Professional Documents

Culture Documents

Microcontroller Plant Irrigation

Uploaded by

Sri Harsha KoppakaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Microcontroller Plant Irrigation

Uploaded by

Sri Harsha KoppakaCopyright:

Available Formats

A PROJECT REPORT ON

MICROCONTROLLER BASED PLANT IRRIGATION SYSTEM

LIST OF FIGURES

FIGURE NO. 1.1 1.2 1.3 1.4 1.5 1.6 3.1 3.2 3.3 3.4 3.5

FIGURE NAME Ditch Irrigation Terraced Irrigation Drip Irrigation Sprinkler System Rotary System System Block Diagram Block Diagram Power Supply Design in Multisim 10 software Internal Circuit Diagram of LM339 Final Schematic Diagram Final PCB Layout

PAGE NO. 8 9 9 9 10 11 18 20 21 23 25

CHAPTER 1 INTRODUCTION

This chapter includes the problem statement, system block diagram and explanation about the each block. It also includes the relevance of our project i.e. what are the applications of this projects. 1.1 INTRODUCTION Problem statements: To built automatic plant irrigation system based on microcontroller 8051 . OBJECTIVE: Now days, water shortage is becoming one of the biggest problem in the world. Many different methods are developed for conservation of water. We need water in each and every field. In our day to day life also water is essential. Water is considered to be basic need of human. Water is needed for everyone human beings, animals, plants, etc. Agriculture is one of the fields where water is required in tremendous quantity. Wastage of water major problem in agriculture. Every time excess of water is given to the fields. There are many techniques to save or to control wastage of water from agriculture. Different types of irrigation are used for management of water in agricultural land. IRRIGATION: Irrigation is an artificial application of water to the soil. It is usually used to assist the growing of crops in dry areas and during periods of inadequate rainfall. TYPES OF IRRIGATION SYSTEMS Ditch Irrigation

Fig. 1.1 Ditch Irrigation Ditch Irrigation is a rather traditional method, where ditches are dug out and seedlings are planted in rows. The plantings are watered by placing canals or furrows in between the rows of plants. Siphon tubes are used to move the water from the main ditch to the canals. This system of irrigation was once very popular in the USA, but most have been replaced with modern systems. Terraced Irrigation

Fig 1.2 Terraced Irrigation This is a very labor-intensive method of irrigation where the land is cut into steps and supported by retaining walls. The flat areas are used for planting and the idea is that the watering for each planting water flows down each step, while plot. This allows steep land to be used crops.

Drip Irrigation

Fig 1.3 Drip Irrigation This is known as the most water efficient method of irrigation. Water drops right near the root zone of a plant in a dripping motion. If the system is installed properly you can steadily reduce the loss of water through evaporation and runoff. Sprinkler System

Fig 1.4 Sprinkler System This is an irrigation system based on

overhead sprinklers, sprays or guns, installed on permanent risers. You can also have the system buried underground and the sprinklers rise up when water pressure 4

rises, which is a popular irrigation system for use on golf courses and parks. Rotary Systems

Fig. 1.5 Rotary System This method of irrigation is best suited for larger areas, for the sprinklers can reach distances of up to 100 feet. The word Rotary is indicative of the mechanical driven sprinklers moving in a circular motion, hence reaching greater distances. This system waters a larger area with small amounts of water over a longer period of time. NEED OF AUTOMATIC IRRIGATION:Automatic irrigation systems are convenient, especially for those who travel. If installed and programmed properly, automatic irrigation systems can even save you money and help in water conservation. Dead lawn grass and plants need to be replaced, and that can be expensive. But the savings from automatic irrigation systems can go beyond that. Watering with a hose or with oscillator wastes water. Neither method targets plant roots with any significant degree of precision. Automatic irrigation systems can be programmed to discharge more precise amounts of water in a targeted area, which promotes water conservation. Software and hardware platform used: A] Hardware used: 1. Microcontroller 2. Analog to digital Converter (ADC) 3. Humidity Sensor 4. Voltage Amplifier 5. Comparator 6. Current to Voltage Converter 7. Temperature Sensor 5

8. Solenoid/Relay 9. Diodes, Resisters and Capacitors B] Software platforms use: 1. Multisim 10.2 2. Diptrace 3. Side 51

1.2SYSTEM BLOCK DIAGRAM AND EXPLANATION:

