Professional Documents

Culture Documents

16.properties Related To Strength

Uploaded by

aderancOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

16.properties Related To Strength

Uploaded by

aderancCopyright:

Available Formats

PROPERTIES

RELATED TO

STRENGTH

Strength is the ability of a material to resist

applied forces without yielding or fracturing.

Strength of a material may change considerably

with respect to the way it is deformed.

Mode of stress, type of stress & rate of stress

application may affect the strength of a

material.

Strength data are usually obtained from lab.

Tests which are performed under strictly

standardized specimens under controlled

conditions. These tests also serve for obtaining

- relationships.

- curves can be grouped into three as:

Ductile Materials exhibit both elastic &

plastic behavior

Brittle Materials exhibit essentially elastic

behavior

Viscoelastic Materials exhibit large elastic

deformation

SPECIAL FEATURES OF STRESS-STRAIN

DIAGRAMS

PL

U

A

B

C

D

E

Point A (Proportional Limit): The greatest stress

(

PL

) that can be developed in the material

without causing a deviation from the law of

proportionality of stress to strain. In other

words it is the stress upto which the material

responds following Hookes Law.

Point B (Elastic Limit): Maximum stress (

E

) that

can be developed in a material without

causing permanent deformation. In other

words it is the stress upto which the

deformations are recoverable upon unloading.

Point C (Yield Point): The stress at which the

material deforms appreciably without an

increase in stress. Sometimes it can be

represented by an upper and lower yield

points.

Y,U

represents the elastic strength of

the material and

Y,L

is the stress beyond

which the material behaves plastically.

Point D (Ultimate Strength): It is the maximum

stress that can be developed in a material as

determined from the original X-section of the

specimen.

Point E (Fracture Strength): The stress at which the

material breaks, fails.

In an engineering - plot the original area

(A

0

) & length (l

0

) are used when determining

stress from the load and strain from

deformations.

In the true - plot instantaneous area &

length are used.

The true values of stress & strain for

instantaneous area & length of the specimen

under tension will differ markedly, particularly

close to the breaking point where reduction in

cross-section & elongation of the specimen are

observed.

0

A

P

E

= o

&

0

l

E

A

= c Engineering

i

T

A

P

= o &

i

T

l

A

= c

True

|

|

.

|

\

|

= =

}

0

ln

0

l

l

l

dl

i

l

l

true

i

c

1

1

0 0

0

0 0

0

0

=

= = =

}

l

l

l

l l

l l

dl

i i

l

l

l

l

eng

i

i

c

( )

eng true

c c + = 1 ln

For

eng

0.1 ln(1+0.1) 0.1

For small strains

true

eng

i

true

A

P

= o

&

0

A

P

eng

= o

If you assume no volume change:

i i

l A l A V = =

0 0

i

i

l

l

A A

0

0

=

( )

eng eng

i

eng

i

true

l

l

l

l

A

P

c o o o + = = = 1

0

0

0

( )

eng eng true

c o o + = 1

DUCTILITY & BRITTLENESS

Ductility can be defined as strain at fracture.

Ductility is commonly expressed as:

a) Elongation

b) % reduction in cross-sectional area

A ductile material is the one which deforms

appreciably before it breaks, whereas a brittle

material is the one which does not.

Ductility in metals is described by:

100 %

0

0

=

A

A A

R

f

A

If %R

A

> 50 %

Ductile metal

TOUGHNESS & RESILIENCE

Toughness is the energy absorption capacity

during plastic deformation.

In a static strength test, the area under the

- curve gives the amount of work done to

fracture the specimen.

This amount is specifically called as Modulus

of Toughness.

It is the amount of energy that can be

absorbed by the unit volume of material

without fracturing it.

T (Joule/m

3

)

PL

PL

The area under the - diagram can be determined

by integration.

If the - relationship is described by a parabole.

f u

T c o

3

2

=

Resilience is the energy absorption capacity

during elastic deformation.

R

PL

PL

c o

PL

R

2

1

=

E

PL

o

c =

Since

( )

E

R

PL

2

2

1 o

=

If you assume

PL

=

y

E

R

y

2

2

o

=

YIELD STRENGTH

It is defined as the maximum stress that can

be developed without causing more than a

specified permissible strain.

It is commonly used in the design of any

structure.

If a material does not have a definite yield

point to measure the allowable strains, Proof

Strength is used.

Proof strength is determined by approximate

methods such as the 0.2% OFF-SET METHOD.

At 0.2% strain, the initial tangent of the -

diagram is drawn & the intersection is located.

