentration of sanitizing solution was adequate, records were available. CCP 9 1. The process well-controlled. Capping (water 2. No critical defect (glass bottles no signs of rust, foreign bodies, chip and hairline crack). bottles) O'PRP 8 1. Plating time not exceeding 30 minutes. Assembling / 2. Record was available. Plating O'PRP 10 1. Water temperature was hot (82 - 86C) Disinfecting 2. Monitoring method was appropriate. 3. Records were available O'PRP 11 1. UV light was working Filtering 2. Controls and monitoring were carried out. Records were available.

Page 10 of 16

Document No. : ISO22000-HYG-R-09 Implementation Date: 14 Nov 2011

Revision No. 0 Page: 1 of 1

ISO 22000 / SFSMS AUDIT KITCHEN / BAR CHECKLIST

POLICIES ITEMS TO CHECK

COMPLIANCE Y N

COMMENTS

Cleaning and Sanitizing Violations refer to but not limited to: e.g. unhygienic environment, dirty exhaust hood, ceiling, wall, floor, floor gullys

Pest Management Violations refer to but not limited to: e.g. pest sighting, signs of infestation; rat and cockroach dropping electric zapper fly trap used in food preparation areas

Facilities and Maintenance Violations refer to but not limited to: e.g. chipped/ broken tiles; rusty equipment, gap in ceiling

Food Transportation Violations refer to but not limited to: e.g. Dirty or poor condition of mobile food warmers, chillers, hotbox

Page 11 of 16

Document No. : ISO22000-HYG-R-09 Implementation Date: 14 Nov 2011

Revision No. 0 Page: 1 of 1

ISO 22000 / SFSMS AUDIT KITCHEN / BAR CHECKLIST

POLICIES ITEMS TO CHECK

COMPLIANCE Y N

COMMENTS

Environmental Hygiene Hazard Violations refer to but not limited to: e.g. storing of food on floor directly; uncovered food near hazardous item, room temperature at high risk area exceed 20degC

Chemical Usage Violations refer to but not limited to: e.g. wrong ppm or concentration of chemical sanitizer

Reusable Packaging Violations refer to but not limited to: e.g. Reusable food containers not durable , not easy to clean, torn

Training & Documentation-Competency Violations refer to but not limited to: e.g. documents not properly filled and filed, staff not trained/unaware

Page 12 of 16

Auditee:

Ms. M. Paunan. Mr. J. Cordova Ms. G. Budiongan, Mr. F. Chio Ms. G. Legaspi, Mr. A. Gatdula

Audit Date: November 15, 2011

Document No. : ISO22000-HYG-R-09b Implementation Date: 14 Nov 2011 Revision No. 0 Page: 1 of 1

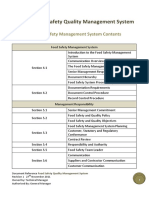

ISO 22000 CHECKLIST

REQ

Management Commitment P52 - HR

ITEMS TO CHECK

1. Company profile is updated 2. Company Policy on Food Safety, Objective and Scope are updated 3. Organization chart, reporting structures, HACCP team profile are updated 4. Management review is planned or scheduled, - minutes form previous meetings were available - Agenda for discussion was complete based on the Management Review procedure - Inputs and outputs from the meeting were clearly recorded. 5. GM to attend SFSMS meetings once every 4 months and RM to attend once a month 1. Team member profile was updated 2. All team members had been trained. 3. SFSMS Meetings were carried out as planned, minutes were available. 4. What was the general percentage of attendance? 1. Communications remained to be effective, no breakdown. 2. Procedure was updated 3. Reference standards were updated 4. Means of communication with regulatory agencies were updated 1. Information and contact list were updated

COMPLIANCE Y N

COMMENTS

Food Safety / SFSMS Team P52 - HR Communications

Emergency Response

Page 13 of 16

Ms. G. Budiongan, Mr. F. Chio Ms. G. Legaspi, Mr. A. Gatdula

Document No. : ISO22000-HYG-R-09b Implementation Date: 14 Nov 2011

Revision No. 0 Page: 1 of 1

ISO 22000 CHECKLIST

REQ

PRP Vendor Approval

ITEMS TO CHECK

1. Approved vendor's list was updated, vendors' information was updated 2. Internal incoming material specs were available

COMPLIANCE Y N

COMMENTS

3. All suppliers had signed of the Minimum requirements for suppliers. 4. Information and documents from supliers were updated. 5. Vendor visits were carried out, reports were available 6. Performance of vendors were evaluated, records were available.