Temp. Sensor

Amplifier

Humidity Sensor

LM 339

I to V converter

Voltage Amplifier

Comparator

MicroController

LED

Fig. 1.6 System Block Diagram Humidity Sensor: The humidity sensor just senses the humidity or moisture of the soil. The change in humidity is proportional to the amount of current flowing through the soil. 6

I to V Converter and Voltage Amplifier: The current to voltage converter converts current coming from the humidity sensor into voltage and this voltage is given to the voltage amplifier for amplification. Comparator: It compares the reference voltage and the amplified voltage coming from I to V convertor. Temperature Sensor and LM339: IC LM35 senses the surrounding temperature. The output of this IC is analog voltage. This voltage is given to the LM339 for comparing the present condition with the ideal one. Microcontroller: The entire automation of the project is done by the microcontroller.

1.3 RELEVANCE: Automatic irrigation systems are convenient, especially for those who travel. If installed and programmed properly, automatic irrigation systems can even save you money and help in water conservation. Dead lawn grass and plants need to be replaced, and that can be expensive. But the savings from automatic irrigation systems can go beyond that. Watering with a hose or with an oscillator wastes water. Neither method targets plant roots with any significant degree of precision. Automatic drip irrigation systems can be programmed to discharge more precise amounts of water in a targeted area, which promotes water conservation. Thus, a number of researchers have put in interest to develop various kind of automatic water saving irrigation technique. The system can also be implemented on farms at large scale which would 7

help in increasing the per unit production, with less capital and manpower. It can be used in domestic lawns and gardens also. In Poly and Green Houses also the technique seems beneficial. Thus, they help in enhancing the beauty of a number of landscapes and lawns and also help in saving gallons of water. It is the solution to the biggest hindrance i.e. water scarcity. The farmer can even pass out specific amount of fertilizers and chemicals to the roots of the plant directly.

CHAPTER 2 LITERATURE REVIEW

The chapter covers an overview about the previous and future projects related to the system. 2.1 PREVIOUS RELATED WORK In India, normal irrigation technique, which are manually operated are used widely due to its low cost and high profits. Automatic irrigation techniques are not so prevalent here. But various methods like the automatic sprinklers, which are used widely for domestic gardening purpose; these are designed to supply water for a particular period of the day only. They are time controlled. The volume of water to be supplied and the rate of flow of water are essential to calculate the time interval. More over Volume control system are more advantageous than time control system. The amounts of water they supply are fixed irrespective of continuous electricity availability but still time controlled systems are more popular due to its cheap value. Here volume meters are connected, which emits a pulse after delivering a specific amount of water and the controller measures these pulses to keep a check on the supply. The most recent type is the rainfall detector for detecting a set amount of rainfall. This functions to interrupt the normal operation of an automatic sprinkler or irrigation system upon detection of the set amount of rainfall, it includes a rainwater-collection tray having an opening and mounted so that the portion of the opening exposed to rainwater during a rainstorm is adjustable. The rainwatercollection tray may be able to slide and is mounted below a detector housing which houses a switching circuit with two sensors extending into the tray, and it also prevents from the debris to fall in the tray. When water in the tray is filled up to the mark of reference the sensor completes the circuitry and isolates the irrigation system from the supply and thus prevent from excessive water supply to the plants. This method is patent to Richard E. Morrison, (Salt Lake City, UT) and Kent C. Erickson (Centerville, UT). In addition to the above there are two more methods they are closed loop and open loop irrigation system. The closed loop type of system requires feedback from one or more sensors. The operator develops a general control strategy. Once the general strategy is defined, the control system takes over and makes detailed decisions of when to apply water and how much water to apply. Irrigation decisions 10

are made and actions are carried out based on data from sensors. In this type of system, the feedback and control of the system are done continuously. But in an open loop system, the operator makes the decision on the amount of water that will be applied and when the irrigation event will occur. This information is programmed into the controller and the water is applied according to the desired schedule. Open loop control systems use either the irrigation duration or a specified applied volume for control purposes. The drawback of open loop systems is their inability to respond automatically to changing conditions in the environment. In addition, they may require frequent resetting to achieve high levels of irrigation efficiency. 2.2 STATE OF ART The scientists are developing an underground irrigation system. The major drawback of water evaporation taking place at the surface level irrigation is overcome by this method. In this method various sensors are placed below the ground level to determine the moisture percentage in the soil. The water supply in this case is directly to the root system and as the moisture level at the root level is essential to be known the sensor are placed near the roots. This will optimize the water consumption further and will make maximum use of all agricultural resource.