DETERMINATION OF E FROM -

DIAGRAMS

For materials like concrete, cast iron & most non-

ferrous metals, which do not have a linear

portion in their - diagrams, E is determined by

approximate methods.

1. Initial Tangent Method: Tangent is drawn to the

curve at the origin

2. Tangent Method: Tangent is drawn to the curve

at a point corresponding to a given stress

3. Secant Method: A line is drawn between the

origin & a point corresponding to a given stress

3

2

1

HARDNESS

Hardness can be defined as the resistance of a

material to indentation.

It is a quick & practical way of estimating the

quality of a material.

Early hardness tests were based on natural

minerals with a scale constructed solely on the

ability of one material to scratch another that

was softer.

A qualitative & somewhat arbitrary hardness

indexing scheme was devised, temed as Mohs

Scale, which ranged from 1 on the soft end for

talc to 10 for diamond.

1. Talc

2. Gypsum

3. Calcite

4. Fluorite

5. Apatite

6. Orthoclase

7. Quartz

8. Topaz

9. Corundum

10. Diamond

HARDER

An unknown material will

scratch a softer one & will

be scratched by harder

one.

EX:

Fingernail-(2.5)

Gold, Silver-(2.5-3)

Iron-(4-5)

Glass-(6-7)

Steel-(6-7)

The hardness of a metal is determined by

pressing an indenter onto the surface of the

material and measuring the size of an

indentation.

The bigger the indentation the softer is the

material.

Common hardness test methods are:

Brinell Hardness

Vickers Hardness

Rockwell Hardness

1. Brinell Hardness

Load P is pressed for 30

sec. and the indentation

diameter is measured as

d.

P

d

( )

2 2

2

d D D D

P

t

Brinell Hardness =

(kgf/mm

2

)

2. Rockwell Hardness

Instead of the indentation

diameter, indentation depth

is measured.

However, the surface

roughness may affect the

results.

So, an initial penetration is

measured upto some load,

and the penetration depth is

measured with respect to

this depth.

H = H

2

H

1

P

1

Initial

load

H

1

P

2

Final

load

H

2

3. Vickers Hardness

Instead of a sphere a

conical shaped indenter is

used.

P

Top

View

Indentation

d

2

d

1

(kgf/mm

2

)

2

2 1

d d

d

+

=

Vickers Hardness =

2

854 . 1

d

P

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- FP918C Bondstrand 2000M-7000M Inc Taper Taper 01.08.11Document28 pagesFP918C Bondstrand 2000M-7000M Inc Taper Taper 01.08.11Venessa MejiaNo ratings yet

- Heat ExchangerDocument17 pagesHeat ExchangerMedariTrinadh100% (2)

- Reverse Dial Indicator MethodDocument14 pagesReverse Dial Indicator MethodvinothenergyNo ratings yet

- 15 ViscoelasticityDocument30 pages15 ViscoelasticityaderancNo ratings yet

- Steam-Water & Flue Gas AnalyzersDocument67 pagesSteam-Water & Flue Gas AnalyzersAshwani DograNo ratings yet

- Rockwool 2Document8 pagesRockwool 2leroniusNo ratings yet

- Sym Euro MX 125 (EN)Document193 pagesSym Euro MX 125 (EN)manualsym0% (1)

- Structural ImperfectionsDocument23 pagesStructural ImperfectionsaderancNo ratings yet

- Examples Related To Atomic StructureDocument8 pagesExamples Related To Atomic StructureaderancNo ratings yet

- Noncrystalline Solid StructuresDocument3 pagesNoncrystalline Solid StructuresaderancNo ratings yet

- MILLER System of IndicesDocument18 pagesMILLER System of IndicesaderancNo ratings yet

- Atomic Bonding in Solids: Bonding Energy, Interatomic SpacingDocument14 pagesAtomic Bonding in Solids: Bonding Energy, Interatomic SpacingaderancNo ratings yet

- 17.creep & FatigueDocument20 pages17.creep & FatigueaderancNo ratings yet

- Interatomic BondingDocument22 pagesInteratomic BondingaderancNo ratings yet

- States of Aggregation: AND Crystal StructuresDocument29 pagesStates of Aggregation: AND Crystal StructuresaderancNo ratings yet

- 13 ThermoelasticityDocument18 pages13 ThermoelasticityaderancNo ratings yet

- Atomic StructureDocument9 pagesAtomic StructureaderancNo ratings yet

- 14 PlasticityDocument25 pages14 PlasticityaderancNo ratings yet

- 12.elastic ConstantsDocument18 pages12.elastic ConstantsaderancNo ratings yet

- 10.concepts of Force-Stress and Deformation-StrainDocument25 pages10.concepts of Force-Stress and Deformation-StrainaderancNo ratings yet