PRP

1. All food handles has been sent for medical screening and physical checks.

Health Control

PRP Training

2. Certificates and reports were available. 3. Annual checks were monitored and tracked. 4. Was there any food handlers who had not completed the medical check cycle? If yes, what was the percentage? 1. Training plan was available. 2. SFSMS/HACCP team: HACCP & ISO22000 training every 3 years, records were available. 3. All food handlers: SFSMS Training annually, records were available. 4. New food handling employees: trained on SFSMS, HACCP, ISO22000 - within 3 months 5. New employees: oreintation on SFSMS, HACCP, ISO22000 - within 2 months 6. Training records were available. 7. Tracking of training status was available.

Page 14 of 16

Ms. G. Budiongan, Mr. F. Chio Ms. G. Legaspi, Mr. A. Gatdula

Document No. : ISO22000-HYG-R-09b Implementation Date: 14 Nov 2011

Revision No. 0 Page: 1 of 1

ISO 22000 CHECKLIST

REQ

PRP Preventive Maintenance P52 PRP

ITEMS TO CHECK

1. Preventive maintenance schedule was available, and complete. 2. PM was carried out as planned. 3. PM checklist and records were available. 4. Maintenance work order were followed-up and handled. 5. Numbers of unclosed work orders? 1. Bait Station Layouts were updated - randomly verify on-site if necessary.

COMPLIANCE Y N

COMMENTS

Pest Management

2. Inspection and progress report were available. 3. MSDS available for poison used.

P52 PRP Complaint & Traceability

4. Infestation trending reports were available, and reviewed for actions 5. Any key issues on infestation? 1. Complaints were recorded and closed in a timely manner. 2. Investigations were completed in 48 hours as indicated in G9.3 3. Any trends on the complaints? 4. Any actions taken based on the trending of the complaints?

Page 15 of 16

Ms. G. Budiongan, Mr. F. Chio Ms. G. Legaspi, Mr. A. Gatdula

Document No. : ISO22000-HYG-R-09b Implementation Date: 14 Nov 2011

Revision No. 0 Page: 1 of 1

ISO 22000 CHECKLIST

REQ

PRP Cleaning & Sanitation - Stewarding

ITEMS TO CHECK

1. Approved chemical list is available and updated 2. Chemical MSDS and PIS is available for all chemicals and updated 3. Service report is available from chemical suppliers - dish washing. 4. Kitchen cleaning inspection checklists were in-place and completed. 5. Sanitizer solution changing records were in-place. 6. Dish washing temperature records were in-place. 7. Ice machine, chiller, freezer, ice cream freezer box cleaning records were in-place.

COMPLIANCE Y N

COMMENTS

PRP Cleaning & Sanitation -Housekeeping PRP QC Plan

1. Approved chemical list is available and updated 2. Chemical MSDS and PIS is available for all chemicals and updated 3. Sanitizer solution changing records were in-place. 4. Ice machine cleaning records were in-place. 1. Food sampling for microbiological testing was carried out as planned. 2. Surface swab for microbiological testing was carried out as planned. 3. Reports were available. 4. Results were reviewed for trends. 5. Actions were carried out for failed test results. 6. Actions were appropriate and effective.

Page 16 of 16

Ms. G. Budiongan, Mr. F. Chio Ms. G. Legaspi, Mr. A. Gatdula

Document No. : ISO22000-HYG-R-09b Implementation Date: 14 Nov 2011

Revision No. 0 Page: 1 of 1

ISO 22000 CHECKLIST

REQ

Product Information Flow Diagram

ITEMS TO CHECK

COMPLIANCE Y N

COMMENTS

1. Food product information was updated 2. Incoming material information was updated 1. Flow diagram was updated and reflects on the process 2. Layout on process flow was updated 3. Layout on people movement was updated 4. Layout on waste movement was updated 5. Layout in equipment was updateds Hazard Analysis & 1. Hazard analysis and risk assessment were updated for all HACCP Plans Control Measures 2. Control measures were updated CCP & O' PRP 1. Identification of CCP was updated CL 2. Identification of Operational PRP was updated 3. Critical limits was updated and remained to be effective Monitoring & 1. Monitoring method was updated and remains to be valid Corrective A. 2. Corrective actions were updated Verification 1. Verification of CCP and O'PRP were carried out as planned. P52 - HR 2. Internal audit was carried out as planned. Report was available. Traceability 1. Procedure was updated 2. Traceability challenge was carried out as planned 3. What was the success rate? Control of 1. Internal operations non-conformities were addressed and closed Non-conformities 2. Non conformities from previous internal audit were closed 3. Non conformities from previous external audit were closed 4. Food products that were affected during non-conformities were handled appropriately Verification 1. Verification procedure, planning & schedule is updated Validation 2. Results of verification activities were analysed and reviewed: Improvement - Food sampling test results - Internal audit results - External audit results 3. Improvements were carried out based on results from verification activities