11

CHAPTER 3 EXPERIMENTATION & RESULTS

12

The main content of the chapter is about the total block diagram and detailed designing of the system. 3.1 BLOCK DIAGRAM

Temp. Sensor Temp. Sensor

Amplifier Comparato r

Humidity Sensor Humidity Sensor

LM339 ADC

I to V converter I to V converter

Voltage Amplifier Voltage Amplifier

Comparator Comparato r

MicroController MicroController

LED Solenoid/ Relay

Fig 3.1 Block Diagram 3.2 MODULE/BLOCK WISE DESIGN

3.2.1 Design of Humidity sensor: The humidity sensors available in market are too costly to be used for such small household applications. So for domestic purpose, we have designed a simple humidity sensor which works on the principle of conductivity of the soil i.e. whenever the soil is dry the conductivity of soil is less and vice-versa. Our humidity sensor consists of two metal rods and 9V battery. The two conducting metal rod used are of Aluminium. These two rods are separated by wooden block for supporting the two rods and keeping the spacing between them constant. The two rods are inserted in soil. The 9V battery is connected in series 13

with these rods. So, the current flows from the rods through the soil. Here, if soil is dry, current flowing is negligible. And if soil is wet, current is sensed. This current is then converted into voltage using I to V converter. The readings given by these sensors are not accurate but they are approximate. 3.2.2 Design of power supply:Power supply consists of a transformer, bridge rectifier, and voltage regulating ICs 7805, 7812, 7912. +5 V,-5V,+12V DC power supply is designed to provide VCC as well as reference voltage to the various ICs. Power supply design has following stages:Step down transformer (230V to 15V AC):Here, step down transformer converts 230V from AC mains into 15V AC. We have used a center tap transformer having -15V, 0V, 15V and 0.5 ampere. Transformer selection is based on the fact that regulator ICs require around 14v as input considering dropout voltage (around 2v), in order to obtain 12v power supply. And current demand of ICs 741, ADC, microcontroller, comparator etc is satisfied using 500mA transformer. Transformer steps down ac voltage from 230v ac to 15v ac. It is then given to bridge rectifier. Bridge rectifier converts ac voltage into pulsating dc. It is then given to regulator ICs which output constant dc voltage. These voltages are given to other ICs as VCC or reference. Outputs of ICs 7805, 7812 &7912 are +5v, +12v &12v respectively. Bridge rectifier: Rectifier converts ac voltage into dc voltage. 4 diodes are connected in bridge. Its input is from transformer and output is given to the voltage regulator ICs. Voltage Regulator IC: Voltage regulator IC gives constant DC voltage at output in spite of fluctuations in input. 14

3.1Power Supply Design in Multisim 10 software:

Fig. 3.2 Power Supply Design in Multisim 2. Temperature sensor IC LM 35:LM 35 IC senses instantaneous temperature, and converts it into voltage. This voltage is then amplified and given to ADC. 4. I to V converter IC 741:This IC converts current into voltage. IC 741 is used for this purpose. voltage is then amplified and given to comparator. 5. Voltage Amplifier IC 741:This amplifies the voltage given as an input to it. Its gain is calculated as:Av=1+Rf/R1 15 Output

6. Comparator IC LM 339:Comparator IC LM 339 compares 2 voltages. Vref is adjusted by adjusting pot. Vref is given by formula:Vref= (R2/ (R1+R2)) X 5 In our project Vref for first comparator IC is 5V. This IC compares the Vref and amplified output of I to V convertor. We have used two comparator ICs. As discussed above the first comparator IC compares amplified voltage from I to V convertor. Now the second comparator IC is used to compare different temperature conditions. LM 339 IC has four internal comparators. Out of those four comparators we are using only two comparators. The one comparator compares whether temperature is above or below 20 degree Celsius. Another one compares whether temperature is above or below 30 degree Celsius. The output of this IC is given to the microcontroller. 3.2Internal Circuit Diagram of LM339:-