- 11.mechanical Properties of MaterialsDocument22 pages11.mechanical Properties of MaterialsLakshmi Prasad V KNo ratings yet

- Temel MATLAB KomutlarıDocument9 pagesTemel MATLAB KomutlarıaderancNo ratings yet

- Slope Deflection MethodDocument87 pagesSlope Deflection MethodFian ArdiyanaNo ratings yet

- CE 221 Materials Science: Assist. Prof - Dr. Hanifi BINICIDocument21 pagesCE 221 Materials Science: Assist. Prof - Dr. Hanifi BINICIaderancNo ratings yet

- 04 MomentDistribution PDFDocument88 pages04 MomentDistribution PDFSimran Radheshyam SoniNo ratings yet

- Chapter 8 Large Equipment & Furnishing "Over Equipping Not OnlyDocument5 pagesChapter 8 Large Equipment & Furnishing "Over Equipping Not Onlydagzy100% (4)

- English Assignment (Full Essay-Final Term by Saima)Document9 pagesEnglish Assignment (Full Essay-Final Term by Saima)Md MahfuzNo ratings yet

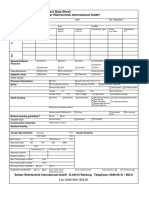

- Agitator Data Sheet Stelzer Rührtechnik International GMBH: CompanyDocument1 pageAgitator Data Sheet Stelzer Rührtechnik International GMBH: CompanyDeepikaNo ratings yet

- Qi Lu: Professional ExperienceDocument4 pagesQi Lu: Professional ExperienceShiva DagalNo ratings yet

- Almasol 1250-1251 Product Info PDFDocument2 pagesAlmasol 1250-1251 Product Info PDFmehmetaliozgurNo ratings yet

- Mohammed Et Al. (2022) - Graphene-CelluloseDocument8 pagesMohammed Et Al. (2022) - Graphene-CellulosealhassanNo ratings yet

- Bombas Vacio Serie ErDocument14 pagesBombas Vacio Serie ErAna AltamiranoNo ratings yet

- Report On Cascading TransformersDocument28 pagesReport On Cascading Transformerspalak yadavNo ratings yet

- Technical Service Manual: Section TSM 144 1 of 10 Issue DDocument10 pagesTechnical Service Manual: Section TSM 144 1 of 10 Issue DHector_Cornejo_5673No ratings yet

- 87a-207-01-Stainless Steel Asme Class 150 Flanged Full Port Ball Valve - 1.5" Thru 2.5Document1 page87a-207-01-Stainless Steel Asme Class 150 Flanged Full Port Ball Valve - 1.5" Thru 2.5Hung NguyenNo ratings yet

- Advantages of Steel As A Structural MaterialDocument3 pagesAdvantages of Steel As A Structural MaterialIrfan MunirNo ratings yet

- 11 CR-CB Data SheetDocument2 pages11 CR-CB Data SheetJLZ972No ratings yet

- Sub Title IodoformDocument3 pagesSub Title IodoformReni whynNo ratings yet

- KM Epm D CBL Acc 11 Heat Terminations F05Document25 pagesKM Epm D CBL Acc 11 Heat Terminations F05Rajeeb MohammedNo ratings yet

- CT - L1, L2Document9 pagesCT - L1, L2Rohna IqbalNo ratings yet

- SC2057 PDFDocument3 pagesSC2057 PDFA MahmoodNo ratings yet

- Kim Lighting CCL Curvilinear Cutoff Luminaires Brochure 1987Document18 pagesKim Lighting CCL Curvilinear Cutoff Luminaires Brochure 1987Alan Masters100% (1)

- Vechi RWX62Document18 pagesVechi RWX62Mihai ConstantinescuNo ratings yet

- Piping 110 KTPD & 190 KTPDDocument47 pagesPiping 110 KTPD & 190 KTPDgasparyyoNo ratings yet

- High-Density Polyethylene - WikipediaDocument3 pagesHigh-Density Polyethylene - Wikipediakirthi83No ratings yet

- Eclipse Airheat Burners: Ah-Ma SeriesDocument4 pagesEclipse Airheat Burners: Ah-Ma Seriespanait trofinNo ratings yet

- Hard Turning On LatheDocument105 pagesHard Turning On LatheJitendraNo ratings yet

- Modern spinning technology guideDocument6 pagesModern spinning technology guideParthrajPuranikNo ratings yet

- STL FileDocument60 pagesSTL FileR RAJESWARINo ratings yet