You might also like

- HACCP Audit Check ListDocument28 pagesHACCP Audit Check List23906157100% (4)

- Haccp Audit ChecklistDocument8 pagesHaccp Audit Checklistkarthikeyan G100% (1)

- Iso 22000-1 PDFDocument22 pagesIso 22000-1 PDFFarhan Gohar100% (1)

- Oriental Fruits HACCP ManualDocument22 pagesOriental Fruits HACCP ManualHasrat abfc100% (5)

- GHP Manual and HACCP PlanDocument55 pagesGHP Manual and HACCP PlanMohammad Abd Alrahim Shaar0% (1)

- Weekly Food Safety AuditDocument4 pagesWeekly Food Safety AuditNina YoungNo ratings yet

- 2012 Monthly Kitchen AuditDocument3 pages2012 Monthly Kitchen AuditgadmaleNo ratings yet

- Haccp CateringDocument12 pagesHaccp Cateringkhaled100% (3)

- ISO 22000 Food Safety Audit ChecklistDocument21 pagesISO 22000 Food Safety Audit ChecklistOsama Elsayed100% (4)

- HACCP Prerequisite Programs Food Safety Systems ManualDocument83 pagesHACCP Prerequisite Programs Food Safety Systems ManualIrina75% (4)

- Prerequisite programs requirementsDocument68 pagesPrerequisite programs requirementsRoss100% (2)

- CAC Codex HACCP Check ListDocument14 pagesCAC Codex HACCP Check ListEdward Danish83% (6)

- Complete Prerequisite Program v2Document78 pagesComplete Prerequisite Program v2Ramasubramanian Sankaranarayanan100% (1)

- ISO 22000 Internal Audit ChecklistDocument1 pageISO 22000 Internal Audit Checkliststevierayo100% (1)

- HACCP Hotel CateringDocument29 pagesHACCP Hotel CateringHACCPEuropaNo ratings yet

- HACCP Food Safety Audit ChecklistDocument15 pagesHACCP Food Safety Audit ChecklistTrương Liêm67% (6)

- Hazard Analysis & Critical Control Point: Prepared By: Eng / Walid I. GahferDocument38 pagesHazard Analysis & Critical Control Point: Prepared By: Eng / Walid I. GahferWalid Gahfer100% (5)

- III Haccp PDP 2016-17 NewDocument190 pagesIII Haccp PDP 2016-17 NewBharathGunafg100% (1)

- Sop HaccpDocument28 pagesSop HaccpPrashant TripathiNo ratings yet

- Checklist & Guideline ISO 22000Document14 pagesChecklist & Guideline ISO 22000Documentos Tecnicos75% (4)

- ISO 22000 - Documentation Requirement SummaryDocument10 pagesISO 22000 - Documentation Requirement SummaryminhajurrehmanNo ratings yet

- Checklist For Kitchen AuditDocument11 pagesChecklist For Kitchen AuditkiruthikaNo ratings yet

- Food DefenceDocument46 pagesFood DefenceNitesh Kumar67% (3)

- Food Defense ChecklistDocument2 pagesFood Defense Checklistemailgalih209671% (7)

- Basic HACCP Training ModuleDocument20 pagesBasic HACCP Training Moduleyashyash_007100% (8)

- Hazard Analysis Worksheet (Apple Juice)Document8 pagesHazard Analysis Worksheet (Apple Juice)JyShe_la100% (1)

- Kitchen Inspection ChecklistDocument8 pagesKitchen Inspection ChecklisttzryadNo ratings yet

- Sample Audit Checklist: Company Name: Luscious Bites Date of Audit: AuditorDocument16 pagesSample Audit Checklist: Company Name: Luscious Bites Date of Audit: AuditorMonica SinghNo ratings yet

- FSMS Compliance ChecklistDocument18 pagesFSMS Compliance ChecklistJose III LlanetaNo ratings yet