8. Microcontroller IC AT 89C51:Program is given to microcontroller to check values of temperature and output of comparator which compares the Vref and amplified voltage of I to V convertor, and make the LED ON for particular time interval. Time interval is different for different ranges of temperature. Program is written in assembly language. 16

9. Flip flop IC 7474:Microcontroller AT89C51 has clock frequency 12MHz.For ADC 0808, 680KHz frequency is required. So, this frequency is derived from microcontroller clock using flip flops. IC 7474 is used as the flip flop IC. 10. LED:It indicates the need of sprinkler. When LED is on, that means sprinkler should be on. If it is off, there is no need of water.

17

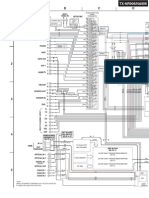

3.3 FINAL SCHEMATIC DAIGRAM :

Microntroller Comparato r

ADC

Amplifier

I to V

Power Supply Amplifier

LM35 18

3.3 FINAL PCB LAYOUT

We have used dip-trace software to make the design of PCB.

19

CHAPTER 4 CONCLUSION & FUTURE SCOPE

20

4.1 CONCLUSION The system provides with several benefits and can operate with less manpower. The system supplies water only when the humidity in the soil goes below the reference. Due to the direct transfer of water to the roots water conservation takes place and also helps to maintain the moisture to soil ratio at the root zone constant to some extend. Thus, the system is efficient and compatible to the changing environment. 4.2 FUTURE SCOPE

Advantages

1. Saves water - Studies show that drip irrigation systems use 30 - 50% less water than conventional watering methods, such as sprinklers. 2. Improves growth - Smaller amounts of water applied over a longer amount of time provide ideal growing conditions. Drip irrigation extends watering times for plants, and prevents soil erosion and nutrient runoff. Also, because the flow is continuous, water penetrates deeply into the soil to get well down into the root zone. 3. Discourages weeds - Water is only delivered where it's needed. 4. Saves time - Setting and moving sprinklers is not required. A timer delay as per environment can be added to the system for automatic watering. 5. Helps control fungal diseases, which grow quickly under moist conditions. Also, wet foliage can spread disease. 6. Adaptable - A drip irrigation system can be modified easily to adjust to the changing needs of a garden or lawn. 7. Simplest Method - Start by drawing a map of your garden and yard, showing the location of plantings. Measure the distances required for lengths of hose or plastic tubing to reach the desired areas. With a numerous fields of application and various advantages of the system has made it one of the major option available for the farmers. The increasing interest in this area of research may bring about more and more consumer efficient system. Water scarcity the major problem is well handled by the system. The changing climatic condition and global warming issues prevailing 21

throughout the world can be overcome only through this system. The automatic irrigation system will be every farmers choice in a decade or so. The improper advertising was the sole reason for the late adoption and acquaintance of the system that took place in the late eighties. But with the awareness spreading all over the globe the system is earning acceptance and so, a number of scientist are investing their time to perfect the system.

APPDIENCES 22

It includes 1] Datasheets for technical assistance as follows 1. LM35 2. LM339 3. AT89C51 4. OP741

REFERENCES 23

1. Integrated Circuits by R.S. Botkar 2. http://www.alldatasheets.com 3. http://www.wikipedia.com 4. 8051projects.info 5. M.A. Mazidi for 8051 programming

24

You might also like

- Microcontroller Drip IrrigationDocument9 pagesMicrocontroller Drip IrrigationPance RafailovskiNo ratings yet

- Automatic Irrigation System Using Microcontroller Main DocumentDocument39 pagesAutomatic Irrigation System Using Microcontroller Main Documentmyhomenet119188180% (15)

- Micro Controller Based Drip Irrigation SystemDocument34 pagesMicro Controller Based Drip Irrigation SystemSoresa JemalNo ratings yet

- Smart Irrigation Using Low Cost Moisture Sensor and Cortex Arm m3Document7 pagesSmart Irrigation Using Low Cost Moisture Sensor and Cortex Arm m3meenachiNo ratings yet

- Chapter OneDocument47 pagesChapter Onewako safayiNo ratings yet

- Automatic Plant Irrigation System Using RTCDocument51 pagesAutomatic Plant Irrigation System Using RTCRajeshMudulakarNo ratings yet