- FSSC v4.1 ChecklistDocument100 pagesFSSC v4.1 Checklistjamil voraNo ratings yet

- HACCP ChecklistDocument3 pagesHACCP ChecklistTim Qu100% (4)

- Sample Audit Checklist For HACCPDocument16 pagesSample Audit Checklist For HACCPAprilJoyBascosNo ratings yet

- Checklist ISO 22000Document21 pagesChecklist ISO 22000anggirasti100% (1)

- SAFE Food Safety Audit ChecklistDocument54 pagesSAFE Food Safety Audit ChecklistHaroon Valiyil100% (2)

- GMP Policy ManualDocument3 pagesGMP Policy ManualAgnes_Agnes_AgnesNo ratings yet

- Standard Operating ProceduresDocument27 pagesStandard Operating ProceduresWasimraja Nanjwani100% (1)

- HACCP Food Safety ManualDocument32 pagesHACCP Food Safety Manualacroali100% (12)

- Quality SOP Manual in Catering and RestaurantsDocument88 pagesQuality SOP Manual in Catering and RestaurantsMohamed100% (4)

- Food Defence Training PresentationDocument14 pagesFood Defence Training PresentationTASTETECH100% (7)

- Food Allergen PlanDocument11 pagesFood Allergen PlanManuelito Maratas AndayaNo ratings yet

- ISO 22000 OPRPs vs HACCPDocument47 pagesISO 22000 OPRPs vs HACCPsadbad667% (3)

- HACCP Audit ChecklistDocument8 pagesHACCP Audit ChecklistJaykishan Parmar100% (3)

- Haccp Checklist Guidiance Notes - Doc: Belema .04.2017Document7 pagesHaccp Checklist Guidiance Notes - Doc: Belema .04.2017Godwin A.udo-akan100% (1)

- Ha CCP Guide For Spices Seasonings 2006Document45 pagesHa CCP Guide For Spices Seasonings 2006jamilvora100% (2)

- Checklist Audit ISO 22000Document18 pagesChecklist Audit ISO 22000Abhishek Kumar Singh95% (20)

- 2.audit Report BRCDocument34 pages2.audit Report BRCCôn LuânNo ratings yet

- Allergen Control Checklist Manufacturer 0908Document4 pagesAllergen Control Checklist Manufacturer 0908shakeyken100% (1)

- SopDocument71 pagesSopwithraviNo ratings yet

- HACCP Infomation All 1102Document98 pagesHACCP Infomation All 1102Rose DNNo ratings yet

- Catering Service Sop 06 611Document23 pagesCatering Service Sop 06 611Dr Gajanan Shirke100% (1)

- GMP and HACCP Checklist for Food Safety AuditsDocument16 pagesGMP and HACCP Checklist for Food Safety Auditsdiansyahputra100% (5)

- Food Management SystemDocument24 pagesFood Management Systemsaisridhar99No ratings yet

- Food Allergen Information SheetDocument7 pagesFood Allergen Information SheetJohn Henry WellsNo ratings yet

- 19.0528 Guidance Food Fraud Mitigation Version 5Document9 pages19.0528 Guidance Food Fraud Mitigation Version 5andikaprakosoNo ratings yet

- Food Control System Assessment Tool: Dimension B – Control FunctionsFrom EverandFood Control System Assessment Tool: Dimension B – Control FunctionsNo ratings yet

- Food Defense A Complete Guide - 2020 EditionFrom EverandFood Defense A Complete Guide - 2020 EditionRating: 1 out of 5 stars1/5 (1)

- HACCP & Sanitation in Restaurants and Food Service Operations: A Practical Guide Based on the USDA Food CodeFrom EverandHACCP & Sanitation in Restaurants and Food Service Operations: A Practical Guide Based on the USDA Food CodeRating: 2 out of 5 stars2/5 (5)

- c01 P Hygiene, Safety and Food HandlingDocument13 pagesc01 P Hygiene, Safety and Food HandlingAmira Azani67% (3)

- Food Hygiene CodeDocument28 pagesFood Hygiene Codesherio9No ratings yet

- 57 Lean InventoryDocument4 pages57 Lean InventoryNabilKnouziNo ratings yet

- BS Iso 4120-2004Document22 pagesBS Iso 4120-2004NabilKnouzi100% (1)

- Cross DockingDocument2 pagesCross DockingNabilKnouziNo ratings yet

- Chocolate ProcessDocument4 pagesChocolate ProcessNabilKnouziNo ratings yet

- Chocolate ProcessDocument4 pagesChocolate ProcessNabilKnouziNo ratings yet

- Successful Gluten Free BakingDocument25 pagesSuccessful Gluten Free BakingNabilKnouzi100% (2)

- Central Limit TheoremDocument4 pagesCentral Limit TheoremNabilKnouzi100% (1)

- The Star News November 20, 2014Document37 pagesThe Star News November 20, 2014The Star NewsNo ratings yet

- Human Kinetics Library Platform - Benefits and Values of Outdoor RecreationDocument17 pagesHuman Kinetics Library Platform - Benefits and Values of Outdoor RecreationMihail RonnyNo ratings yet

- Nursing Process in Drug TherapyDocument60 pagesNursing Process in Drug TherapyYra JhaneNo ratings yet

- SolidtumorsinchildrenDocument24 pagesSolidtumorsinchildrenPriyaNo ratings yet

- Introduction of PhobiaDocument2 pagesIntroduction of PhobiawoodenskyNo ratings yet

- GHQ 2Document8 pagesGHQ 2miji_ggNo ratings yet

- 2-1-2021 Response To LandlordDocument2 pages2-1-2021 Response To LandlordJessica SwarnerNo ratings yet

- SJCTs Pilot Examination Information & InstructionsDocument6 pagesSJCTs Pilot Examination Information & InstructionsSkep100% (1)

- GRADE 5 - WEEK 6 Catch UpDocument8 pagesGRADE 5 - WEEK 6 Catch Upbutchabdon1992No ratings yet

- Buku Koding 1Document74 pagesBuku Koding 1indra_igrNo ratings yet

- Reflective Essay: Writing in The Genetics DiscourseDocument5 pagesReflective Essay: Writing in The Genetics DiscourseAnonymous AY6XDZHBxPNo ratings yet

- KCC Mall 69kV Substation DesignDocument18 pagesKCC Mall 69kV Substation DesignRomie ArazaNo ratings yet

- Lista Cartilor Elsevier AchizitionateDocument57 pagesLista Cartilor Elsevier AchizitionateLucica PleșcaNo ratings yet

- Serial number verification formDocument1 pageSerial number verification formArjelyNo ratings yet

- Mozart, Beethoven, Yesudas Effect Class 2Document12 pagesMozart, Beethoven, Yesudas Effect Class 2Dr Suvarna NalapatNo ratings yet

- MSDS - CRC Seal Coat ® Urethane Coating - ClearDocument3 pagesMSDS - CRC Seal Coat ® Urethane Coating - ClearLailal HaqimNo ratings yet

- Single/ Exam Zone Centre DetailsDocument5 pagesSingle/ Exam Zone Centre DetailsHarsh AroraNo ratings yet

- Bailey SafeMedPharmacyTechnicianDocument10 pagesBailey SafeMedPharmacyTechnicianRazak AbdullahNo ratings yet

- Cholera FinalDocument57 pagesCholera FinalBinayaNo ratings yet

- What Is Dissociation and What To Do About It?Document2 pagesWhat Is Dissociation and What To Do About It?Tommy ThompsonNo ratings yet

- Breast Feeding Final ProposalDocument16 pagesBreast Feeding Final ProposalDeborah BoahemaaNo ratings yet

- Performa Stereo Quick User GuideDocument2 pagesPerforma Stereo Quick User GuideJUAN CARLOSNo ratings yet

- Bio SaftyDocument7 pagesBio Saftyapi-283956320No ratings yet

- Vanessa Tarot BookletDocument36 pagesVanessa Tarot BookletClassic Bobby100% (2)

- International Journal of Radiology and Imaging Technology Ijrit 7 082Document3 pagesInternational Journal of Radiology and Imaging Technology Ijrit 7 082Zafitri AsrulNo ratings yet

- Burns Guide: Causes, Types, TreatmentDocument4 pagesBurns Guide: Causes, Types, TreatmentMartin KoaNo ratings yet

- Solutions For RefugeesDocument24 pagesSolutions For RefugeesjacquelineNo ratings yet

- USMLE High YieldDocument8 pagesUSMLE High YieldNajia ChoudhuryNo ratings yet

- CHN Assignment (Community Health Nursing)Document21 pagesCHN Assignment (Community Health Nursing)binjuNo ratings yet

- PALLIATIVE CARE SYMPTOM MANAGEMENTDocument153 pagesPALLIATIVE CARE SYMPTOM MANAGEMENTrlinao100% (3)