- Automatic Plant Irrigation System Using ArduinoDocument4 pagesAutomatic Plant Irrigation System Using ArduinoMUSIC IS LIFENo ratings yet

- Catalog PDFDocument55 pagesCatalog PDFYongki NugrohoNo ratings yet

- Soil Moisture Sensor Base Automatic Irrigation System Powered by Solar EnergyDocument6 pagesSoil Moisture Sensor Base Automatic Irrigation System Powered by Solar EnergyfarizalNo ratings yet

- Automatic Soil Moisture Sensor Irrigation System PIC MicrocontrollerDocument8 pagesAutomatic Soil Moisture Sensor Irrigation System PIC MicrocontrollerJhasper Managyo100% (1)

- Automatic Plant Irrigation System Using Soil Moisture SensorDocument3 pagesAutomatic Plant Irrigation System Using Soil Moisture SensorShafaq NigarNo ratings yet

- GSM Based Irrigation SystemDocument122 pagesGSM Based Irrigation Systemmayur_rughani86% (7)

- Cellphone Based Agricultural Water Pump ControlDocument3 pagesCellphone Based Agricultural Water Pump Controlpraveen_kodgirwarNo ratings yet

- Smart Watering SystemDocument6 pagesSmart Watering SystemDhiraj BhattNo ratings yet

- Micro Irrigation Report PDFDocument84 pagesMicro Irrigation Report PDFठाकुर प्रशान्त सिंहNo ratings yet

- Automated Irrigation ProjectDocument10 pagesAutomated Irrigation ProjectSubham PaulNo ratings yet

- Smart Irrigation SystemDocument13 pagesSmart Irrigation SystemSAURABH SRIVASTAVNo ratings yet

- Design and Monitoring of Water Level System Using Sensor TechnologyDocument3 pagesDesign and Monitoring of Water Level System Using Sensor TechnologyIJSTENo ratings yet

- Greenhouse Automation Using Wireless Sensors AI Published-1Document23 pagesGreenhouse Automation Using Wireless Sensors AI Published-1Yoko KoNo ratings yet

- Project Report On Automatic Crop Irrigation SystemDocument15 pagesProject Report On Automatic Crop Irrigation SystemShahabaaz muhammadNo ratings yet

- Highway Speed CheckerDocument24 pagesHighway Speed Checkerritesh chauhanNo ratings yet

- Automatic Irrigation System SynopsisDocument5 pagesAutomatic Irrigation System SynopsisASHUTOSH SRIVASTAVANo ratings yet

- An Automated Irrigation System Using Arduino MicrocontrollerDocument12 pagesAn Automated Irrigation System Using Arduino MicrocontrollerAshwin DuhonarrainNo ratings yet

- Operating Instructions SITRANS Probe LU (HART) 08/2017 Edition Ultrasonic TransmittersDocument837 pagesOperating Instructions SITRANS Probe LU (HART) 08/2017 Edition Ultrasonic TransmittersvladimirNo ratings yet

- Automated Irrigation SystemDocument73 pagesAutomated Irrigation SystemNaeem GulNo ratings yet

- Center Pivot Irrigation Systems ExplainedDocument90 pagesCenter Pivot Irrigation Systems Explainedamin alzuraiki100% (1)

- Prospect GardenaDocument24 pagesProspect Gardenagetic2001No ratings yet

- Water Softeners CatalogDocument101 pagesWater Softeners CatalogSinergroup Water Filters Water Purifiers Water SoftenersNo ratings yet

- Automatic Irrigation SystemDocument15 pagesAutomatic Irrigation Systemrajat sharmaNo ratings yet

- Project Report On Automatic Crop Irrigation SystemDocument17 pagesProject Report On Automatic Crop Irrigation SystemAnkit Sharma77% (30)

- Iot Based Smart Irrigation SystemDocument5 pagesIot Based Smart Irrigation SystemReddy RNo ratings yet

- Gas Leakage Alert ServiceDocument6 pagesGas Leakage Alert Serviceaamir sohailNo ratings yet

- Design of A Center Pivot Irrigation SystemDocument5 pagesDesign of A Center Pivot Irrigation Systemamin alzuraikiNo ratings yet

- A Microcontroller Based Water Level Indicator Using Radio Frequency RF Technology and Ultrasonic Sensor1Document6 pagesA Microcontroller Based Water Level Indicator Using Radio Frequency RF Technology and Ultrasonic Sensor1amey salunke100% (1)

- Automatic Irrigation SystemDocument17 pagesAutomatic Irrigation SystemGagandeep Virdi100% (1)

- REPORT (Automatic Sreet Light Controlling Based On Vehicle Movement)Document20 pagesREPORT (Automatic Sreet Light Controlling Based On Vehicle Movement)Arbab AslamNo ratings yet

- Center Pivot Irrigation DesignDocument55 pagesCenter Pivot Irrigation DesignSCERVANTESLUIS100% (1)

- Irrigation System DesignDocument90 pagesIrrigation System Designmirza_adil99100% (2)

- Seminar ReportDocument25 pagesSeminar ReportSaurabh100% (1)

- Water Level Controller of Overhead Tanks Using Water Level Sense - Project ReportDocument29 pagesWater Level Controller of Overhead Tanks Using Water Level Sense - Project ReportIrfan DanishNo ratings yet

- Design of Drip Irrigation SystemDocument7 pagesDesign of Drip Irrigation Systemroop singhNo ratings yet

- 05 Drip IrrigationDocument21 pages05 Drip IrrigationDileesha WeliwaththaNo ratings yet

- Solar Smart Irrigation SystemDocument22 pagesSolar Smart Irrigation SystemSubhranshu Mohapatra100% (1)

- Chapt8 Sprinklerirrigationsystem PDFDocument15 pagesChapt8 Sprinklerirrigationsystem PDFgladNo ratings yet

- Automatic Irrigation System AbstractDocument3 pagesAutomatic Irrigation System Abstractlastruler100% (1)

- Precision Mobile Drip IrrigationDocument24 pagesPrecision Mobile Drip IrrigationMostafa FayedNo ratings yet

- Agriculture Multipurpose RobotDocument2 pagesAgriculture Multipurpose RobotUNITED CADD100% (1)

- AGR558 Lab Drip Irrigation SystemDocument3 pagesAGR558 Lab Drip Irrigation SystemNoor Syazwan NasirNo ratings yet

- Waste Water Pumping StationDocument624 pagesWaste Water Pumping StationRomoex R RockNo ratings yet

- Solar Water PumpingDocument16 pagesSolar Water Pumpingchethan50% (2)

- Hybrid ManualDocument15 pagesHybrid ManualJoan GeneNo ratings yet

- IoT Based Smart Irrigation SystemDocument9 pagesIoT Based Smart Irrigation SystemIJRASETPublicationsNo ratings yet

- Wireless Irrigation SystemDocument109 pagesWireless Irrigation SystemAmit DhanawadeNo ratings yet

- Project Doc UpdateDocument33 pagesProject Doc Update19-423 JagadishNo ratings yet

- Optimizing Irrigation with SensorsDocument4 pagesOptimizing Irrigation with SensorsGokul RahateNo ratings yet

- Soil Moisture SensorsDocument29 pagesSoil Moisture SensorsScientistNo ratings yet

- Automatic Sprinkler Control SystemDocument27 pagesAutomatic Sprinkler Control SystemYayati Pathak80% (5)

- Design and Construction of An AutomaticDocument74 pagesDesign and Construction of An AutomaticAbdallaNo ratings yet

- Solar Power Auto Irrigation SystemDocument36 pagesSolar Power Auto Irrigation Systemakshay sajwan100% (1)

- Sensor Based Automatic Drip Irrigation SystemDocument4 pagesSensor Based Automatic Drip Irrigation SystemJournal 4 ResearchNo ratings yet

- ''Magnets in Orthodontics''Document102 pages''Magnets in Orthodontics''Anubha VermaNo ratings yet

- MTN Hybrid power system installation and SWAP guideDocument41 pagesMTN Hybrid power system installation and SWAP guideErin Peter Tai100% (1)

- Nanotechnolgy in ElectronicsDocument23 pagesNanotechnolgy in ElectronicsB.venkata krishnanNo ratings yet

- Step3S: 3-4 Axes Stepper Motor Driver BoardDocument2 pagesStep3S: 3-4 Axes Stepper Motor Driver BoardIzzHyukNo ratings yet

- Line Distance Protection REL650: Product GuideDocument80 pagesLine Distance Protection REL650: Product Guidehaichau199No ratings yet

- MW PropagationDocument4 pagesMW PropagationJanu Dwi KristiantoNo ratings yet

- Telco XPOL MIMO Industrial Class Solid Dish AntennaDocument4 pagesTelco XPOL MIMO Industrial Class Solid Dish AntennaOmar PerezNo ratings yet

- Ac Motor Control by Inverter TrainerDocument2 pagesAc Motor Control by Inverter TrainerDeborah MalanumNo ratings yet

- E1.2B 1250 Ekip Dip LSI 3p F FDocument3 pagesE1.2B 1250 Ekip Dip LSI 3p F FM. ShaatNo ratings yet

- ABL8RED24400: Product Data SheetDocument8 pagesABL8RED24400: Product Data Sheetindra yantomoNo ratings yet

- November 2021 (v3) QP - Paper 2 CAIE Physics IGCSEDocument20 pagesNovember 2021 (v3) QP - Paper 2 CAIE Physics IGCSEUswa IftikharNo ratings yet

- Vishay - VOM 3052Document7 pagesVishay - VOM 3052Laercio MarquesNo ratings yet

- Samsung s803jDocument41 pagesSamsung s803jСергей Гончаров100% (1)

- IEEE STD C62.21-Corrigendum-1-2008 PDFDocument18 pagesIEEE STD C62.21-Corrigendum-1-2008 PDFnisarbashaNo ratings yet

- SE Commercial braking resistor reference tableDocument2 pagesSE Commercial braking resistor reference tablemax_ingNo ratings yet

- Model Hmp35C Temperature and Relative Humidity Probe Instruction ManualDocument14 pagesModel Hmp35C Temperature and Relative Humidity Probe Instruction ManualEdinson Vallejo VidalNo ratings yet

- Durable UPS Series for Data Centers & Critical SystemsDocument1 pageDurable UPS Series for Data Centers & Critical SystemsAbdelwhab ElsaftyNo ratings yet

- Pfizer Graphene Microscope (Versión Inglesa)Document17 pagesPfizer Graphene Microscope (Versión Inglesa)Ameli ApuyNo ratings yet

- KE20SDocument2 pagesKE20SFelipe VegaNo ratings yet

- Introduction to Metallic Transmission LinesDocument58 pagesIntroduction to Metallic Transmission LinesOdellien SajaNo ratings yet

- Hyosung China Supply Reference - 201509Document34 pagesHyosung China Supply Reference - 201509fahadNo ratings yet

- Advanced IGBT/MOSFET Driver: ApplicationsDocument18 pagesAdvanced IGBT/MOSFET Driver: Applicationsbokic88No ratings yet

- Type Fronius ECO 25.0-3-S: InverterDocument2 pagesType Fronius ECO 25.0-3-S: InverterMuraryspottyNo ratings yet

- Onkyo TX-nr906 Service ManualDocument64 pagesOnkyo TX-nr906 Service ManualSclaffenNo ratings yet

- Power Management For Industrial PlantsDocument35 pagesPower Management For Industrial PlantsRavi GargNo ratings yet

- DHBVN MASTER Technical Specifiaction 1Document24 pagesDHBVN MASTER Technical Specifiaction 1Ashish bhattNo ratings yet

- Chittagong University of Engineering & Technology: Chittagong - 4349 Course Registration FormDocument1 pageChittagong University of Engineering & Technology: Chittagong - 4349 Course Registration FormTahsin AlamNo ratings yet

- Manual de Operacao Analisadro Seguranca Eletrica PDFDocument222 pagesManual de Operacao Analisadro Seguranca Eletrica PDFJonathan ScottNo ratings yet

- Design of Auxiliary Systems and Equipment for Small Hydro ProjectsDocument116 pagesDesign of Auxiliary Systems and Equipment for Small Hydro ProjectsNARENDER KUMARNo ratings yet

- Patent US4858141 - Non-Intrusive Appliance Monitor Apparatus - Google PatentsDocument11 pagesPatent US4858141 - Non-Intrusive Appliance Monitor Apparatus - Google PatentsFernando Marcos WittmannNo ratings yet